Patents

Literature

53results about How to "Moderate flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

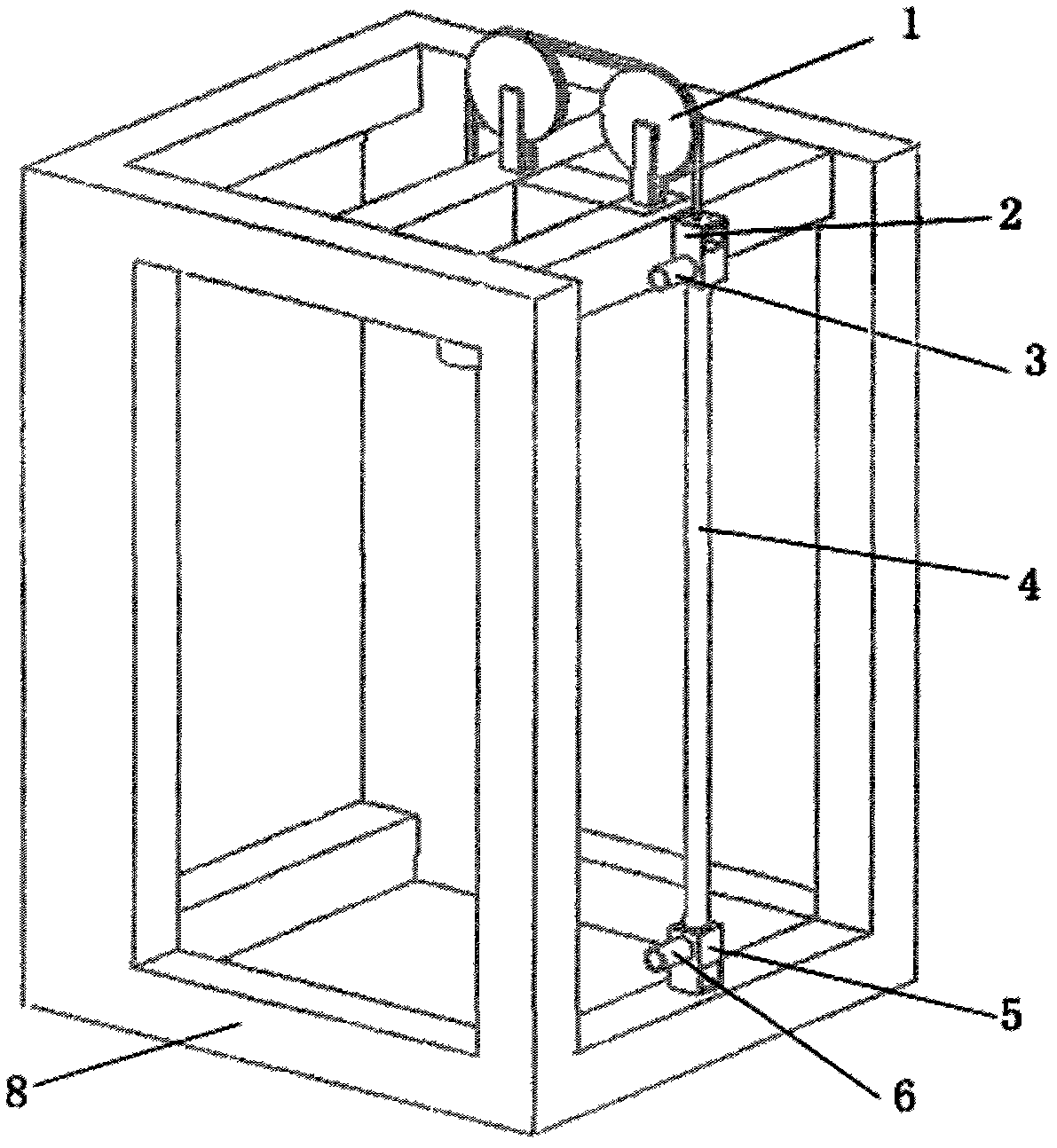

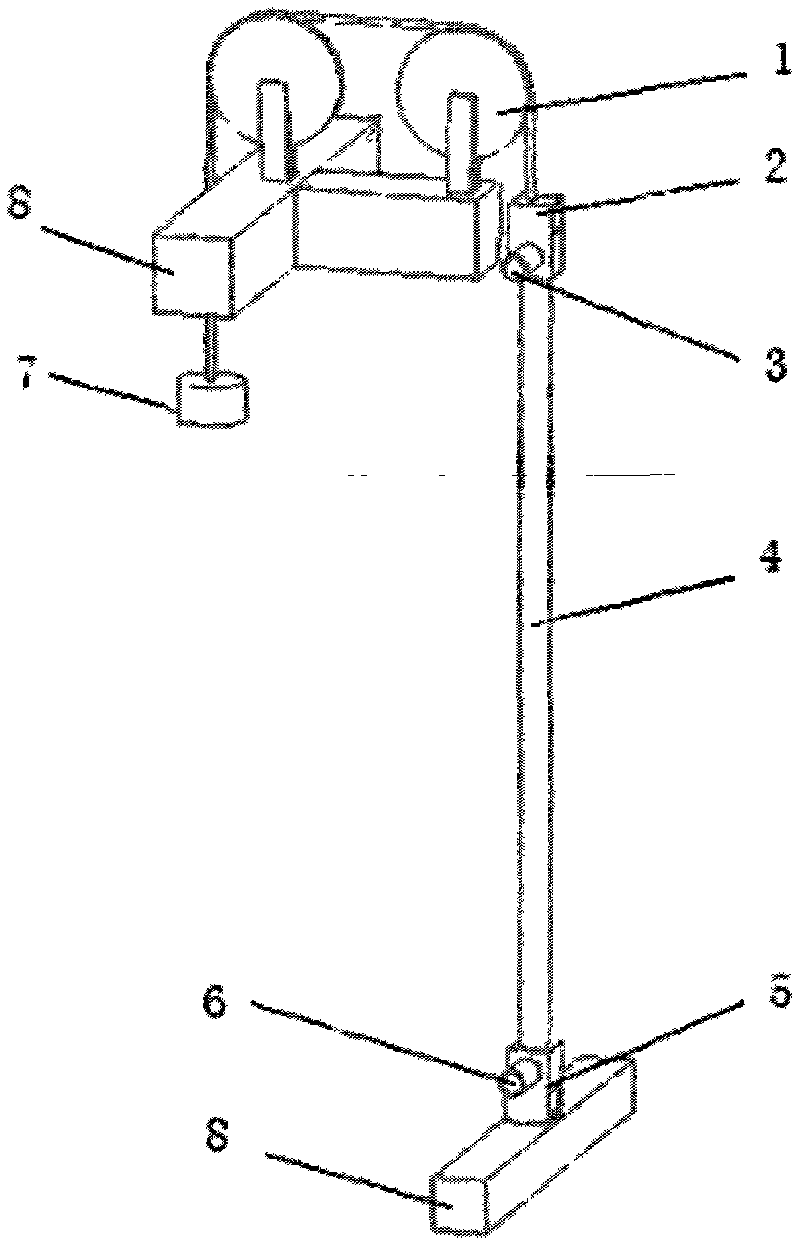

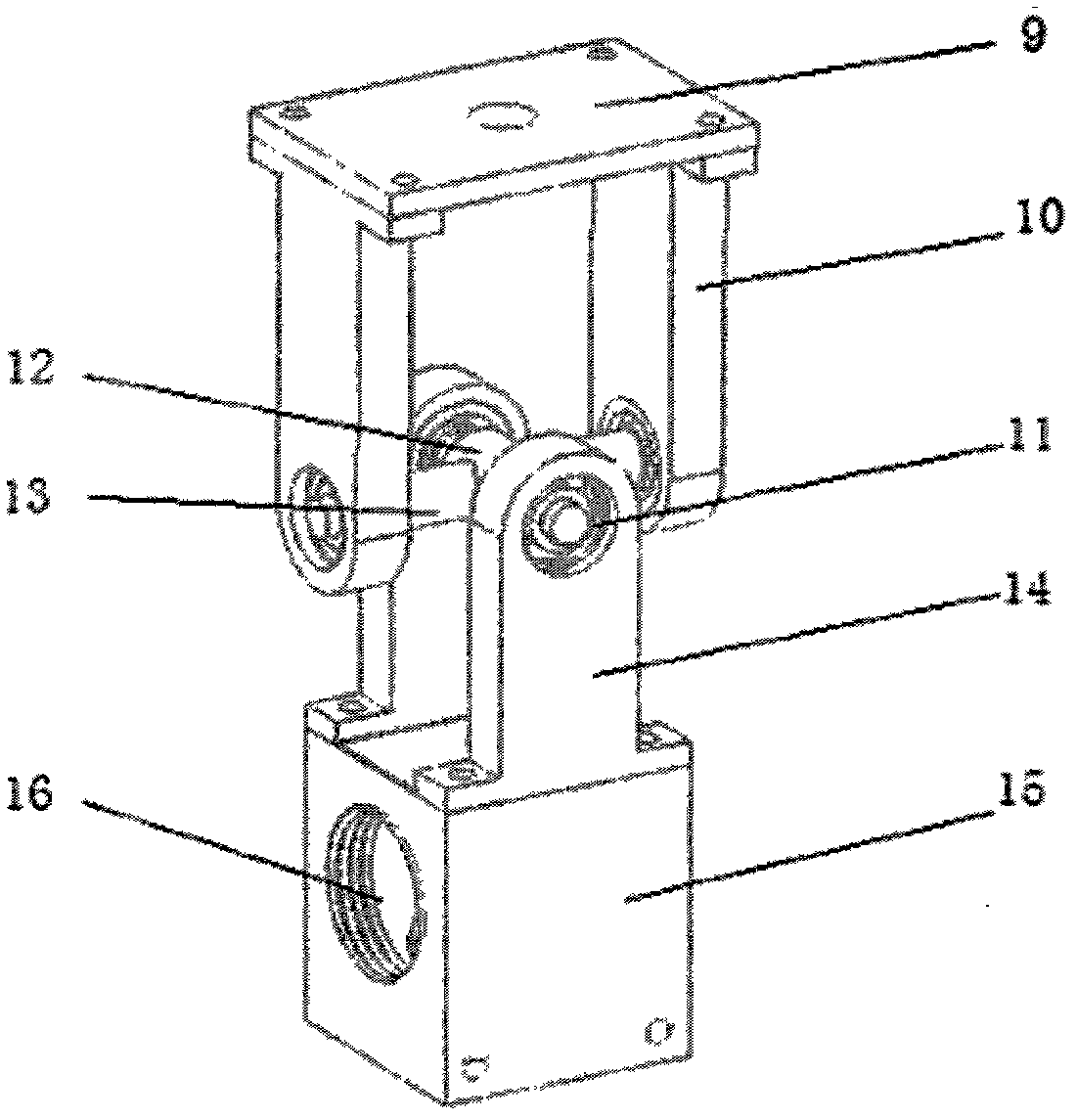

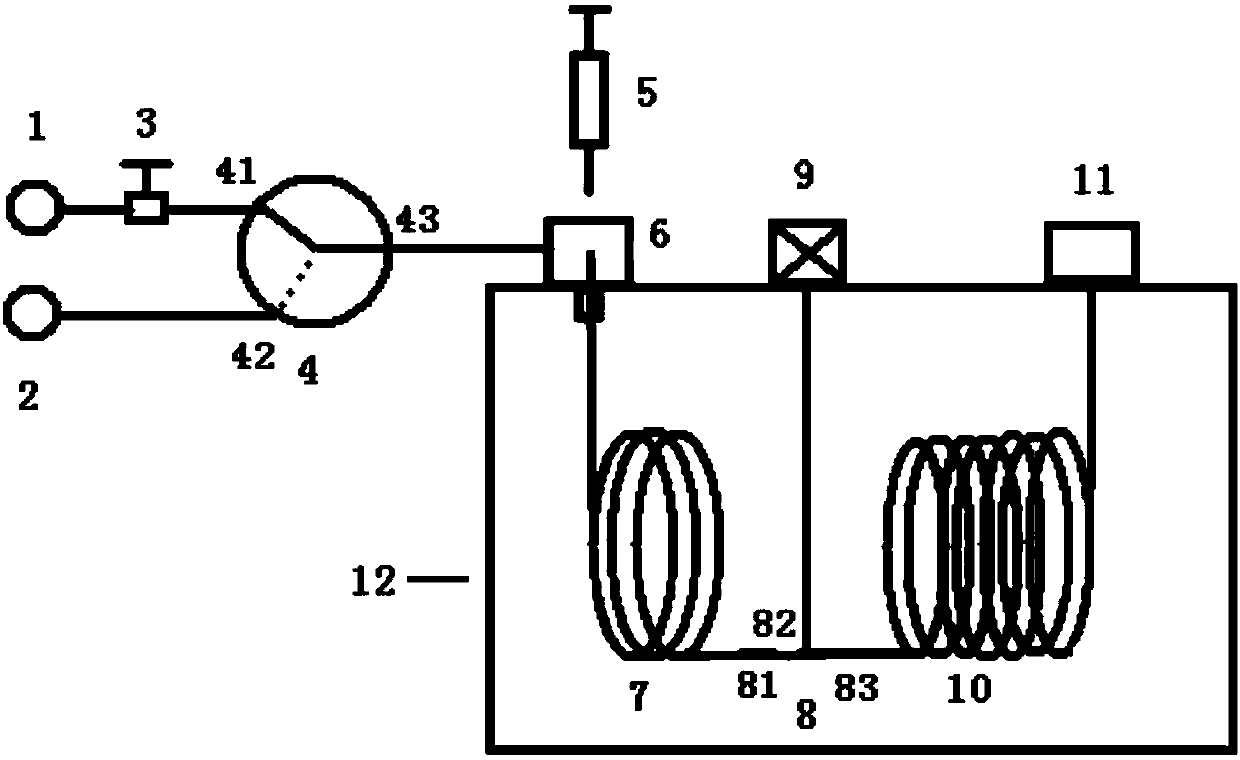

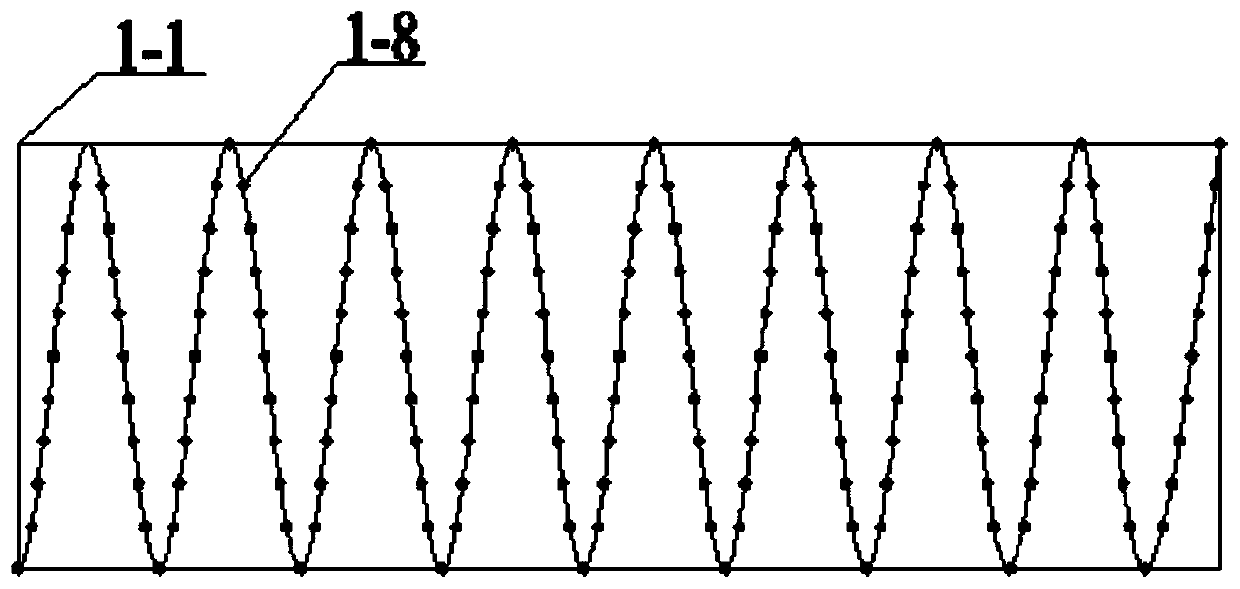

Method for testing influences of internal flow to dynamic property of marine risers

The invention belongs to the technical field of pavement of marine riser facilities, and particularly relates to a test method and a device. By the aid of the test method and the device, internal flow and top tension can be effectively applied during analog study of a marine riser vortex induced vibration law, and influences of the internal flow to the dynamic property of marine risers are tested. When in marine riser vortex induced vibration test study by the aid of the test device applying the internal flow and the top tension and the test method realized by the device, the top tension with the known intensity is continuously applied, and the intensity of the internal flow and the intensity of external flow are respectively changed, so that the influences of the internal flow to the dynamic property of the marine risers are determined by a strain gauge and a fiber bragg grating testing method. During the analog study of the marine riser vortex induced vibration law, the influences of the internal flow to the dynamic property of the marine risers can be tested, so that accuracy of a marine riser vortex induced vibration model test is improved, and an accurate test conclusion can be obtained.

Owner:OCEAN UNIV OF CHINA

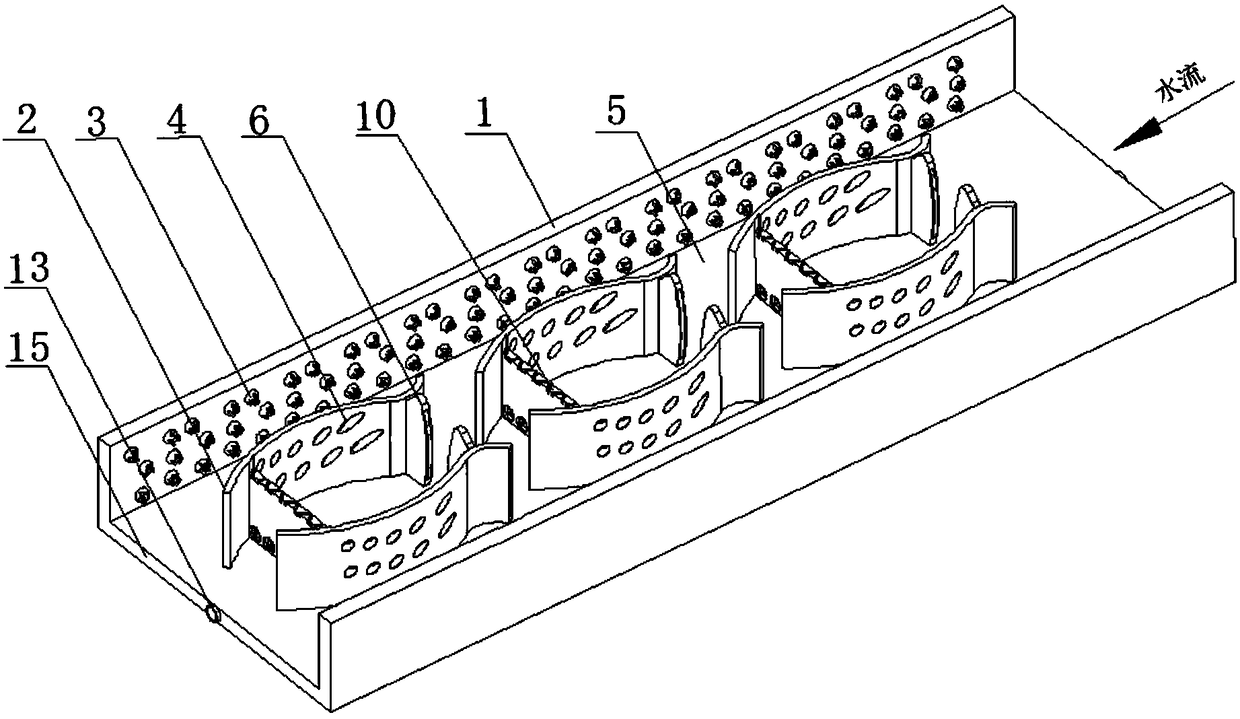

