Grain sample splitter

A sampler and grain technology, which is applied to other granular materials and their pulverized sample sampling devices, oil plants, grain, grain sampler, and seeds, can solve the problems of time-consuming, cumbersome operation, and large reduction ratio. , to achieve the effect of large sample volume, simple operation and fast mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

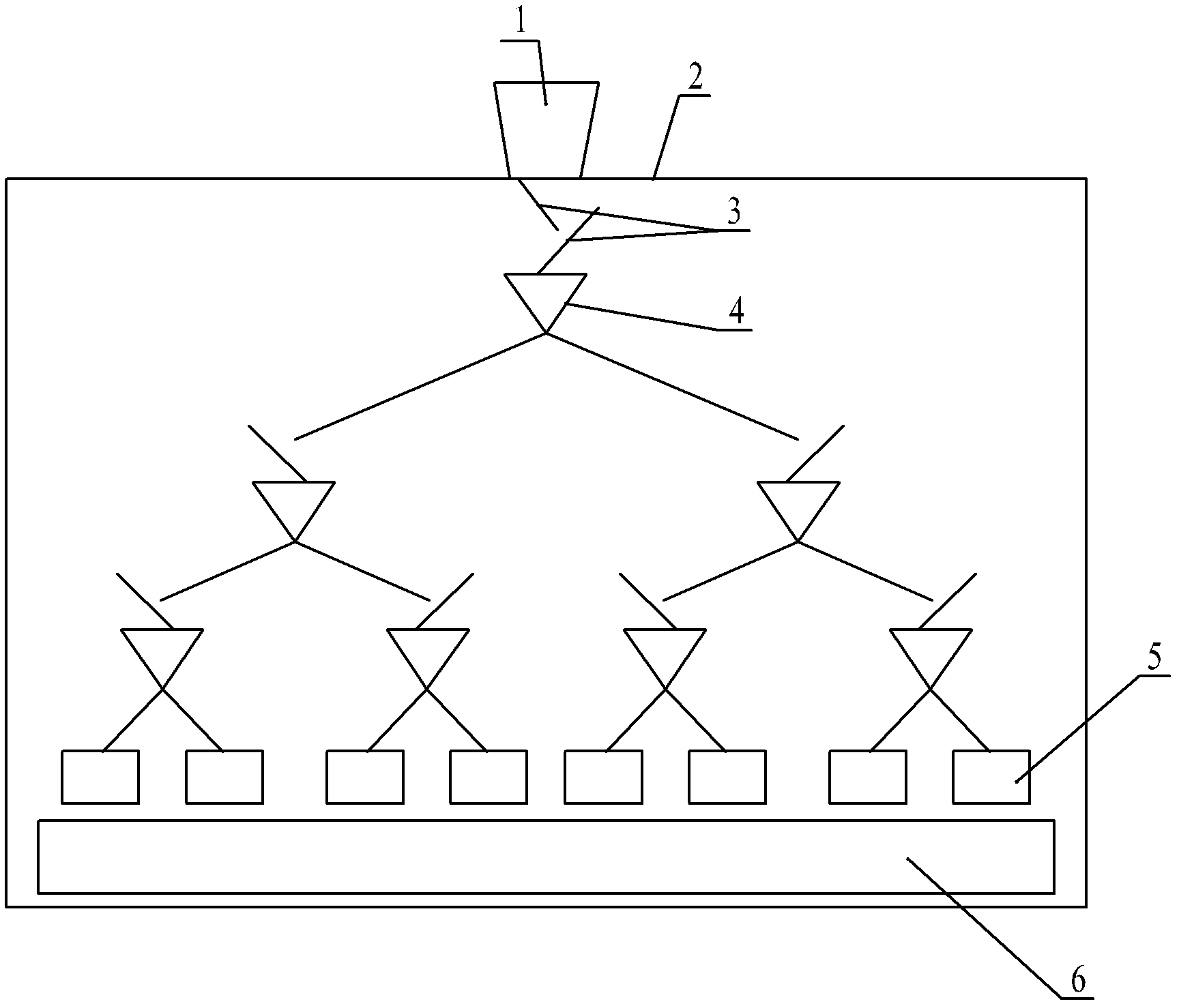

[0021] As shown in the figure: the grain sampler in the embodiment is mainly composed of a hopper 1, a box body 2, a multi-stage sampling system and a sample box 5, the hopper 1 is arranged above the box body 2, and the top of the box body 2 is provided