Car body intensity fatigue and airtight fatigue test stand

A fatigue test and car body technology, which is applied in the direction of using liquid/vacuum for liquid tightness measurement, railway vehicle testing, etc. It can solve the problems that cannot be completed on the same test bench, and achieve convenient and fast testing and high testing efficiency. , the effect of low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

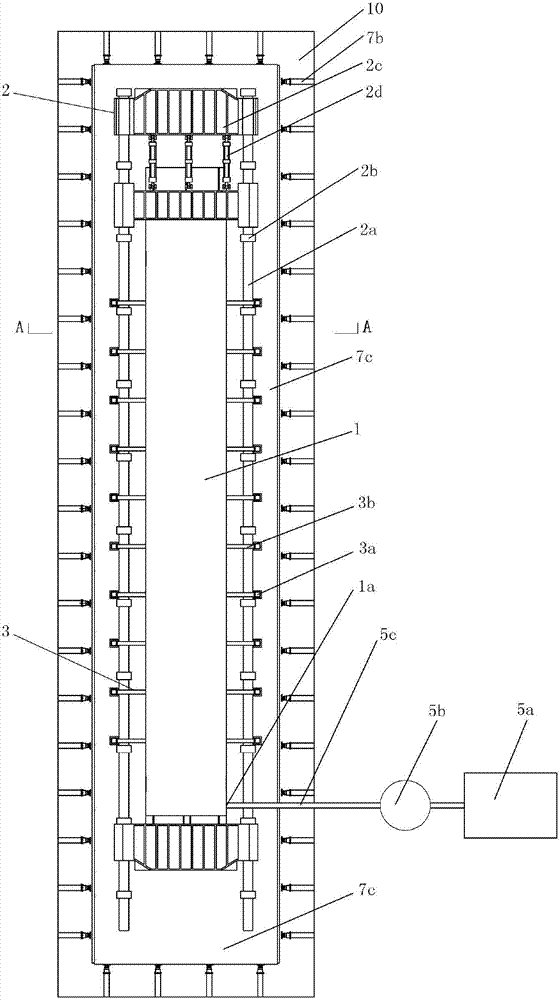

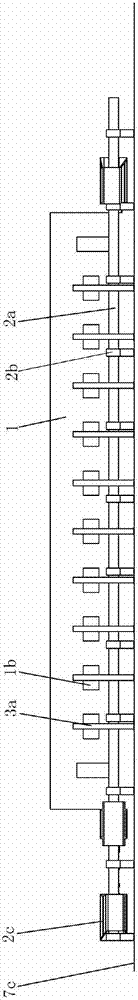

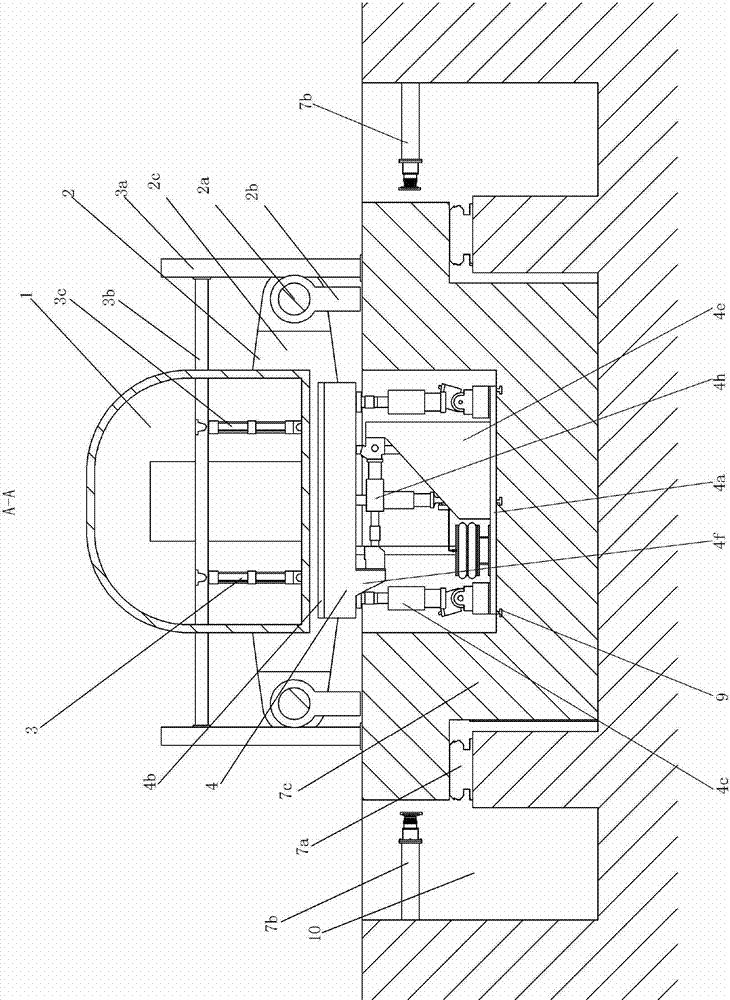

[0040] Figure 1~3Shown, a specific embodiment of this invention is: a car body strength fatigue and airtight fatigue test bench, including the car body 1 of the test train, the longitudinal loading device 2 at one end of the car body 1, and the car body 1 The vertical loading device 3 connected to the inner floor, a plurality of vibration excitation devices (usually three or more) installed under the car body 1, and the longitudinal loading device 2, the vertical loading device 3, and the vibration excitation device Hydraulic system; the vibration excitation device is a six-degree-of-freedom vibration device 4, and the six-degree-of-freedom vibration device 4, the longitudinal loading device 2, and the vertical loading device 3 are all installed in the pit 10 through a vibration isolation device , the vehicle body 1 is connected with the airtight device. in:

[0041] The specific composition of the vibration isolation device is: the inner bottom of the rectangular pot-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com