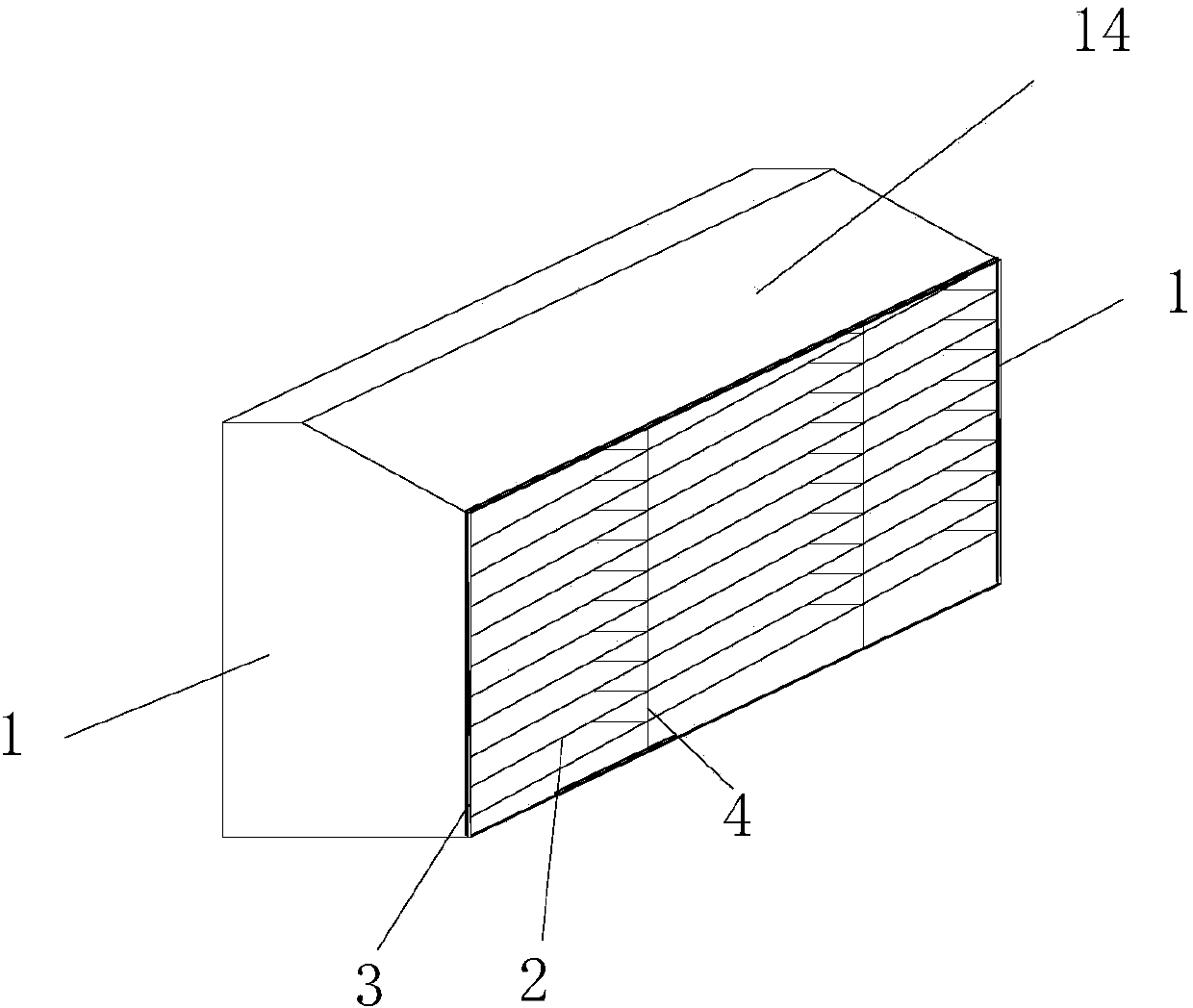

Nature-imitated fishway adapted to fishes with different swimming abilities

ActiveCN108277784AIncrease wall roughnessReduce water velocityBarrages/weirsClimate change adaptationSwimming capacityWing wall

The invention discloses a nature-imitated fishway adapted to fishes with different swimming abilities, and relates to the ecological field of fish passing structures and water conservancy and hydroelectric engineering. The nature-imitated fishway comprises fishway outer wing walls, a fishway bottom plate and a plurality of fishway units. Fish upstream outer passages with the small flowing speed are formed between the fishway outer wing walls and fishway inner wing walls, and fish upstream inner passages with the large flowing speed are formed between the fishway inner wing walls of the same fishway unit; the outer passages and the inner passages are combined to form multiple hydrodynamic conditions to meet the upstream demands of the fishes with the different swimming abilities; and the fishway units are internally provided with deflection plates which automatically adjust the magnitude of the opening degree according to the flow magnitude and water depth change, so that the proper flow speed for passing of the fishes is easily formed at fish passing vertical seams. Compared with a tradition fishaway, according to the nature-imitated fishway adapted to the fishes with the differentswimming abilities, the diversified water flow conditions can be formed, environmental suitability of fish upstream is enhanced, and the migratory efficiency of the fishes with the different swimmingabilities is improved.

