Patents

Literature

33results about How to "Large sample size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

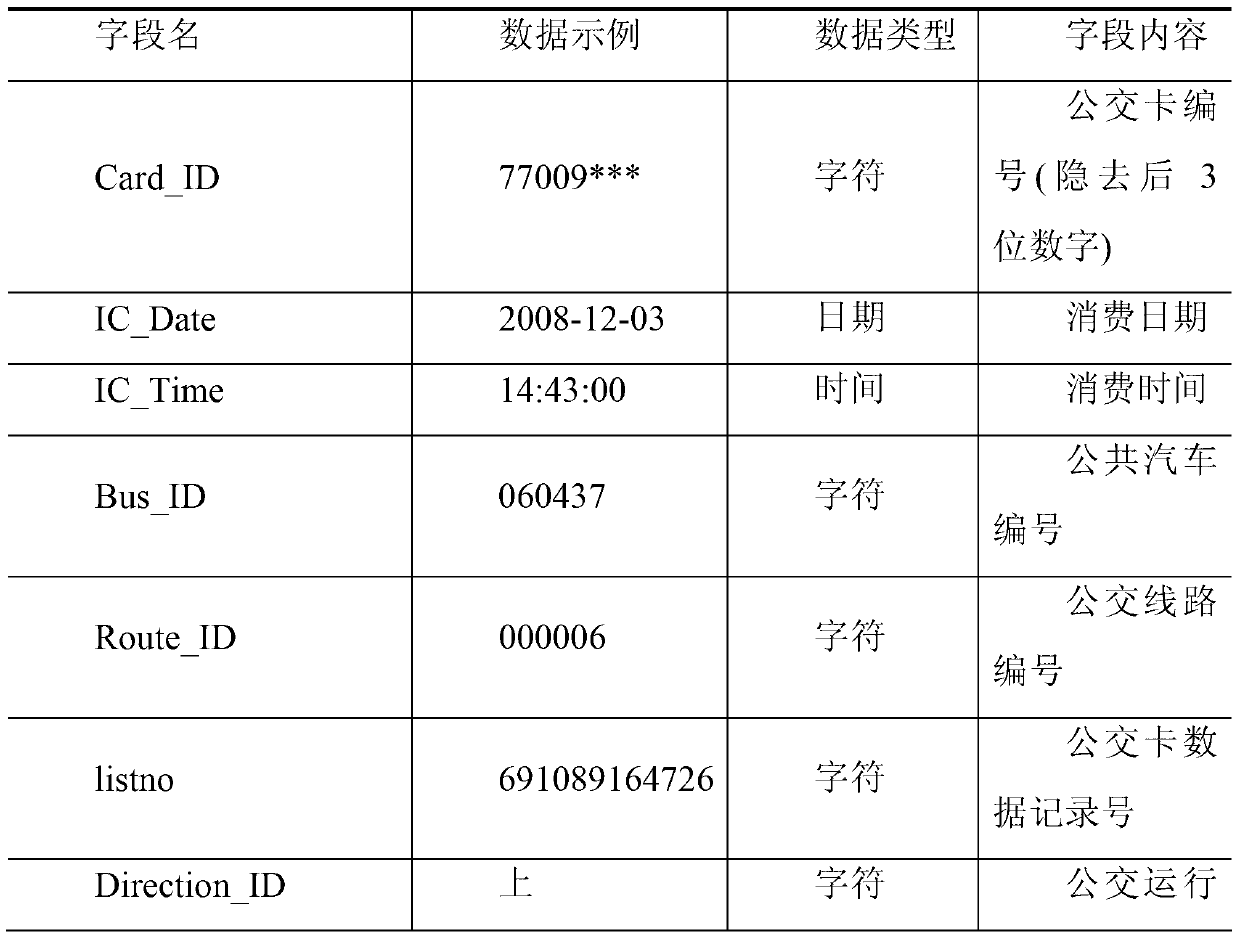

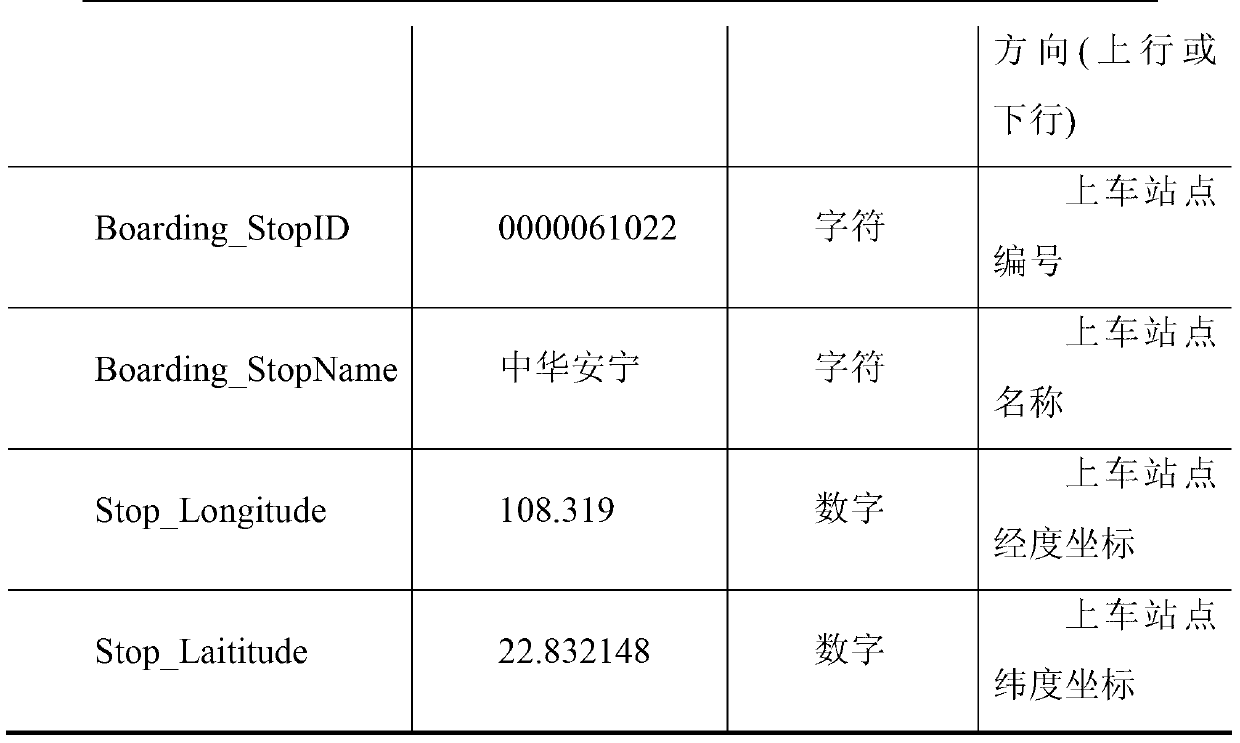

Public transport card passenger commuter OD (origin and destination) distribution estimation method based on APTS (advanced public transportation systems)

ActiveCN103279534ALow costLarge sample sizeSpecial data processing applicationsTraffic congestionMorning

The invention provides a public transport card passenger commuter OD (origin and destination) distribution estimation method based on APTS (advanced public transportation systems). The method includes collecting APTS data, obtaining station information where public transport passengers getting on according to association between public transport IC (intelligent card) data and intelligent scheduling system data, judging public transport commuters according to travel frequency of morning and evening peaks, and determining places of residence and places of work according to time and space characteristics of commuter traveling. The public transport card passenger commuter OD distribution estimation method has the advantages of high accuracy and strong operability, a novel manner for obtaining public transport commuter OD distribution rapidly and economically is provided, ratio of the commuters traveling by public transport can be increased, and the urban traffic congestion problem can be relived effectively.

Owner:西安华清科教产业(集团)有限公司

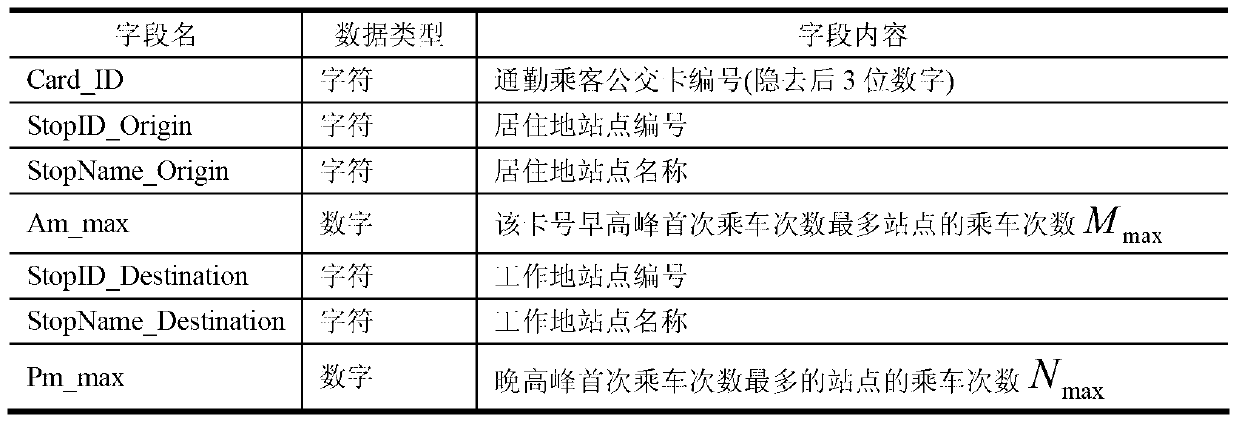

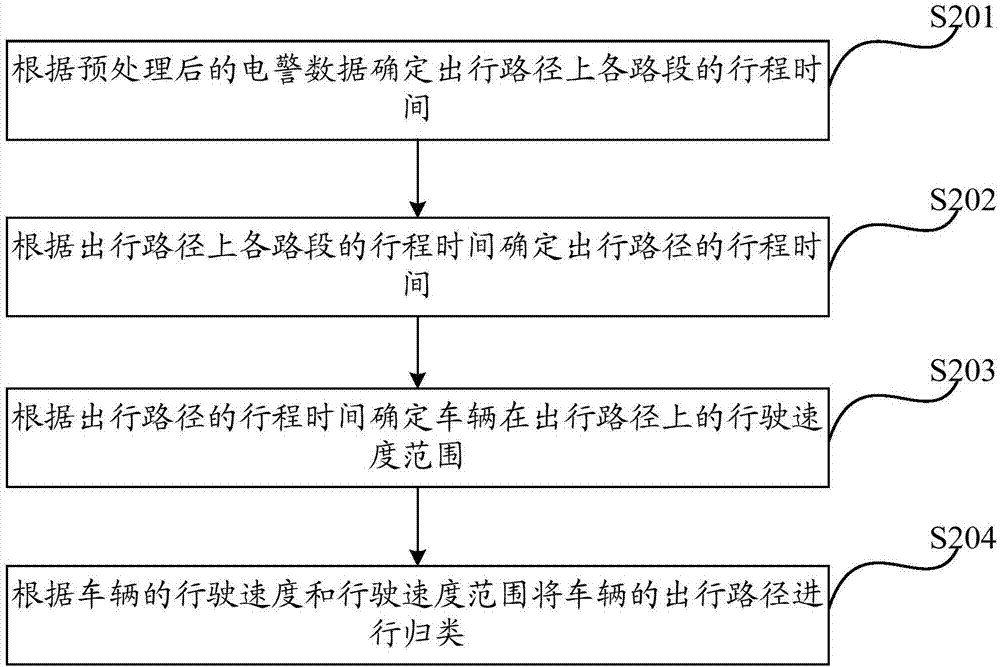

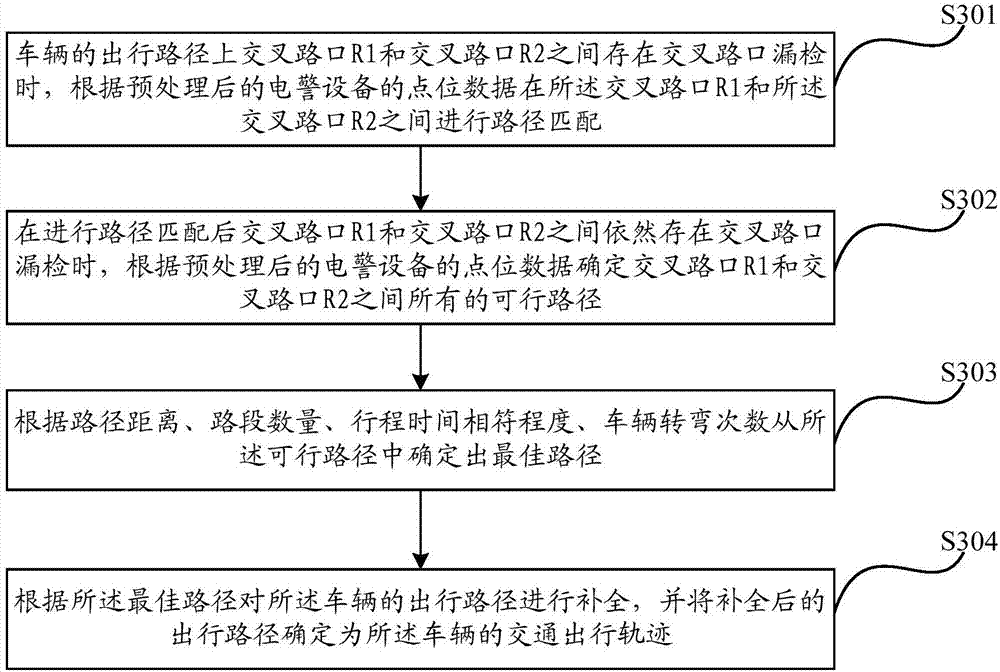

Traffic trajectory extraction method and device based on e-police data

ActiveCN107195180ASingle data sourceLarge sample sizeDetection of traffic movementPoint locationOperating speed

The invention provides a traffic trajectory extraction method and device based on e-police data. Preprocessed point location data and e-police data of e-police equipment is obtained, travel paths of a vehicle are extracted according to the preprocessed point location data and e-police data of the e-police equipment, the travel paths of the vehicle are classified according to the driving speed of the vehicle and travel time of the travel paths, and a traffic trajectory of the vehicle is determined according to the classified travel paths of the vehicle. According to embodiments of the invention, the traffic trajectory of the vehicle is extracted on the basis of the point location data and e-police data of the e-police equipment, a data source is single, the amount of sample is large, and a traffic trajectory extraction method is simplified. The travel paths of the vehicle are classified after being extracted, different traffic trajectory determining methods are used for different types of travel paths, the obtained traffic trajectory satisfies a practical travel scene more, and the traffic trajectory extracting precision is improved.

