Method and device for testing corrosion fatigue of welding nodes of orthotropic steel bridge deck

A steel bridge deck, orthotropic technology, applied in measurement devices, weather resistance/light resistance/corrosion resistance, using optical devices to transmit sensing components, etc., can solve the problems of not considering corrosion fatigue coupling effect and inaccurate results, etc. Achieve the effect of effective and reliable test data, wide measurement range and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] With reference to accompanying drawing, the test method of steel bridge welded joint corrosion fatigue test device of the present invention may further comprise the steps:

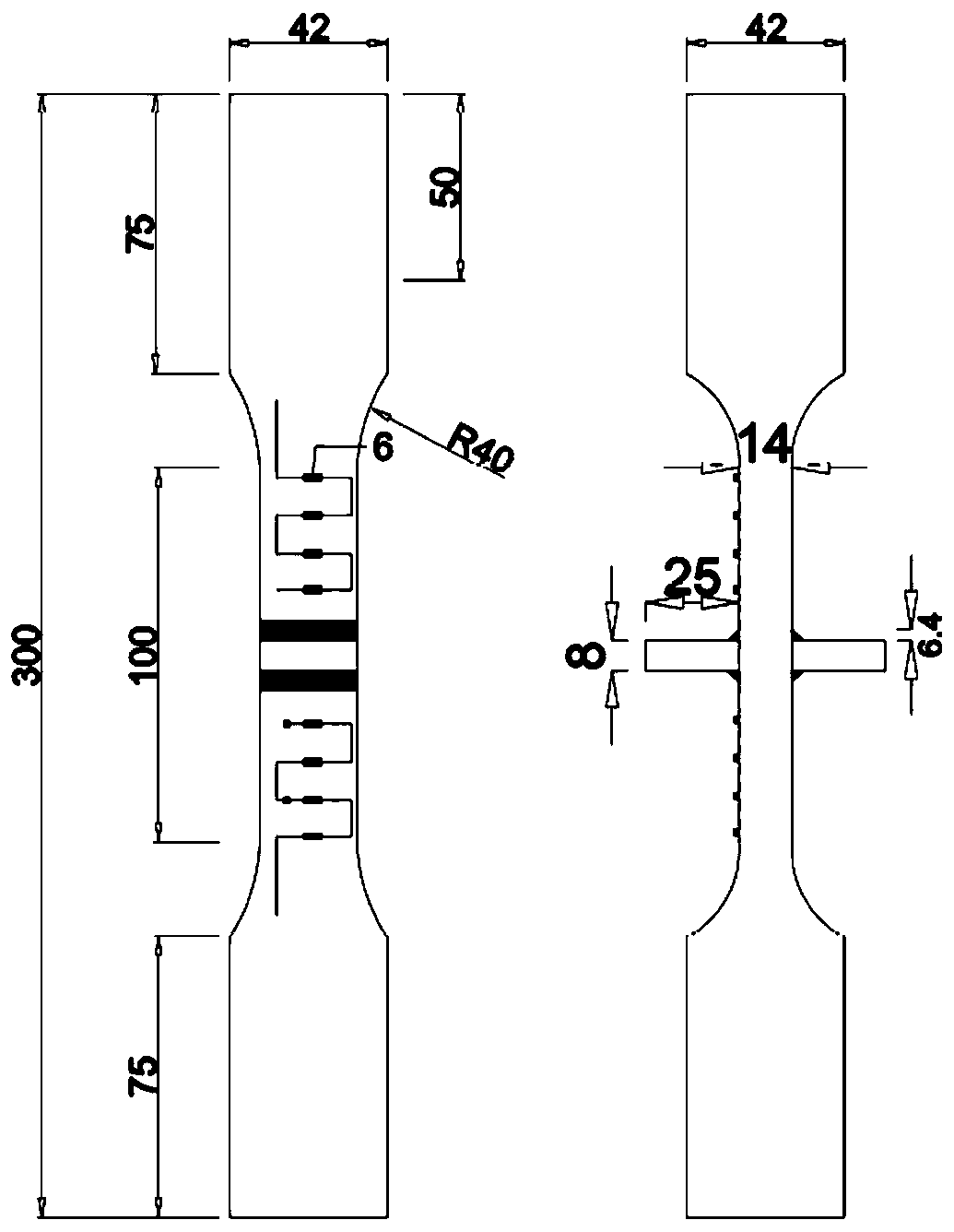

[0030]1) Make a corrosive environment chamber, weld a long cross welding specimen and arrange an optical fiber grating sensor: make and assemble a corrosion environment chamber, weld a long cross-shaped member, and wrap a circle of optical fiber grating strain sensor on the upper part of the weld seam of the long cross member, for Monitor the corrosion of the welded joints of the long cross welded specimen; stick fiber grating strain sensors and optical fiber grating temperature sensors circumferentially at the lower part of the weld of the long cross member to monitor the stress change of the welded joints and the temperature change of the test piece;

[0031] 2) Fatigue test of long cross welded specimens: Take 10 long cross welded specimens, each as a group, 10 groups in total. Using the electro-...