Owner:ANHUI UNIV OF SCI & TECH

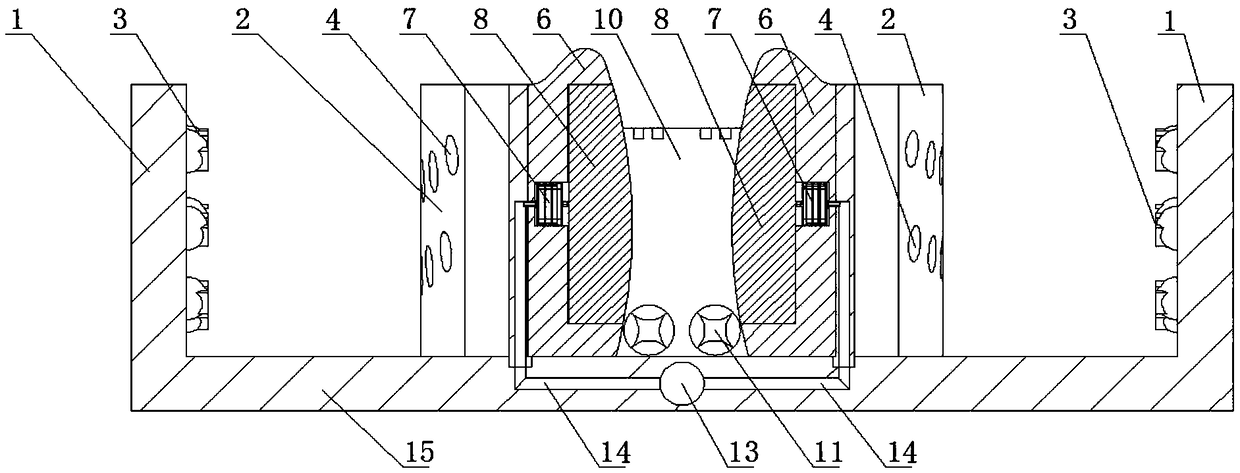

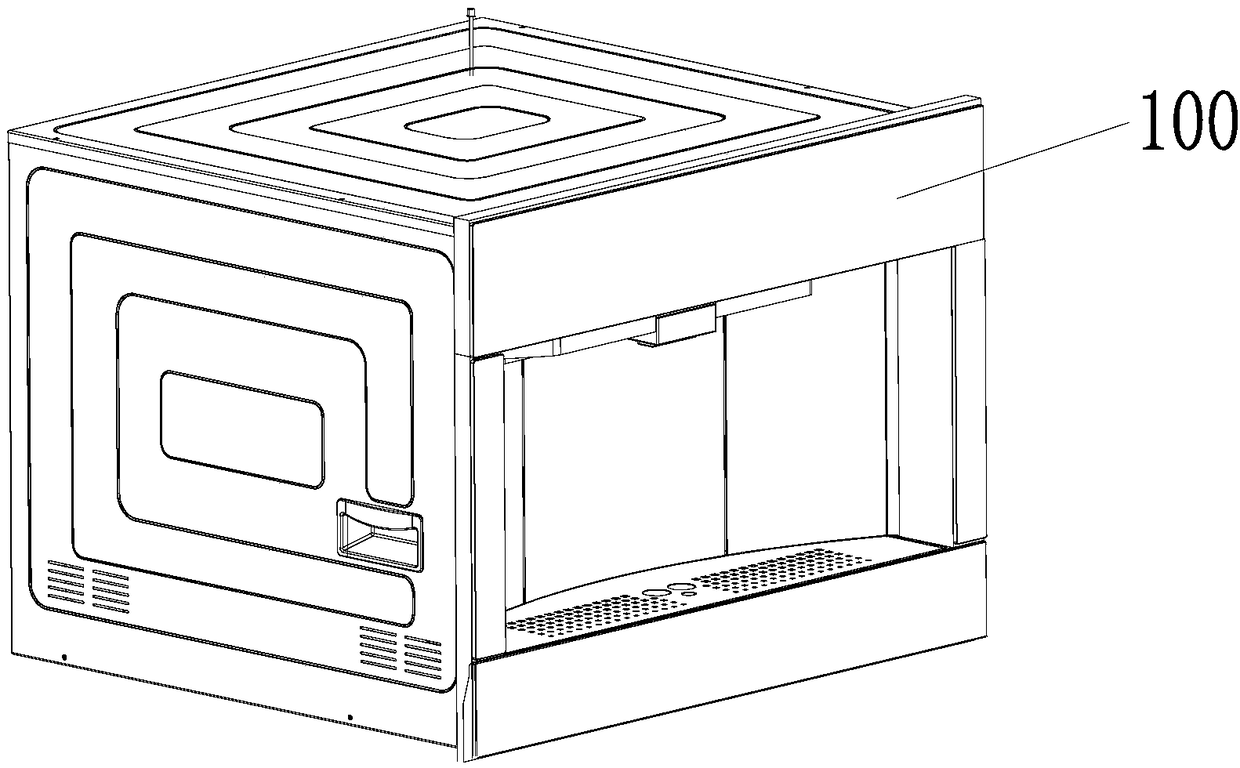

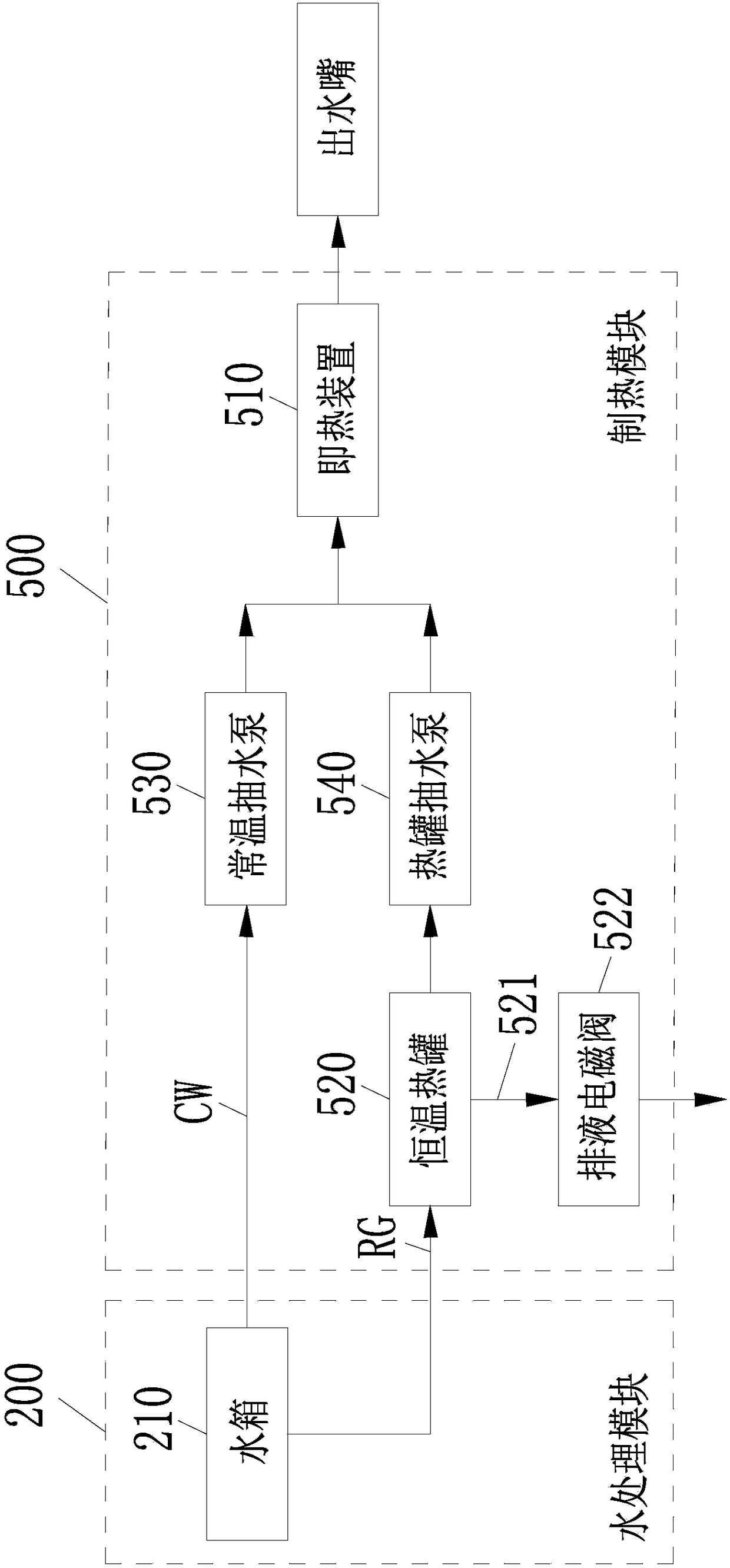

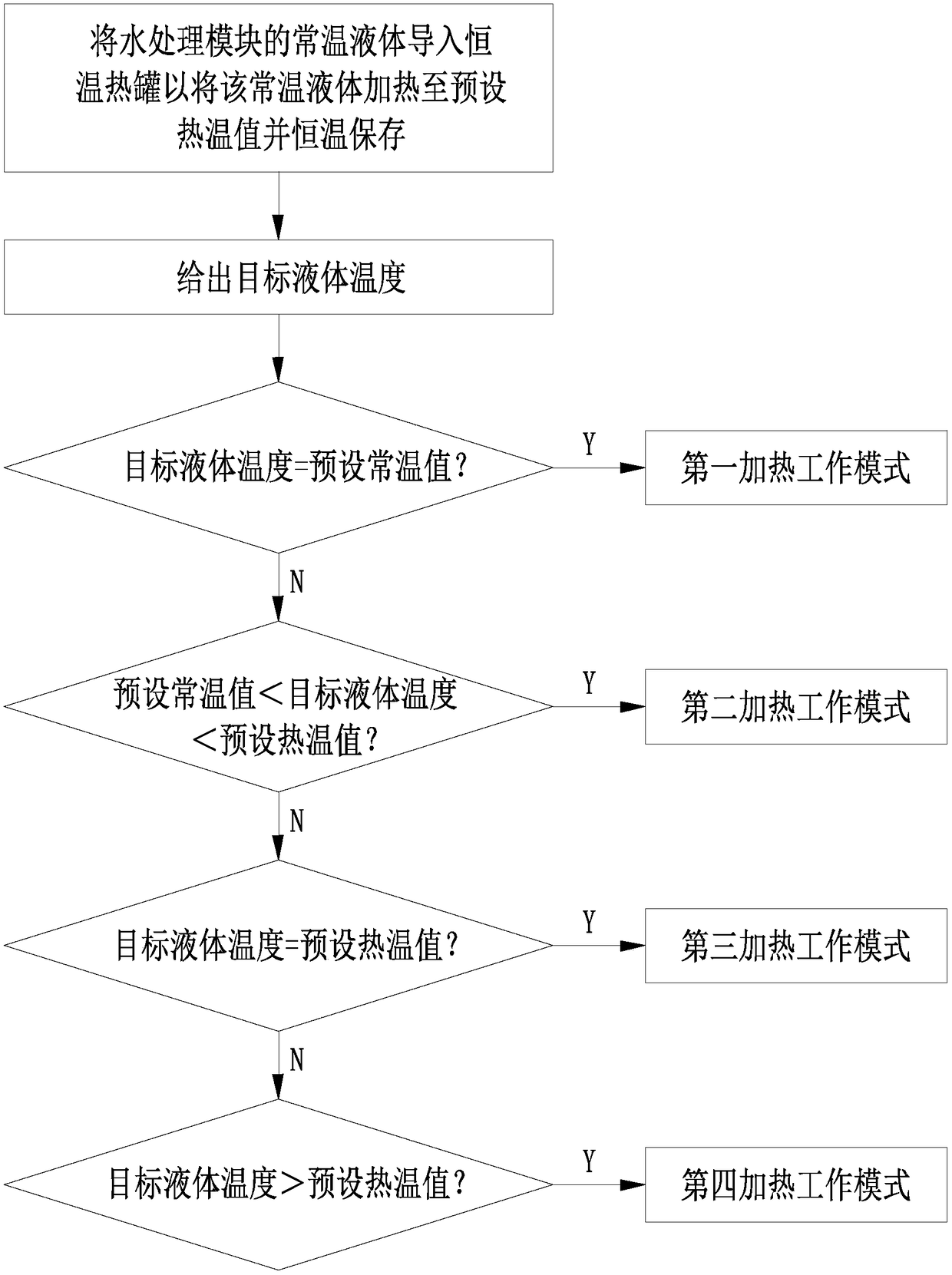

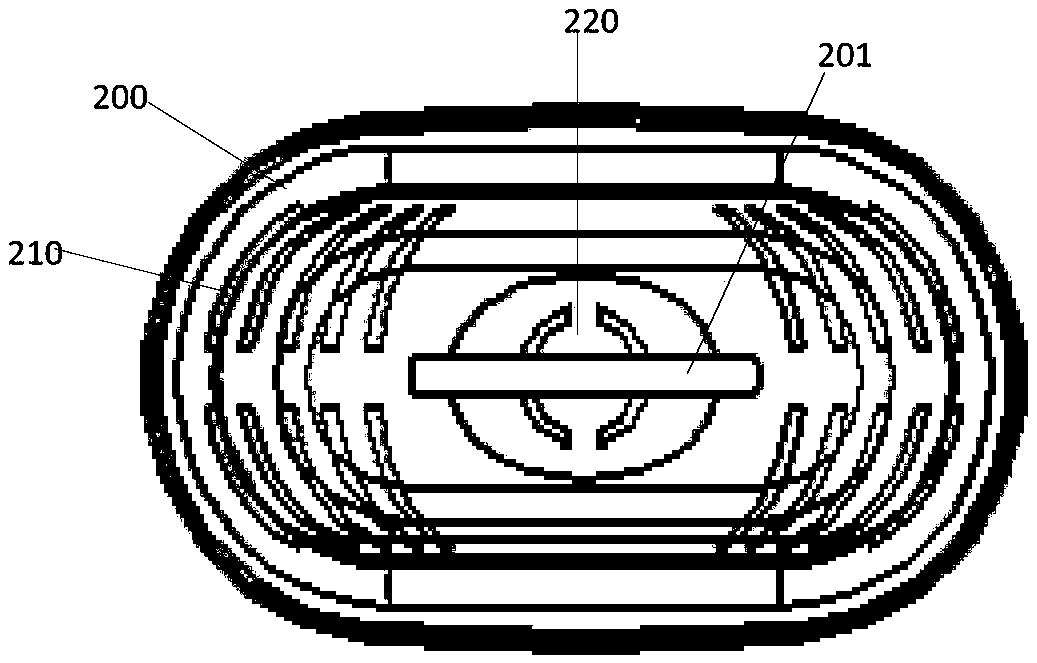

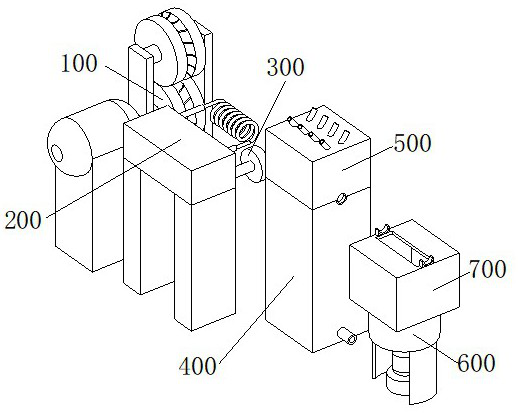

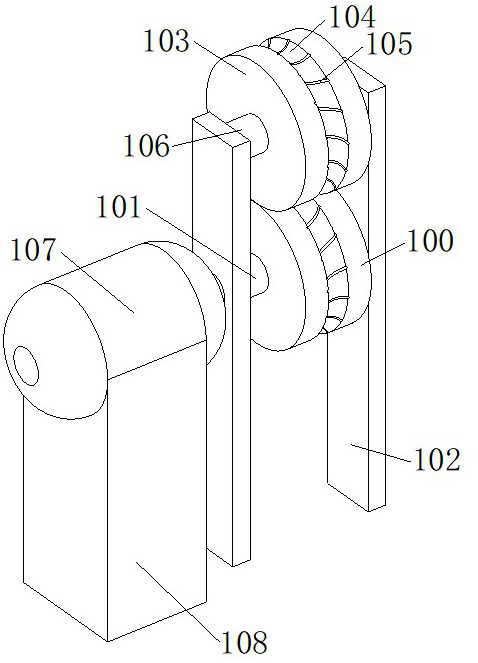

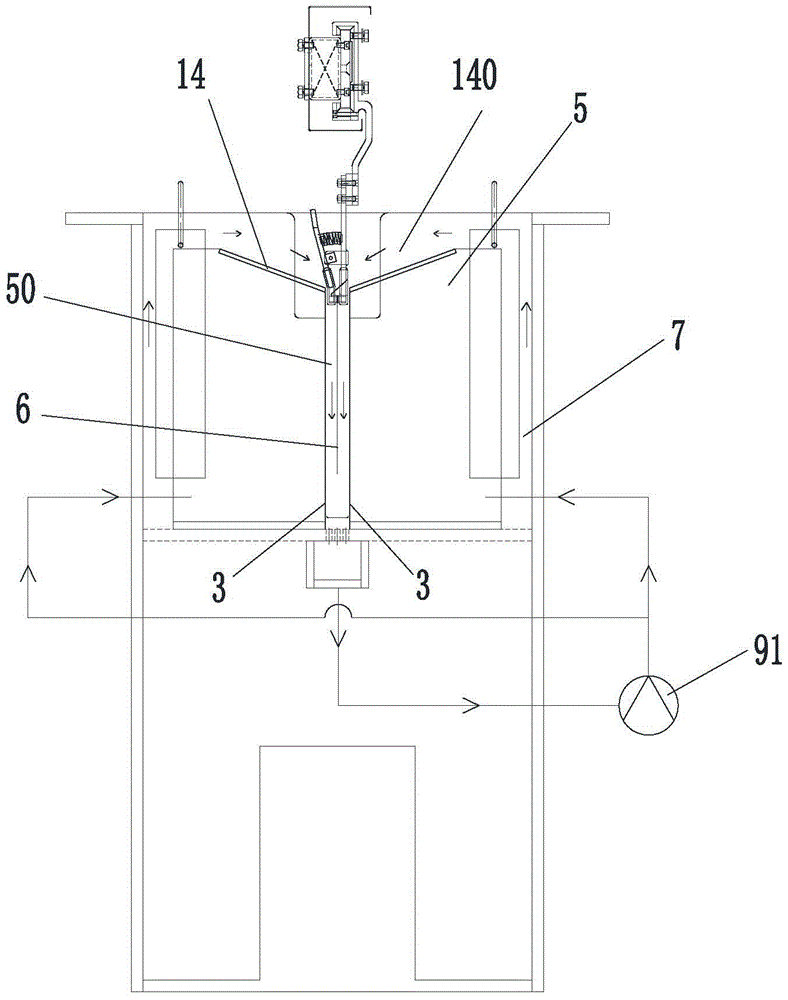

Machine-readable storage medium, purifying water dispenser and liquid heating control method thereof

InactiveCN108594900AAccurate outputModerate flow rateTemperatue controlBeverage vesselsLiquid temperatureWork pattern

The invention belongs to the field of domestic appliances and discloses a machine-readable storage medium, a purifying water dispenser and a liquid heating control method thereof. The liquid heating control method of the purifying water dispenser comprises: introducing a normal temperature liquid from water treatment module (200) into constant temperature heat tank (520) so that the normal temperature liquid is heated to a preset heat value, holding the temperature, and storing; giving a target liquid temperature; comparing the target liquid temperature respectively with a preset normal temperature and a preset heating value, and selecting a corresponding heating mode of heating module (500) according to a comparison signal. The purifying water dispenser herein can discharge liquids at different temperatures precisely; a liquid discharged by the purifying water dispenser is imparted certain speed; therefore, operating is convenient for a user, and user experience can be greatly improved.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

