Corrosion-fatigue testing method for reinforced concrete on basis of optical-fiber sensing and device thereof

A technology for reinforced concrete and reinforced concrete beams, applied in the field of reinforced concrete corrosion fatigue test methods and devices based on optical fiber sensing, can solve the problems of not considering the coupling effect of corrosion fatigue and inaccurate results, and achieve effective and reliable test data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 The reinforced concrete corrosion fatigue test method based on optical fiber sensing comprises the following steps:

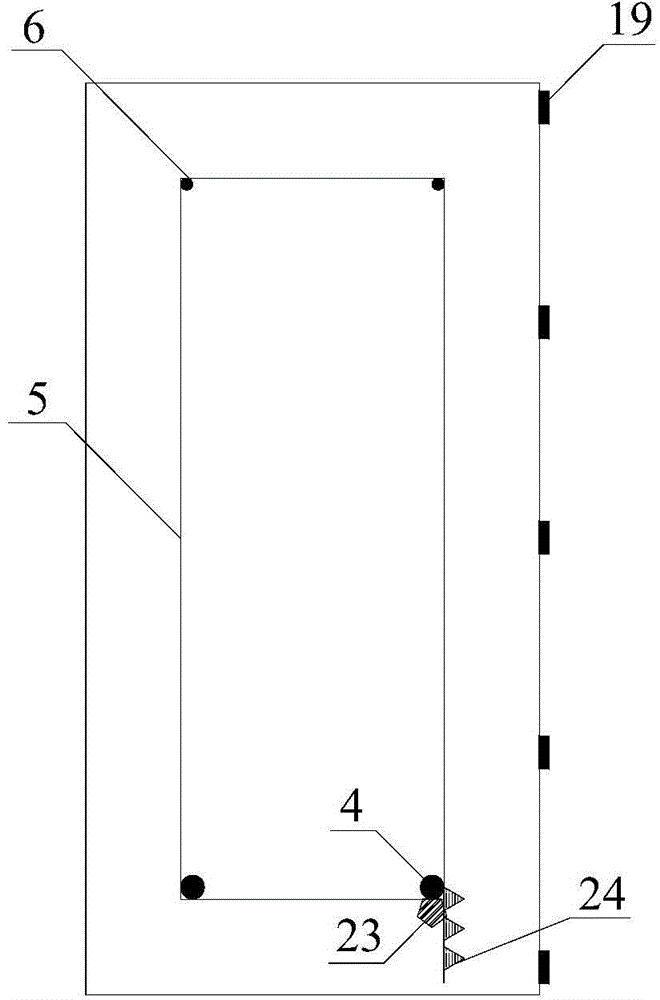

[0048] 1) Pouring reinforced concrete beams and arranging fiber grating sensors: bind the steel skeleton, and wrap a circle of fiber grating strain sensors in the circumferential direction of the longitudinal bending steel bars in the mid-span section of the beam to monitor the corrosion of the steel bars; near the mid-span section of the beam Fiber Bragg Grating strain sensors and fiber Bragg grating temperature sensors for temperature compensation are pasted axially along the longitudinal bending steel bars to monitor the stress changes of the steel bars; fiber Bragg grating pH values are arranged axially along the longitudinal bending steel bars near the mid-section of the beam The sensor is used to monitor the change of PH value on the surface of the steel bar; a structural steel bar perpendicular to the vertical bending steel bar is we...

