Comprehensive test system of shield tunnel construction model

A technology for structural models and shield tunnels, which is applied in the testing of machines/structural components, measuring devices, instruments, etc. It can solve the problems of affecting the proportion of soil materials in the model, inconvenient to replace the tunnel model, and constraints of the model tunnel. The effect of accurate and reliable test data, safe and smooth progress, and accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

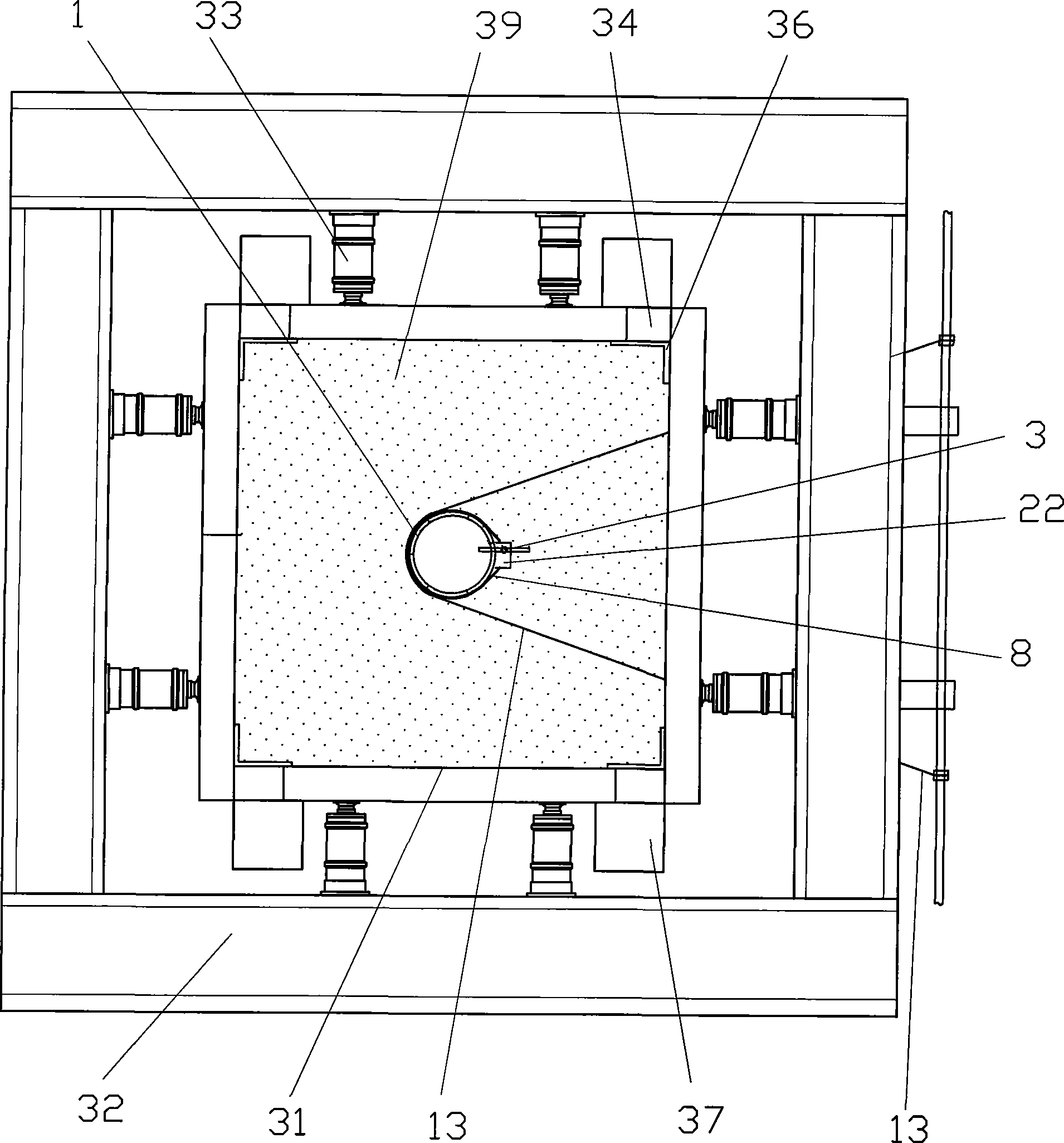