Owner:QINGDAO HISENSE TRANS TECH

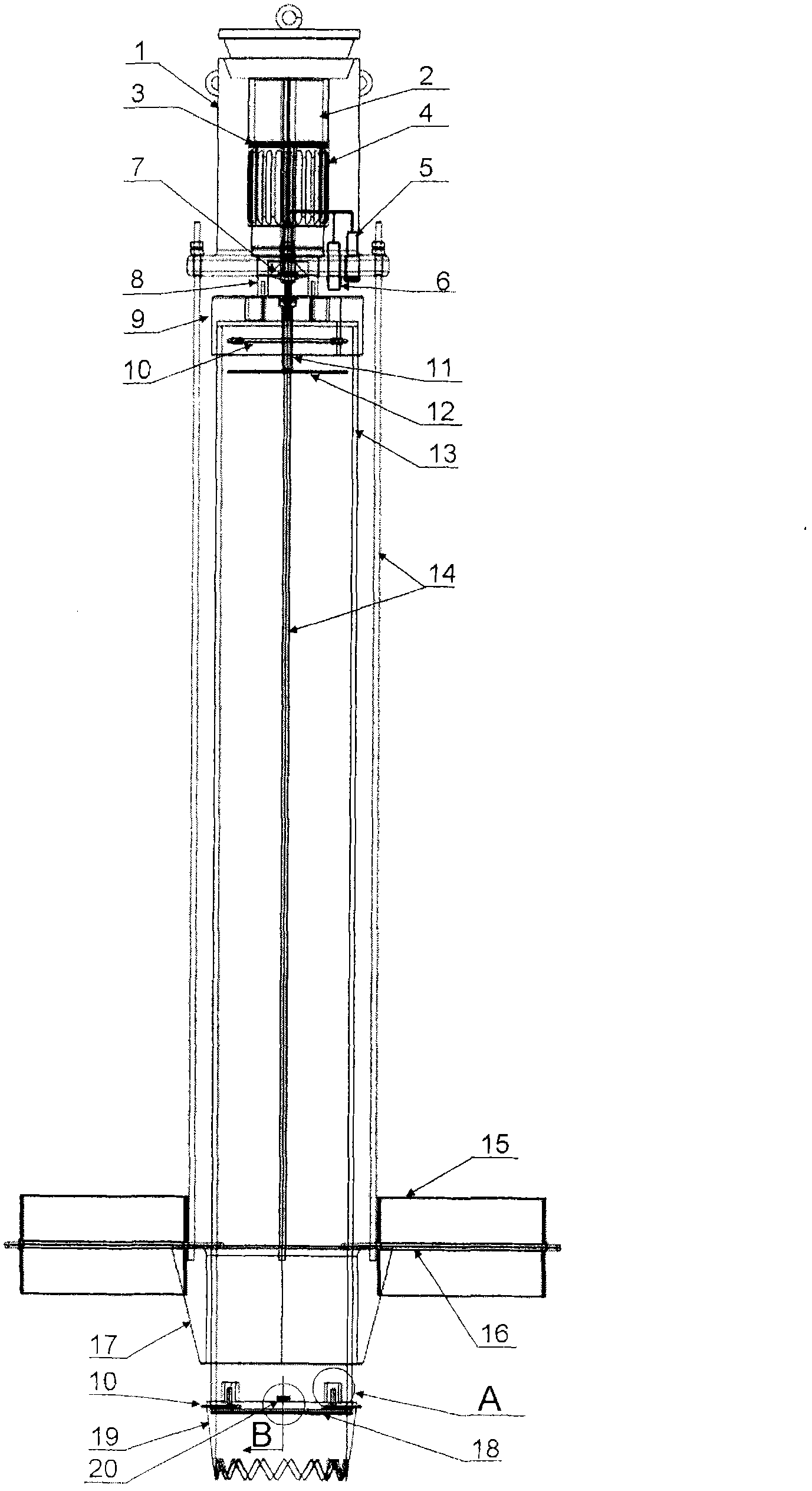

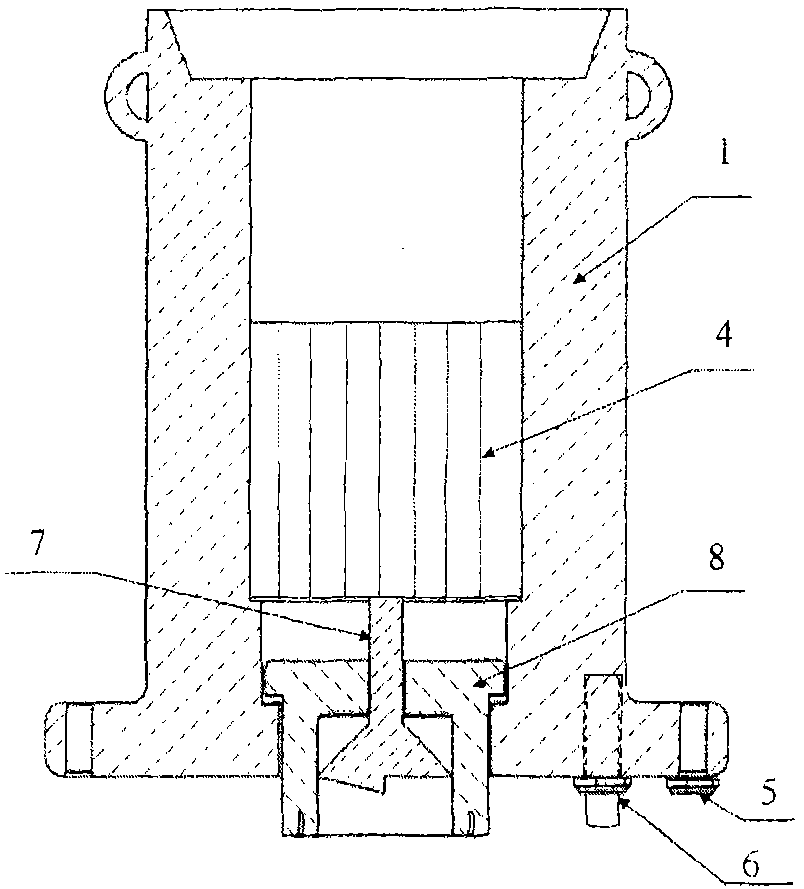

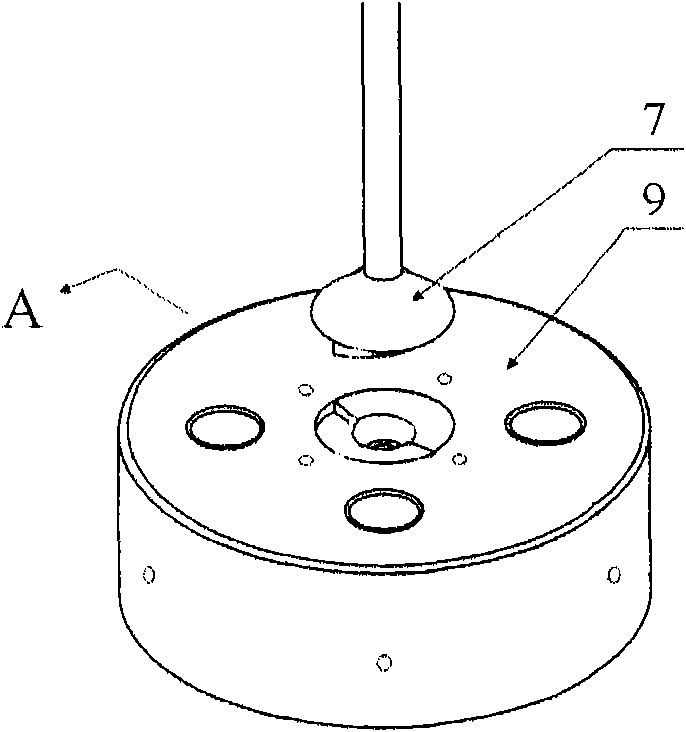

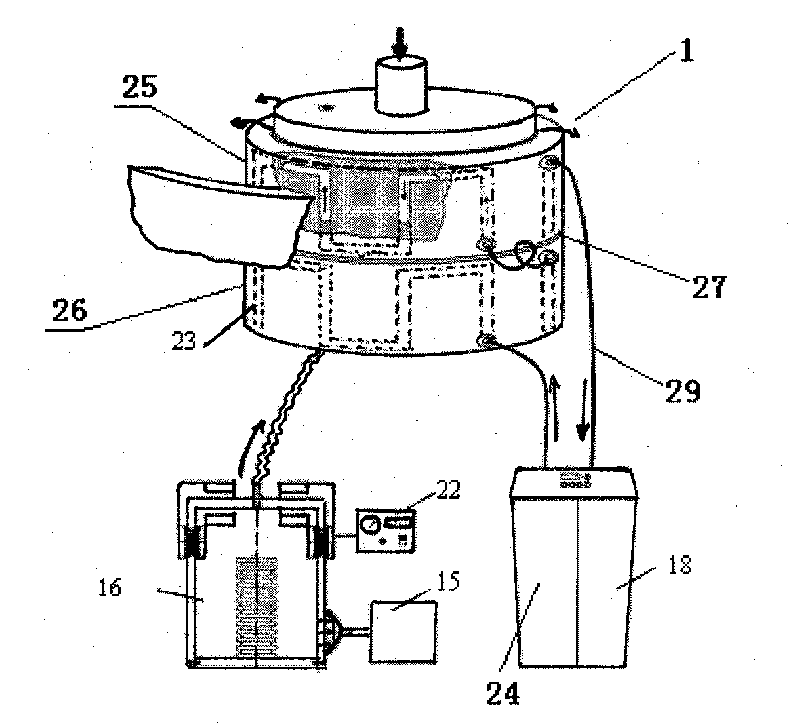

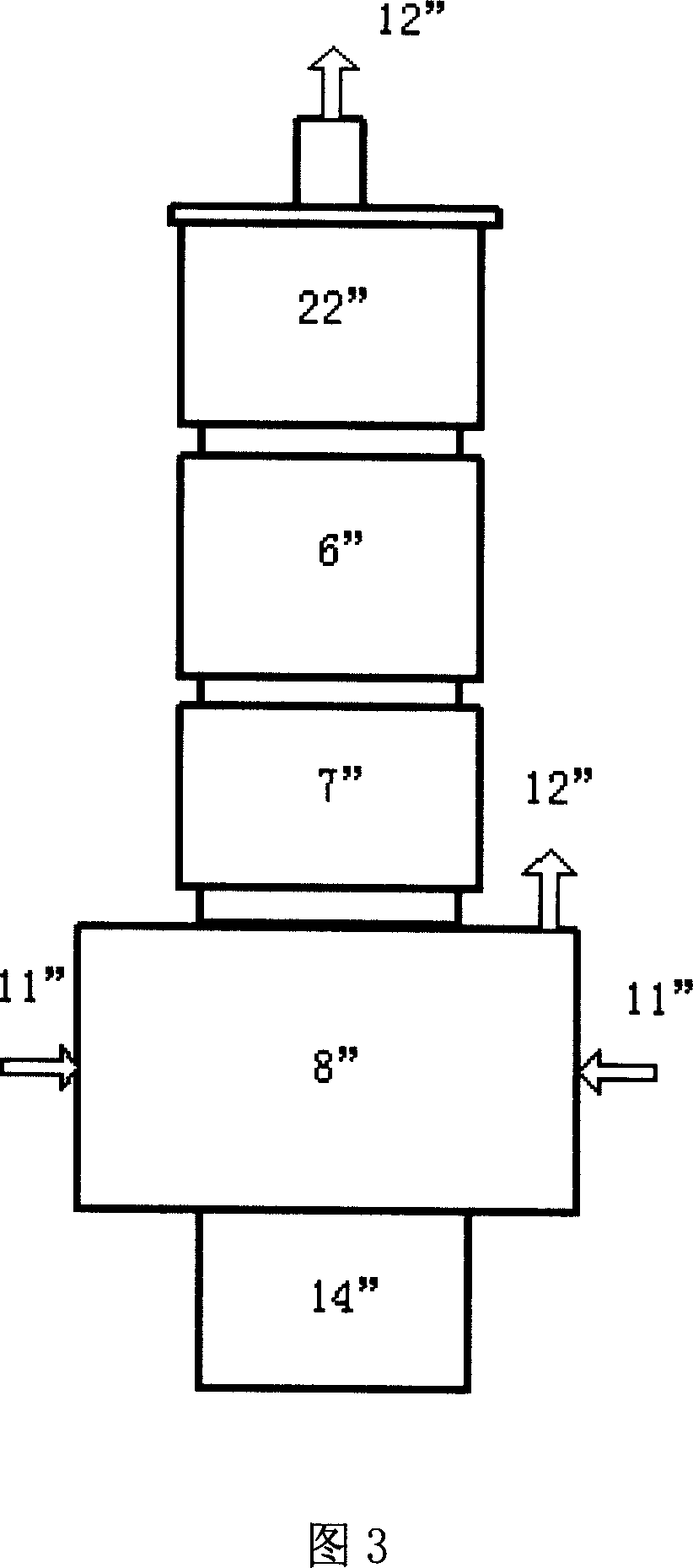

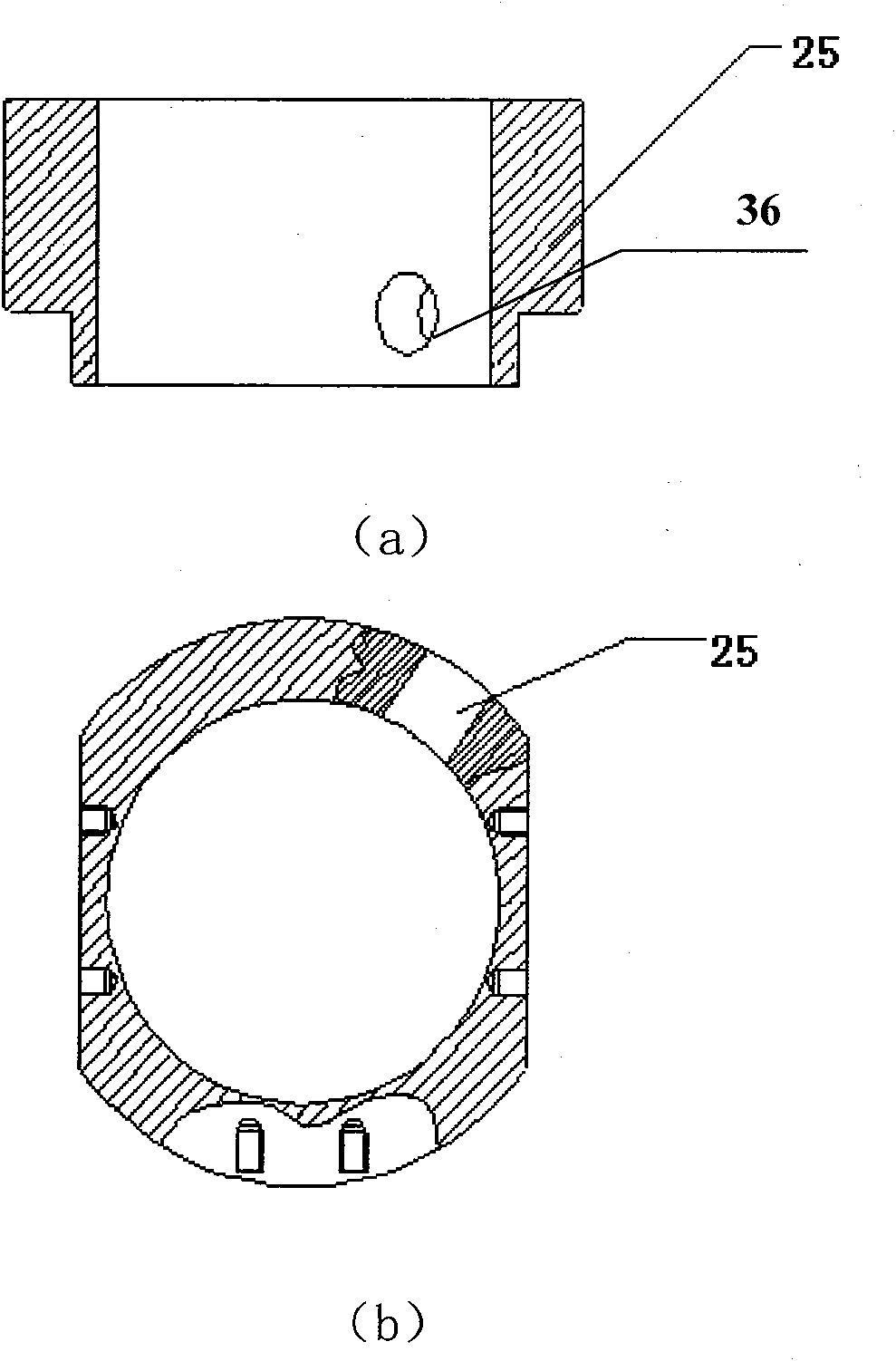

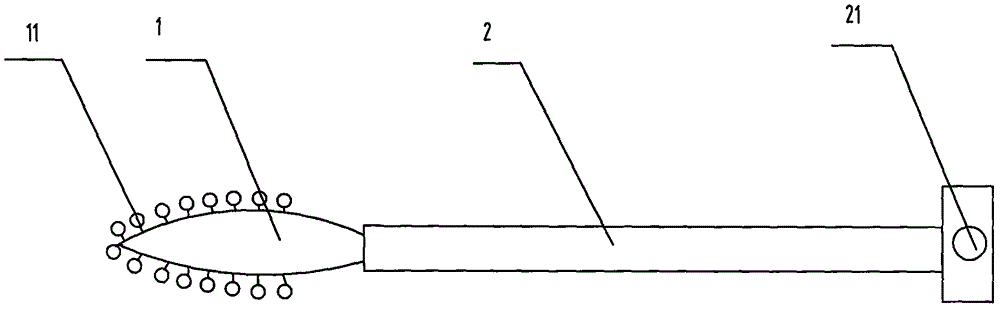

Automatic sampler of undisturbed sediment deposit

InactiveCN102109420ASampling work is simple and easy to implementLarge sample sizeWithdrawing sample devicesEngineeringGravitation

The invention discloses an automatic sampler of undisturbed sediment deposits, and relates to the environment analysis technology. The automatic sampler comprises a power supply part, a cylinder body part, a sampling head, and a seal part. After the automatic sampler enters sediment deposits, a pressure switch is closed by the extrusion between the power supply housing and the sampling cylinder fixed part, and a deceleration motor is started to drive the sampling cylinder and a stainless steel knife edge to rotate and sampling; when the distance between the power supply housing and an annular gravity hammer reaches the detection range of a proximity switch sensor, the sampling is stopped; during the lifting process of the sampler, a rubber diaphragm seals the lower part of the sampling cylinder. The automatic sampler of undisturbed sediment deposits of the invention is specially applicable to undisturbed sampling devices for sediment deposits of rivers, lakes, and neritic regions, and has an obvious advantage for environment with a relatively hard deposition layer; and the invention allows a quick and effective sampling to deposits, and realizes an effective analysis to deposit samples.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

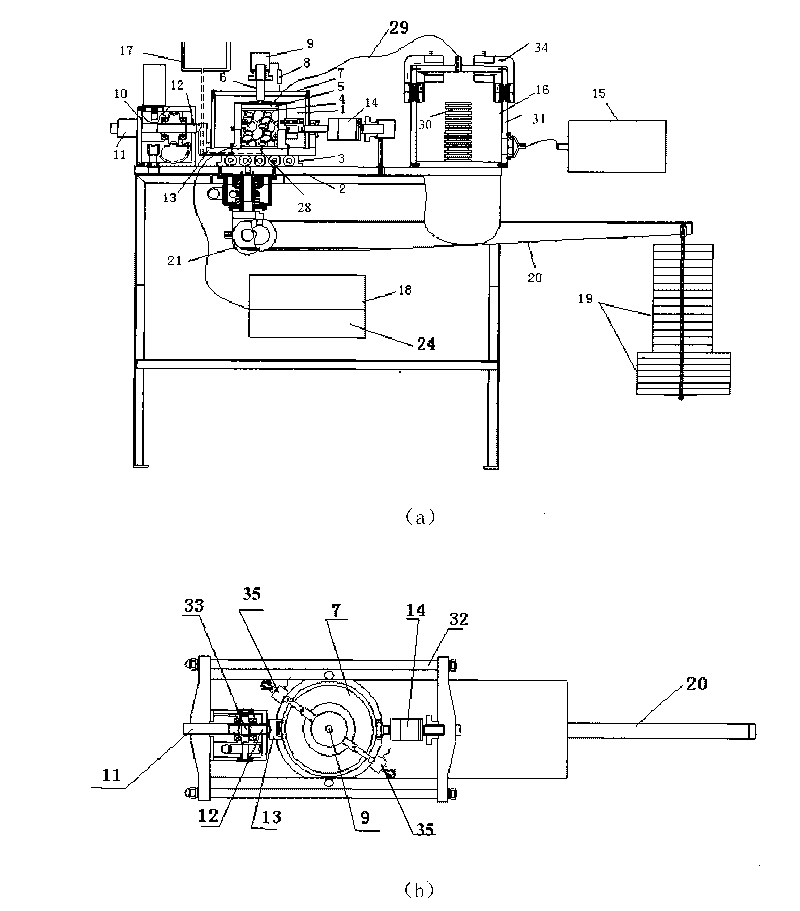

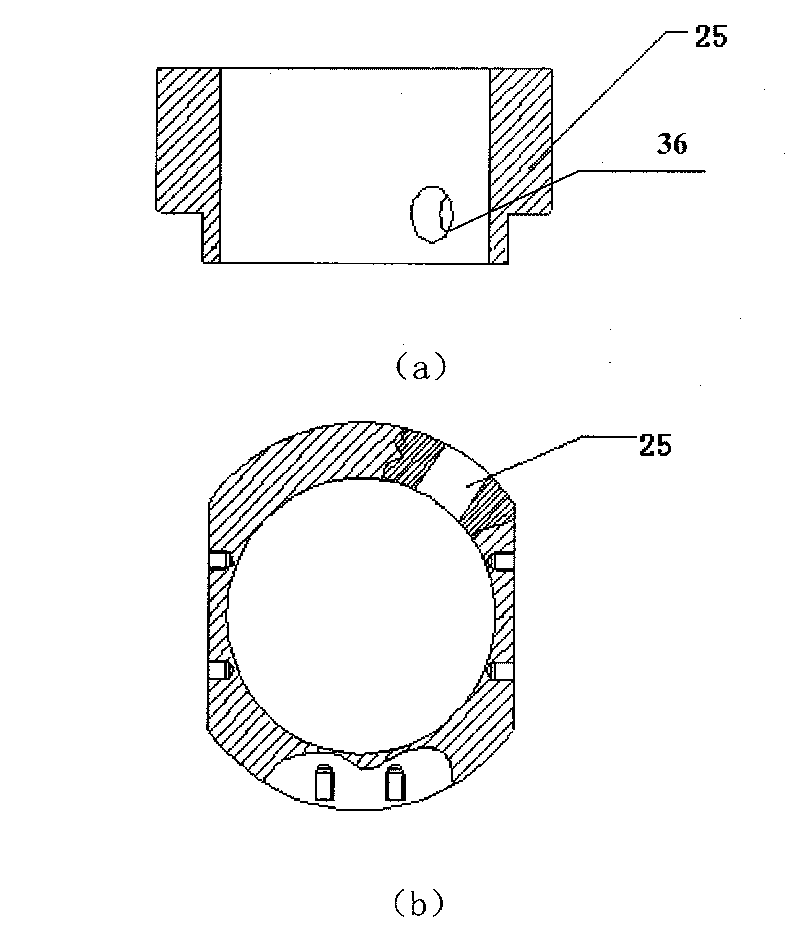

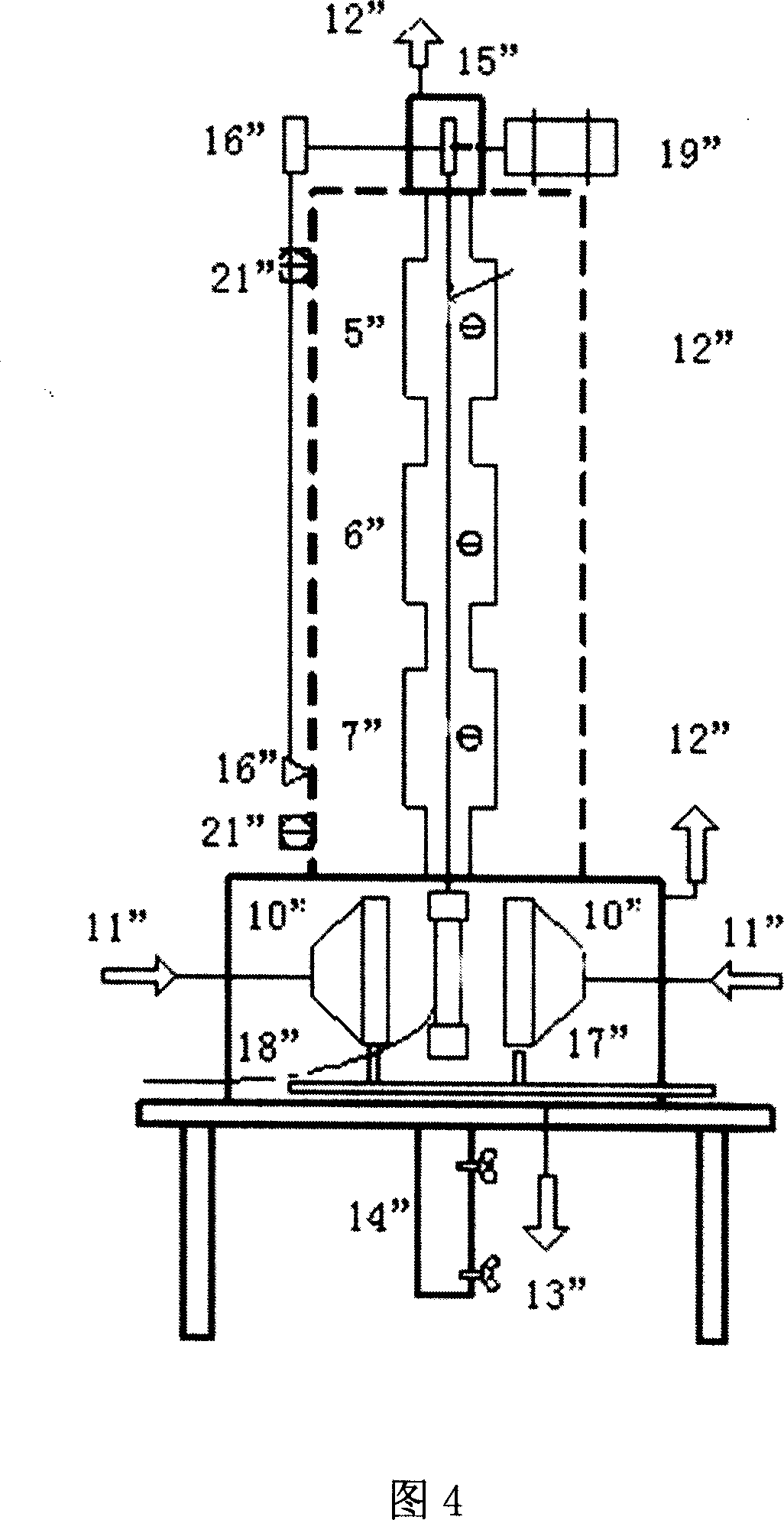

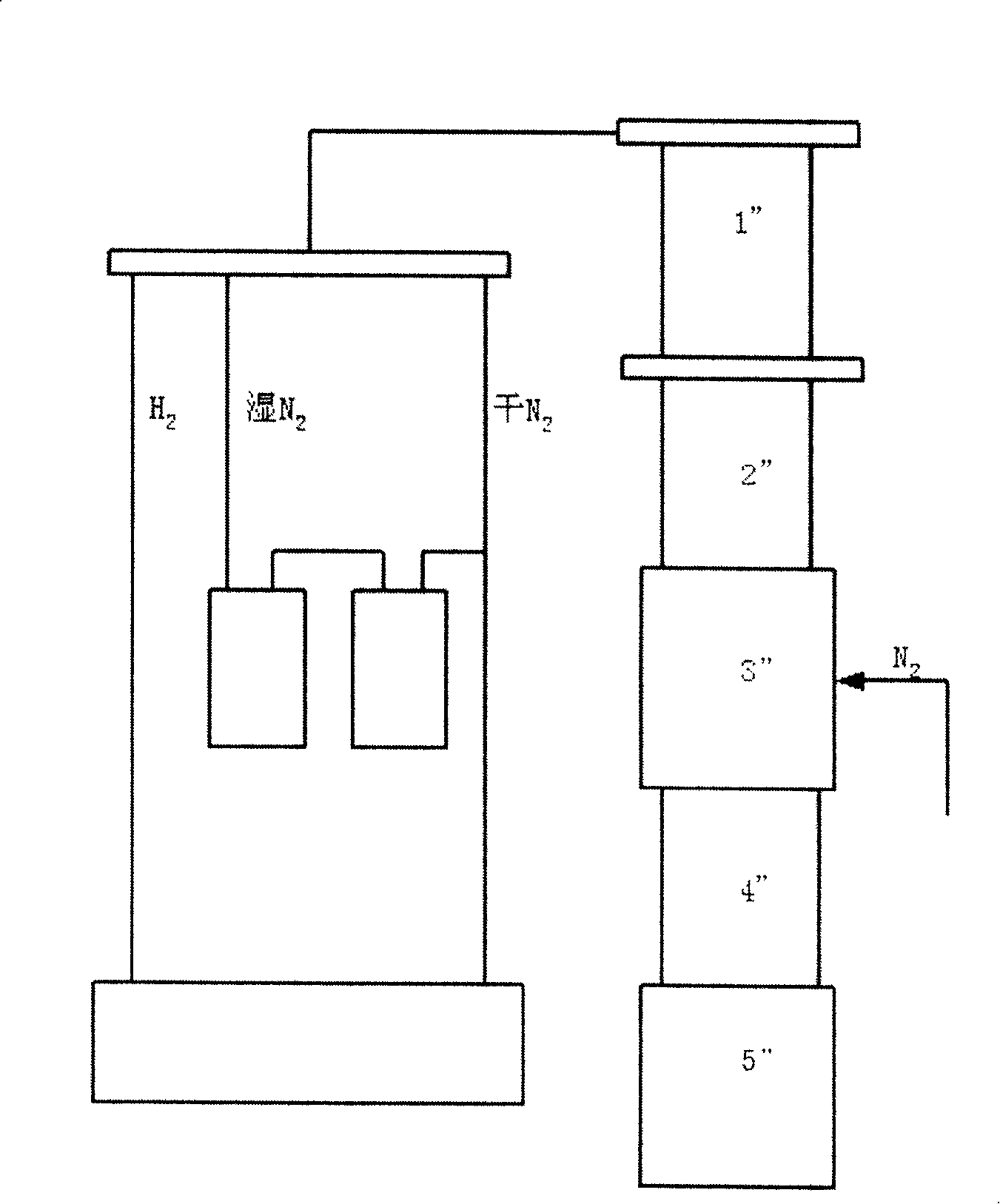

Rock-fill material weathering instrument

InactiveCN101692082AAvoid warpingHeating up fastEarth material testingTemperature controlFilling materials

A rock-fill material weathering instrument comprises a rolling bearing, the rolling bearing is arranged at the upper part of a bracket seat and is provided with a compression shear test box, a water permeable plate, a pressurizing cap, a pressurizing head and a heat preservation cover in sequence, the top beam on the heat preservation cover is connected with the heat preservation cover after being connected to a displacement transducer; a leveling device, a lever, and load weights are arranged under the bracket seat, the shear test box is connected with a low temperature cooling circulating pump and a high temperature circulator; the compression shear test box is connected with a temperature-controlled cabinet and an air compressor; the compression shear test box is connected with a watertank, the sliding plate at the bottom part of the shear test box is connected with a horizontal loading motor, a horizontal load transducer on the beam is connected with the right part of the box, after completing cold-hot circulation and dry-wet circulation, the sample is sheared, and the horizontal load is detected. The invention has the characteristic of realizing coupling of three factors of dry-wet circulation, temperature change and stress.