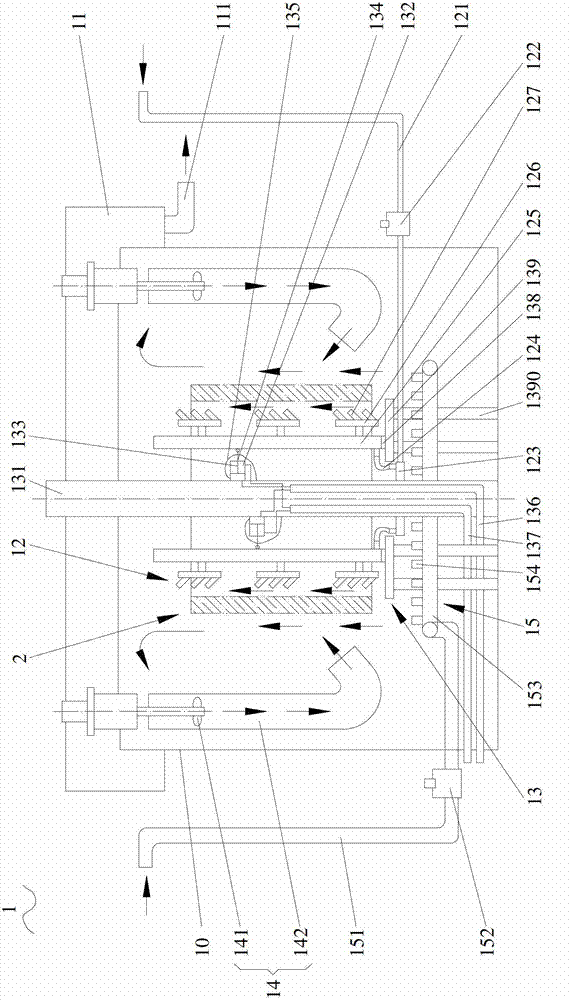

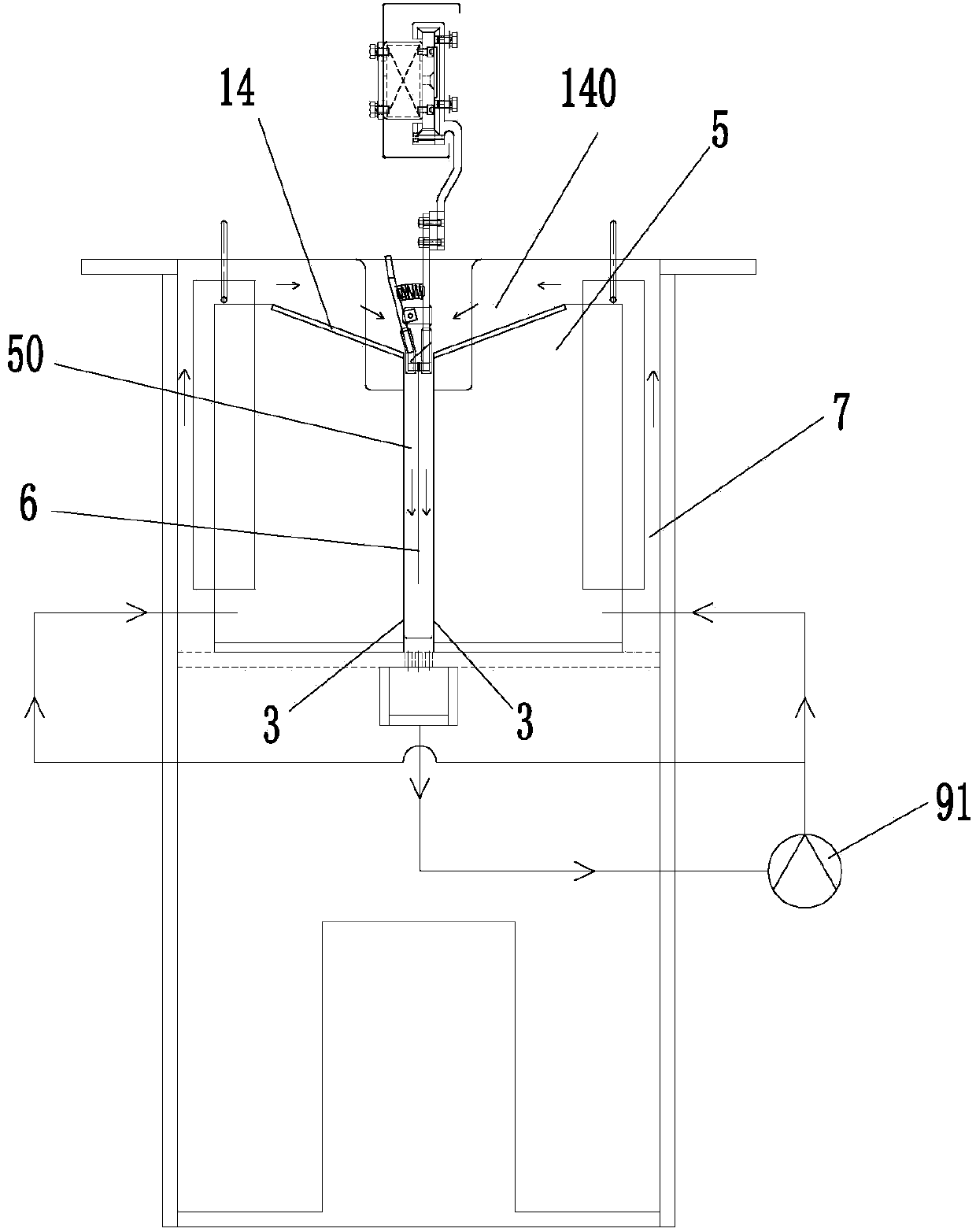

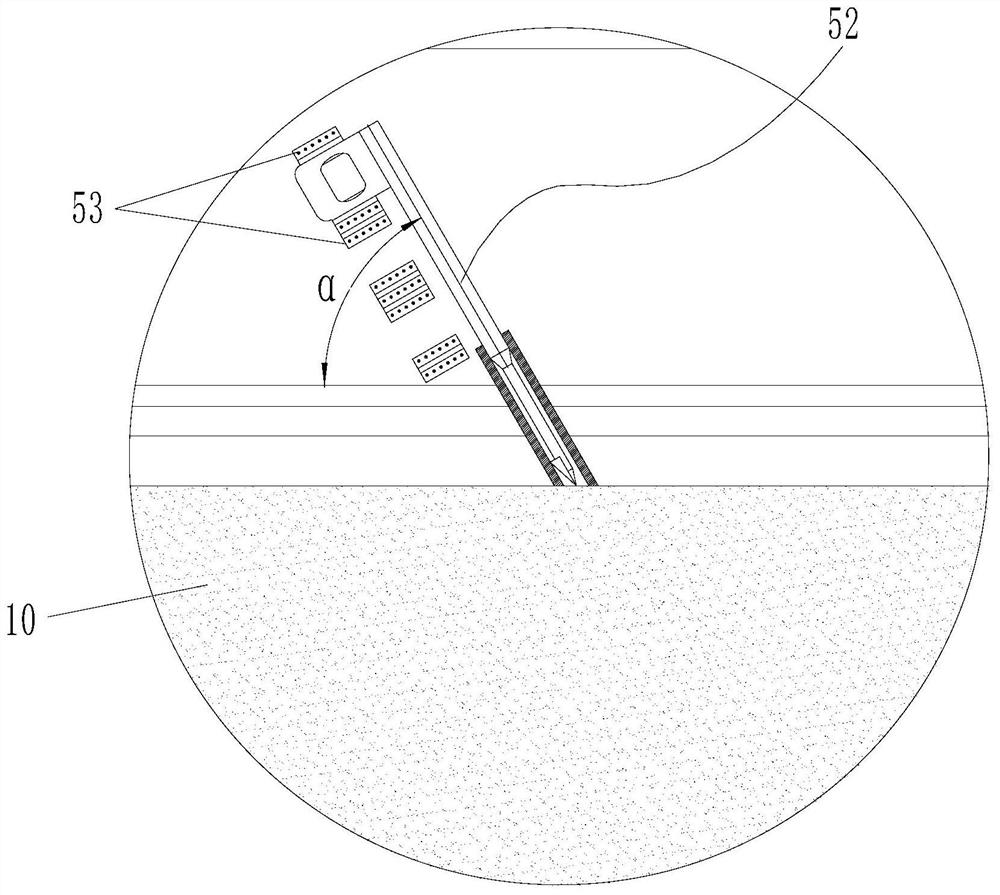

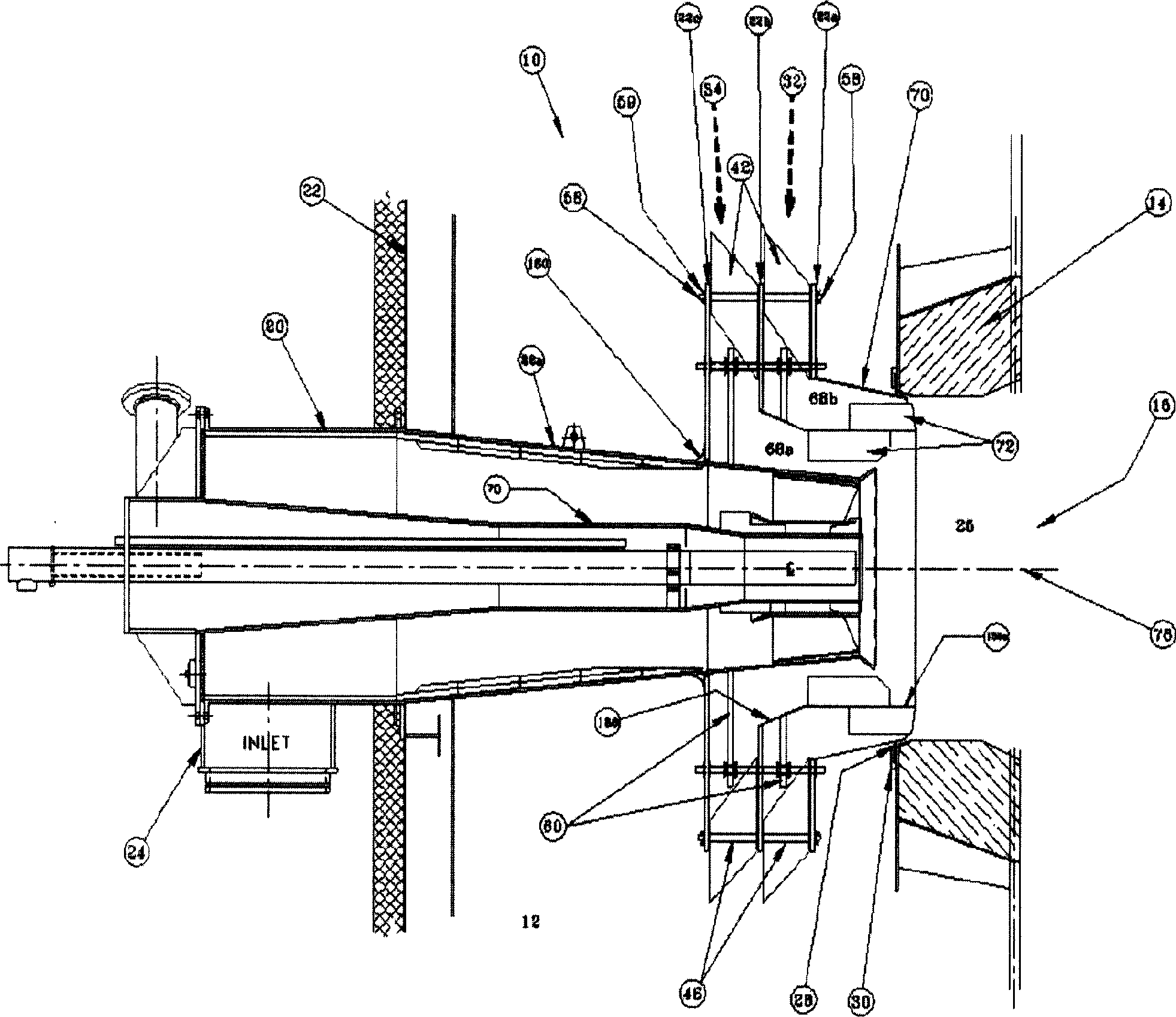

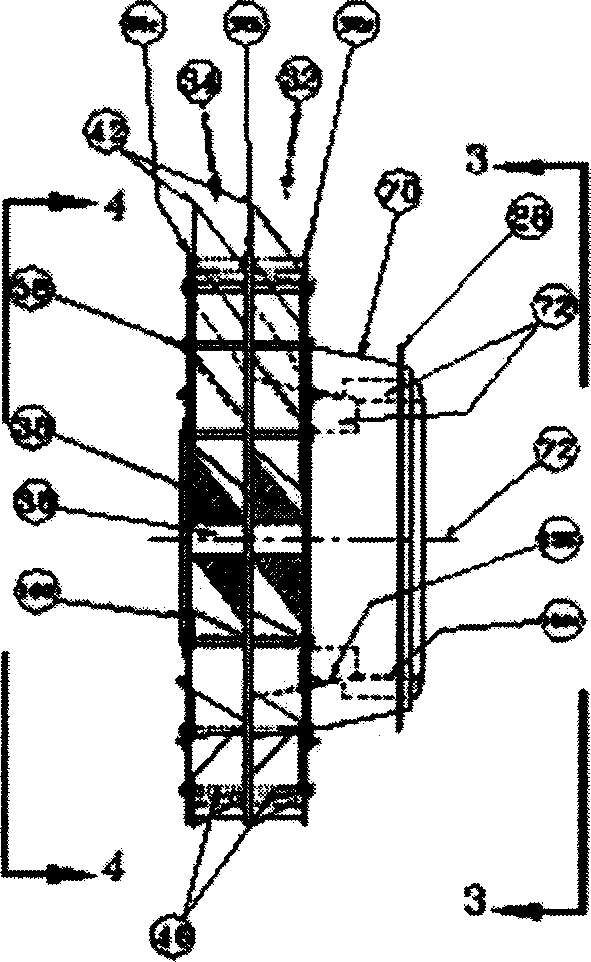

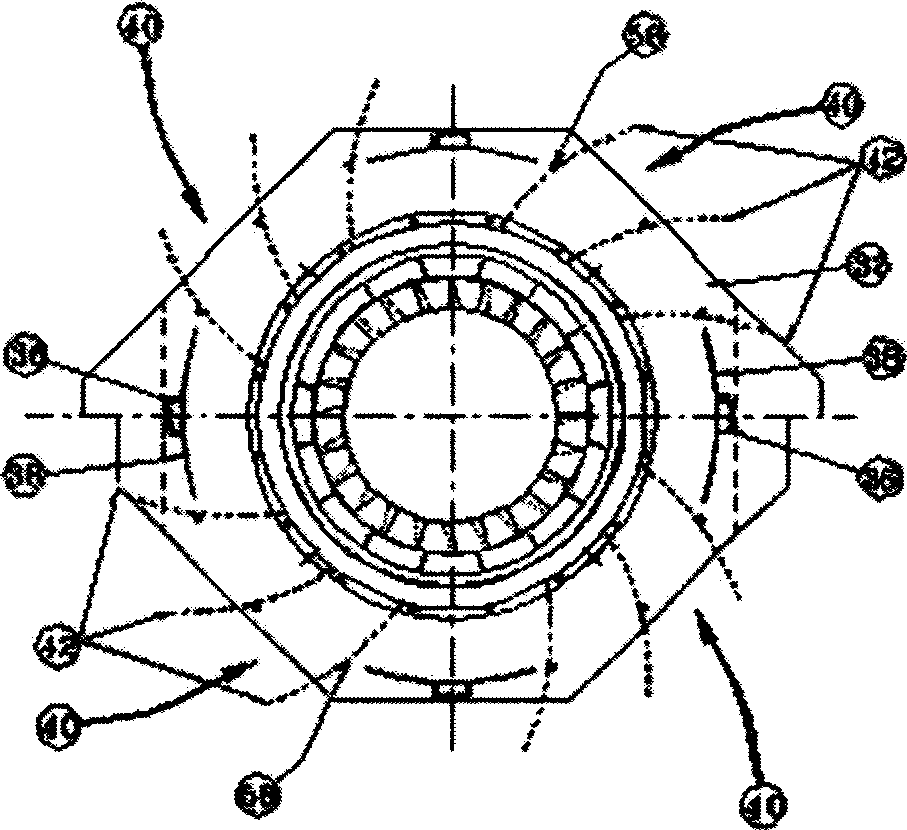

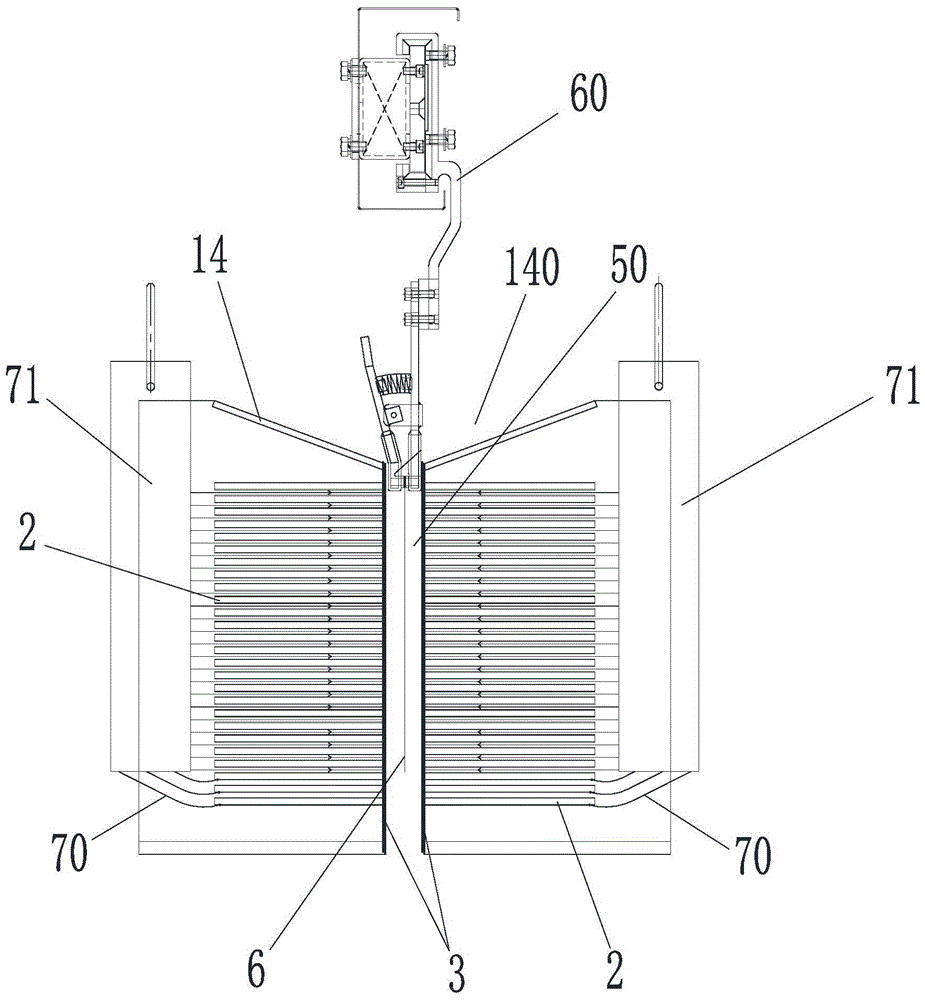

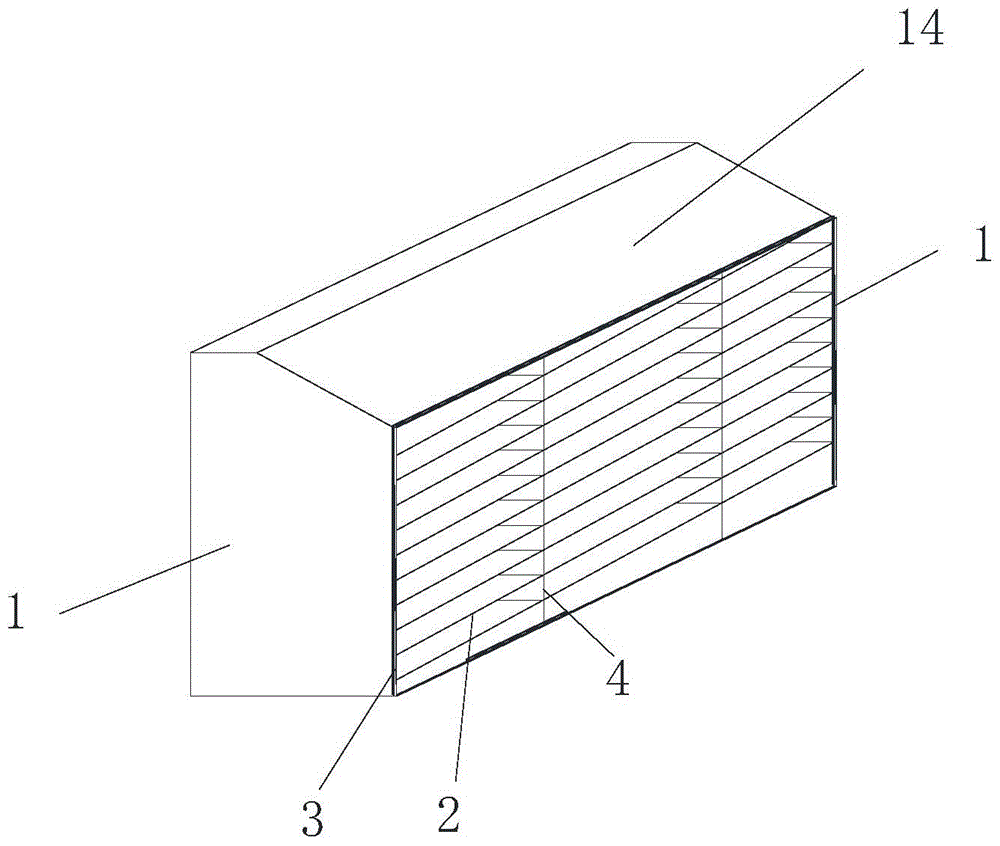

Method for controlling flow fields in quenching water tank of large cylindrical workpiece

InactiveCN102925641AControl of flow field structureUniform flow rateFurnace typesHeat treatment furnacesControl flowPropeller

The invention provides a method for controlling flow fields in a quenching water tank of a large cylindrical workpiece. The method comprises the step of simultaneously forming an inlet communicated with quenching liquid outside the water tank and an inner spraying nozzle jet flow field performing spraying towards the inner lateral wall of the workpiece in an inclined and upward mode, an inlet communicated with the quenching liquid outside the water tank and an outer spraying nozzle jet flow field performing spraying to the outer side of the workpiece from bottom to top, and an inlet communicated with the top of the water tank and a propeller stirring jet flow field performing spraying towards the outer lateral wall of the workpiece in an inclined and upward mode. The workpiece quenching process is adjusted by adjusting the inner spraying nozzle jet flow field, the outer spraying nozzle jet flow field and the propeller stirring jet flow field. By means of the method, the structures of the flow fields in the quenching water tank can be controlled according to the size and the quenching requirements of the workpiece, so that quenching media around the cylindrical workpiece have equal and appropriate flow velocity and can circulate in the quenching water tank well, and quenching quality of the large cylindrical workpiece is ensured effectively.