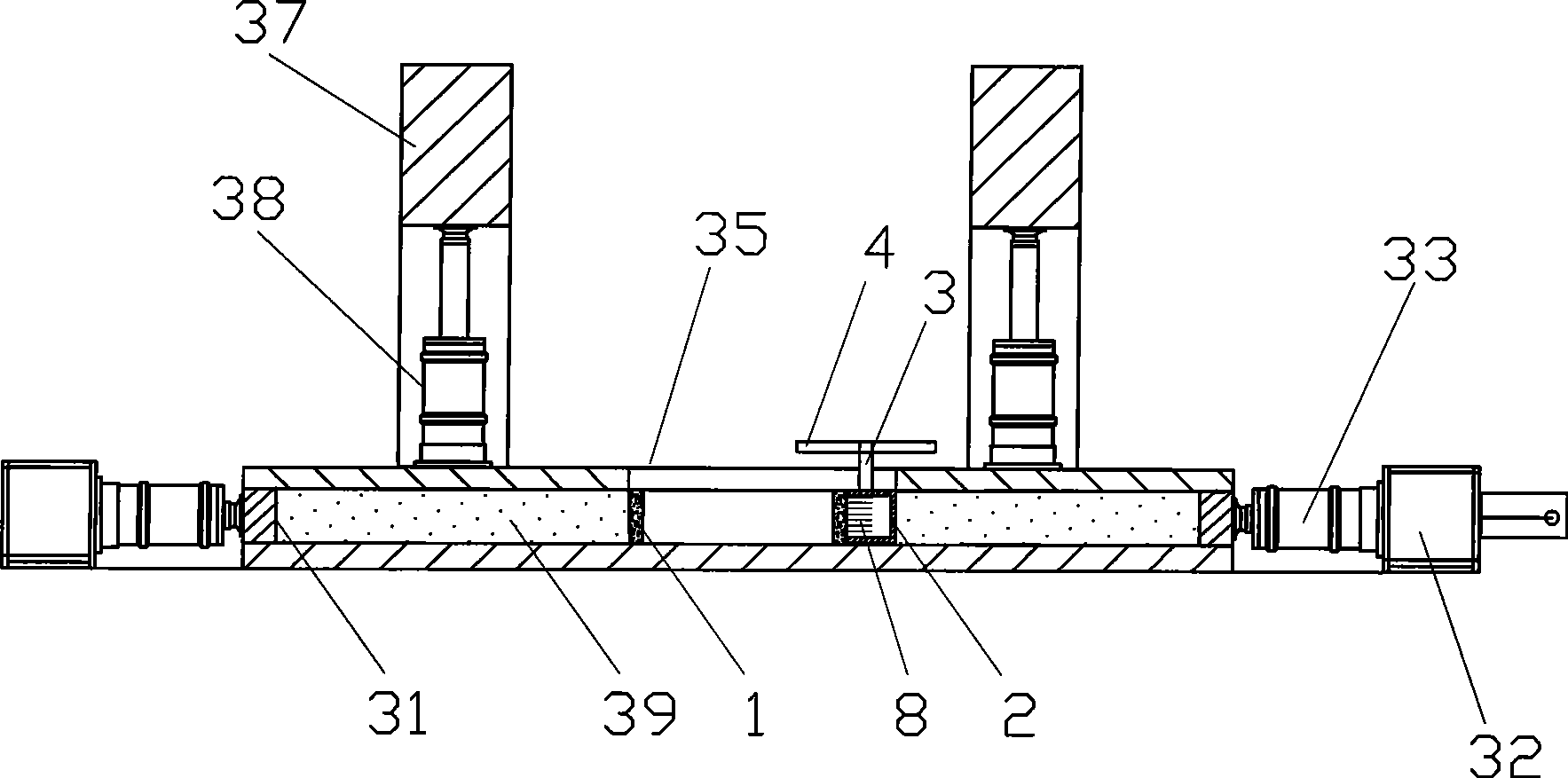

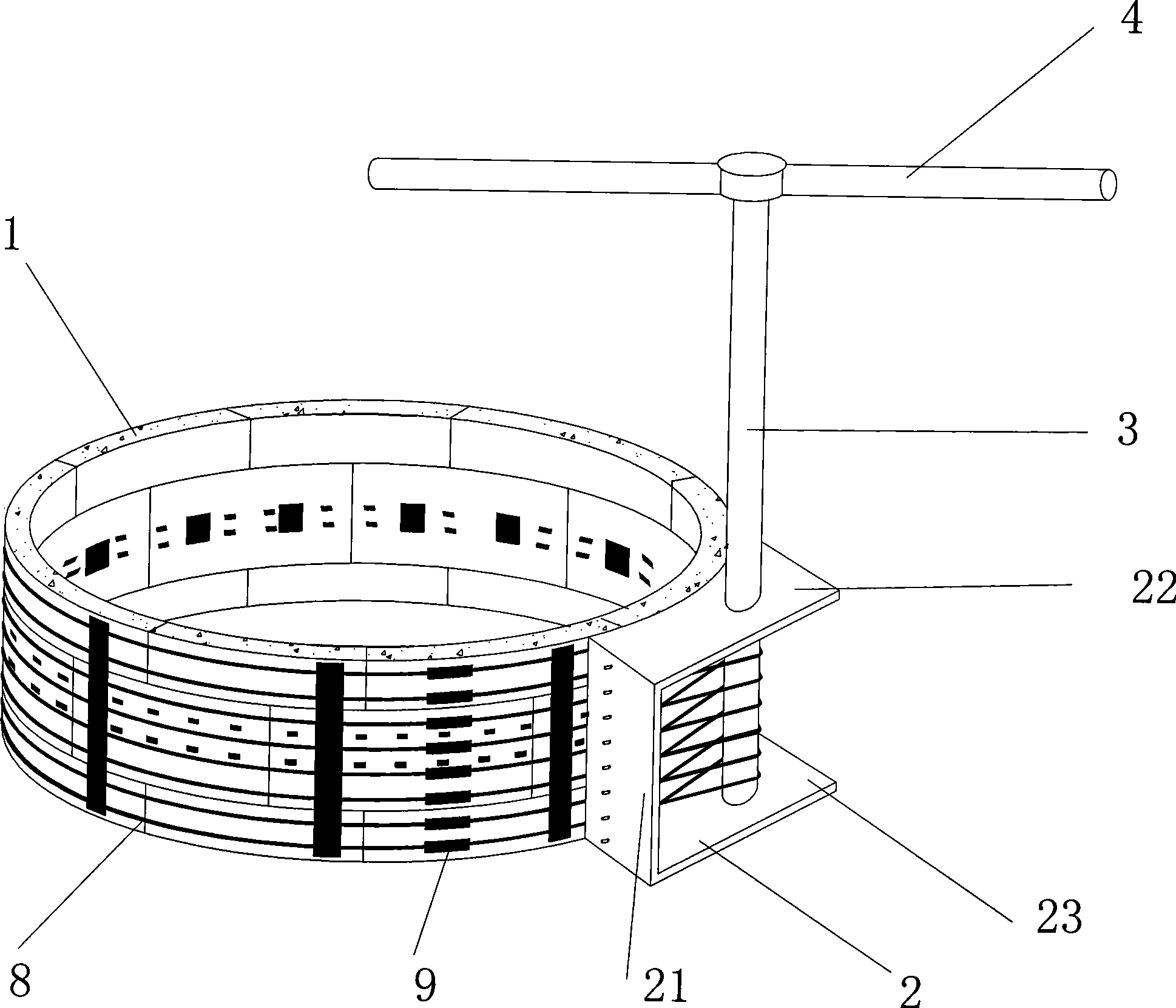

[0028] figure 1 -2 shows that a kind of embodiment of the present invention is: a kind of shield tunnel structure model comprehensive test system, and its composition is:

[0029] The soil layer simulation and soil pressure loading device is surrounded by four steel plates to form a square simulated soil cavity 31 . A square horizontal reaction force frame 32 is arranged outside the soil body cavity 31 , and a horizontal earth pressure jack 33 is connected between each side of the reaction force frame 32 and the corresponding side of the soil body cavity 31 .

[0030] The tunnel structure model 1 with the uniform water pressure loading device and the non-uniform water pressure loading device is placed axially and vertically in the center of the soil cavity 31; 1 and the soil cavity 31 are filled with simulated test soil, and an earth pressure box is placed in the simulated test soil; strain gauges, displacement gauges, joint gauges and earth pressure boxes are all connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com