Fully-coupled dry hole acoustic wave test probe

A sonic probe, fully coupled technology, applied in the direction of material analysis, measuring devices, instruments, etc. using sound waves/ultrasonic waves/infrasonic waves, can solve the problem of failure to solve the coupling between the pressurized water bladder and the hole wall, poor coupling of the sonic probe, Acoustic detection is difficult to carry out and other problems, to achieve stable and reliable test data, meet the needs of high-intensity continuous work, and save water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

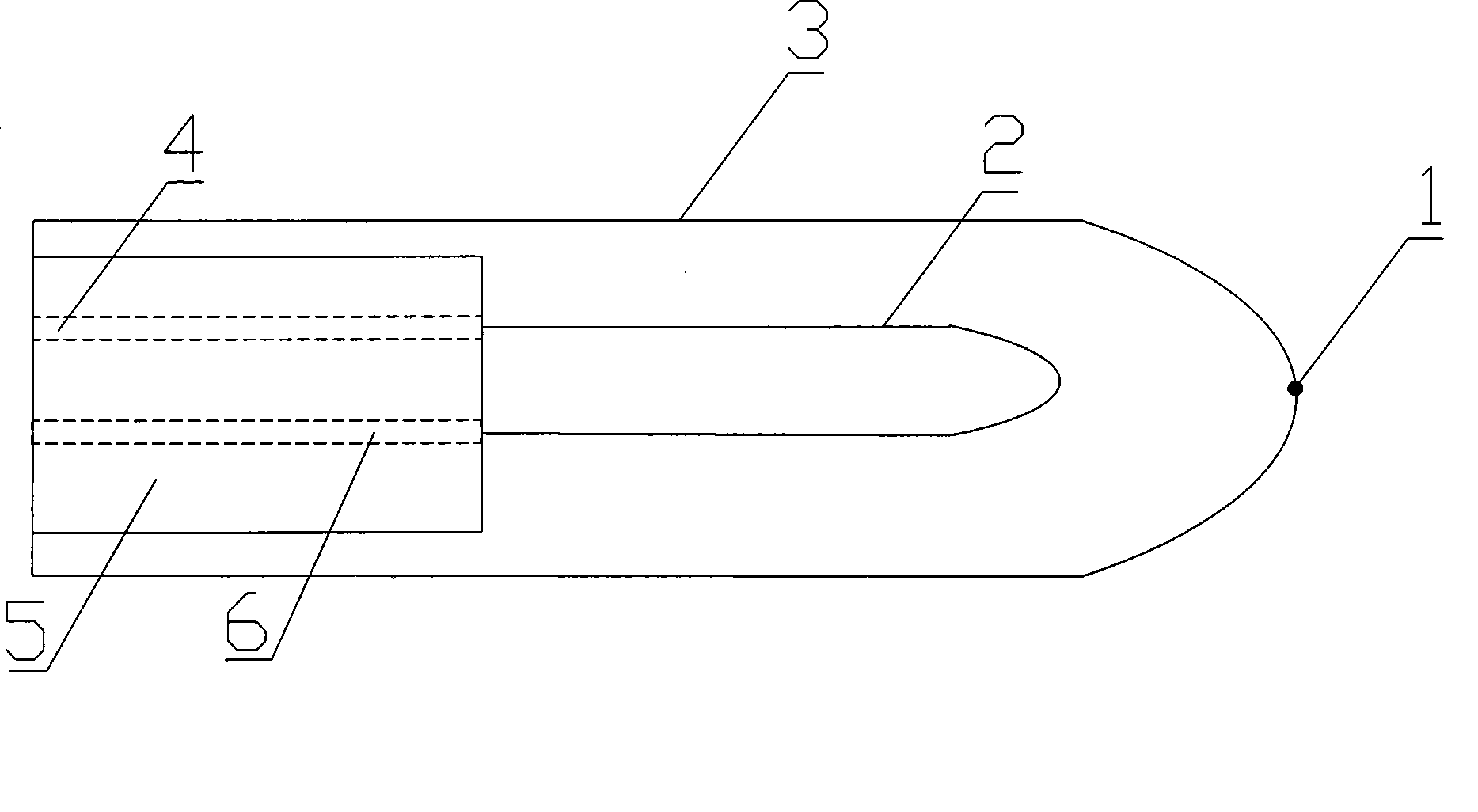

[0013] The fully coupled dry-hole acoustic wave probe of the present invention will be further described in detail below with reference to the accompanying drawings.

[0014] see Attachment

[0015] The fully coupled dry-hole acoustic probe consists of a pressurized water bladder 3, an acoustic probe 2, a water inlet pipe and a connecting device 5. The pressurized water bladder 3 is made of styrene-butadiene rubber, and the pressurized water bladder 3 is cylindrical. One end of the bladder 3 is open and the other end is closed. On the top of the closed end of the pressurized water bladder 3, there is a vent hole 1, the diameter of the vent hole 1 is ≦1mm, and the end of the acoustic wave probe 2 is provided with a connecting device 5. The connecting device 5 is provided with a water inlet channel 4 and a cable channel 6 , the pressurized water bag 3 is set outside the acoustic wave probe 2 , and the opening end of the pressurized water bag 3 is located on the connecting device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com