Owner:TSINGHUA UNIV

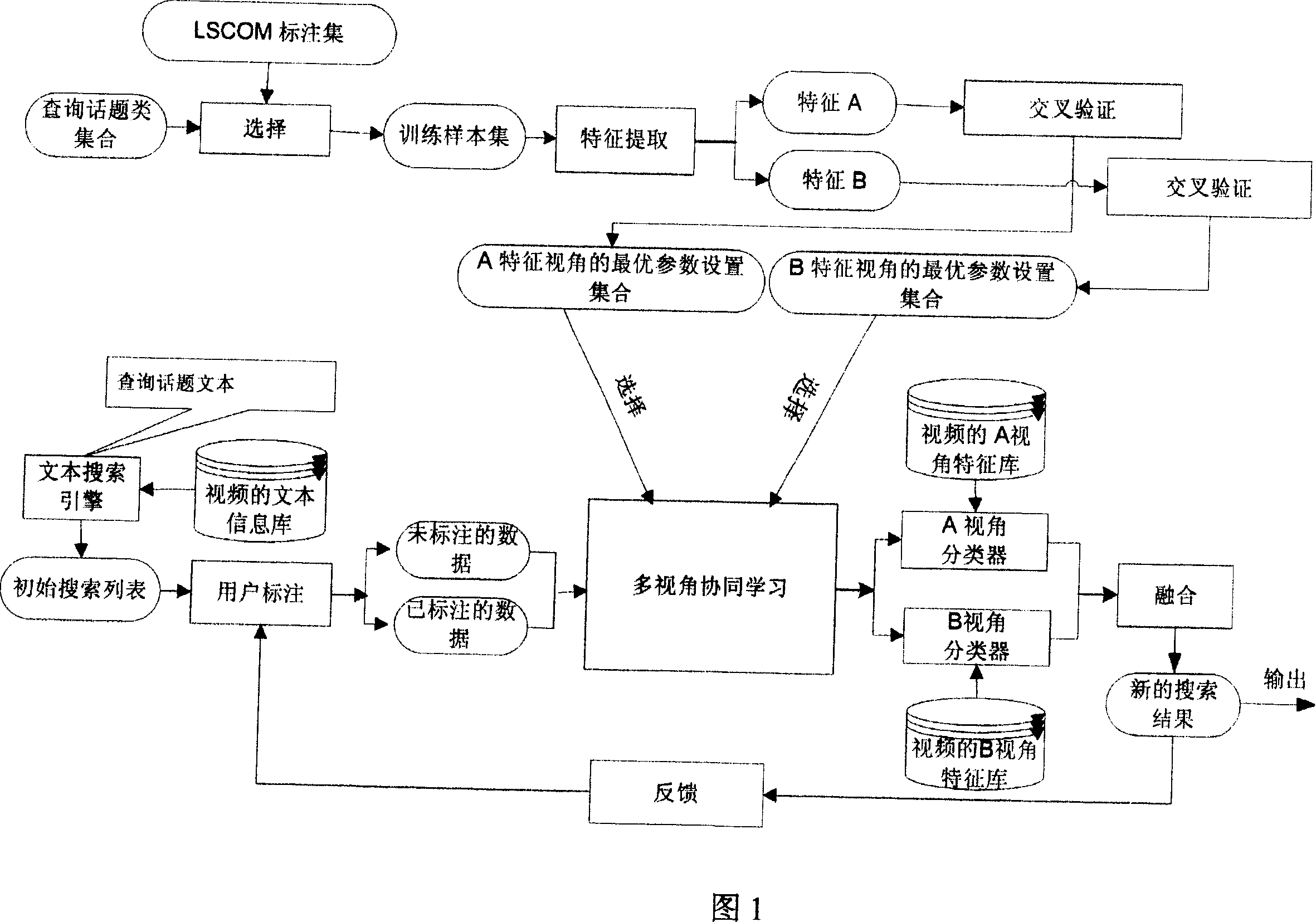

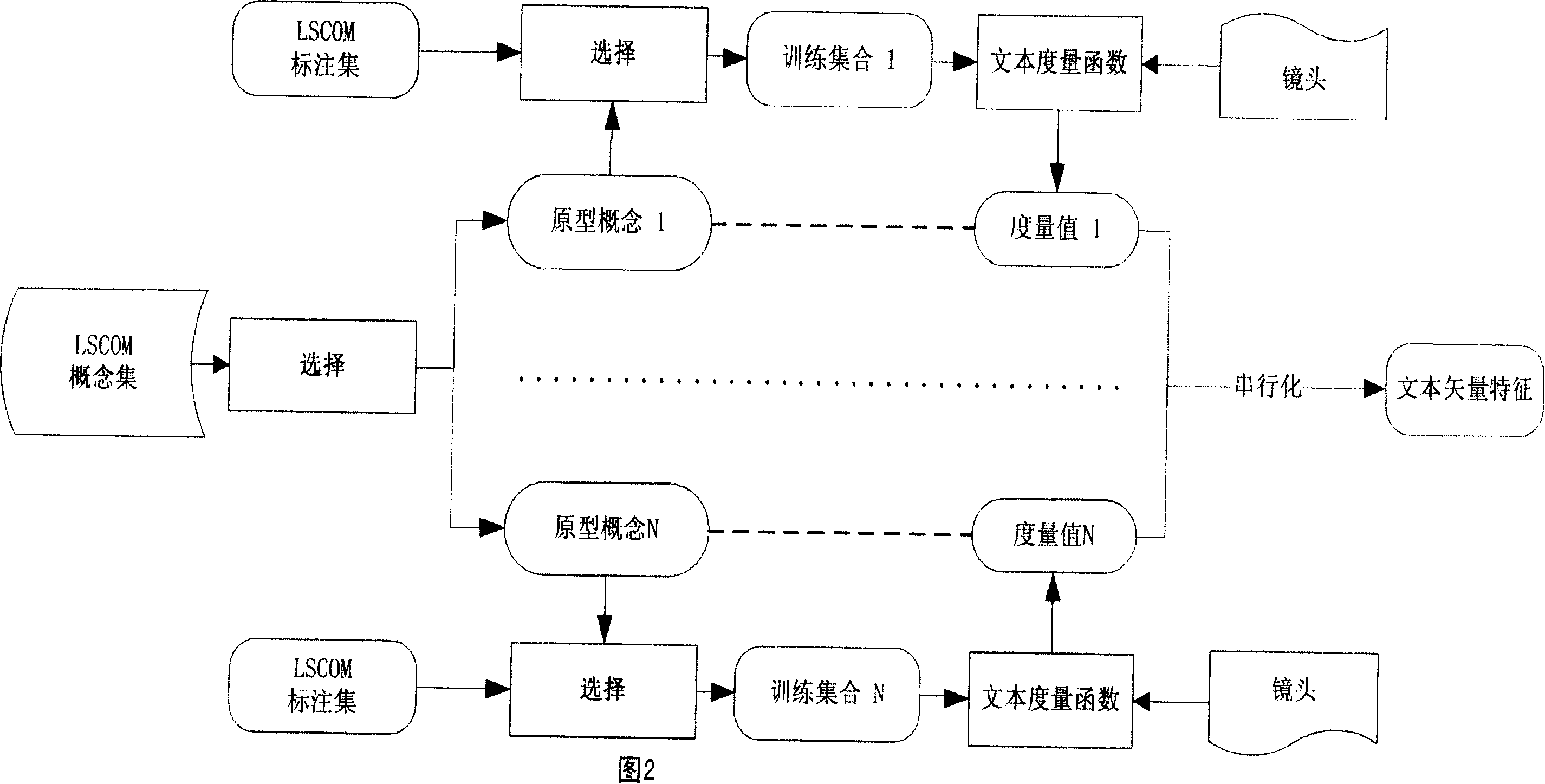

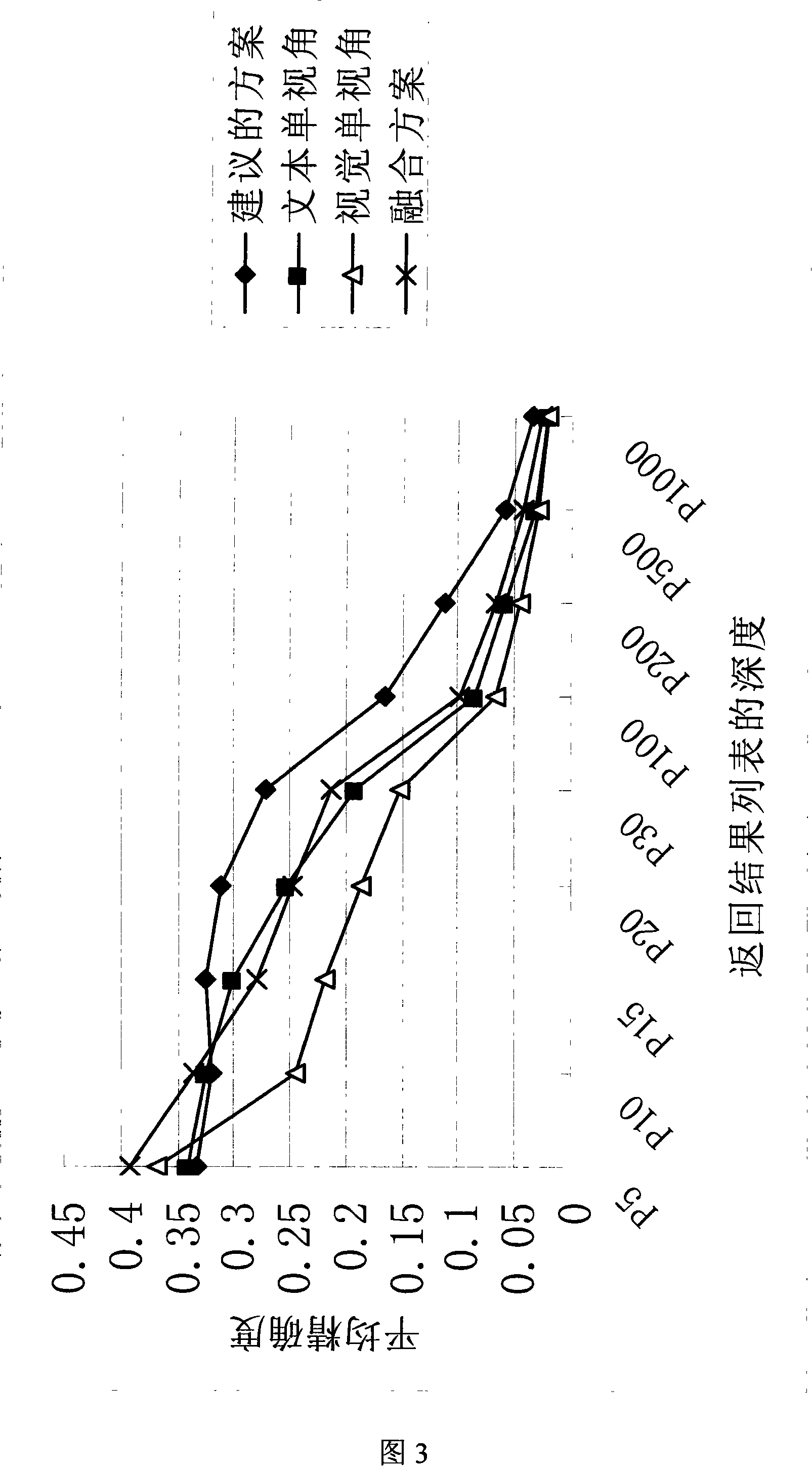

Interactive video searching method based on multi-view angle

InactiveCN101071439AReduce labeling burdenLarge sample sizeSpecial data processing applicationsMultiple perspectiveSemi-supervised learning

The invention discloses a multi-visual angle-based interactive video searching method, belonging to the field of video searching technique. And the invention applies multi-visual angle technique to interactive video searching. And the invention constructs a new arranging function from multiple independent visual angles in a semi-supervised learning mode and its advantage: it only needs very few label samples to be able to start a learning course and iteratively increases sample capacity from multiple visual angles and finally improves searching performance.

Owner:BEIJING JIAOTONG UNIV

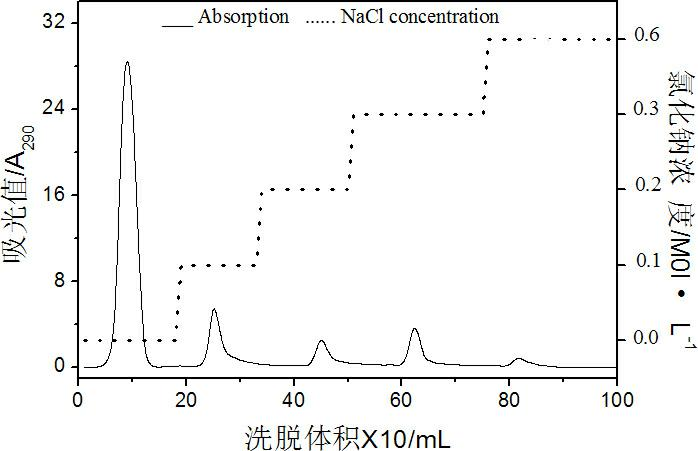

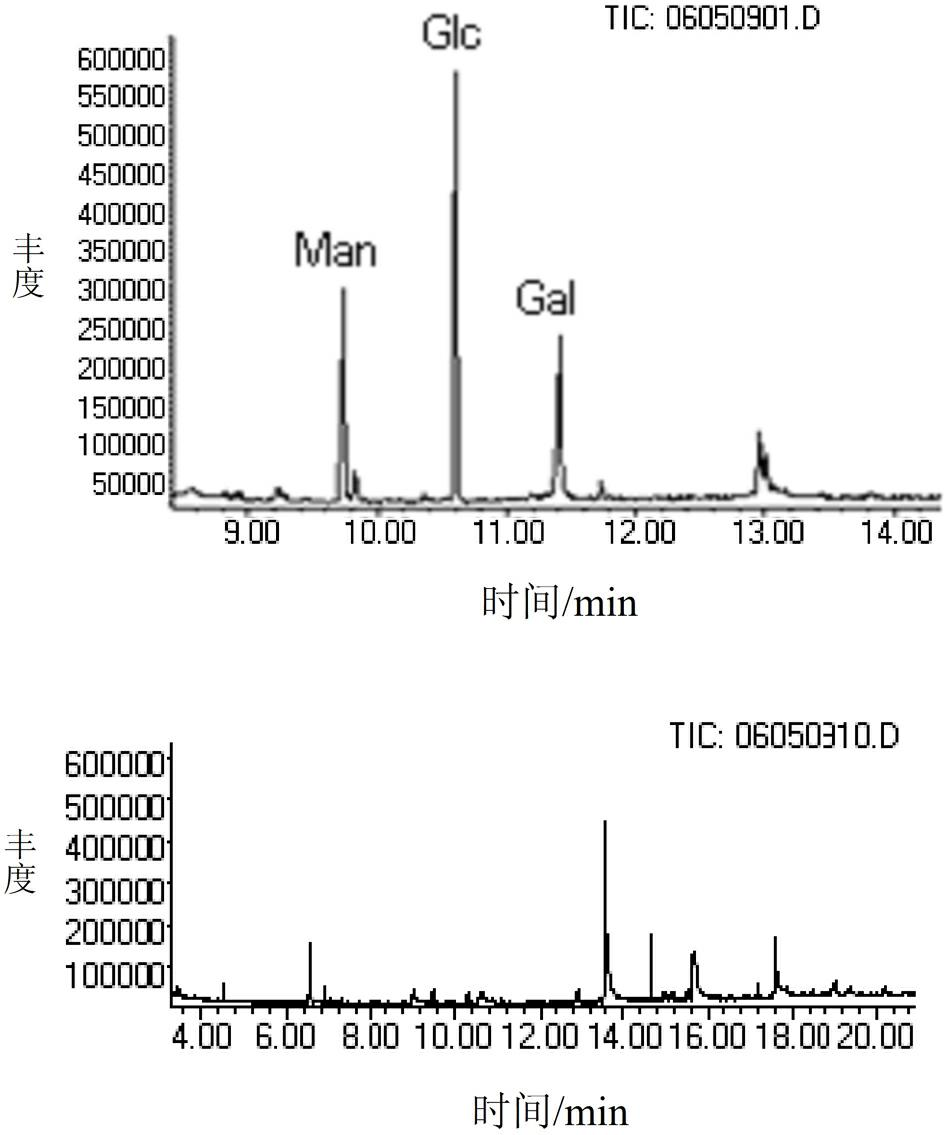

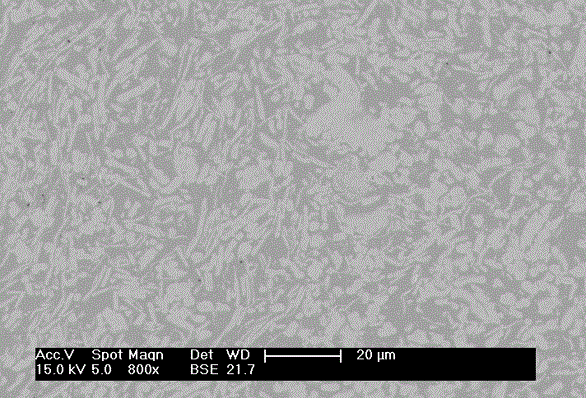

Active dendrobe polysaccharide capable of protecting liver and resisting liver fibrosis and preparation method of antibody affinity chromatography

ActiveCN102504043AImprove purification efficiencyStrong specificityOrganic active ingredientsDigestive systemAntiendomysial antibodiesMedicine

The invention discloses active dendrobe polysaccharide capable of protecting liver and resisting liver fibrosis, whose chemical structural formula is seen in the figure. The active dendrobe polysaccharide is gala glucomannan taking glucose and mannose as a main chain and galactose as a branch, the molecular weight of the gala glucomannan is about 2.2*104dalton, and the mole ratio of glucose to mannose to galactose in the composition is 31:10:8. The invention further discloses extraction, separation and purification methods of the active dendrobe polysaccharide as well as the preparation method of antibody affinity chromatography of the active dendrobe polysaccharide. The active dendrobe polysaccharide prepared by the method has remarkable physiological activity of protecting liver and resisting liver fibrosis and can be used for preparing liver-protecting health care products and medicines for curing liver fibrosis.

