Large-scale in-situ triaxial shear test device and method thereof

A technology of triaxial shearing and testing device, which is used in large-scale in-situ triaxial shearing testing device, the determination of mechanical parameters of in-situ soil samples under the condition of applied confining pressure, and the testing of soil mechanical properties. It reflects the shear strength performance of soil and cannot fully represent the mechanical properties, etc., and achieves the effect of reliable test data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

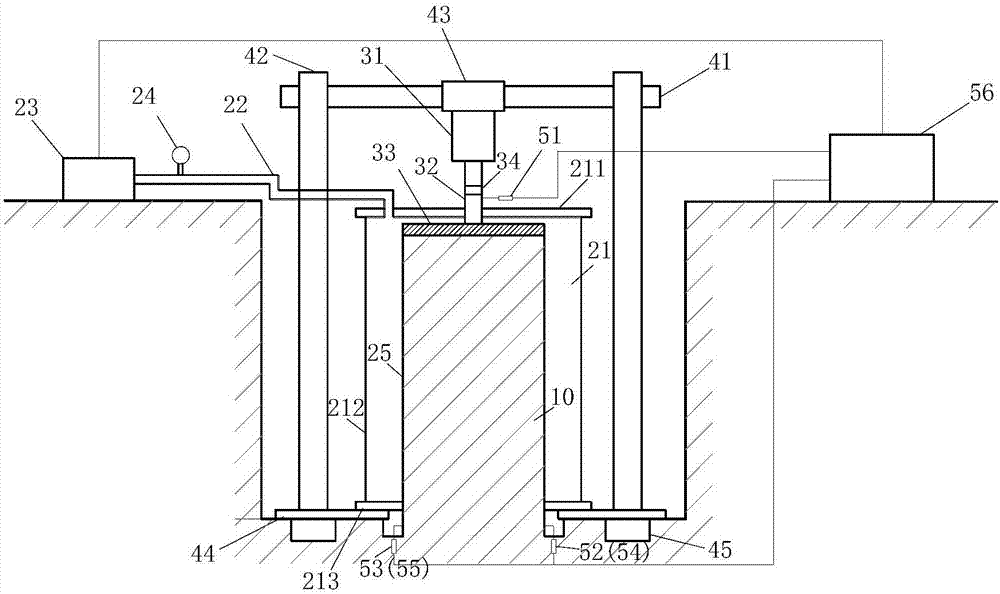

[0041] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0042] 1. Device

[0043] 1. Overall

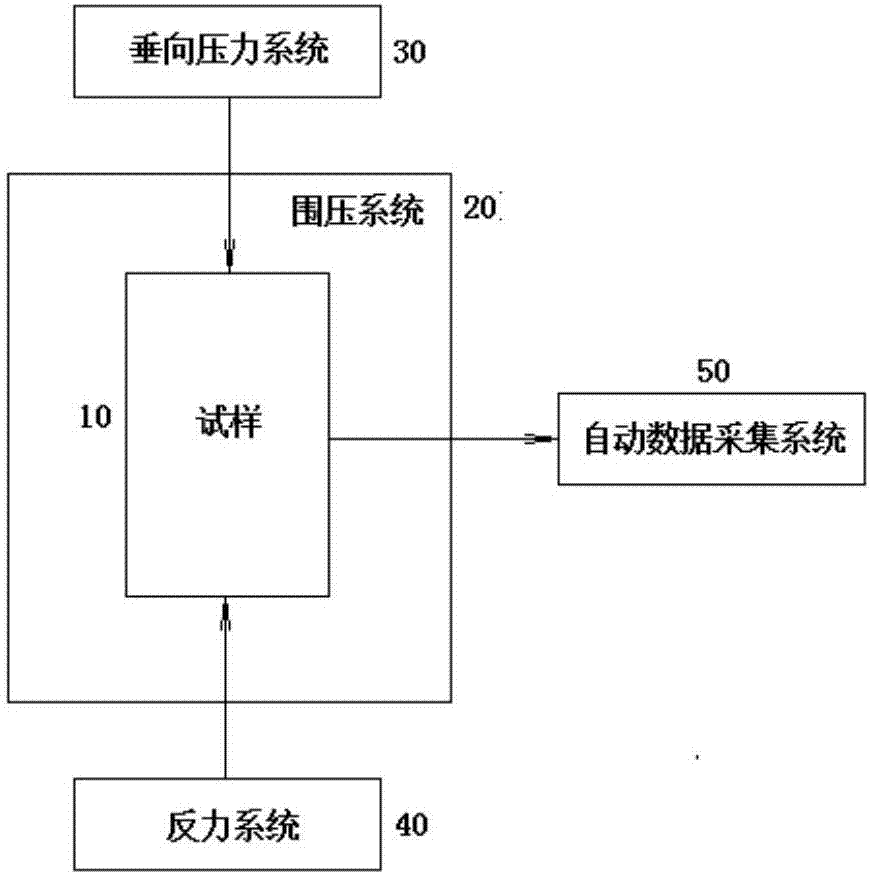

[0044] Such as Figure 1-4 , the device includes a sample 10, a confining pressure system 20, a vertical pressure system 30, a reaction force system 40 and an automatic data acquisition system 50;

