Scouring freeze-thaw splitting test method for porous asphalt mixtures

A technology of freeze-thaw splitting test and asphalt mixture, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., to achieve good promotion and utilization value, easy to implement, and accurate and reliable test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

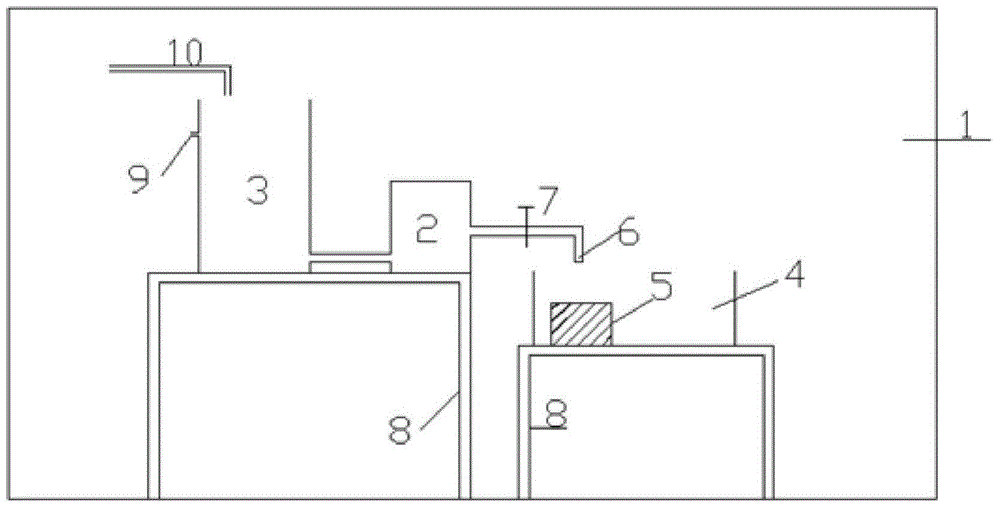

Image

Examples

Embodiment 1

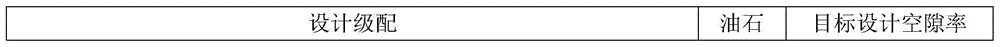

[0051] According to the design of bitumen ratio and gradation of porous asphalt mixture, according to T 0702-2011 compaction method in "Test Regulations of Highway Engineering Asphalt and Asphalt Mixture JTG E20-2011", indoor mixing production of porous asphalt mixture and forming standard Marshall specimens , The adopted design gradation, oil-stone ratio and target design porosity are shown in Table 1.

[0052] Table 1 Mixture design gradation, oil-stone ratio and target design porosity

[0053]

[0054]

[0055] The porosity of the test specimens was within the range of plus or minus 0.5% of the design target porosity, and the non-compliant specimens were discarded, and a total of 32 Marshall specimens meeting the requirements were prepared.

[0056] The test pieces were randomly divided into 8 groups, each group had 4 test pieces, and they were placed in a thermostat at 25°C for 60 minutes. The surface of each group of test pieces was washed vertically at a pressure of 0.6Mpa usin...

Embodiment 2

[0061] According to the design of bitumen ratio and gradation of porous asphalt mixture, according to T 0702-2011 compaction method in "Test Regulations of Highway Engineering Asphalt and Asphalt Mixture JTG E20-2011", indoor mixing production of porous asphalt mixture and forming standard Marshall specimens , The adopted design gradation, oil-stone ratio and target design porosity are shown in Table 3.

[0062] Table 3 Mixture design gradation, oil-stone ratio and target design porosity

[0063]

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com