Owner:HEFEI UNIV OF TECH

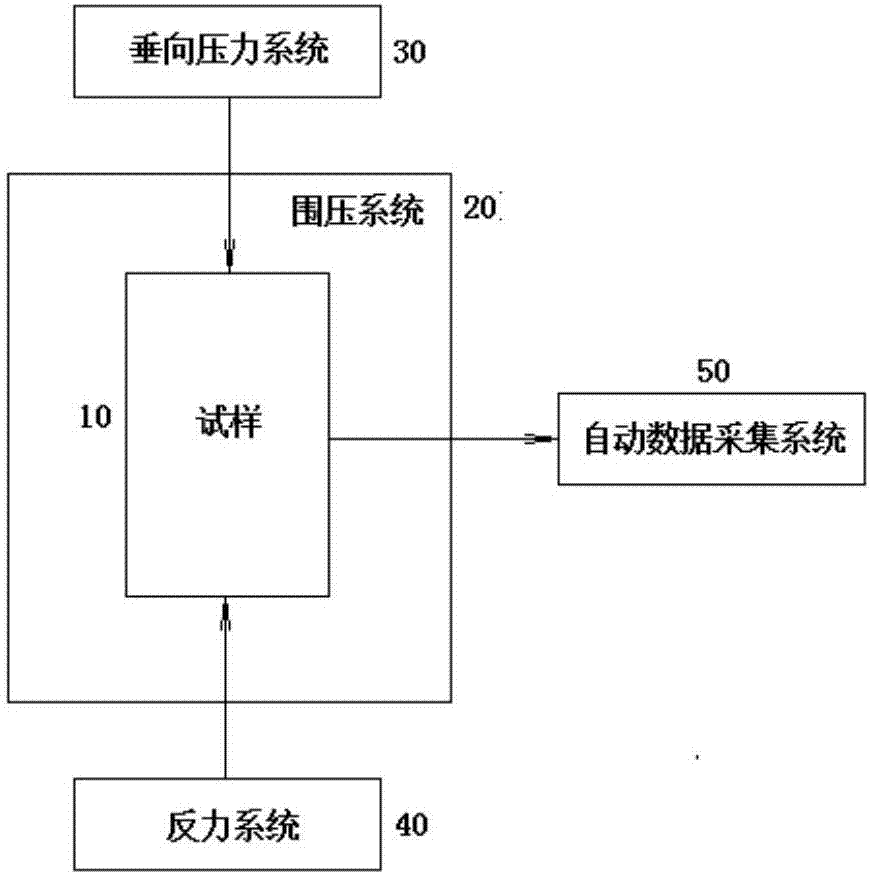

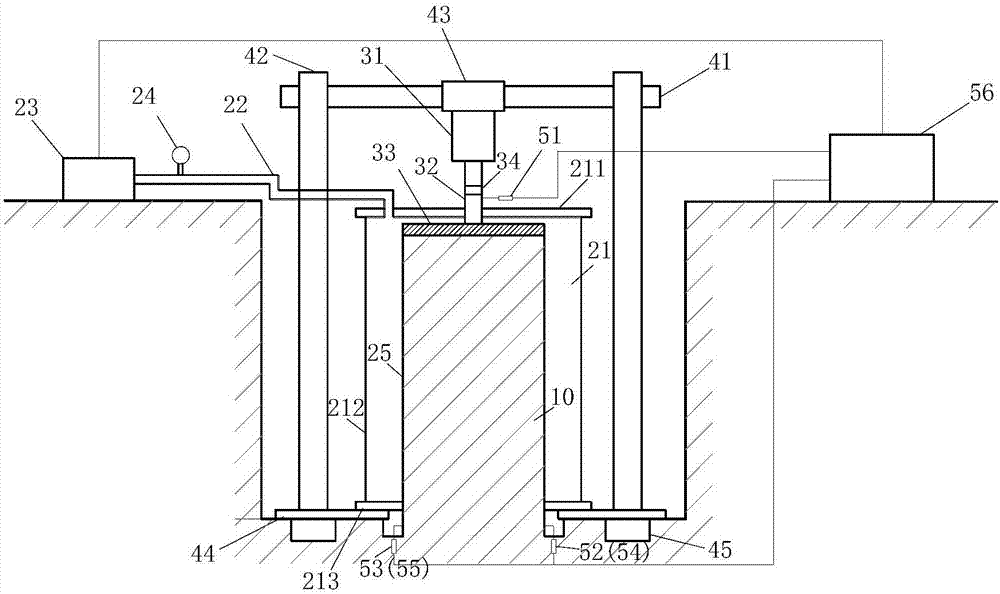

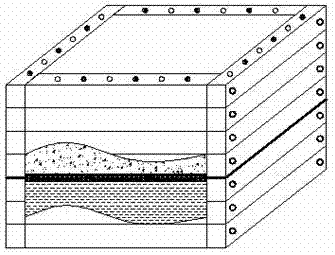

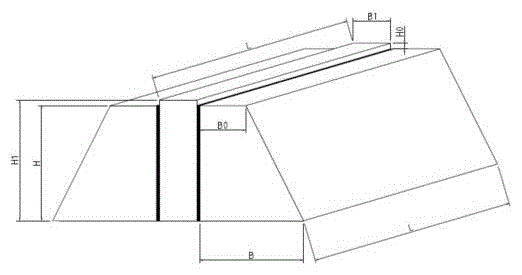

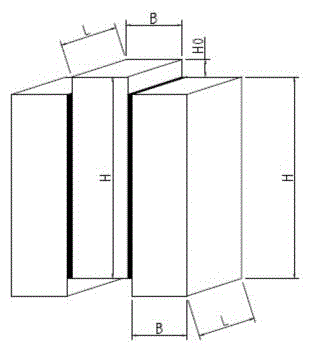

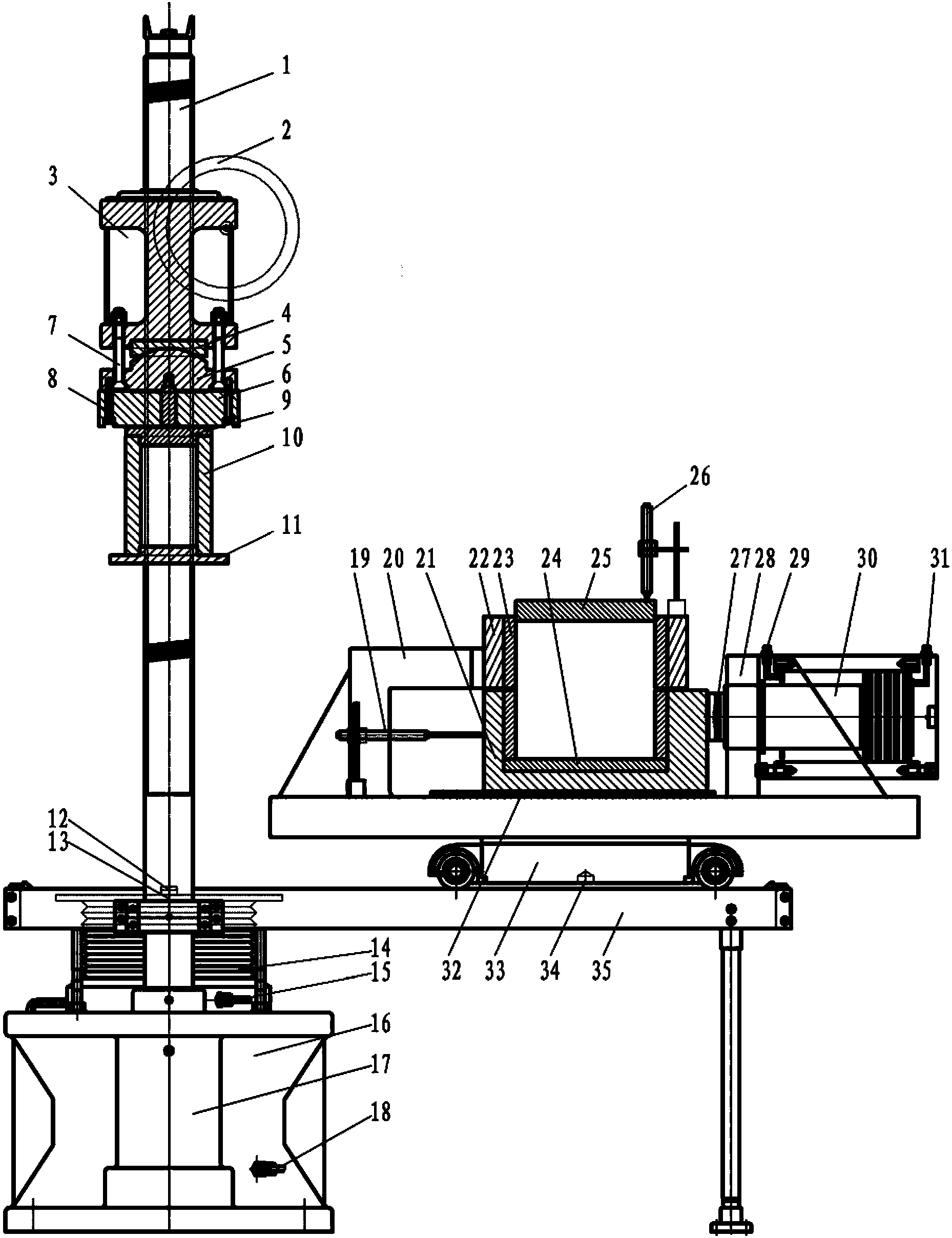

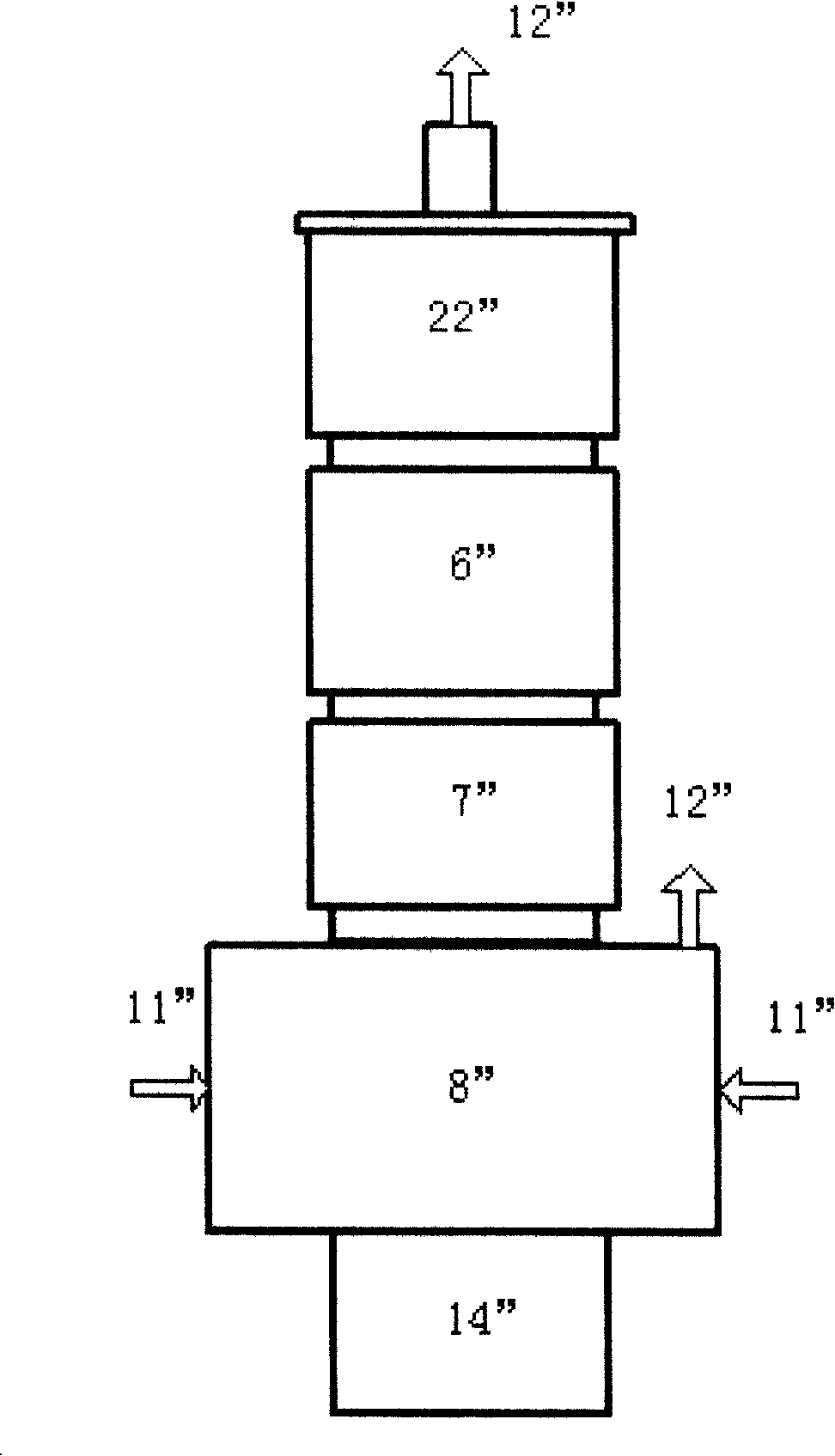

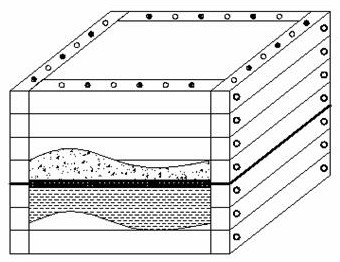

Large-scale in-situ triaxial shear test device and method thereof

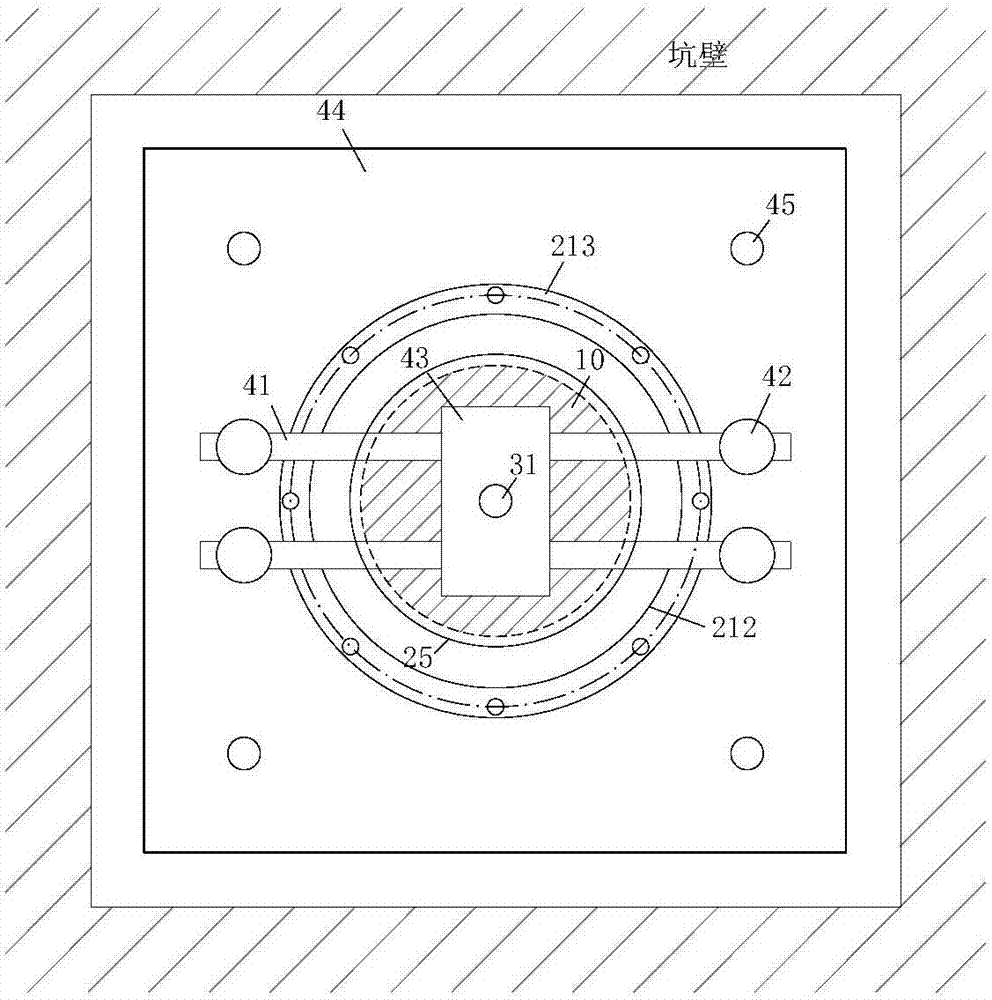

PendingCN107449678AThe test data is reliableLarge sample sizeMaterial strength using steady shearing forcesStress systemTriaxial shear test

The invention discloses a large-scale in-situ triaxial shear test device and a method thereof, and belongs to the technology of mechanical property test of soil in the field of geotechnical engineering. The device comprises a sample (10), a confining pressure system (20), a vertical pressure system (30), a counterforce system (40) and an automatic data acquisition system (50); the sample (10) is arranged in the confining pressure system (20); the vertical pressure system (30) and the counterforce system (40) are respectively arranged above and below the confining pressure system (20); and a vertical displacement meter of the automatic data acquisition system (50) is arranged in the sample (10). Compared with the prior art, an original structure of the sample can be maintained; confining pressure can be applied to the sample; an in-situ stress field of a measured soil body can be reproduced; the soil body can be damaged along the weakest surface thereof; and the size of the sample is large, so that the size effect influence is reduced. The large-scale in-situ triaxial shear test device and the method thereof have the characteristics of being real and comprehensive on the issue of researching the shear strength of the soil body; and test data are reliable, and powerful guarantee is provided for design and construction in the field of geotechnical engineering.

Owner:INST OF GEOMECHANICS

Large-scale real triaxial shear testing device and application thereof

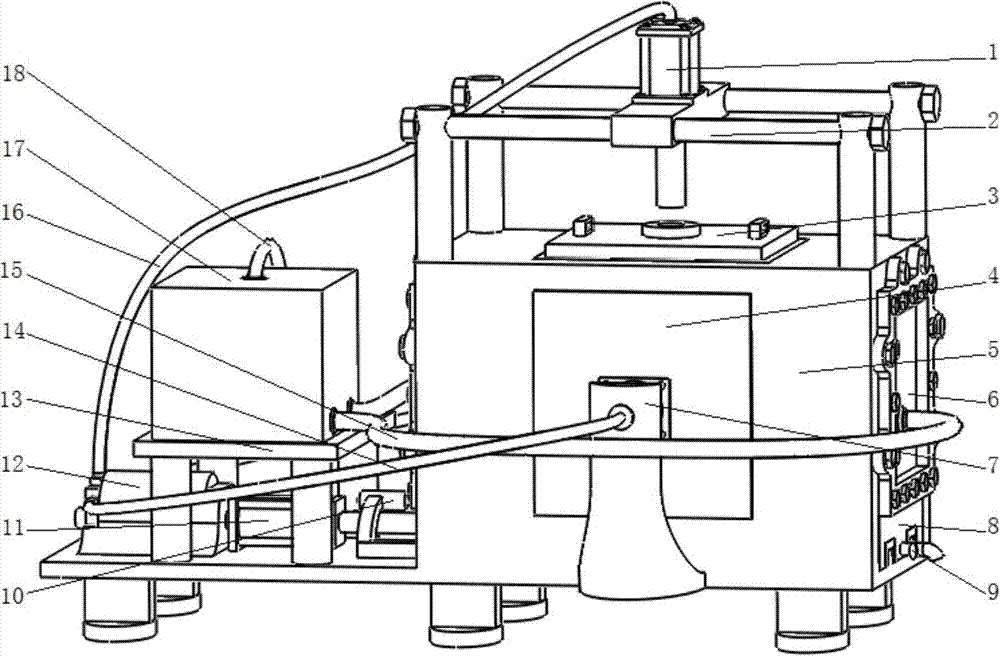

InactiveCN103698228AThe test data is accurate and reliableReproduce the original stress fieldMaterial strength using steady shearing forcesHydraulic cylinderTest sample

The invention relates to a large-scale real triaxial shear testing device and an application thereof. The testing device comprises a testing box, a hydraulic pressurization mechanism and a water pressure pressurization mechanism, wherein the testing box comprises a box frame, a shear box and a soil pocket; the hydraulic pressurization mechanism comprises a hydraulic control box, a vertical hydraulic cylinder, a horizontal hydraulic cylinder and a shear testing hydraulic cylinder; the water pressure pressurization mechanism comprises a water box, a gas pressure tank and a water pressure pocket; the hydraulic control box is used for controlling the pressure of the vertical hydraulic cylinder and the horizontal hydraulic cylinder, the gas pressure tank is used for controlling the pressure of the water pressure pocket and enabling a test sample in the soil pocket to be in a three-dimensional stress state, shear testing is performed on the test sample through the shear testing hydraulic cylinder, whether the test sample has drainage or not is controlled through a drainage valve, and the changes in displacement over time and the changes of pressure applied in each direction over the time are recorded when the test sample is sheared. Compared with the prior art, the large-scale real triaxial shear testing device provided by the invention has the characteristics that the size of the test sample is large, a shear surface is not a traditional fixed horizontal plane, the large-scale real triaxial shear testing device can be used for shear testing of soil in a three-dimensional stress state, and parameters of a soil layer can be determined more accurately.

Owner:TONGJI UNIV

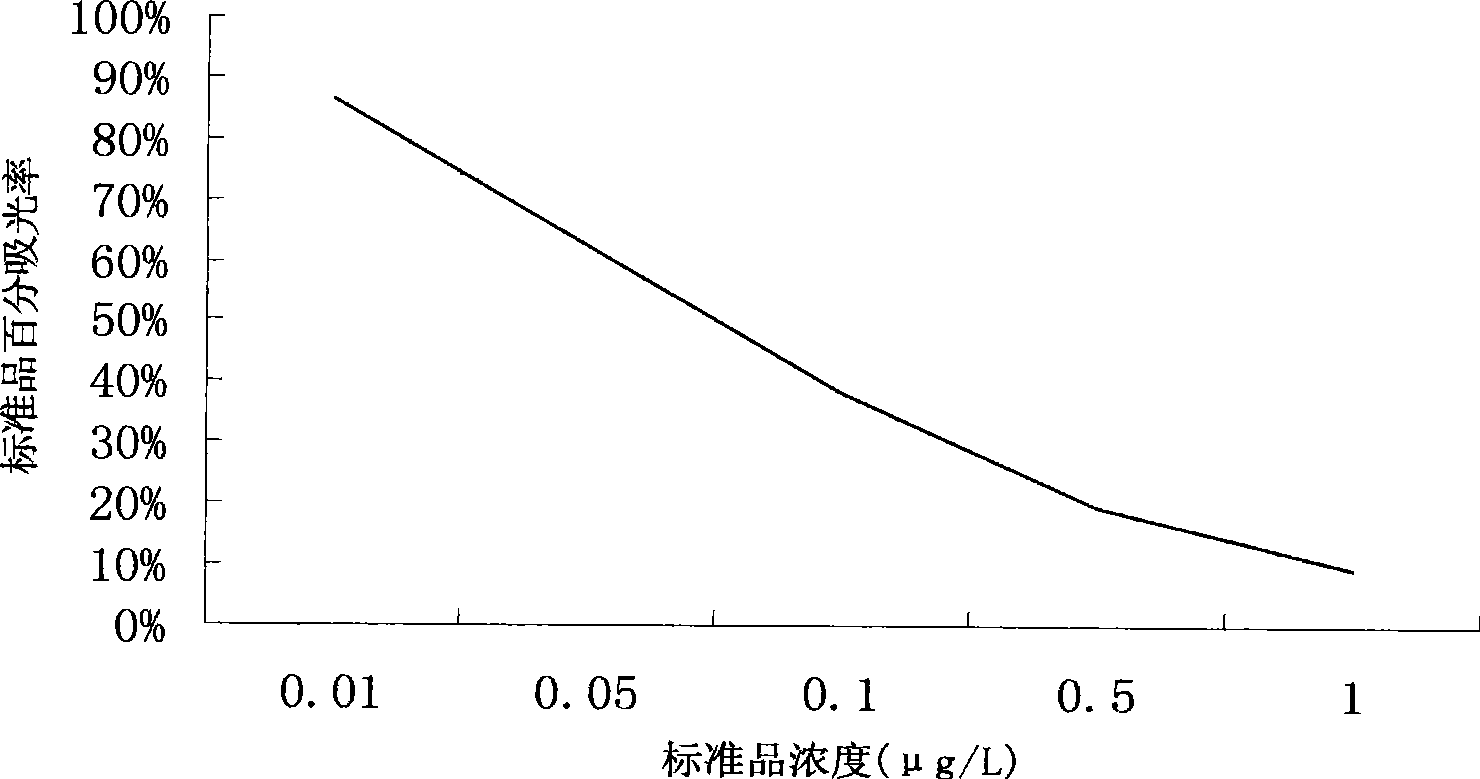

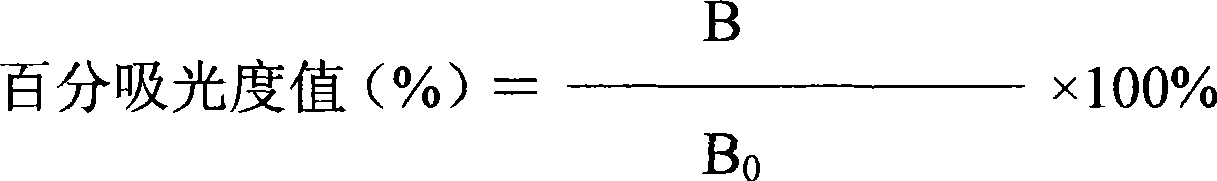

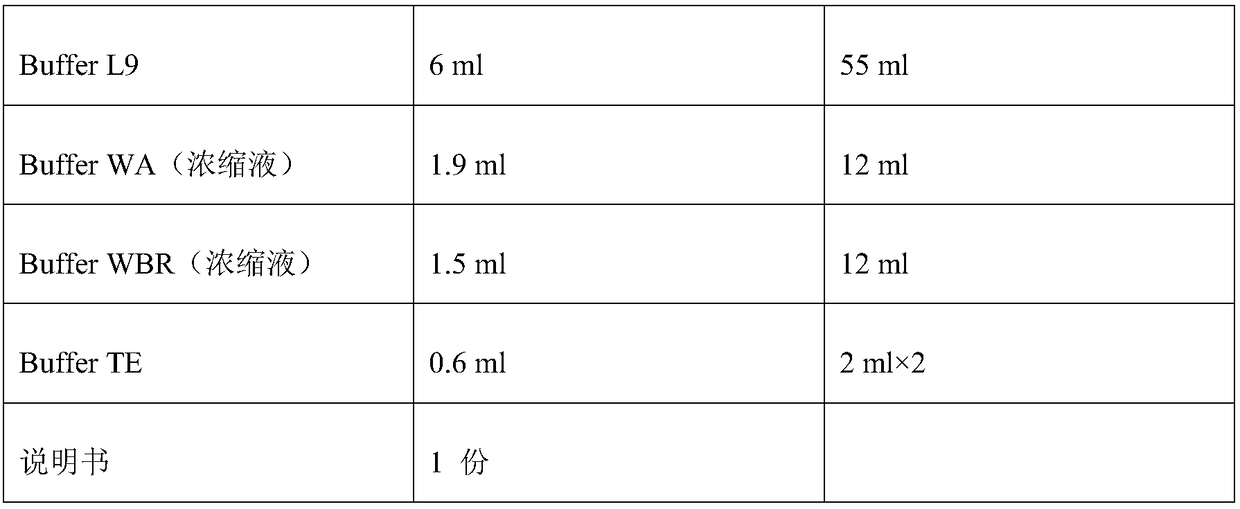

ELISA reagent for detecting malachite green and method

InactiveCN101424686ASimple and fast operationThe pre-processing process is simpleMaterial analysisMalachite greenMalachite green stain

The invention discloses an Elisa agent for detecting malachite green and a method thereof. The Elisa agent comprises a malachite green antigen or antibody coated Elisa plate, an enzyme label, a malachite green specific antibody, a malachite green standard solution, a substrate developing solution, a stop solution, a concentrated cleaning solution, enzyme label diluents and a concentrated combined solution. The Elisa agent is used for the quantitative detection of the content of the malachite green in fishes, shrimps and water samples and has the advantages of high specificity and sensitivity, easy sample pretreatment, short detection time, large sample detection amount, and the like.

Owner:深圳市绿诗源生物技术有限公司

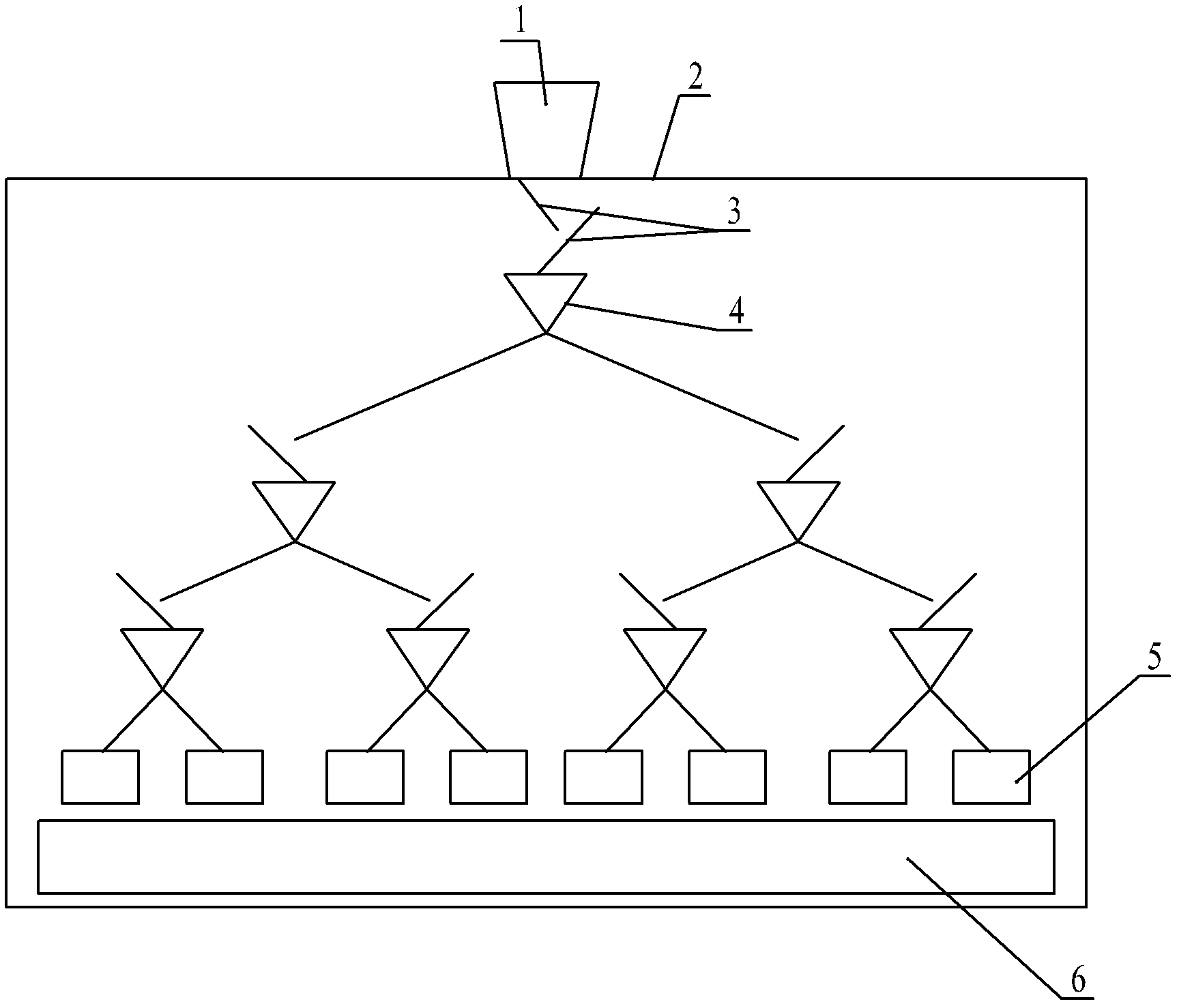

Grain sample splitter

ActiveCN102435479AQuick mixSimple structurePreparing sample for investigationInjection portBulk samples

The invention relates to a grain sample splitter, which comprises a hopper, a box, a multi-stage sample splitting system and sample cases, wherein the hopper is arranged above the box; the top of the box is provided with an injection port opposite to a lower outlet of the hopper; the multi-stage sample splitting system is arranged in the box, and is provided with a plurality of sample splitting discharge holes; and a sample case for collecting split samples is arranged below each sample splitting discharge hole. The grain sample splitter has simple structure, large sample splitting quantity and high efficiency, can quickly mix the samples uniformly, and can split a large number of samples in different ratios at one time to obtain representative samples in different splitting ratios at onetime; the one-time maximum sample splitting quantity is only limited to the size of the sample cases; and the grain sample splitter is easy, convenient and quick to operate, and can meet the requirements of inspection, massive sample preparation and the like.