[0045] A sample 10 is set in the confining pressure system 20, a vertical pressure system 30 and a reaction force system 40 are respectively set above and below the confining pressure system 20, and the vertical displacement meter of the automatic data acquisition system 50 is set in the sample 10 .

[0046] 2. Functional components

[0047] 1) Sample 10

[0048] Sample 10 is an undisturbed and representative in-situ soil selected in the excavated pit, prepared as a cylinder with diameter: height = 1:2, generally 300×600mm or 200×400mm.

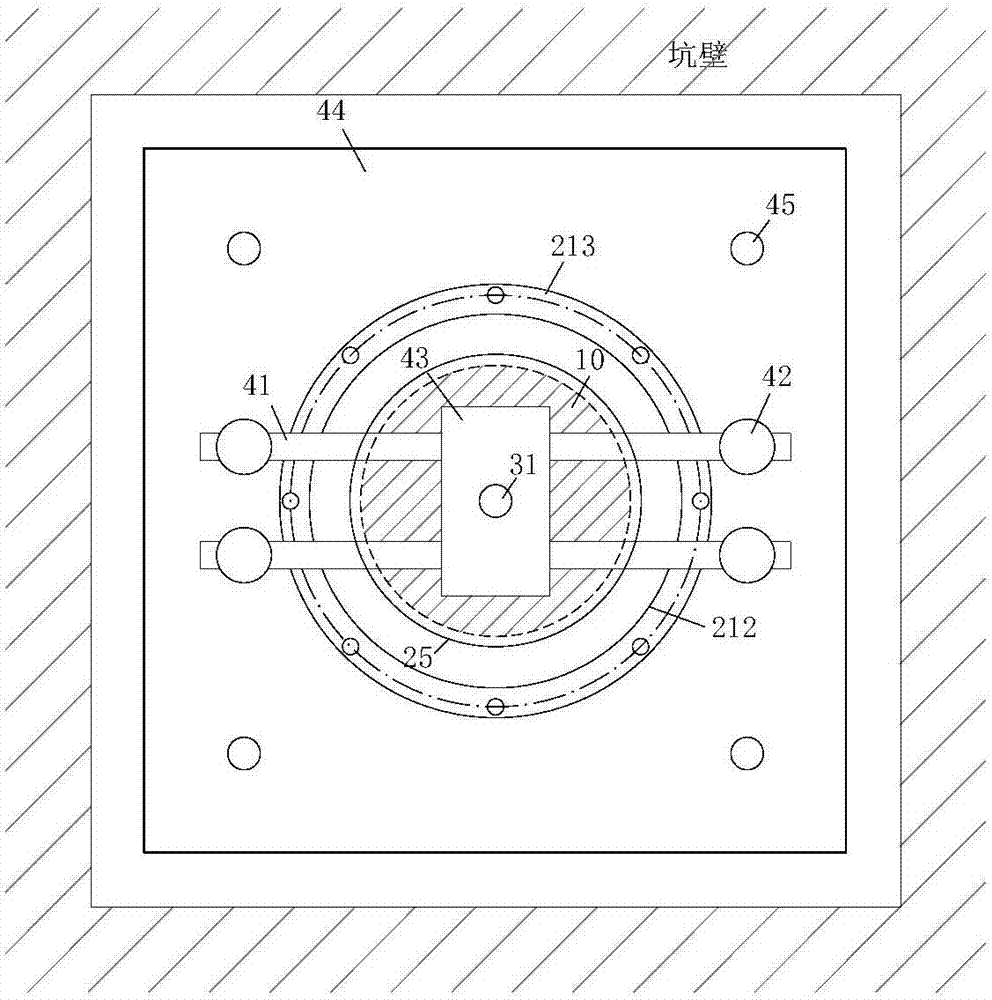

[0049] 2) Confining pressure system 20

[0050] Such as figure 1 , 2 , 3, 4, the confining pressure system 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com