An In-Situ Shear Experiment Apparatus for Determination of Saturated Loess-mudstone Contact Surface

A technology of contact surface and experimental instrument, applied in the direction of applying stable shear force to test the strength of materials, instruments, measuring devices, etc., can solve the problems of water permeability difference between the upper and lower contact surfaces, reduce the strength of loess, etc., and achieve large sample size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

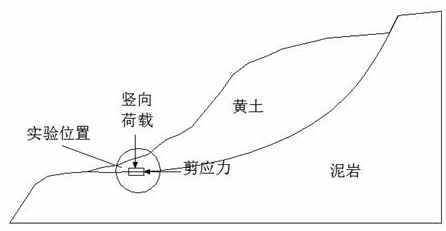

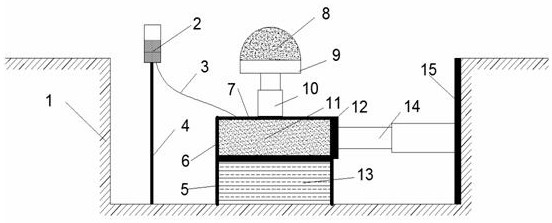

[0021] refer to Figure 1~Figure 4 , an in-situ shear test instrument for measuring saturated loess-mudstone contact surface, the invention is generally used for sliding shear surface of landslides at loess-mudstone contact surface. The device of the present invention includes: a shear box, an axial pressure system, a shear force system, a data acquisition system, and a water saturation system.

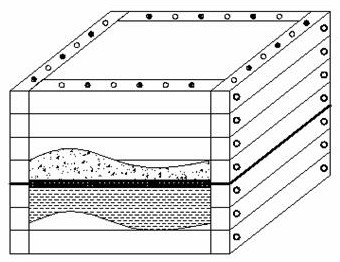

[0022] The in-situ direct shear test selects a sample whose size is 500 mm × 500 mm × 600 mm in length × width × height. The inner diameter of the shear box is the same as the size of the sample. The shear box is divided into three parts: the lower shear box, The upper shearing box and the pressure cover of the shearing box; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com