Owner:WUXI SUI BANG TECH

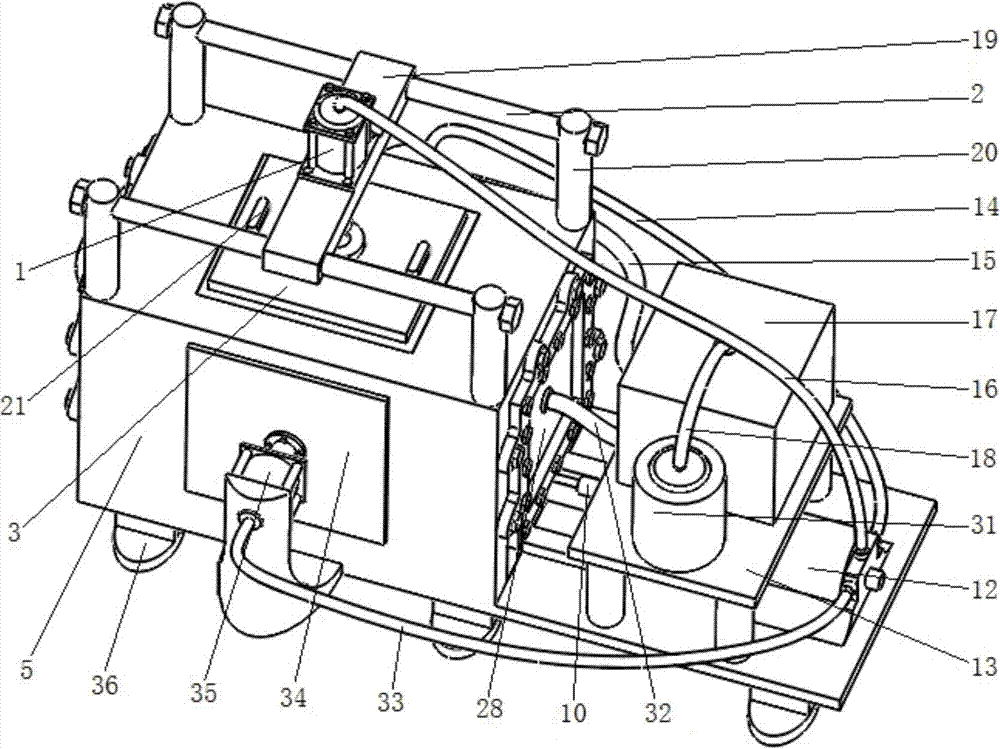

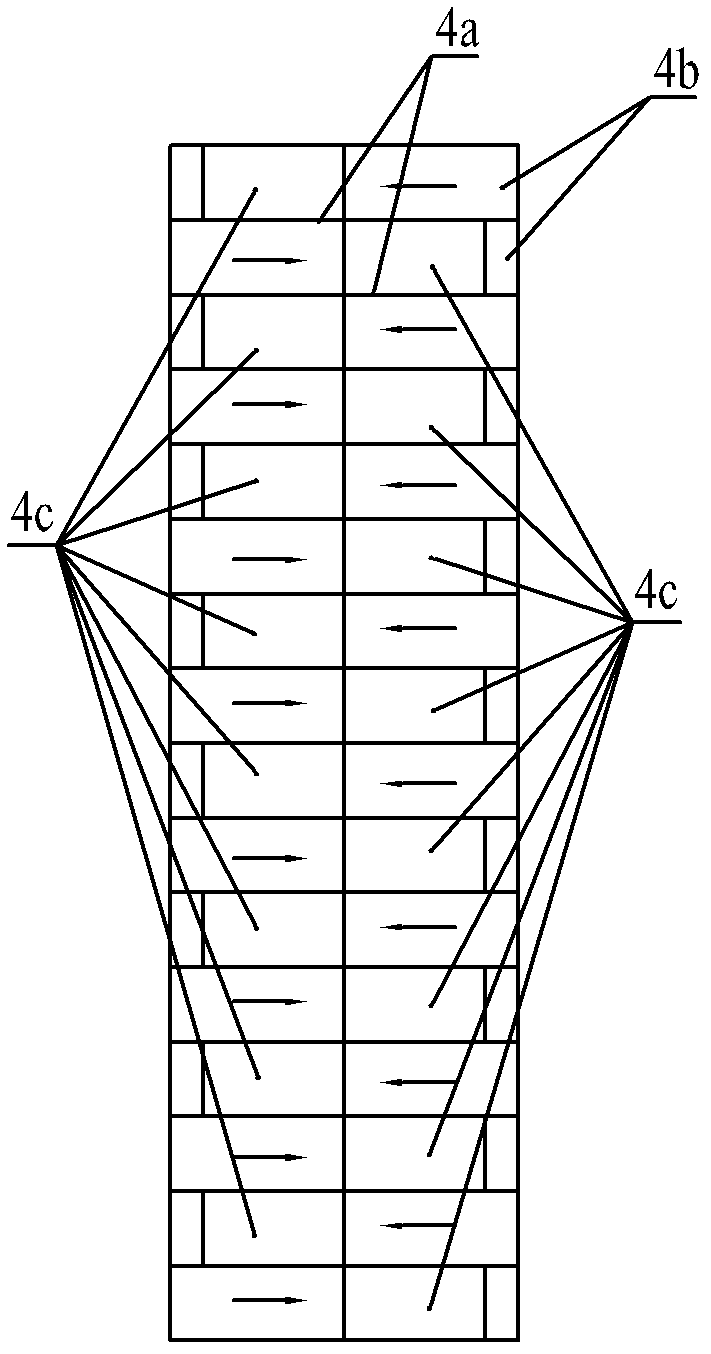

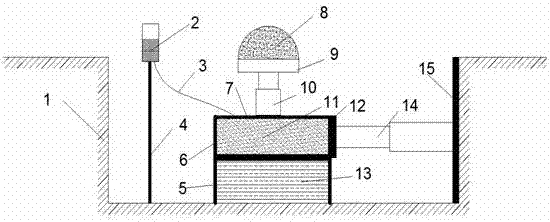

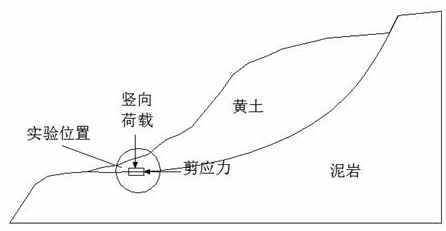

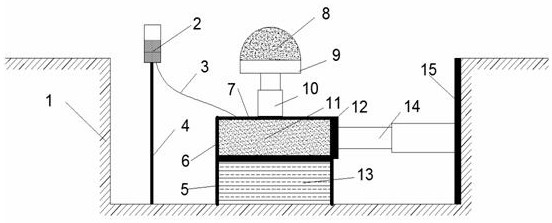

In-situ shearing experimental instrument for measuring saturated loess-mud rock contact surface

ActiveCN107271297ALarge sample sizeMaterial strength using steady shearing forcesTest sampleWater flow

The invention relates to an in-situ shearing experimental instrument for measuring a saturated loess-mud rock contact surface. A lower shearing box is mounted in an experiment foundation pit, an upper shearing box is mounted on the lower shearing box, and a horizontal hydraulic jack is horizontally arranged between the upper shearing box and the experimental foundation pit; a shearing box pressure cover is mounted on the top of the upper shearing box, the shearing box pressure cover is connected to a counterweight supporting plate through an axial hydraulic jack, and a counterweight is mounted on the counterweight supporting plate; a water holder is also mounted in the experimental foundation pit through a supporting rod of the water holder, and the water holder is connected to a water inlet hole in the upper portion of the upper shearing box through a water delivery pipe, so that injected water flows out from the lower portion of the upper shearing box. The in-situ shearing experimental instrument provided by the invention can truly reflect and keep an excessively wet, saturated and soft and plastic state of the loess-mud rock contact surface in situ without disturbance on soil. A test sample for the experiment is large in dimension, and the in-situ shearing experimental instrument is an effective instrument for acquiring in-situ instantaneous shearing strength and long-term creep shearing strength parameters of heterogeneous soil on the saturated loess-mud rock contact surface.

Owner:NORTHWEST UNIV(CN)

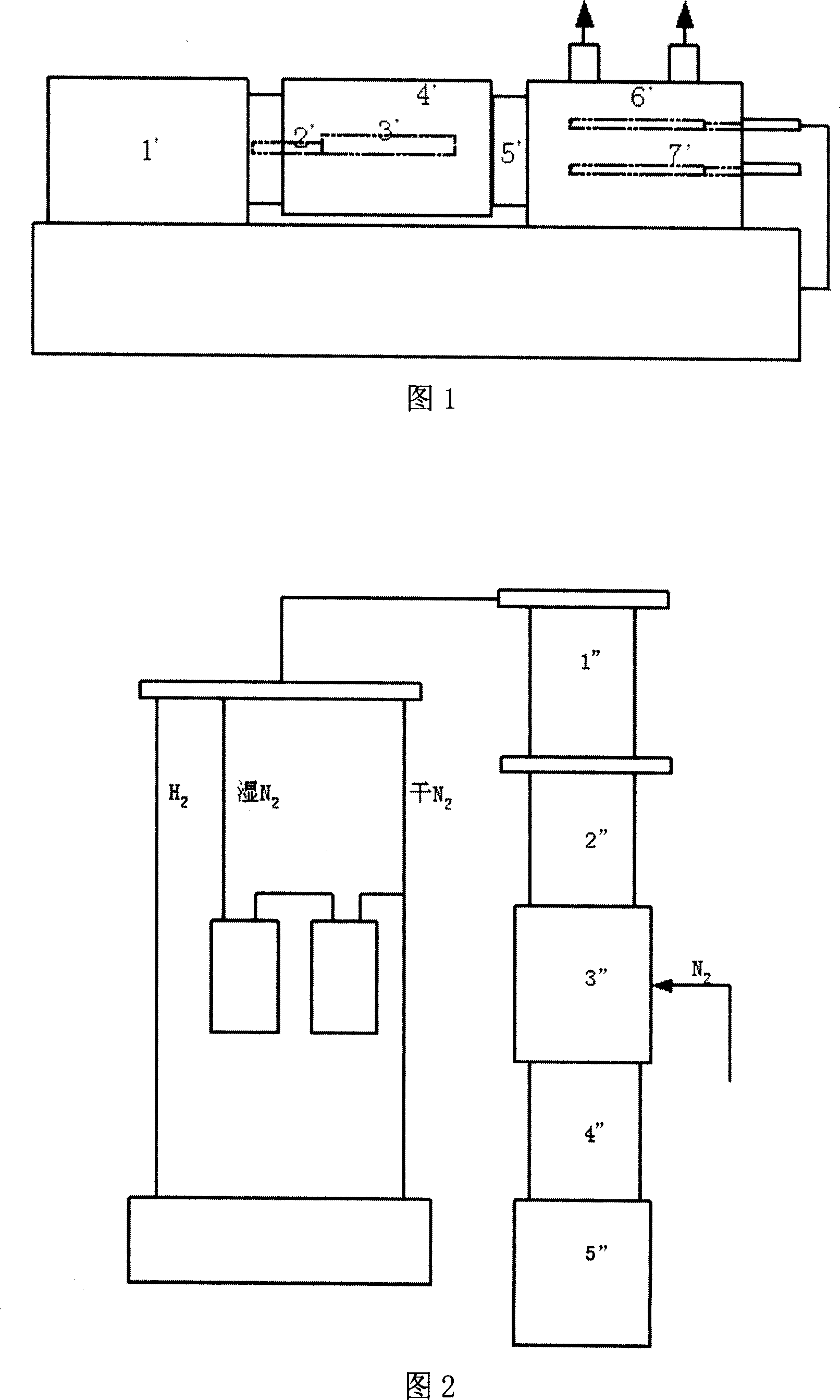

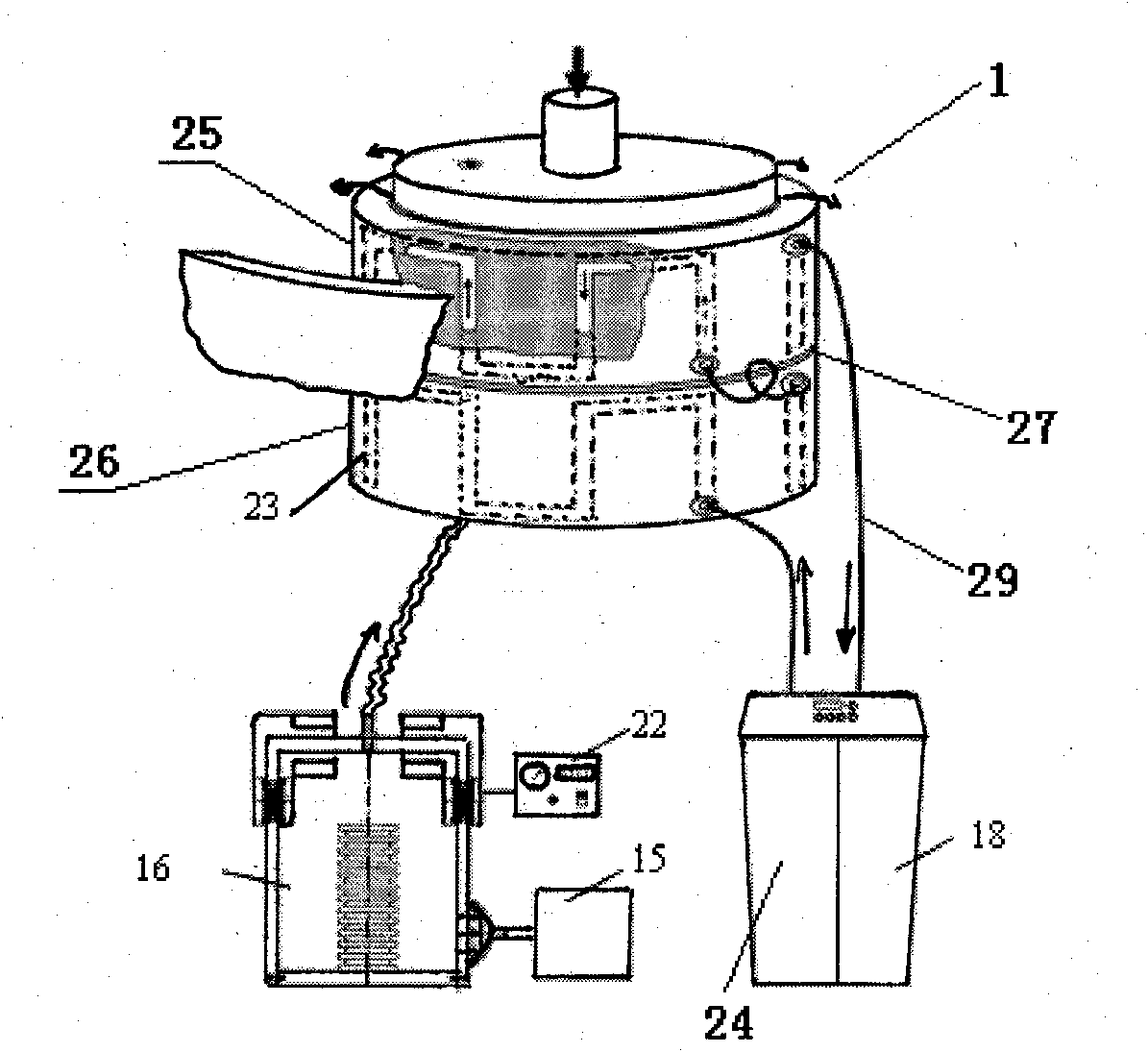

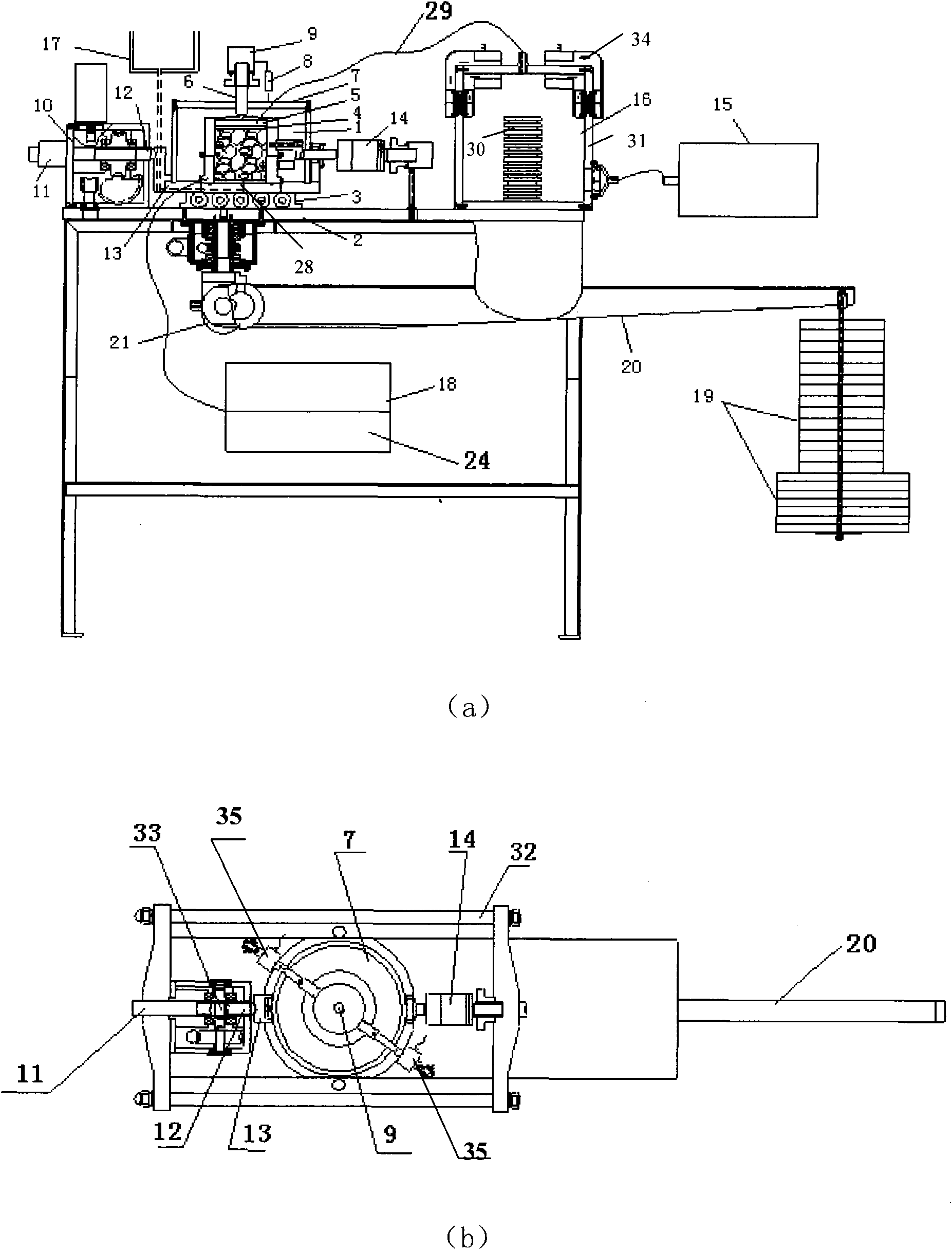

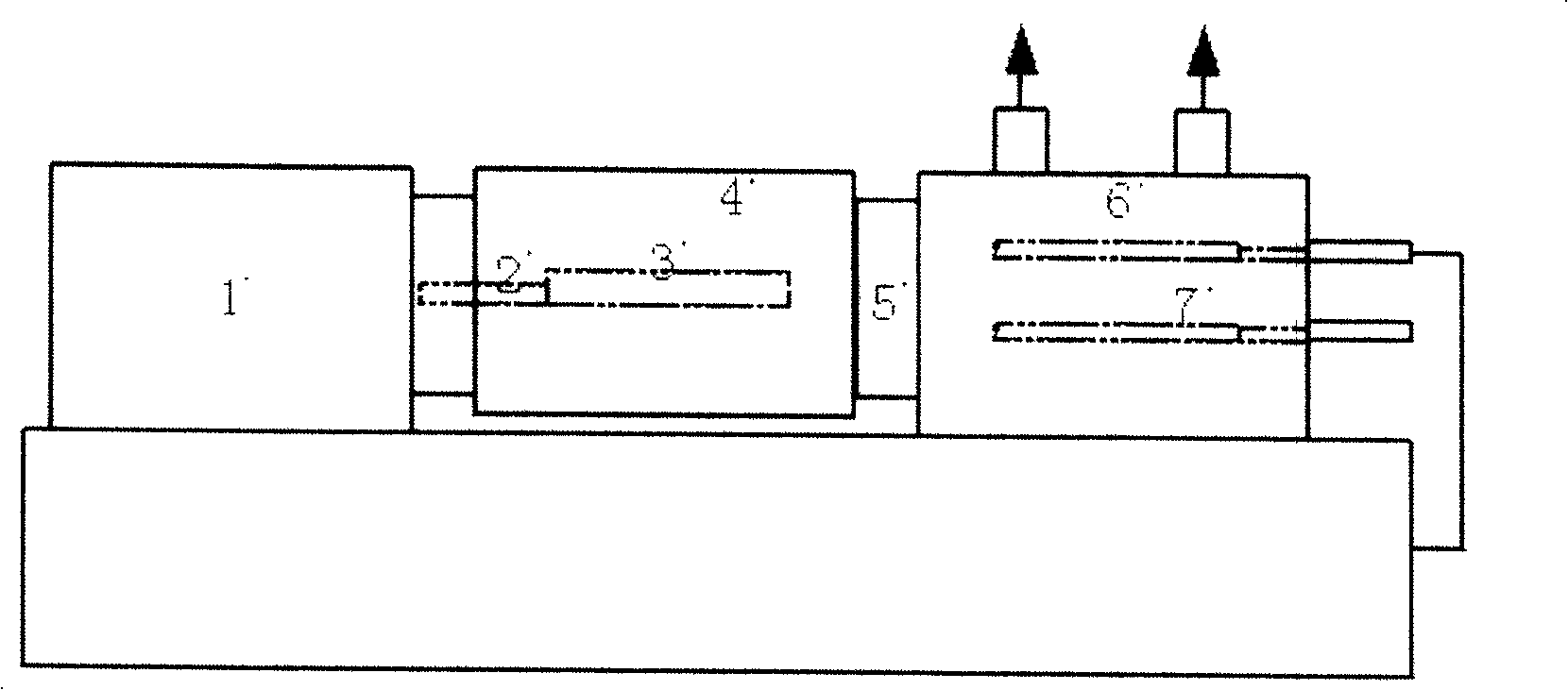

Quick cooling test plant for disk type band steel, and method of use

InactiveCN101092660AEliminate fragileEliminate deformationFurnace typesHeat treatment furnacesFixed frameStrip steel

This invention relates to disk-type strip steel rapid cooling test apparatus for stimulating annealing process requirement of continuous annealing of strip steel, and its usage method. The apparatus comprises: a disk-type case, a disk-type sample fixing frame and a compensating wire that can rotate around a core axis in the case, a sample loading / unloading chamber, a heating / homogenizing chamber, a slow cooling / over-aging chamber, a spray cooling chamber and a water quenching chamber. When used, the compensating wire is connected to the surface of the sample, and then the sample is introduced into the above chambers in sequence. This invention has such advantages of large sample size, a wide variety of cooling methods, high cooling speed, simple apparatus, and low malfunction rate.