Owner:SHANGHAI DIANJI UNIV

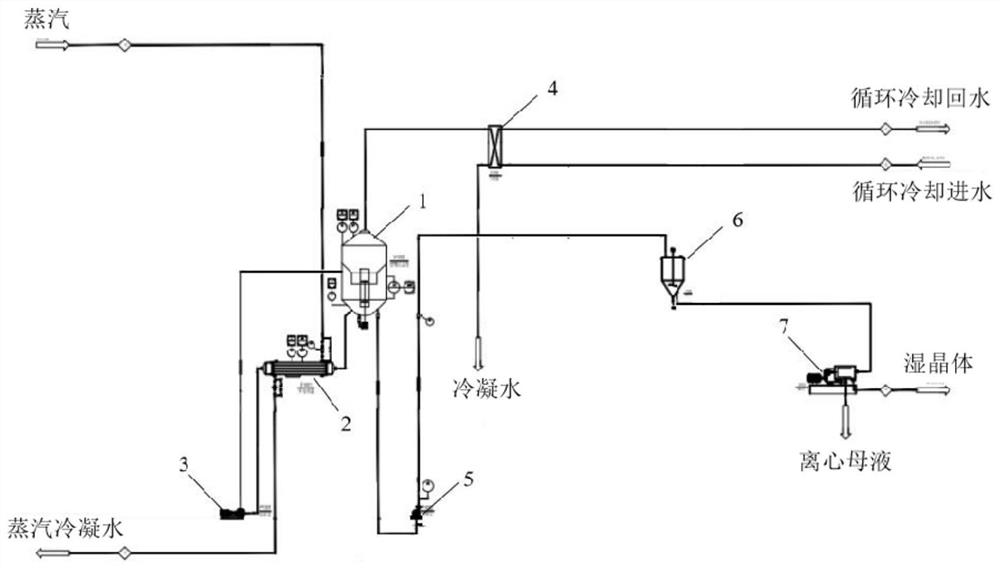

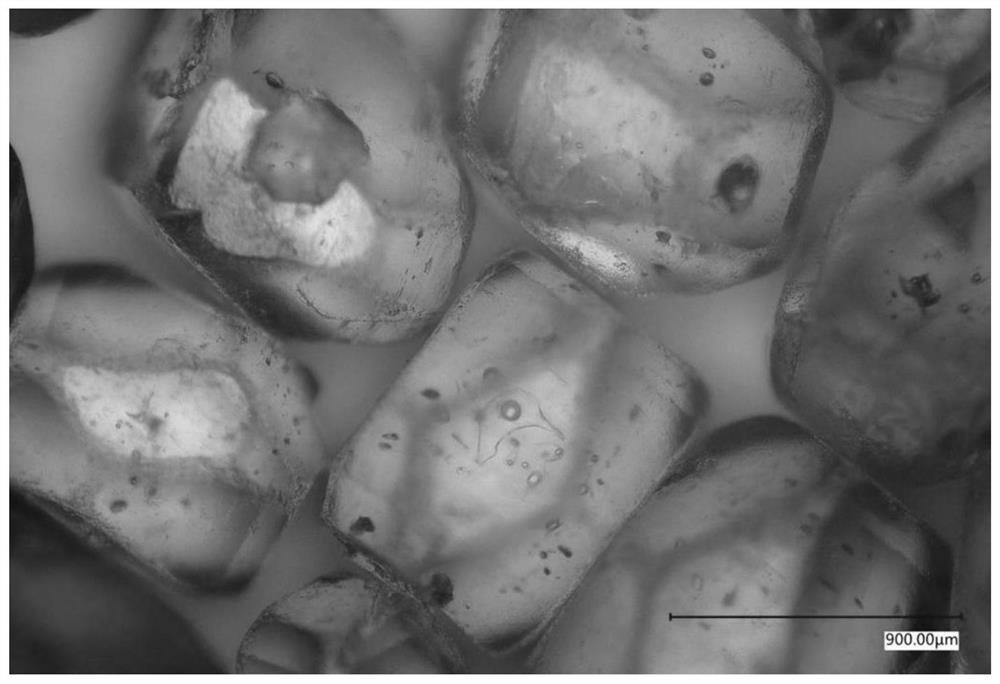

Crystallization system and crystallization process for producing nickel sulfate by continuous method

PendingCN112807734AQuick mixShorten the timeSolution crystallizationCrystallization by component evaporationProcess engineeringParticle-size distribution

The invention belongs to the technical field of industrial production of sulfate, and particularly relates to a crystallization system and a crystallization process for producing nickel sulfate by a continuous method. The invention relates to a crystallization system for producing nickel sulfate through a continuous method. The crystallization system comprises a crystallizer, a fine grain eliminator, a feeding pump, a heat exchanger, a discharging pump, a thickener and a centrifugal machine. According to the crystallization system and the crystallization process for producing the nickel sulfate by the continuous method, uniform supersaturation degree of the nickel sulfate solution in each part of the crystallizer is ensured, so that a nickel sulfate product with uniform particle size distribution and the particle size of more than 800 microns is prepared. Compared with a traditional intermittent crystallization mode, the crystallization system adopts a continuous crystallization mode, and the production capacity is enhanced.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

