Hyper-elastic material high-speed stretching tester and experiment method

A technology of high-speed tensile and test equipment, which is applied in the direction of testing the strength of materials with one-time impact force, and can solve the problems of not being able to obtain the mechanical properties of elastic cable hyperelastic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

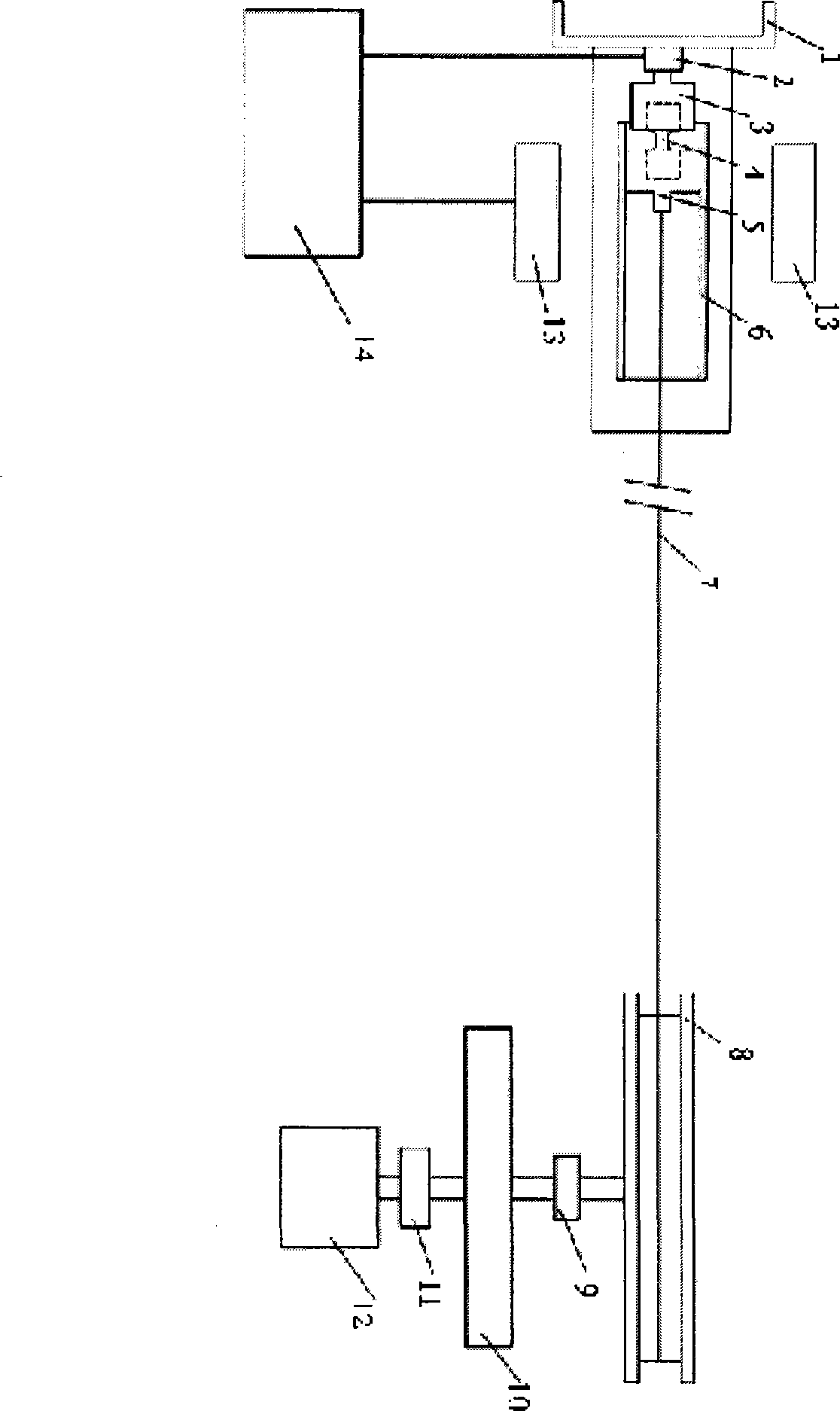

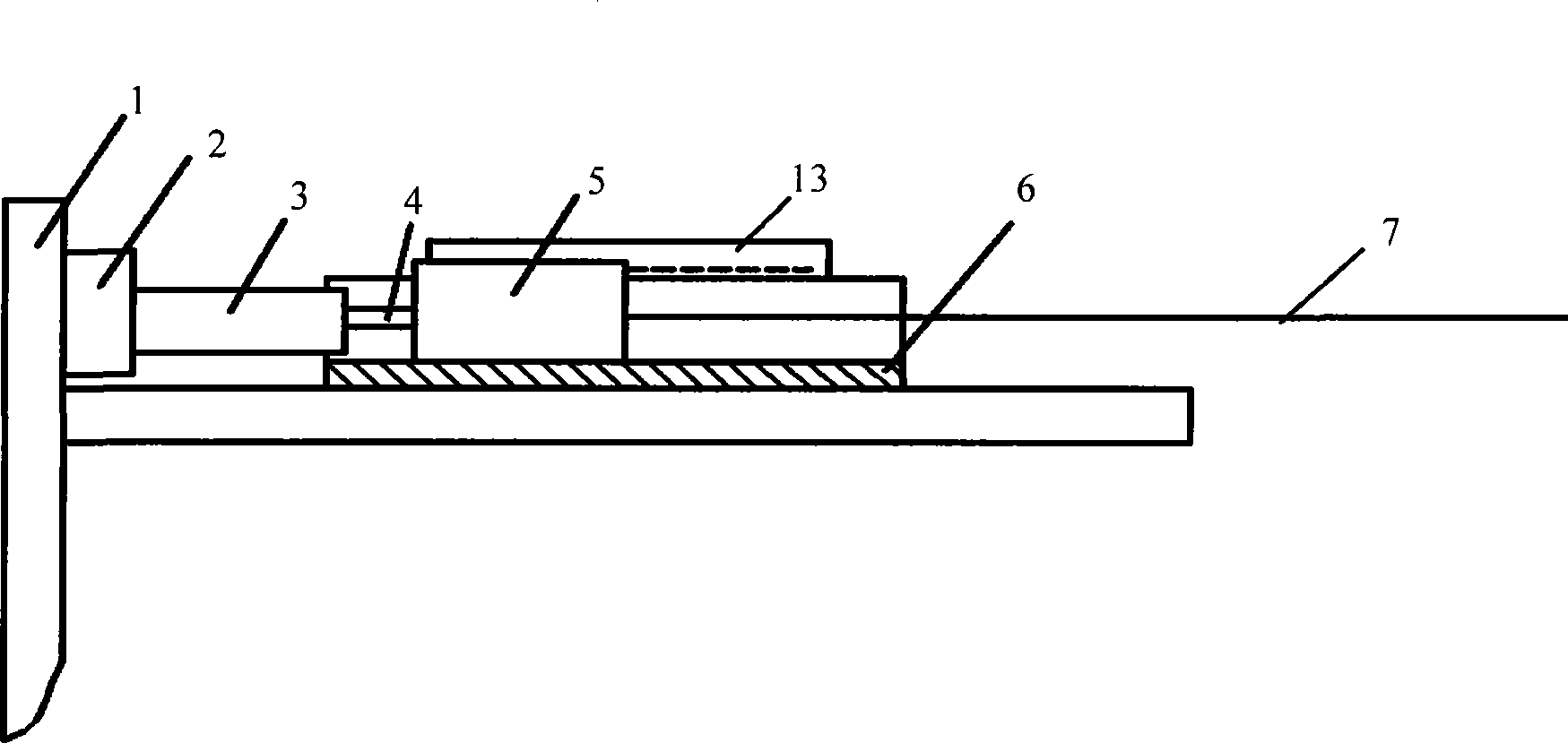

[0021] In this embodiment, a high-power high-speed motor is used as the elastic cable high-speed stretching device of the loading device. Tensile jig 5 , sample 4 , post-tensile jig 3 , load sensor 2 , support 1 , continuous displacement measurement system 13 and data acquisition system 14 . In this embodiment, a laser continuous displacement measurement system is used as the continuous displacement measurement system 13 .

[0022] In a specific implementation, one end of the load sensor 2 is fixed on the support 1 , and the other end is fixedly connected to the rear tensioning fixture 3 . On the horizontal plate of the support 1, a guide groove 6 with a longitudinal section of "concave" shape is fixedly installed, and the front stretching clamp 5 is installed in the guide groove 6, and can move along the guide groove, and its upper surface exposes the guide groove the top of the top; the continuous displacement measurement system 13 is installed on both sides of the guide gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com