Owner:BAOSHAN IRON & STEEL CO LTD

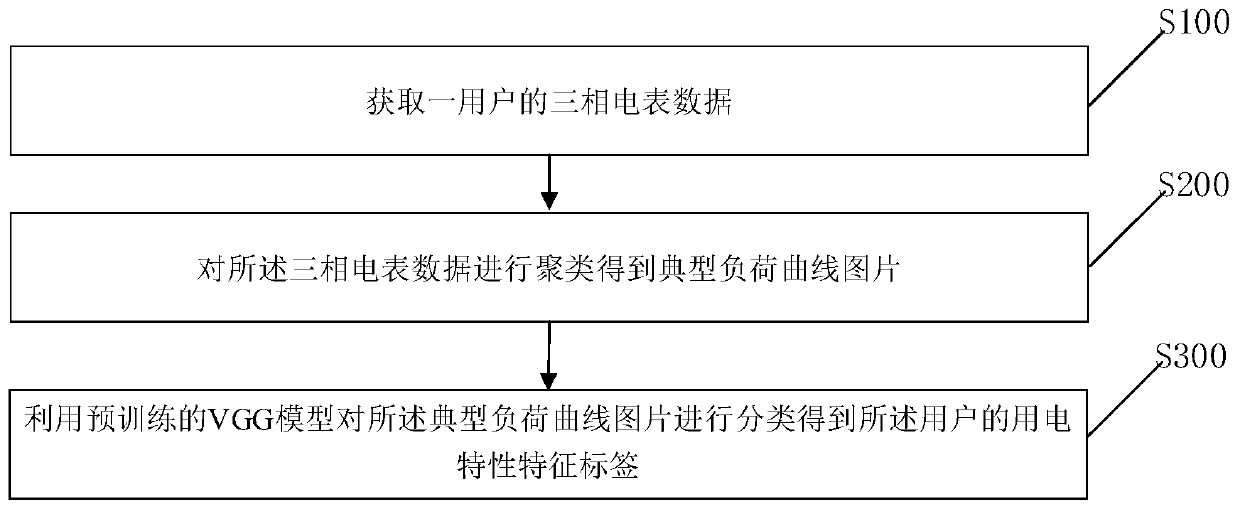

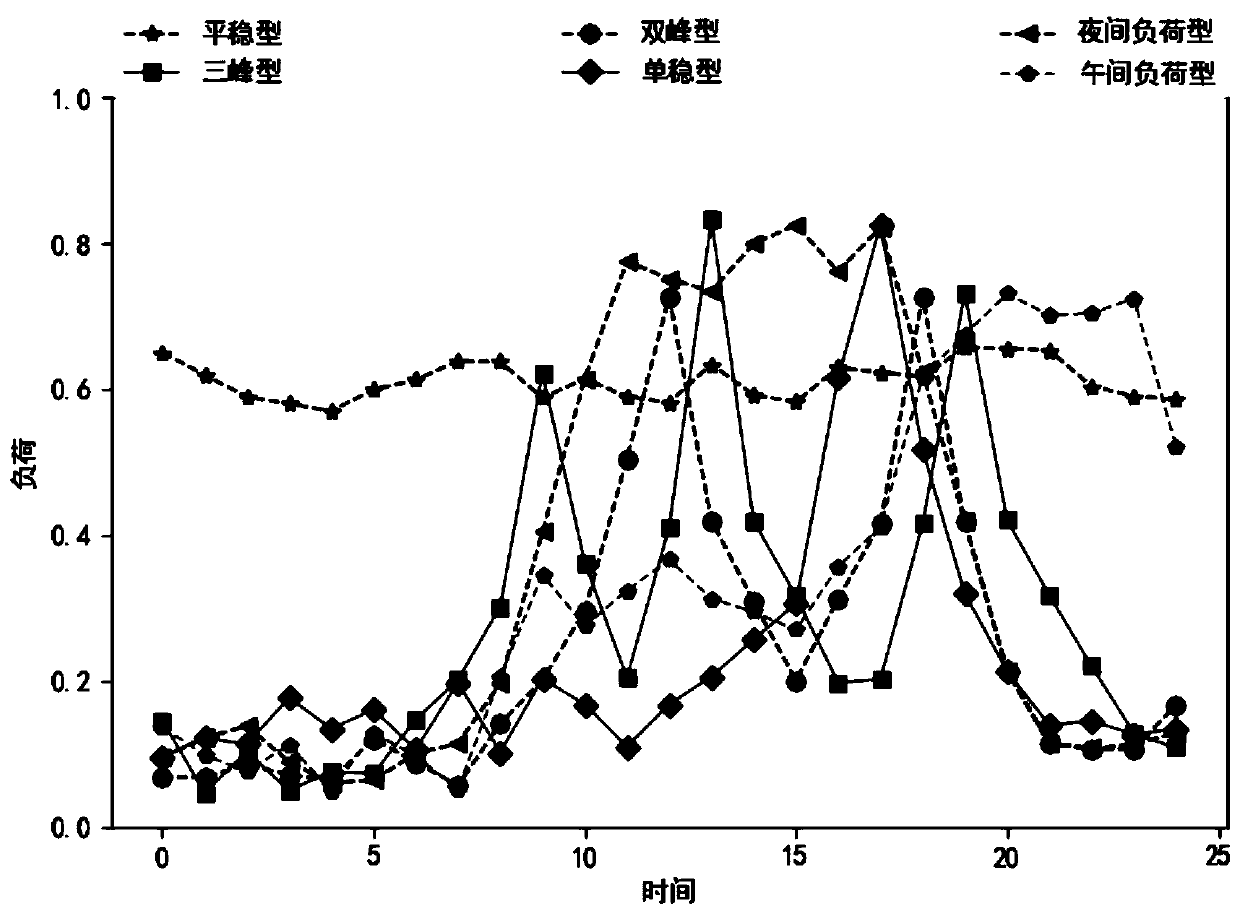

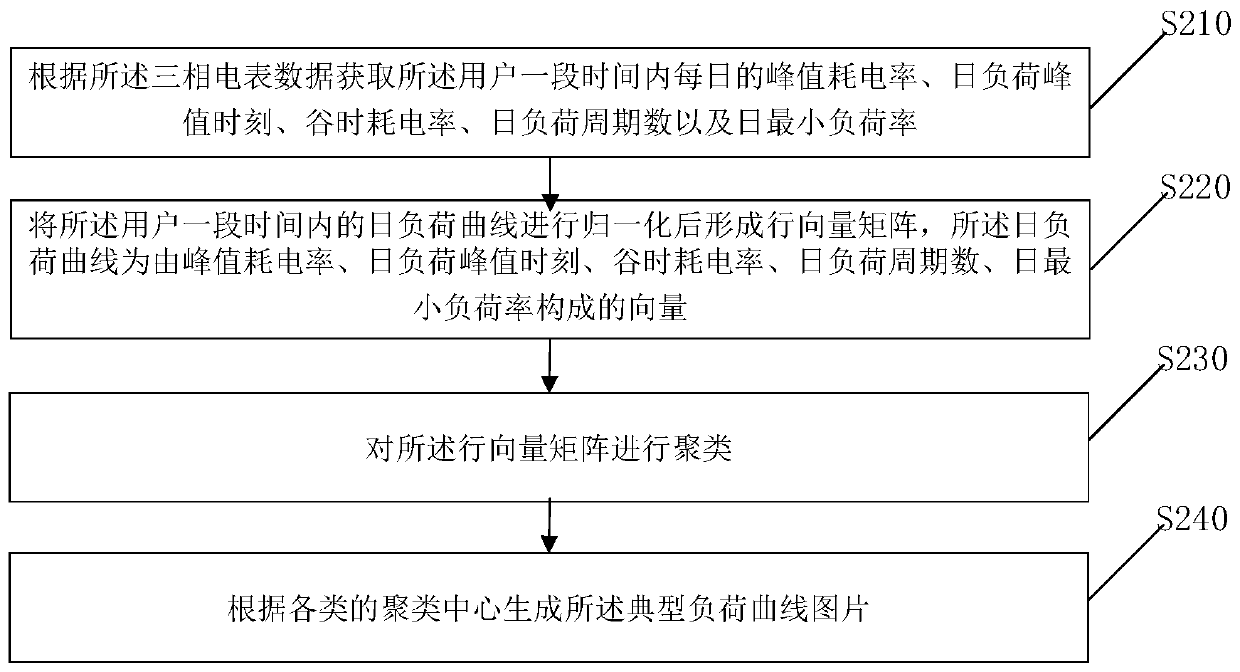

Power consumer information tagging method and device, electronic equipment and storage medium

PendingCN111144468AReduce the difficulty of implementationLarge sample sizeCharacter and pattern recognitionResourcesThree-phase electric powerEngineering

The invention provides a power consumer information tagging method and device, electronic equipment and a storage medium. The method comprises the steps of obtaining three-phase electric meter data ofa user; clustering the three-phase electric meter data to obtain a typical load curve picture; classifying the typical load curve pictures by using a pre-trained VGG model to obtain power utilizationcharacteristic feature tags of the users; combining K-means clustering and a deep convolutional neural network to be used for power consumer information tagging, and obtaining a power consumer behavior portrait. The implementation difficulty is small, the sample size is large, all typical users can be covered, and the accuracy is high.

Owner:STATE GRID JIBEI ELECTRIC POWER COMPANY +5

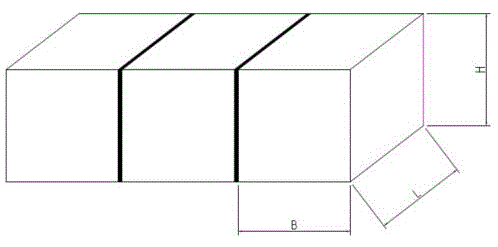

Sample for testing adhesion and anti-shearing strength of refractory mortar and testing method thereof

InactiveCN105004603AEasy to manufactureIncrease bonding areaMaterial strength using steady shearing forcesFire brickUltimate tensile strength

The invention relates to a sample for testing adhesion and anti-shearing strength of refractory mortar and a testing method thereof. According to the scheme, the sample is a whole formed by three refractory bricks in a bonding mode through the refractory mortar to be tested; the sample has three specific shapes that 1, upper planes and lower planes of the three refractory bricks are all flush with each other; 2, the lower planes of the three refractory bricks are flush with one another, and the upper plane of the middle refractory brick is higher than the upper planes of the refractory bricks at the two sides; 3, the upper plane of the middle refractory brick is higher than the upper planes of the refractory bricks at the two sides, and the lower plane of the middle refractory brick is concaved into the lower planes of the refractory bricks at the two sides. Materials of the three refractory bricks are matched with the materials of the refractory mortar to be tested, and refractory mortar bonding surfaces of the three refractory bricks are original brick surfaces of the refractory bricks. The three refractory bricks have the shapes that the middle refractory brick is shaped like a cuboid or a cube, and the refractory bricks at the two sides are each shaped like a cuboid or a cube or a trapezoid with the vertical bonding surface. According to the sample for testing the adhesion and anti-shearing strength of the refractory mortar and the testing method thereof, the preparation is convenient, and the sample is large is size; the testing process of the prepared sample is easy, and the testing result is accurate and reliable.

Owner:WUHAN UNIV OF SCI & TECH

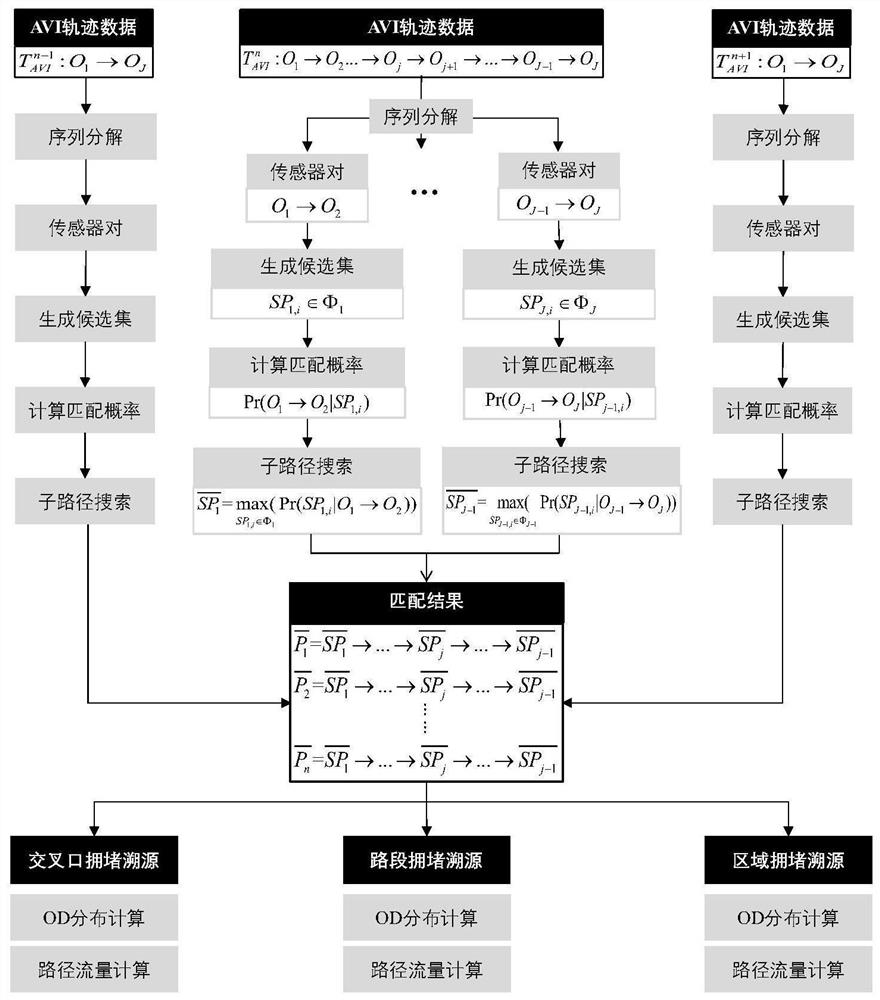

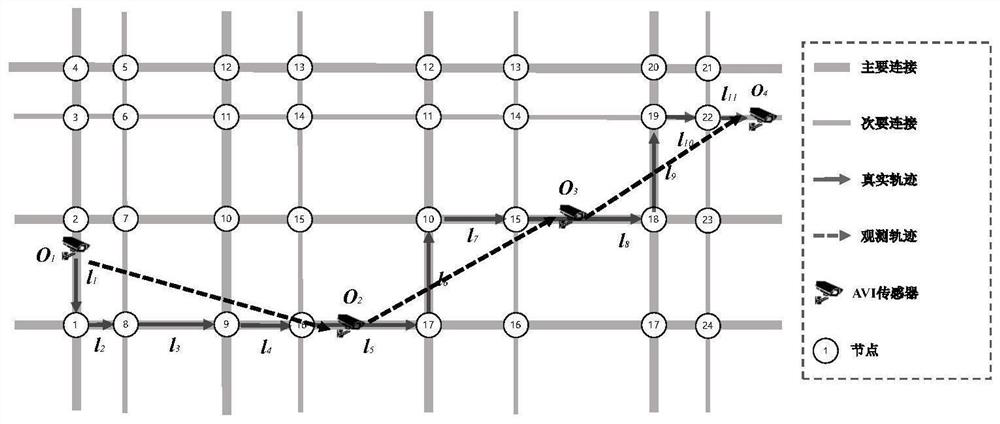

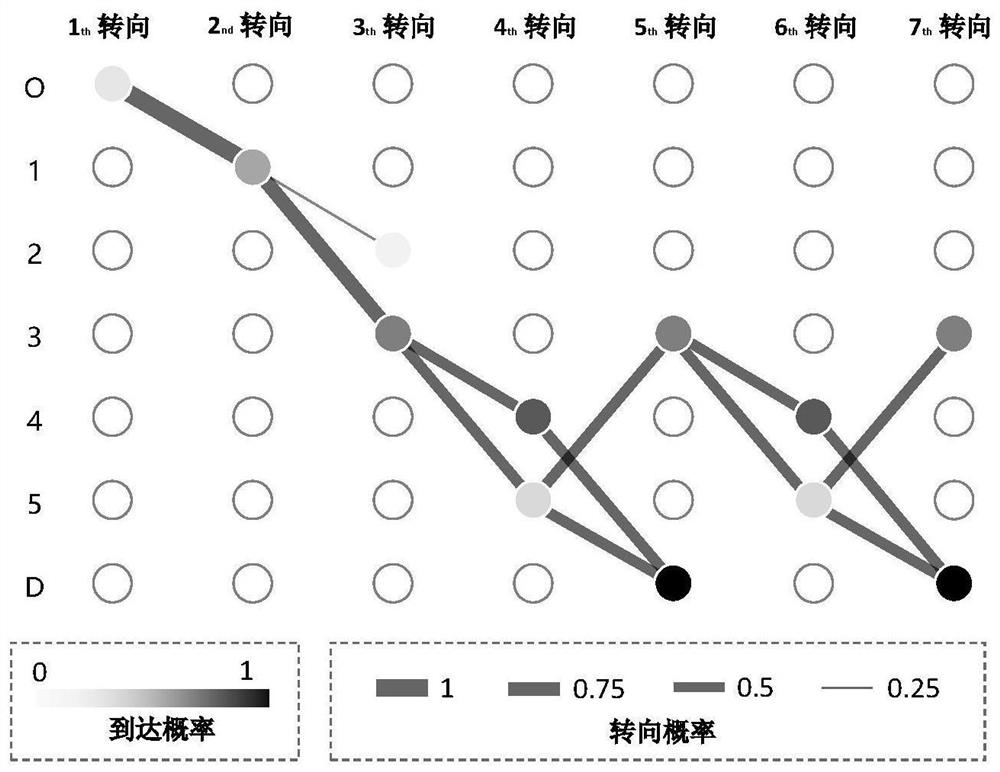

Traffic jam tracing method based on multi-source data

ActiveCN113724489AHigh precisionLarge sample sizeDetection of traffic movementSource dataMap matching

The invention provides a traffic jam tracing method based on multi-source data. The method comprises a map matching algorithm (AVI-MM) based on the multi-source data and a multi-level traffic jam tracing algorithm. The AVI-MM algorithm fuses sparse AVI data and massive GPS data, firstly, a vehicle path candidate set is generated based on a random walk algorithm, then, a prior probability is determined based on a Logit path selection model with the maximum utility, a conditional probability is defined through space-time fusion analysis, and finally, sub-paths with the maximum matching probability are communicated in sequence to obtain a final full path; the multi-level traffic jam traceability algorithm is based on a map matching result, and multi-level vehicle track OD distribution of road sections, nodes and areas is calculated respectively. According to the method, high-precision matching of the quasi-full-sample vehicle track and the driving path is realized, and based on the path matching result of the quasi-full-sample AVI data, the origin-destination distribution and the path distribution of the traffic flow of the congested road section are quantitatively analyzed.

Owner:SOUTHEAST UNIV

Caenorhabditis elegans drunkenness model creation method for rapidly screening alcohol-effect-dispelling plants and application

ActiveCN108670961AShorten the growth cycleGuaranteed accuracyCompounds screening/testingHydroxy compound active ingredientsEvaluation resultHigh-Throughput Screening Methods

The invention discloses a caenorhabditis elegans drunkenness model creation method for rapidly screening alcohol-effect-dispelling plants. The caenorhabditis elegans drunkenness model creation methodincludes taking wild caenorhabditis elegans as a base, and cultivating the caenorhabditis elegans in liquid until the content reaches 2000-2500 worm / mL; after the caenorhabditis elegans just grows into the adulthood, adding an alcoholic solution into the worm liquid until the final concentration of the alcoholic solution reaches 1-5%, and performing 24-hour intervention, wherein the caenorhabditiselegans is drunk at the moment. The method has the advantages that a model organism, namely the caenorhabditis elegans, which is convenient and easy to get, is adopted for evaluation, and accordingly, experiment cost can be reduced effectively; the growth cycle of the caenorhabditis elegans is short, and tens of thousands of the caenorhabditis elegans can be reproduced in a short time to be usedfor experiments, so that enough samples can be guaranteed, experiment errors can be reduced, and accuracy of evaluation results can be guaranteed; high-throughput screening experiments can be carriedout, experiment results can be acquired efficiently, and experiment cycle can be shortened greatly.

Owner:HUNAN AGRICULTURAL UNIV

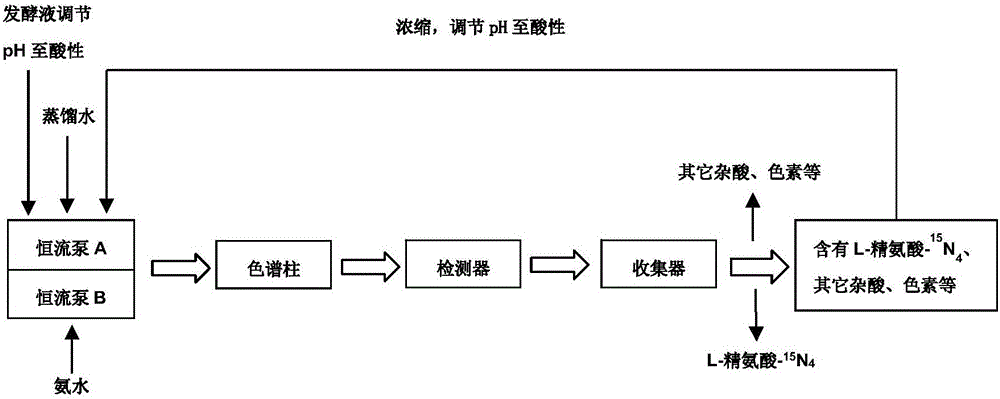

Method for extracting high-abundance L-arginine-15N4 from high-abundance 15N isotope-labeled L-arginine fermentation liquor

InactiveCN105732436ALarge sample sizeHigh column efficiencyOrganic compound preparationOrganic chemistry methodsChemistryVacuum drying

The present invention relates to high-abundance 15 Extraction of high-abundance L-arginine from N-isotope-labeled L-arginine fermentation broth 15 N 4 approach to high-abundance 15 The fermentation broth of N isotope-labeled L-arginine is used as raw material, and a medium-pressure preparative chromatography system is used. After two-step separation, pure L-arginine can be obtained after 8-12 hours. 15 N 4 The single-product solution is then concentrated by catching ammonia, decolorized by activated carbon, crystallized by absolute ethanol, and vacuum-dried at 60°C to separate and extract L-arginine- with a product purity > 98%. 15 N 4 product, the total extraction yield is greater than 80%. The invention not only has simple principle, convenient operation, large and fast processing capacity, but also avoids the long extraction time of the ion exchange resin method and the environmental pollution caused by the discharge of a large amount of waste acid and alkali produced by resin treatment.

Owner:SHANGHAI RES INST OF CHEM IND

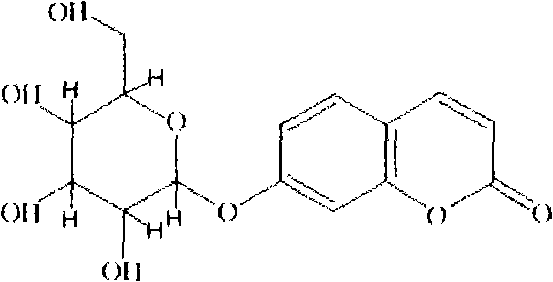

Preparation method of skimmin

InactiveCN102911224AAchieving Countercurrent ContactIncreasing concentration gradientSugar derivativesSugar derivatives preparationAcetic acidElution

The invention relates to a preparation method of skimmin. The method comprises technical steps of: creeping dichondra complete herb is subjected to tissue breaking and extraction 3 times by using acetone; an extraction liquid is subjected to reduced-pressure concentration, such that an extraction paste is obtained; multi-stage countercurrent extraction is carried out by using an ethyl acetate-methanol mixed solvent with a ratio of 10:1; extraction liquids are combined; the solvent is subjected to reduced-pressure recovery; the obtained material is processed by using a polyamide resin column; an obtained elution liquid is concentrated, such that a crude product is obtained; the product is fed into a medium-pressure chromatography column with silica gel of 200-300 meshes; a methanol-dichloromethane mixed solvent system is adopted; elution liquids at target component fragments are collected; the elution liquid is filtered and concentrated, and is subjected to low-temperature drying, such that skimmin is obtained. The skimmin preparation method provided by the invention has the advantages of high product purity and suitability for industrialized enlargement.

Owner:苏州宝泽堂医药科技有限公司

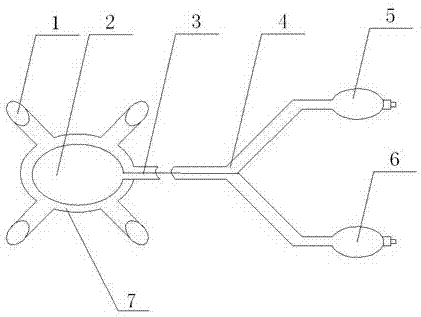

Biopsy expander

The invention discloses a biopsy expander, which comprises an outer air bag, a spatula and a three-way tube, wherein an inner air bag is further arranged in the outer air bag, an inflatable tube is arranged on the outer air bag, and two cavities are arranged in the inflatable tube. One of the cavities is connected with the outer airbag and the spatula, the other cavity is connected with the inner airbag, and the inflatable tube is connected with the three-way tube. The inner airbag, the outer airbag, the spatula and the inflatable tube are integrated during manufacture. forming. The three-way pipe is provided with an outer airbag inflatable ball and an inner airbag inflatable ball, the outer airbag inflatable ball, the inner airbag inflatable ball and the three-way pipe are inserted and connected. The spatula is wrapped with a silica gel layer, and the silica gel layer is provided with a small cavity for containing secretions; the outer wall of the outer air bag and the spatula is further provided with some fluff, and the inner air bag, the outer air bag and the spatula are made of rubber. The invention has the advantages of simple structure, convenient use, time saving and labor saving, and a large amount of extracted samples.