Embodiment 2

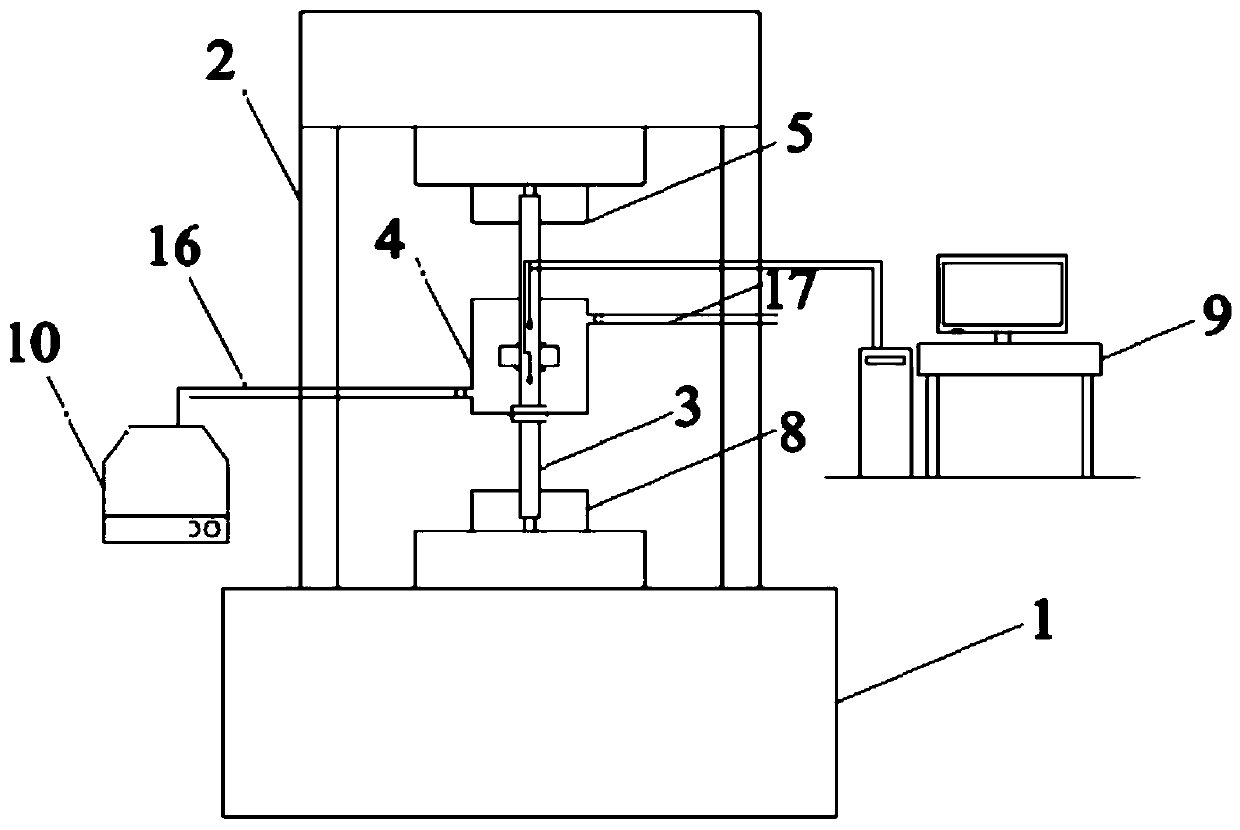

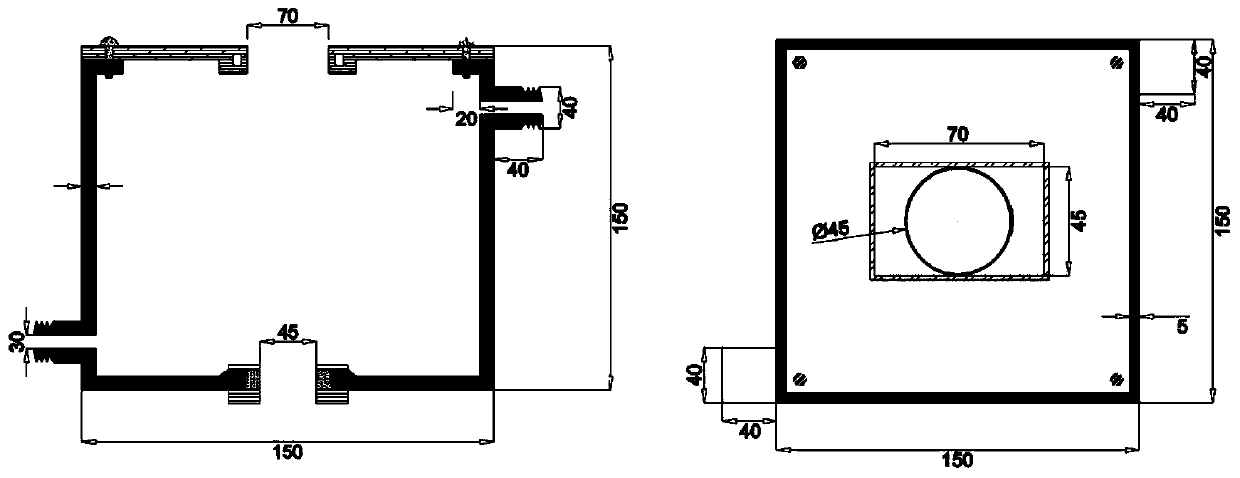

[0037] With reference to accompanying drawing, the device that realizes the test method described in embodiment 1 comprises fatigue testing machine 1, and fatigue testing machine 1 connects hydraulic rod 2, is characterized in that: the upper end of hydraulic rod 2 connects upper clamping end 5, fatigue testing machine 1 is connected to the lower clamping end 8, the two ends of the long cross welding test piece 3 are respectively connected to the upper clamping end 5 and the lower clamping end 8, the middle part of the long cross welding test piece 3 is set in the corrosion environment box 4, and the long cross welding The middle part of the test piece 3 is provided with a weld seam to be tested, and a corrosion paste 18 is arranged on the weld seam to be tested; the inner cavity of the corrosion environment box 4 is connected to the water mist releaser 10 through the water mist injection pipe 16, and connected to the water mist discharge pipe 17;

[0038] The long cross weldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com