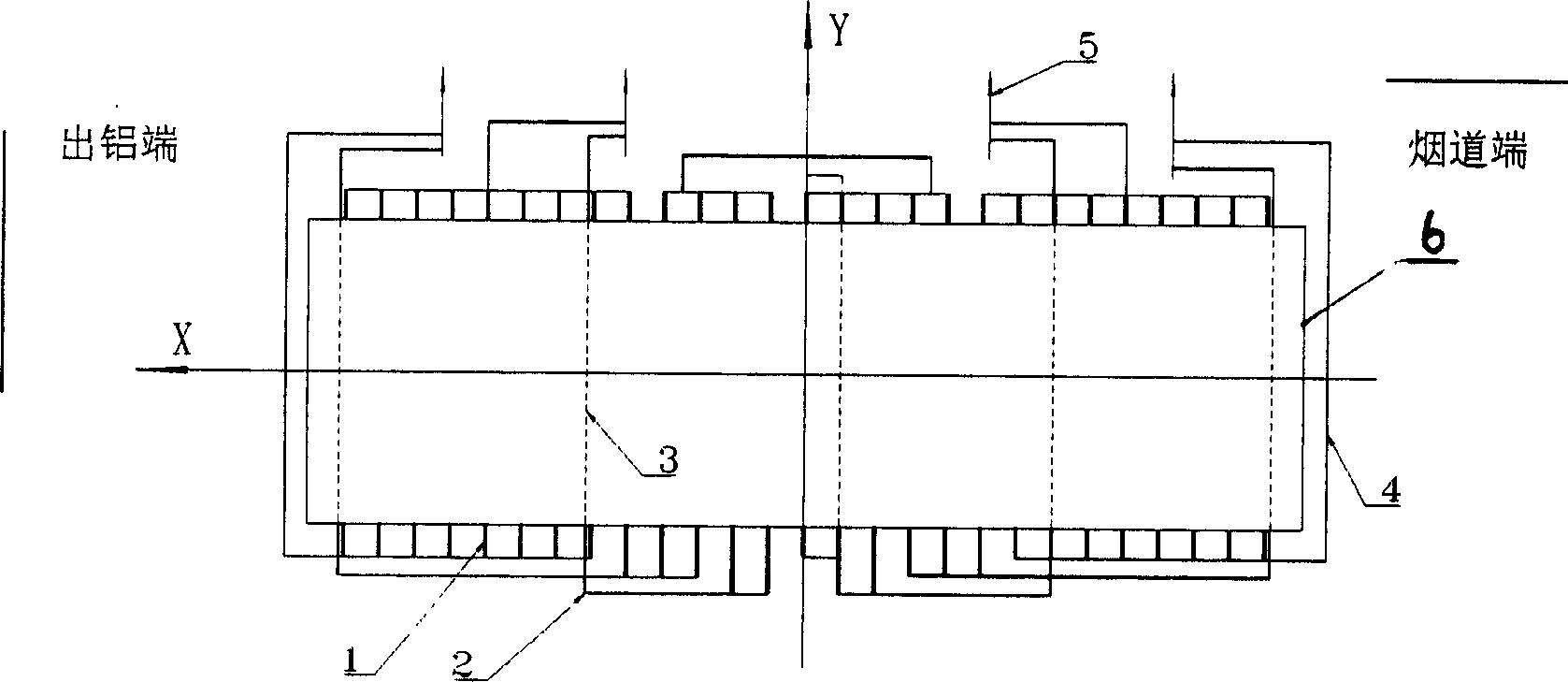

Five power-on bus distributing style with different current

ActiveCN1598068ATroubleshoot Magnetic FieldsHarm reductionBus-bar installationElectricityTransverse magnetic field

The invention discloses a 5-point generatrix configuration method of a large-area inequipotential electricity type. It is composed of the cathode soft generatrix, cathode generatrix, bottom generatrix, side generatrix, lower column generatrix and electrobath. The lower column generatrix is 5-piece configuration. The invention not only can make the current passing every column appropriate and effectively reduce the magnetic field in the slot and the transverse magnetic field, but also match with every slot paramete of the large-scale slot. Especially compared with the two columns, the center columune has low current and is benefit to reduce the danger caused by the middle level magnetic field in the electrobath to make the electrobath more stable.

Owner:GUIYANG AL-MG DESIGN & RES INST

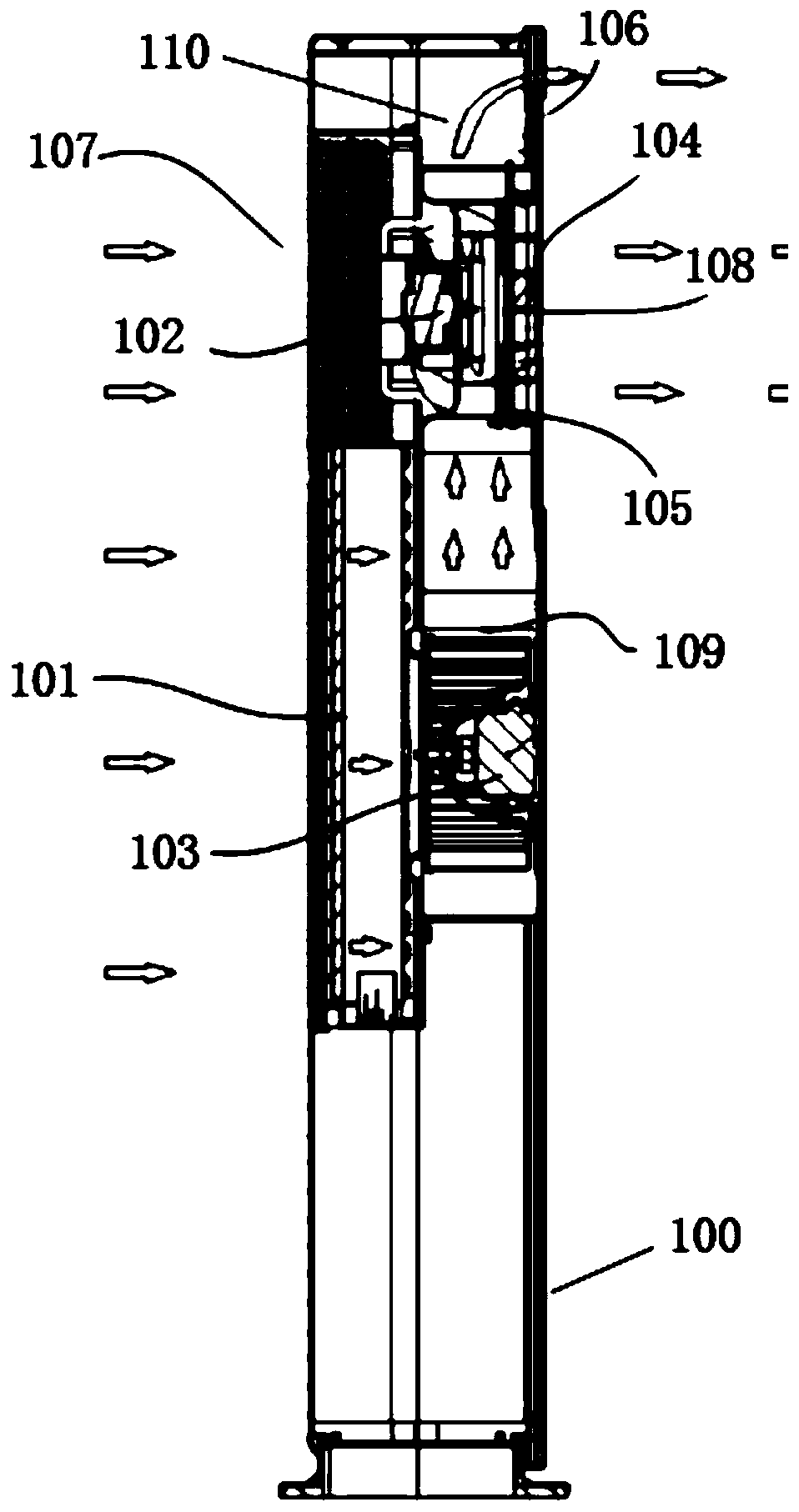

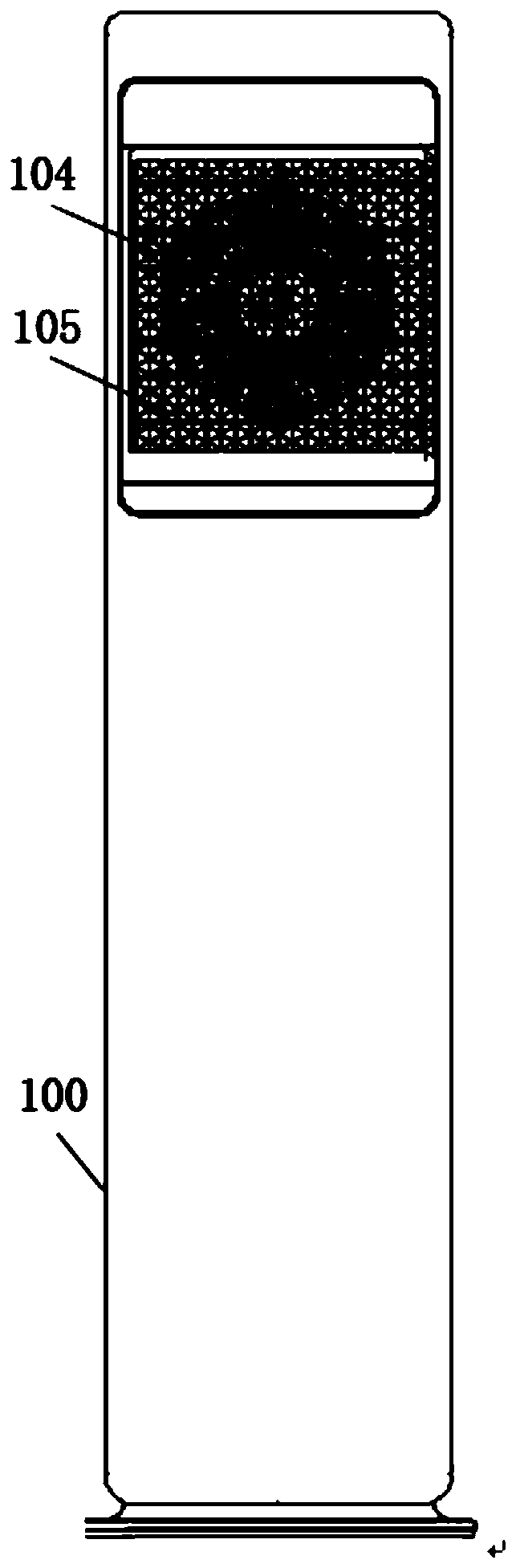

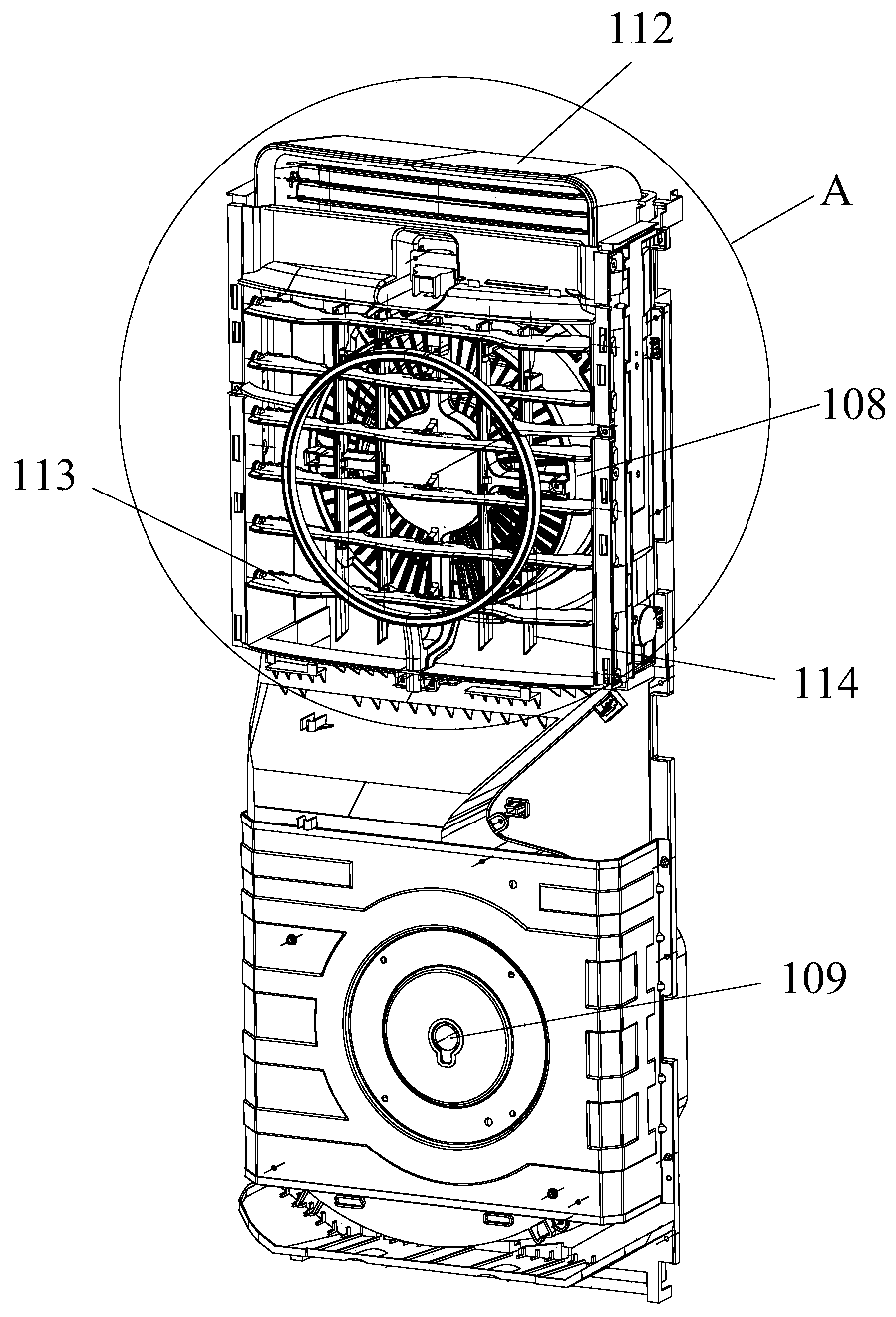

Air conditioner, and control method and device thereof

ActiveCN110848807AComfortable and natural windless wind field stateGuaranteed indoor comfortMechanical apparatusSpace heating and ventilation safety systemsEngineeringWind field