Owner:王素敏

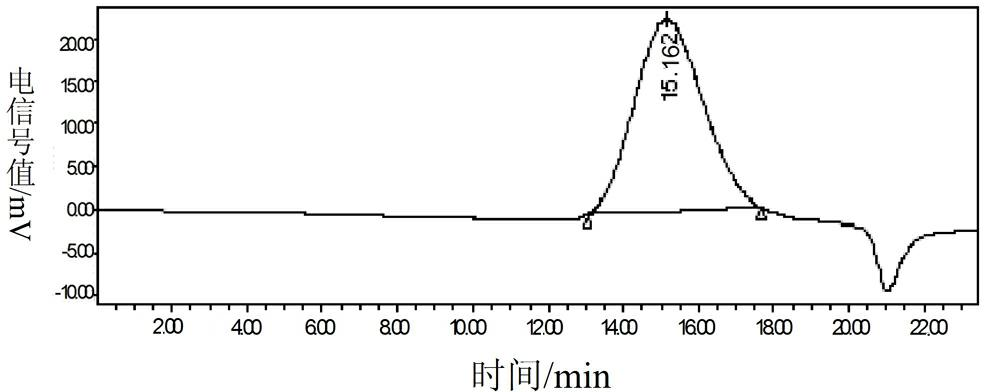

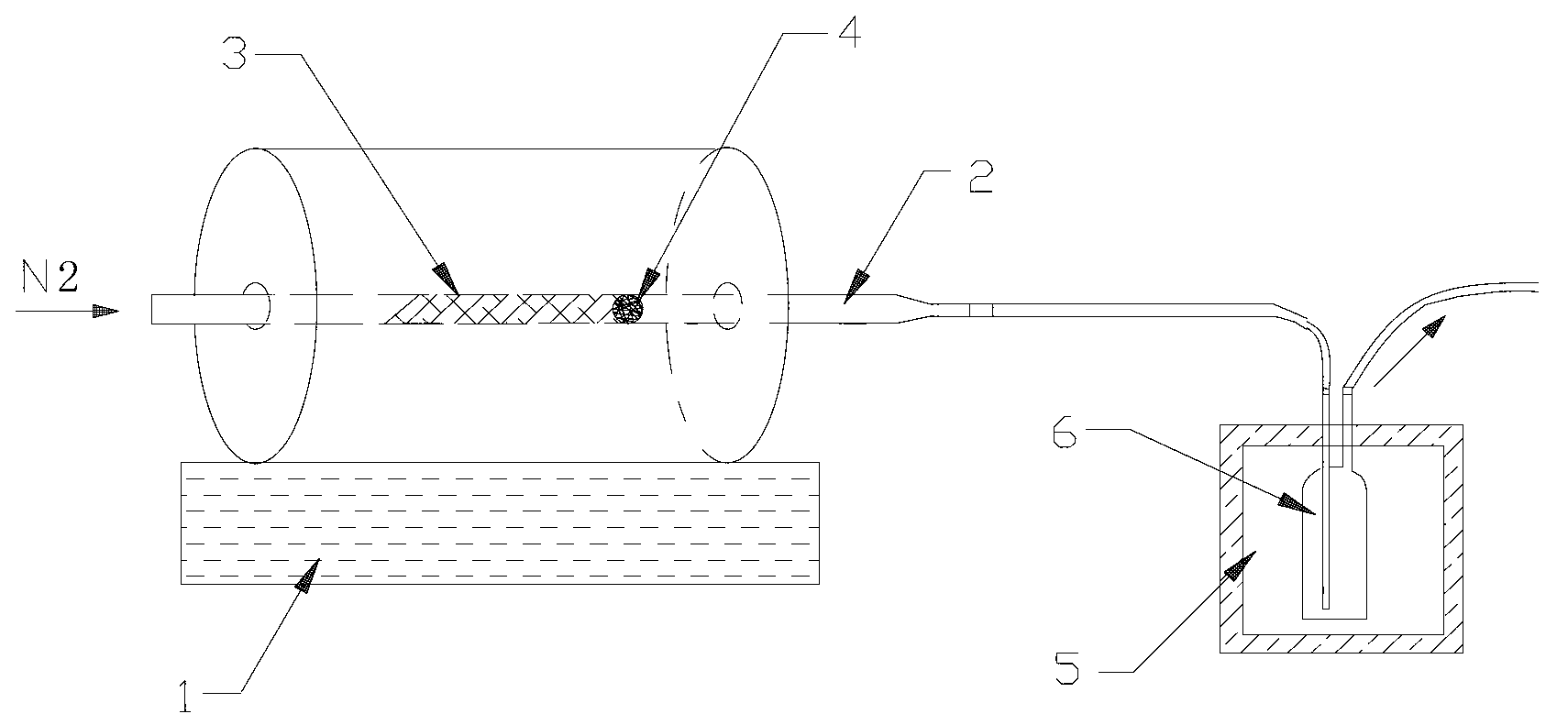

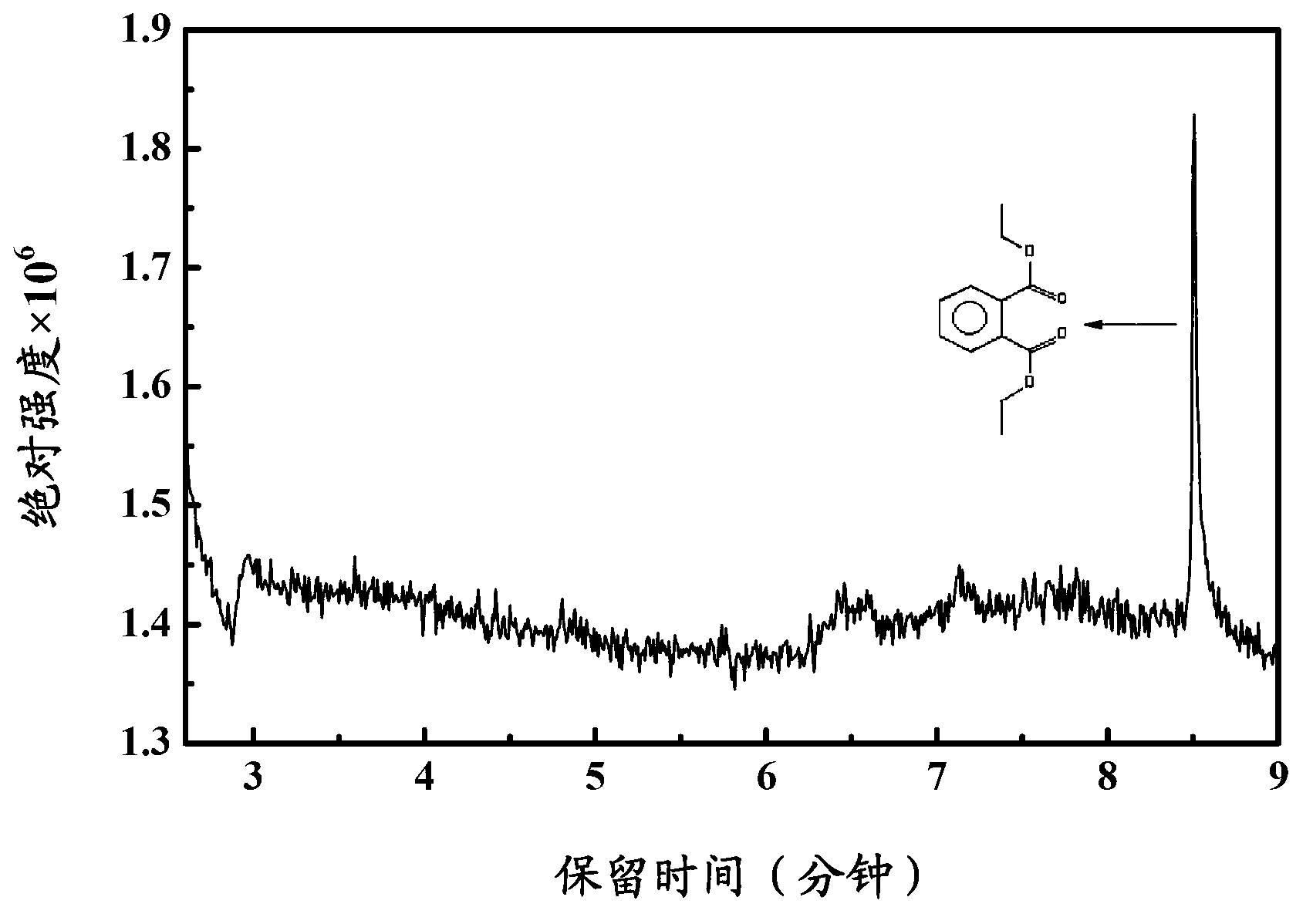

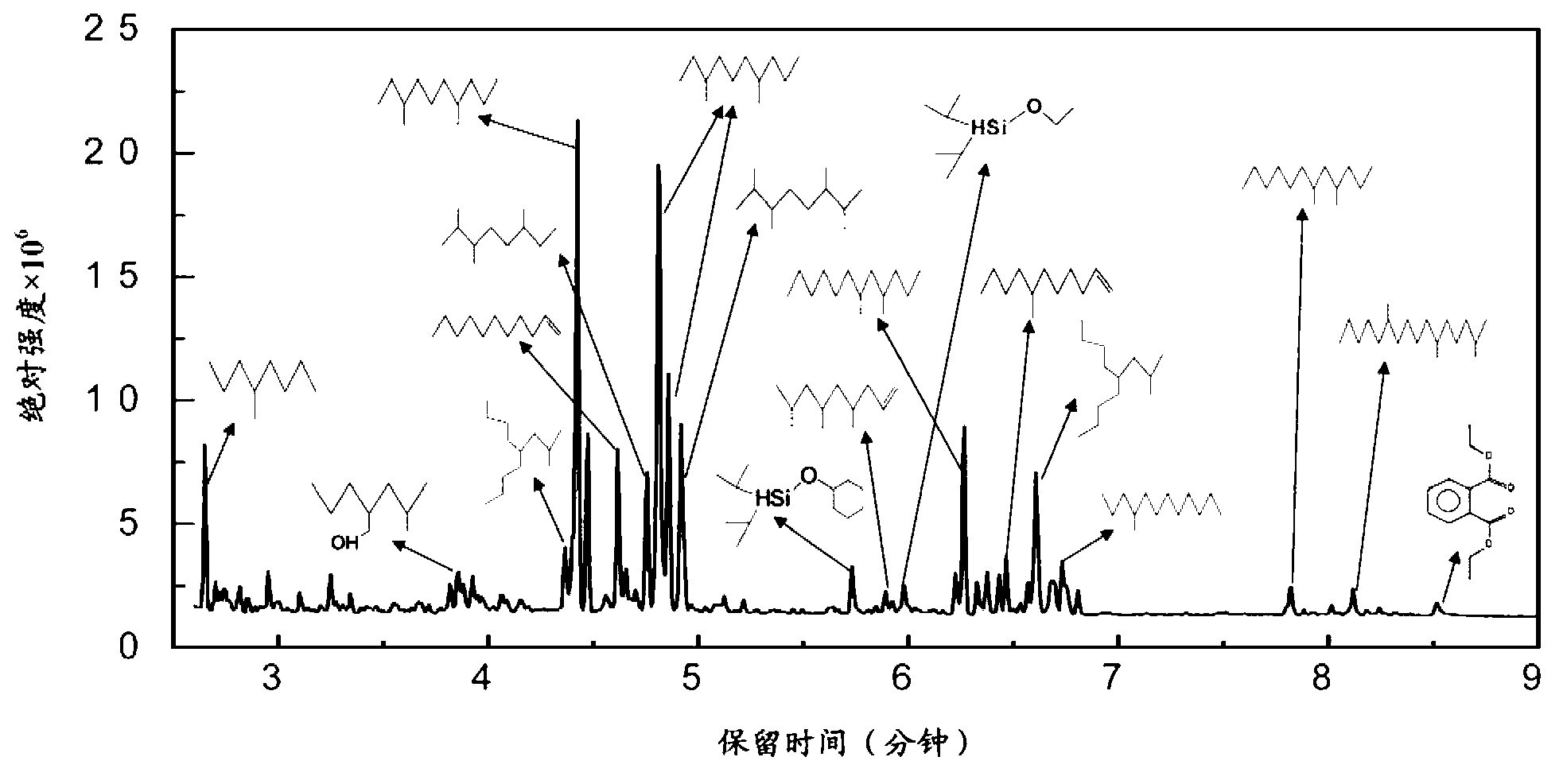

Method for trapping low molecular volatile substances in polypropylene

ActiveCN103175916AAvoid oxidative degradationLarge sample sizeComponent separationAmount of substanceChemistry

The invention discloses a method for trapping low molecular volatile substances in polypropylene. The method comprises the following steps of: (1) thermally desorbing low molecular volatile substances in polypropylene; and (2) condensing and concentrating a carrier gas containing low molecular volatile substances in polypropylene. The method is suitable for trapping low molecular volatile substances in polypropylene industrially produced and analyzing the composition, and has guiding meaning for troubleshooting and control of smell sources in the production process of polypropylene.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Rock-fill material weathering instrument

InactiveCN101692082BAvoid warpingHeating up fastEarth material testingTemperature controlFilling materials

A rock-fill material weathering instrument comprises a rolling bearing, the rolling bearing is arranged at the upper part of a bracket seat and is provided with a compression shear test box, a water permeable plate, a pressurizing cap, a pressurizing head and a heat preservation cover in sequence, the top beam on the heat preservation cover is connected with the heat preservation cover after being connected to a displacement transducer; a leveling device, a lever, and load weights are arranged under the bracket seat, the shear test box is connected with a low temperature cooling circulating pump and a high temperature circulator; the compression shear test box is connected with a temperature-controlled cabinet and an air compressor; the compression shear test box is connected with a watertank, the sliding plate at the bottom part of the shear test box is connected with a horizontal loading motor, a horizontal load transducer on the beam is connected with the right part of the box, after completing cold-hot circulation and dry-wet circulation, the sample is sheared, and the horizontal load is detected. The invention has the characteristic of realizing coupling of three factors of dry-wet circulation, temperature change and stress.

Owner:TSINGHUA UNIV

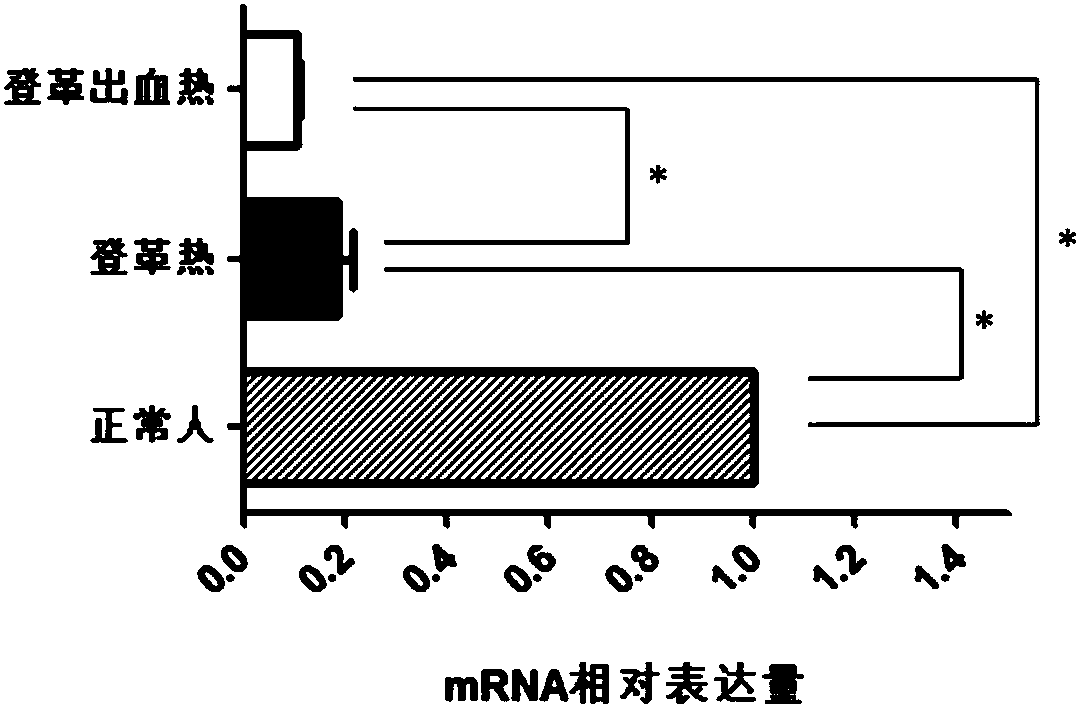

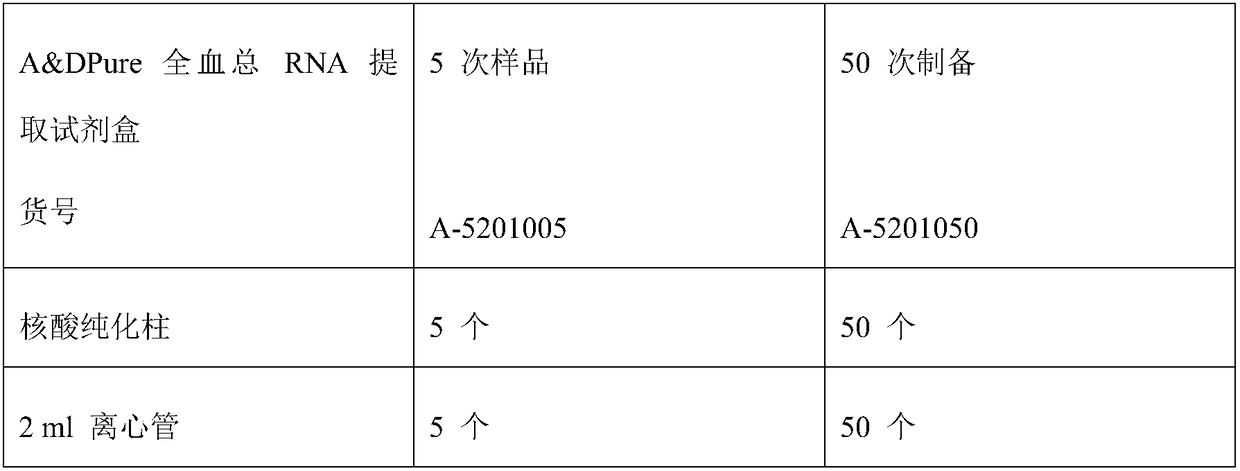

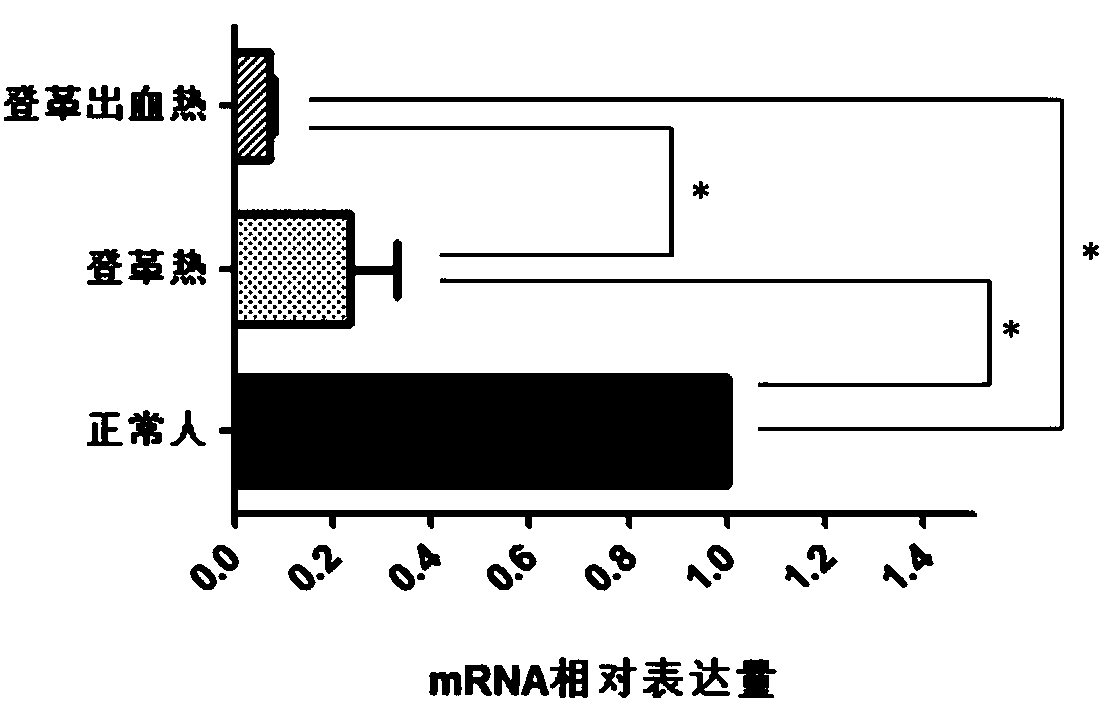

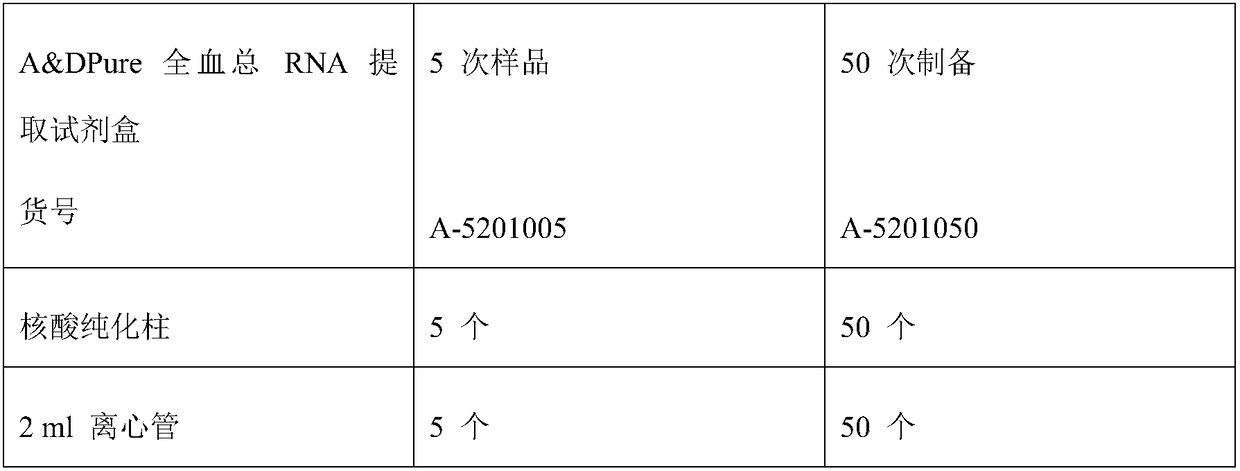

Molecular marker for distinguishing Dengue fever and Dengue hemorrhagic fever

InactiveCN108588281ALarge sample sizeThe result is accurateMicrobiological testing/measurementBiological material analysisPoor correlationBiology

The invention discloses a CMIP gene capable of being used as a molecular marker for distinguishing Dengue fever and Dengue hemorrhagic fever. By a high-throughput sequencing and RT-PCR method, the CMIP gene has significant expression difference in blood of normal people and patients with Dengue fever and Dengue hemorrhagic fever, i.e., whether a subject suffers the Dengue fever or the Dengue hemorrhagic fever can be judged by detecting the expression condition of the CMIP gene in the blood. According to the correlation of the Dengue fever and the Dengue hemorrhagic fever, the invention develops a kit for diagnosing the Dengue fever and the Dengue hemorrhagic fever. The kit is used for performing the Dengue fever and Dengue hemorrhagic fever diagnosis by detecting the CMIP gene expression.The diagnosis kit can be used for early diagnosis of diseases and has wide application prospects in clinics.

