High temperature abrasive particle wear-out detecting device and method

An abrasive wear and testing device technology, applied in the fields of corrosion and protection, and material wear, can solve the problems of collision, complex sample preparation, small resistance furnace volume, etc., and achieve accurate test data, good repeatability, and simple equipment operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

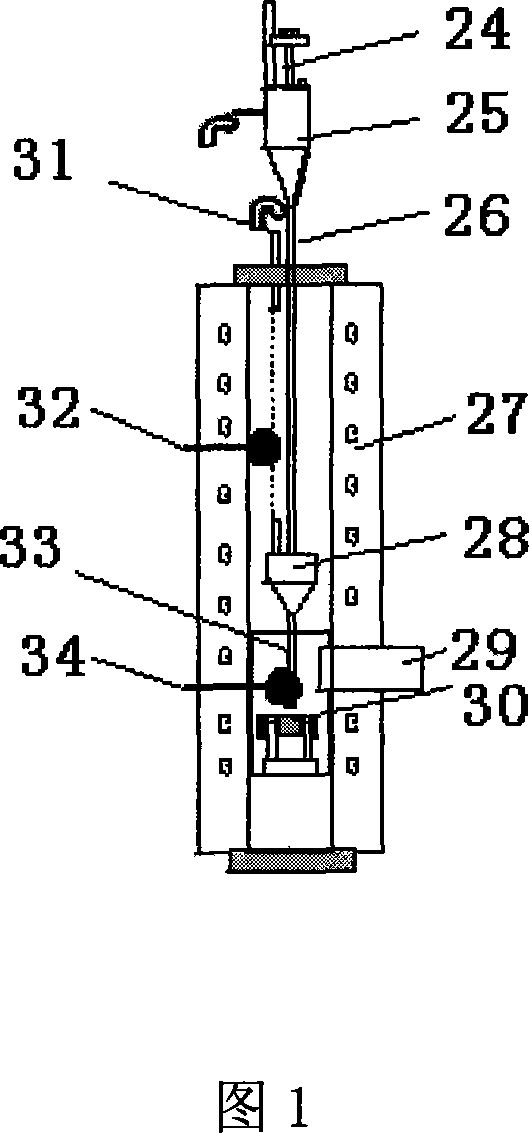

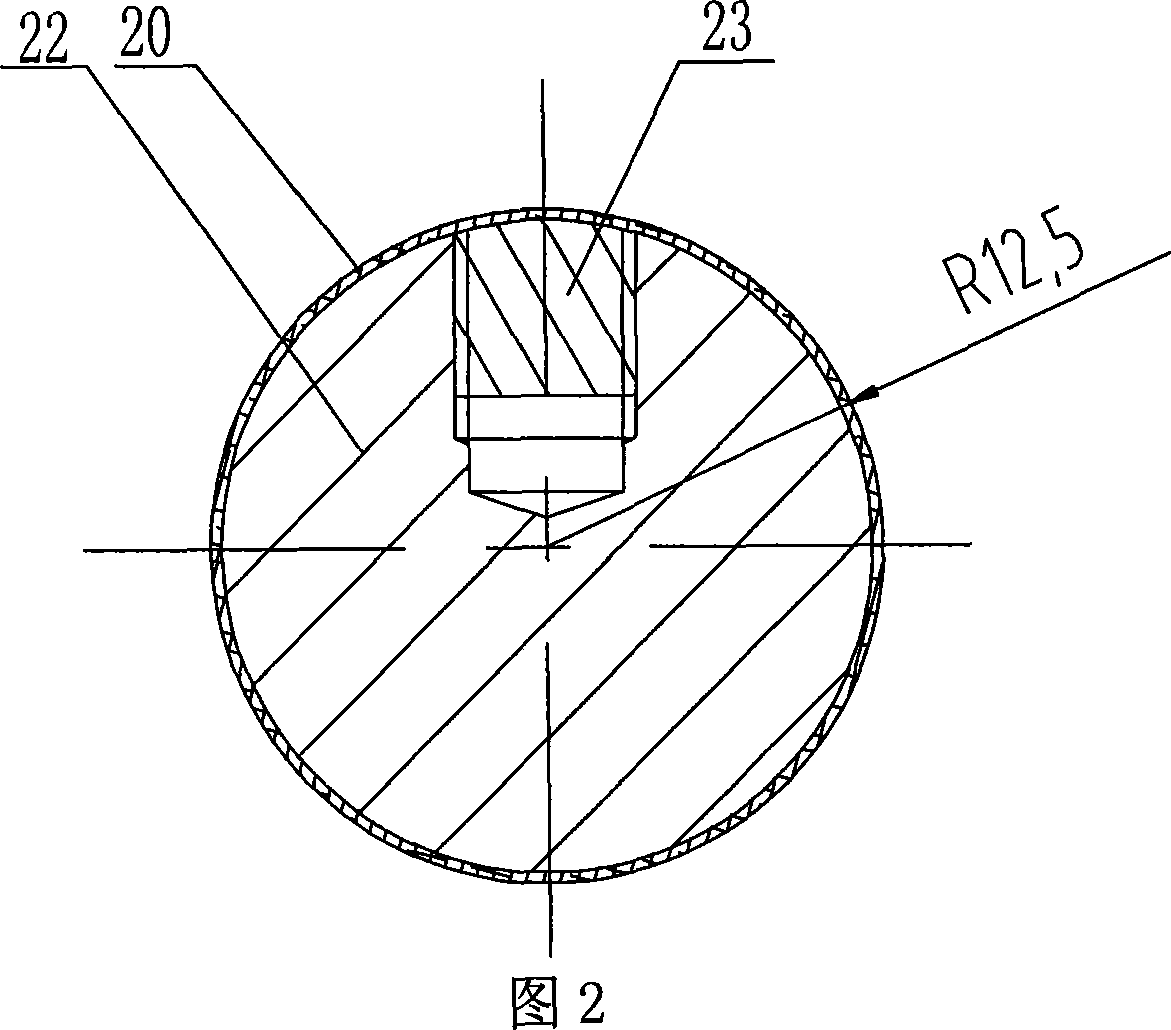

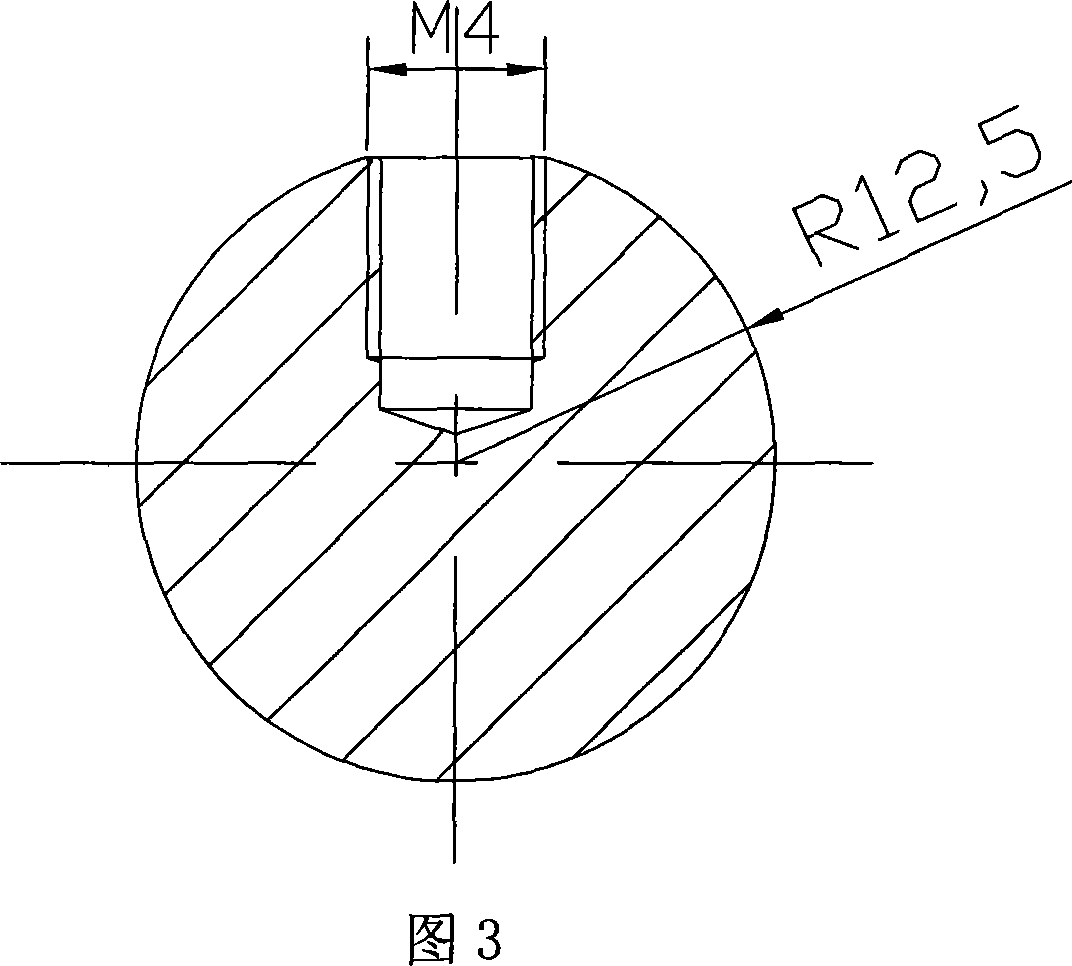

[0030] Embodiments of the present invention will be described in detail below with reference to FIG. 2 to FIG. 5 .

[0031] This embodiment mainly includes a resistance furnace 1 connected with a thyristor temperature controller 17 . Two lifting columns 6 are fixed on the resistance furnace 1, and the tops of the two lifting columns 6 are connected and fixed by a beam 8. A lifting platform 13 is arranged between the beam 8 and the resistance furnace 1, and the lifting platform 13 is connected with the lifting columns 6 through the sliding sleeve 5, and can move up and down along the two lifting columns 6. A motor and a reducer 11 are fixed on the lifting platform 13 , the output shaft of the reducer 11 is downward, and is connected with the rotary stirring fork 12 through a coupling 7 . There is a lifting handle 10 above the crossbeam 8, and a lead screw 9 is arranged below the lifting handle 10, and the leading screw 9 is connected with the lifting platform 13. A grinding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com