Large-scale real triaxial shear testing device and application thereof

A shear test, true triaxial technology, applied in the direction of using a stable shear force to test the strength of materials, can solve the problems of size effect, not suitable for soil shear test, etc., and achieve the effect of reliable test data.

Inactive Publication Date: 2014-04-02

TONGJI UNIV

View PDF9 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The shear interface of the test device in the above patent is fixed, and there is a size effect, so it is not suitable for the shear test of the soil under the three-dimensional stress state

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

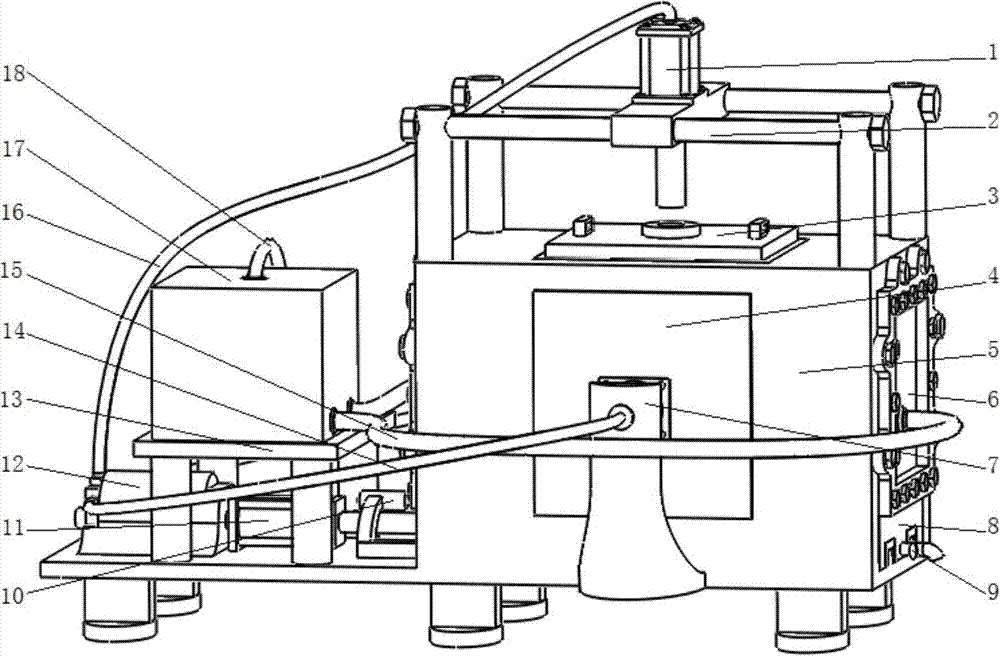

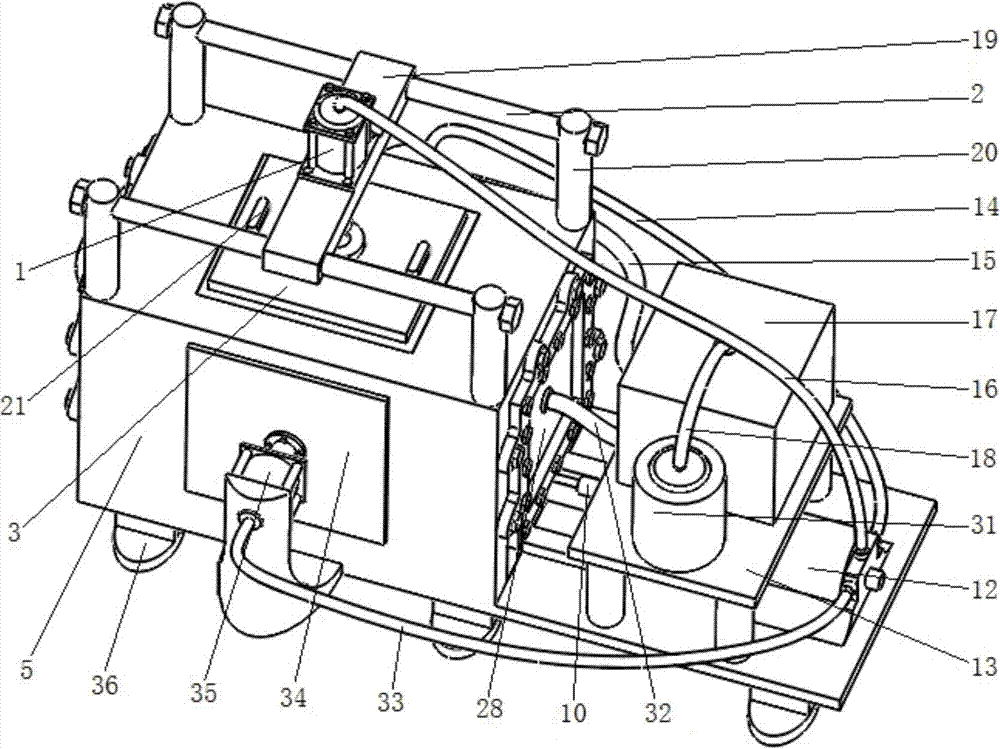

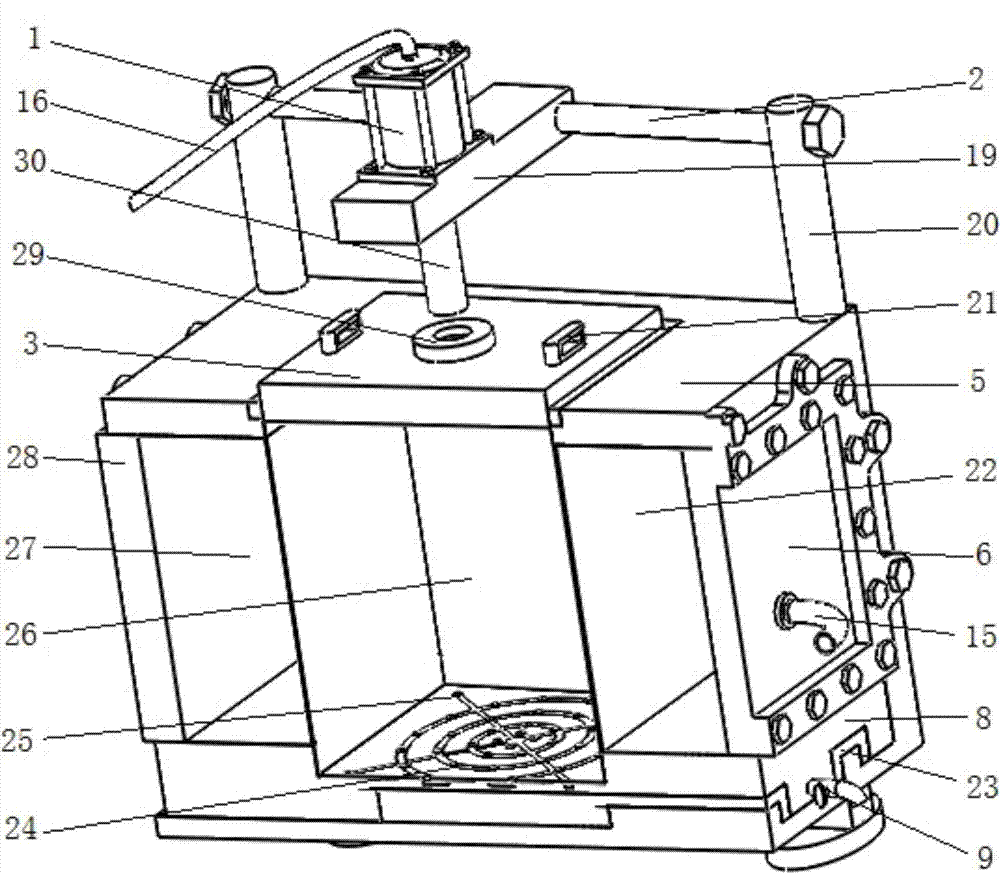

[0044] A large-scale true triaxial shear test device, such as Figure 1 ~ Figure 4 As shown, the device includes a test box, a hydraulic pressurization mechanism and a hydraulic pressurization mechanism, wherein,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a large-scale real triaxial shear testing device and an application thereof. The testing device comprises a testing box, a hydraulic pressurization mechanism and a water pressure pressurization mechanism, wherein the testing box comprises a box frame, a shear box and a soil pocket; the hydraulic pressurization mechanism comprises a hydraulic control box, a vertical hydraulic cylinder, a horizontal hydraulic cylinder and a shear testing hydraulic cylinder; the water pressure pressurization mechanism comprises a water box, a gas pressure tank and a water pressure pocket; the hydraulic control box is used for controlling the pressure of the vertical hydraulic cylinder and the horizontal hydraulic cylinder, the gas pressure tank is used for controlling the pressure of the water pressure pocket and enabling a test sample in the soil pocket to be in a