Owner:QINGDAO MEDINTELL BIOMEDICAL CO LTD

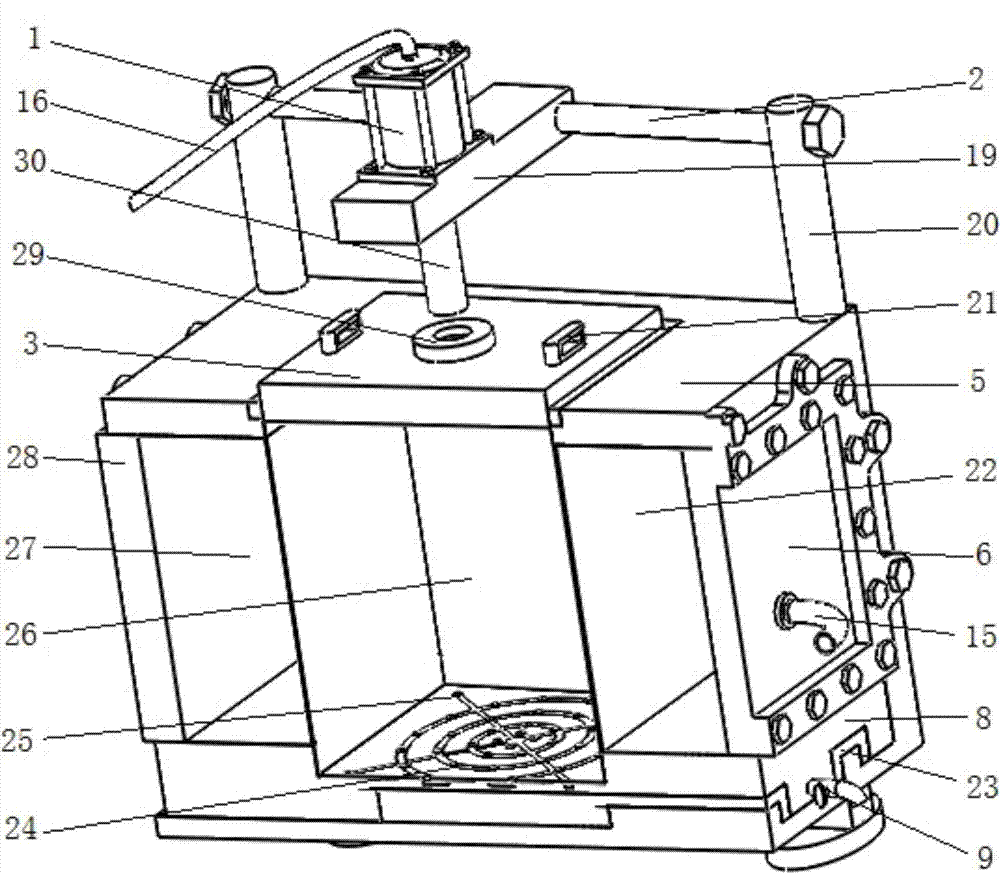

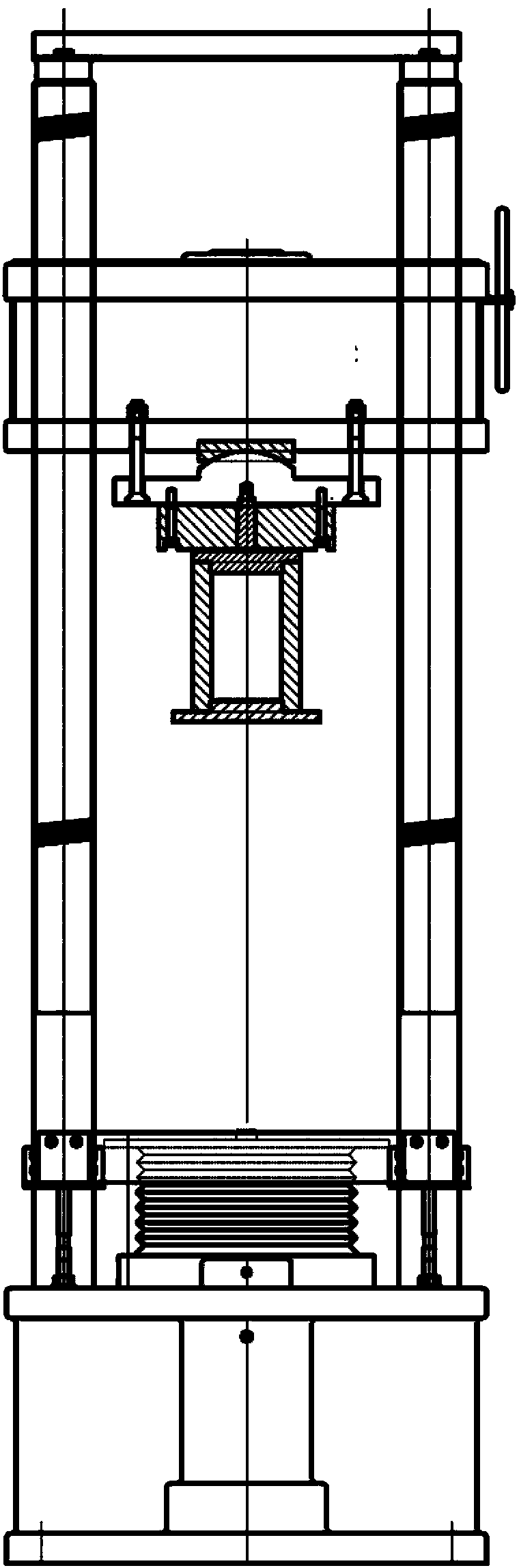

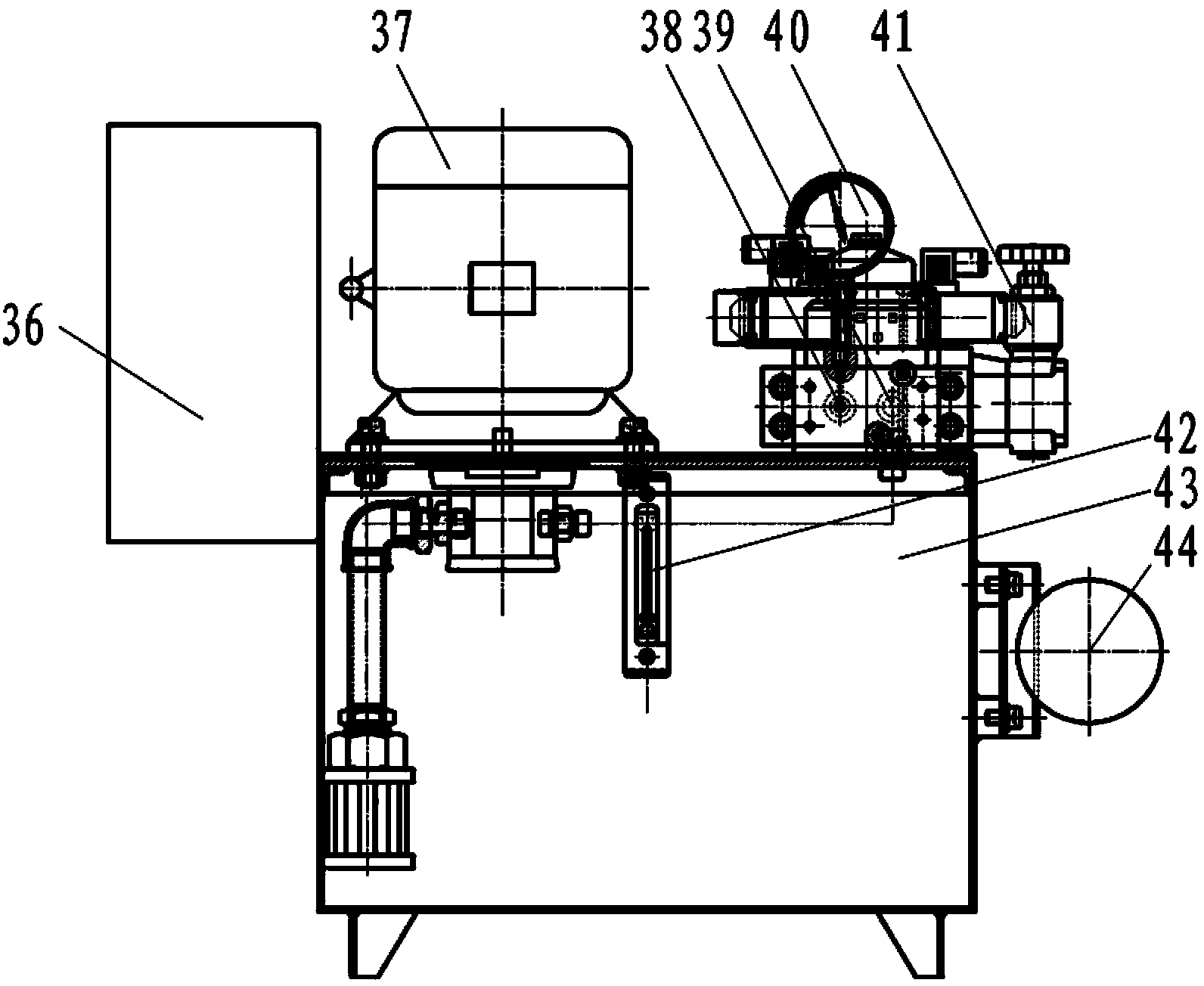

Rock-soil pressure shear rheological testing machine and testing method

InactiveCN103163026BReal-time acquisitionStable handlingMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesResidual strengthTest material

The invention discloses a rock-soil pressure shear rheological testing machine and a testing method, the testing machine comprises a mainframe, a vertical loading system and a horizontal loading system are provided on the mainframe, and a servo oil pressure system controlled by a computer provides oil pressure to the vertical loading system and the horizontal loading system. According to the invention, a shearing apparatus, the horizontal loading system, a servo hydraulic system and an electric control system are added for realizing automation, control and accuracy of the tests. An original waste and old press mainframe and a vertical oil cylinder are used by the testing machine, thereby about 50% of cost can be saved, the testing machine aims at test materials such as rock, rock mass and soil / stone compound body, and can perform with the following tests: a compression test, a shearing test, a residual strength shearing test, a compression rheological and shearing rheological test.

Owner:CHANGAN UNIV

Quick cooling test plant for disk type band steel, and method of use

InactiveCN100447260CEliminate fragileEliminate deformationFurnace typesHeat treatment furnacesFixed frameStrip steel

This invention relates to disk-type strip steel rapid cooling test apparatus for stimulating annealing process requirement of continuous annealing of strip steel, and its usage method. The apparatus comprises: a disk-type case, a disk-type sample fixing frame and a compensating wire that can rotate around a core axis in the case, a sample loading / unloading chamber, a heating / homogenizing chamber, a slow cooling / over-aging chamber, a spray cooling chamber and a water quenching chamber. When used, the compensating wire is connected to the surface of the sample, and then the sample is introduced into the above chambers in sequence. This invention has such advantages of large sample size, a wide variety of cooling methods, high cooling speed, simple apparatus, and low malfunction rate.

Owner:BAOSHAN IRON & STEEL CO LTD

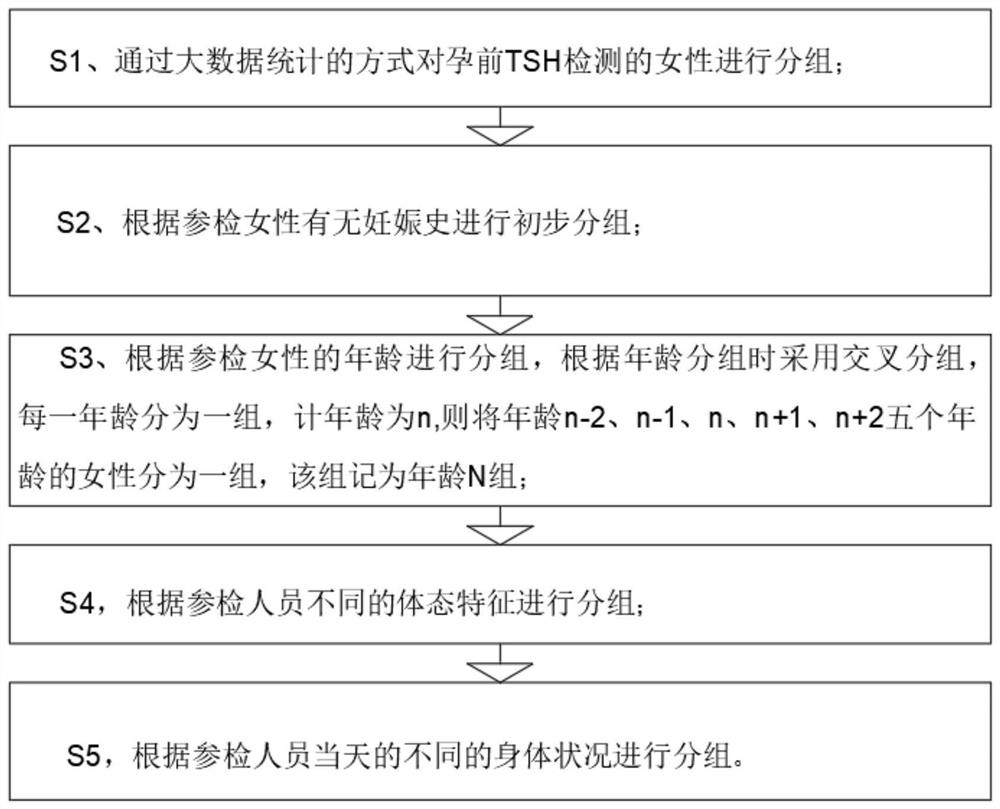

Establishment method and application of pre-pregnancy TSH abnormal reference value

InactiveCN112992360AWide range of investigationsLarge sample sizeMedical data miningHealth-index calculationAge groupsPregnancy

The invention discloses a method for establishing a pre-pregnancy TSH abnormal reference value, and relates to the technical field of maternal and child health care, and the method comprises the following steps: S1, grouping women subjected to pre-pregnancy TSH detection through a big data statistics mode; S2, performing preliminary grouping according to whether the examined women have the pregnancy history or not; S3, performing grouping according to the ages of the women to be examined, adopting cross grouping during age grouping, taking each age as one group, marking the age as n, taking the women of the age n-2, the age n-1, the age n, the age n + 1 and the age n + 2 as one group, and marking the group as an age N group; S4, performing grouping according to different posture characteristics of the examined persons; S5, performing grouping according to different physical conditions of the examinees on the same day. Under the coordination and cooperation effect of big data, samples are expanded as much as possible on the basis of crowds; through the pre-pregnancy detection system, the TSH values of the tested women are compared, an alarm is given for abnormal values, and guidance is provided for research of the pre-pregnancy TSH abnormal values.

Owner:昆明市官渡区妇幼健康服务中心

Digestive tract mucosa biopsy sampling device

The invention discloses a digestive tract mucosa biopsy sampling device, and relates to the field of medical appliances. The digestive tract mucosa biopsy sampling device comprises a sample extraction component and a handle, wherein the sample extraction component is made into a long rubber strip with the projected middle part and the two pointed ends; a plurality of tiny scraping spoons are distributed on the outer surface of the rubber strip; the sample extraction component is connected with the handle; the handle is made into a rotating shaft driven to rotate by a motor; a switch is arranged on the handle. The long rubber strip with the projected middle part and the two pointed ends is designed and used as a main body for extracting a sample; the scraping spoons are arranged on the outer surface; the sample extraction is more convenient; the quantity of extracted samples is great; injury cannot be caused on the respiratory tract of a patient; the rotatable handle is designed; the sample extraction process is completed after a switch is turned on and is fast rotated for one circle; the pain of the patient and the workload of medical care personnel are reduced.

Owner:石殿忠

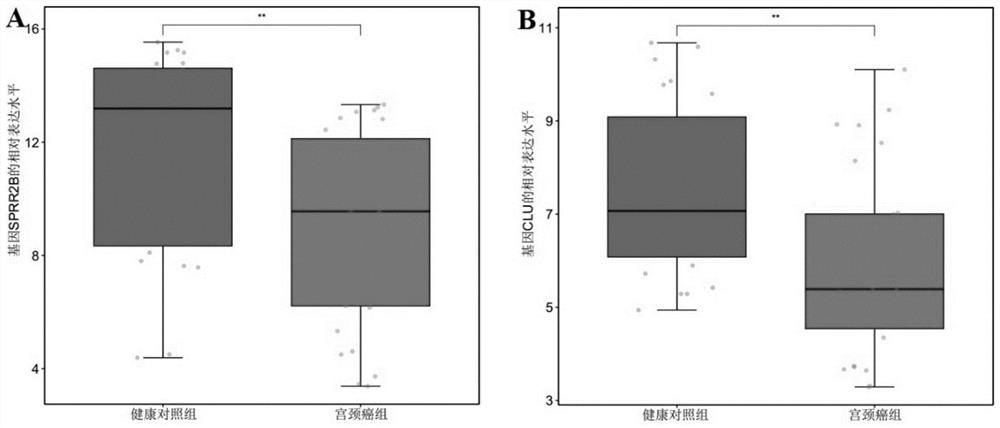

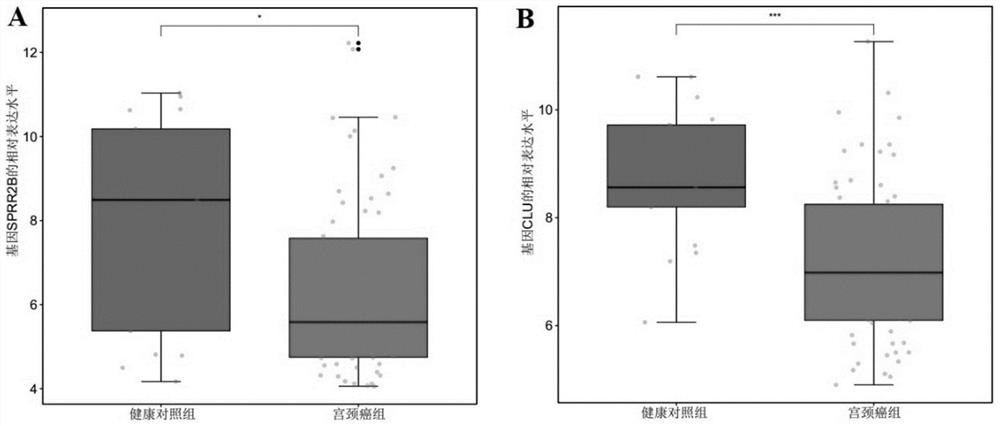

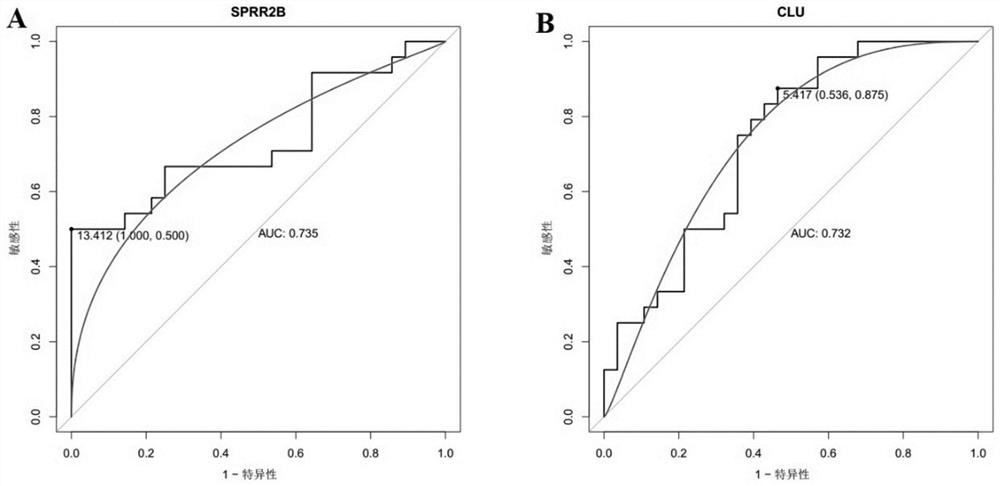

Gene marker for early cervical cancer screening and product and application thereof

ActiveCN113736882AEasy diagnosisIncreased sensitivityMicrobiological testing/measurementBiological material analysisCervical cancer screeningCervical ca

The invention discloses a gene marker for early-stage cervical cancer screening as well as a product and application thereof, the gene marker is a combination of genes SPRR2B and CLU, verification finds that the gene marker has relatively good diagnostic efficiency, relatively high accuracy, sensitivity and specificity on cervical cancer, and in addition, the invention further provides a product for early screening of cervical cancer, and the product has important significance on early screening and early intervention treatment of cervical cancer and improvement of survival and living quality of patients.

Owner:THE SECOND HOSPITAL OF HEBEI MEDICAL UNIV

An In-Situ Shear Experiment Apparatus for Determination of Saturated Loess-mudstone Contact Surface

ActiveCN107271297BLarge sample sizeMaterial strength using steady shearing forcesSoil scienceTest sample

An in-situ shear experimental instrument for measuring the contact surface of saturated loess-mudstone. The lower shear box is installed in the experimental foundation pit. The upper shear box is installed on the lower shear box. The upper shear box is connected to the inner wall of the experimental foundation pit. A horizontal hydraulic jack is set horizontally in the middle; a shear box pressure cover is installed on the top of the upper shear box. The shear box pressure cover is connected to the counterweight support plate through the axial hydraulic jack, and the counterweight support plate is equipped with a counterweight; in the experimental foundation pit The water container is also installed through the water container support rod, and the water container is connected to the water inlet hole on the upper part of the upper shear box through a water pipe, so that the injected water flows out from the lower part of the upper shear box. The in-situ shear tester provided by the present invention can truly reflect and keep the contact surface between loess and mudstone in a state of overhumidity, saturation and soft plastic for a long time in situ without disturbing the soil. The size of the test sample is large, which is an ideal way to obtain loess- An effective instrument for in-situ instantaneous shear strength and long-term creep shear strength parameters of "heterogeneous soil" at the mudstone contact surface.

Owner:NORTHWEST UNIV

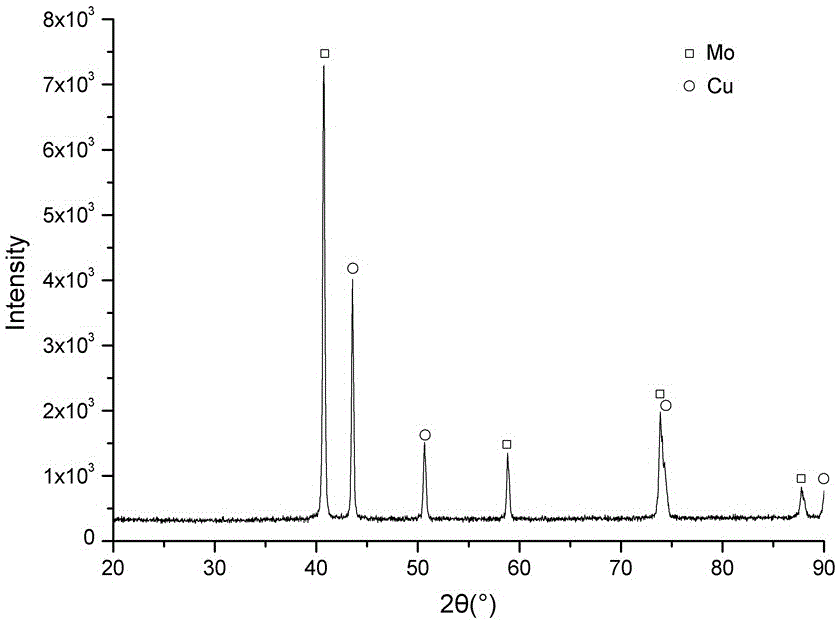

A hot isostatic pressing method for preparing high-density molybdenum-copper alloy

InactiveCN104762498BHigh degree of densificationUniform distribution of two phasesSmall sampleHeat conducting

The invention discloses a hot isostatic pressing preparation method of a high-density molybdenum-copper alloy and the hot isostatic pressing preparation method is used for solving the problems that material heat conductivity and device air tightness are influenced by defects such as relatively low relative density, non-uniform component distribution and relatively small sample sizes existing in a process of preparing a molybdenum-copper alloy by using an existing method. The hot isostatic pressing preparation method comprises the following steps: performing ball milling on weighed raw materials, firstly preparing a cold-pressed billet, and then removing a low-density oxide phase by virtue of hydrogen reduction. By adopting a high-vacuum hot isostatic pressing dense sintering method, the density problem of the molybdenum-copper alloy can be successfully solved, the sintering temperature can also be greatly reduced, interface structures of the materials can be effectively controlled, uniform distribution of components can be achieved, and the heat-conducting properties of the materials can be optimized. By adopting the hot isostatic pressing preparation method disclosed by the invention, the molybdenum-copper alloy with high density, high copper content and large size can be successfully prepared, requirements of electronic packaging and heat sink materials for the properties such as material strength and heat conductivity can be met, relatively good market application prospects can be achieved, and the molybdenum-copper alloy is worthy of being popularized and applied in large scale.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Gene ARRDC1 for diagnosing dengue fever and dengue hemorrhagic fever and application thereof

InactiveCN108588280ALarge sample sizeThe result is accurateMicrobiological testing/measurementAgainst vector-borne diseasesDengue feverPediatrics

The invention discloses application of a gene ARRDC1 in diagnosis of dengue fever and dengue hemorrhagic fever. The content of the gene ARRDC1 in the blood with dengue fever and dengue hemorrhagic fever is obviously different from the content of the gene ARRDC1 in the blood of a normal person; a patient with dengue fever and dengue hemorrhagic fever and the normal person can be distinguished according to the difference. The invention also discloses a product for diagnosing the dengue fever and dengue hemorrhagic fever. The diagnosing product can be used for diagnosing the dengue fever and dengue hemorrhagic fever by detecting the gene ARRDC1 in the blood.

Owner:QINGDAO MEDINTELL BIOMEDICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com