Embodiment 2

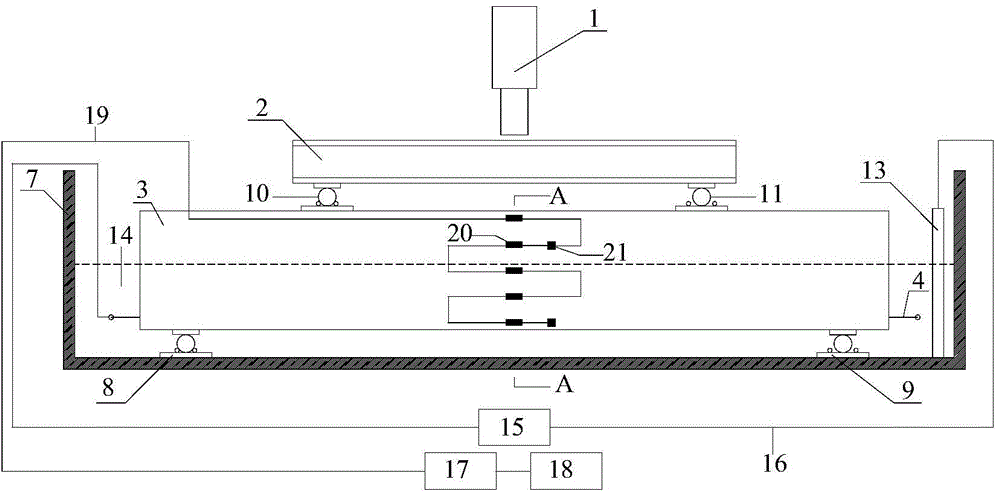

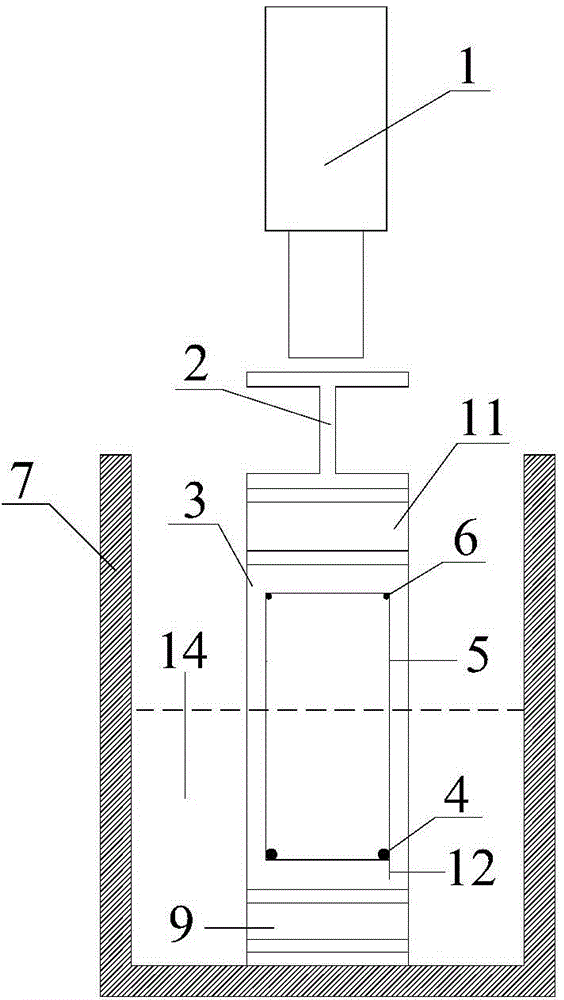

[0053] Embodiment 2 The device constructed according to the test method described in Embodiment 1 is characterized in that: the reinforced concrete beam 3 to be tested, the load distribution beam 2, the support device, the corrosion tank 4 with the upper end open, the hydraulic jack 1, the monitoring device, DC stabilized power supply 15;

[0054] A stainless steel plate 13 is placed on the inner bottom plate of the corrosion tank 7, and a 3% to 5% sodium chloride solution 14 for immersing the longitudinal bending steel bars 4 of the reinforced concrete beam 3 to be tested is housed in the corrosion tank 7;

[0055] The support device includes an upper support and a lower support, the upper support and the lower support are respectively located on the upper and lower surfaces of the reinforced concrete beam 3 to be tested, and the simply supported supports (8, 9) of the lower support are The lower backing plate is fixedly connected to the inner bottom plate of the corrosion ta...

Embodiment 3

[0065] Example 3 In this example, a reinforced concrete beam whose size is length x width x height = 2500 mm x 120 mm x 250 mm is selected as the beam for the test to explain the design idea of the test device and the layout plan of the fiber grating sensor.

[0066] 1. Design and implementation of corrosion fatigue test device:

[0067] ⑴Design and manufacture of corrosion tank

[0068] The material is taken as a 5mm thick steel plate. The inner length dimension of the corrosion groove should be 250-500mm longer than the longitudinal bending steel bar, and the width direction dimension should be 100-150mm wider than the reinforced concrete beam. Here, the size of the corrosion tank is taken as length×width×height=3100mm×250mm×400mm. The inner side of the corrosion tank is painted with epoxy resin, with a thickness of about 1mm.

[0069] ⑵Design and manufacture of support device

[0070] The material is selected as steel, and the exposed parts of the supporting device ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com