three-dimensional stress state, shear testing is performed on the test sample through the shear testing hydraulic cylinder, whether the test sample has drainage or not is controlled through a drainage valve, and the changes in displacement over time and the changes of pressure applied in each direction over the time are recorded when the test sample is sheared. Compared with the prior art, the large-scale real triaxial shear testing device provided by the invention has the characteristics that the size of the test sample is large, a shear surface is not a traditional fixed horizontal plane, the large-scale real triaxial shear testing device can be used for shear testing of soil in a three-dimensional stress state, and parameters of a soil layer can be determined more accurately.

Description

technical field [0001] The invention belongs to the field of rock and soil tests, and in particular relates to a large-scale true triaxial shear test device and its application, and is especially suitable for measuring the basic mechanical parameters of various coarse and fine-grained soil samples under a three-dimensional stress state. Background technique [0002] In the field of geotechnical engineering, the failure of soil is usually shear failure. The bearing capacity of building foundations, the earth pressure of retaining walls and underground structures, and the stability of various slopes are all controlled by the shear strength of the soil. Whether the shear strength of the soil can be obtained correctly is often the key to the success of a project. The essential. [0003] The direct shear test is a routine method for determining the shear strength of soil. At present, many scholars use different direct shear test devices to measure the shear strength of soil. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/24

Inventor 徐前卫唐卓华朱合华丁文其蔡永昌李晓军庄晓莹武伯弢苏培森金威叶亮

Owner TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com