with A sample inlet, the sample inlet is facing the lower outlet of the hopper 1; the multistage sample dividing system is arranged in the casing 2, and the multistage sample dividing system has a plurality of sample dividing discharge ports, and each divided sample A sample box 5 for collecting the divided samples is arranged below the discharge port. The sample box 5 is provided with a handle for easy access, and the bottom plate of the sample box 5 is twitchable so that the sample can flow out.

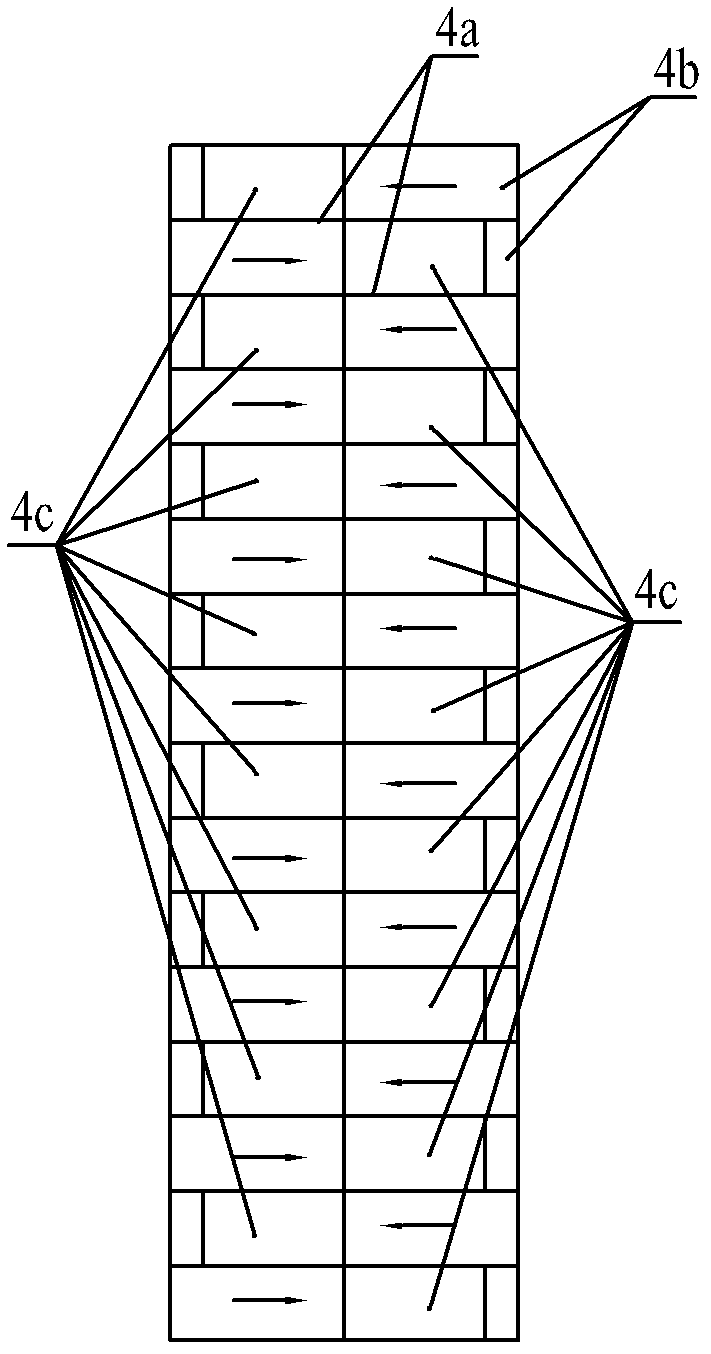

[0022] Such as figure 1 As shown, the multi-stage sample dividing system is mainly composed of a plurality of ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com