The invention discloses an air conditioner, and a control method and device thereof. The air conditioner comprises a first fan, a second fan, a compressor, an air guiding mechanism and a top air outlet mechanism. The top air outlet mechanism is arranged on the top of an indoor unit of the air conditioner in the manner of being capable of moving vertically. The air guiding mechanism comprises a horizontal air guiding bar and a vertical air guiding bar. The method comprises the steps that in a cooling mode, a starting instruction of a none-windy-feel mode is received; the top air outlet mechanism is controlled to ascend to a preset highest position, the horizontal air guiding bar is adjusted to be at the maximum opening as well, and the vertical air guiding bar is adjusted to be at the maximum opening angle as well; the current indoor temperature is acquired; and the first fan, the second fan and a compressor are controlled according to the indoor temperature and the set temperature of the air conditioner. With the method of the air conditioner, in the operational process of the air conditioner, the working state of the first fan, the working state of the second fan and the working state of the compressor can be matched with the none-windy-feel mode, then the comfortable and natural none-windy-feel wind field state can be created, and the temperature reduction effect is guaranteed while the indoor comfort level is guaranteed.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

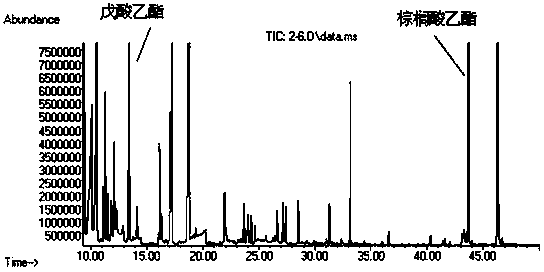

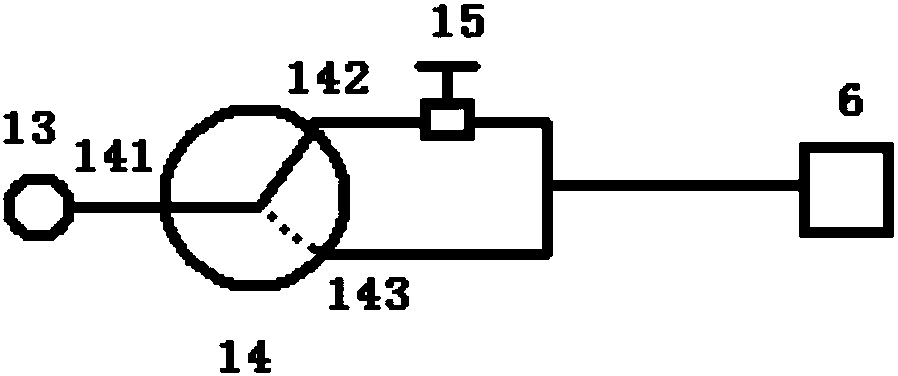

Gas chromatographic column large-volume injection technology and application thereof

ActiveCN107656002AChanging the constant pressure carrier gas evaporation methodImproving Technical Results for Large Volume InjectionsComponent separationInjection portGas phase

The invention belongs to the technical field of gas chromatography and relates to a gas chromatographic column large-volume injection technology and application thereof. The invention provides a gas chromatographic column large-volume injection system, which comprises a carrier gas injection part and a chromatographic injection part. The chromatographic injection part comprises an injection port,a pre-column, a drain valve, a capillary chromatographic column and a chromatographic column box. The carrier gas injection part comprises a constant-current mode carrier gas access and a constant-voltage mode carrier gas access. The invention also further provides application of the gas chromatographic column large-volume injection device and an injection method. The invention provides a gas chromatographic column large-volume injection technology and application thereof. According to the invention, pure pressure control mode is changed into constant current-constant voltage switching mode. Thus, solvent evaporation is faster and more stable, and solvent evaporation end point is easier to control, thus being beneficial to performance of solvent effect and analysis of volatile matter. Thetechnology is widely applied.

Owner:SHANGHAI TOBACCO GRP CO LTD

Cavitation piece of micro-bubble generator, micro-bubble generator and washing device

PendingCN111206380AGuaranteed foam making abilitySimple structureFlow mixersTransportation and packagingWater flowEngineering

The invention discloses a cavitation piece of a micro-bubble generator, the micro-bubble generator and a washing device. The cavitation piece has a cavitation inlet and a cavitation outlet for water flow enters and exits; at least one Venturi channel extending from the cavitation inlet toward the cavitation outlet is defined in the cavitation piece; each Venturi channel, in the water flow direction, sequentially comprises a tapered section, a pipeline and an expanding section; the flow area of the tapered section gradually decreases in the direction from the cavitation inlet to the pipeline, the flow area of the expanding section gradually increases in the direction from the pipeline to the cavitation outlet, and the diameter of the pipeline is 0.2-2.0 mm. The cavitation piece provided bythe invention can guarantee the foaming capacity of the cavitation piece and can control the moderate flow rate on the one hand, and has a simple structure, convenient processing and easy cost controlon the other hand.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

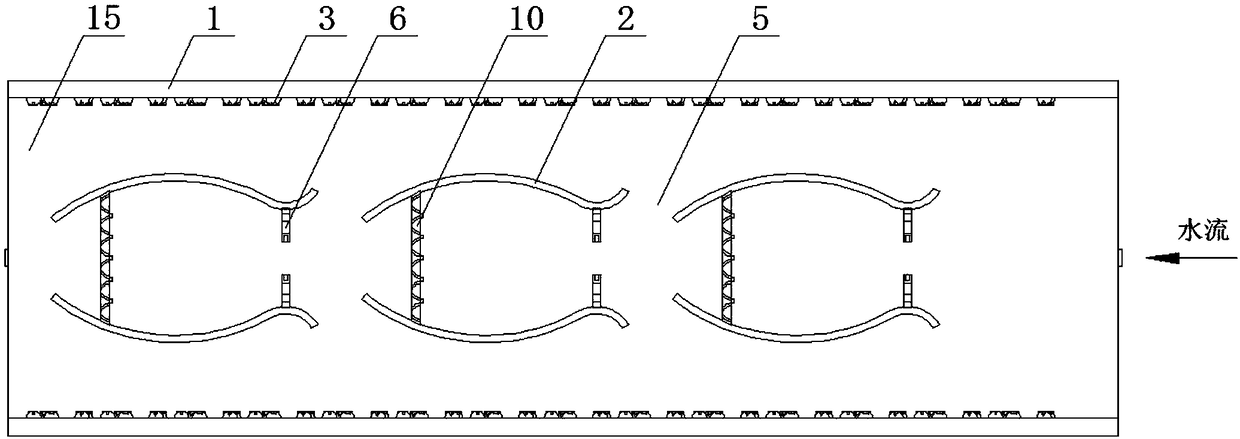

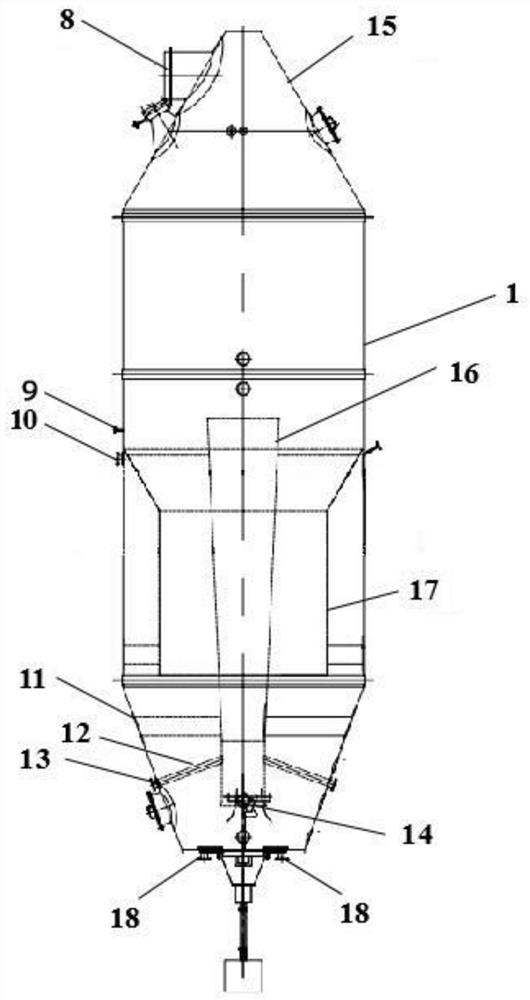

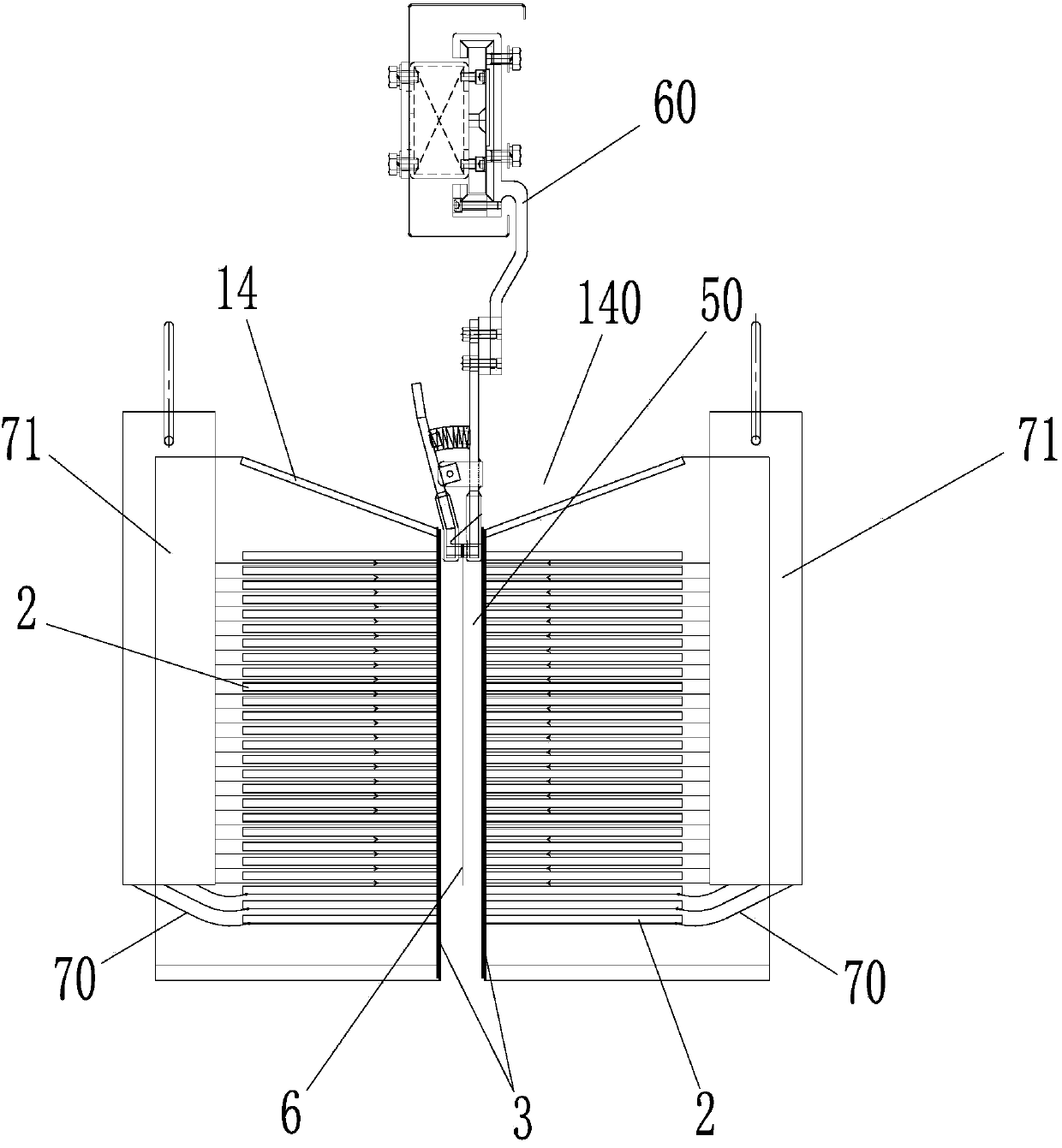

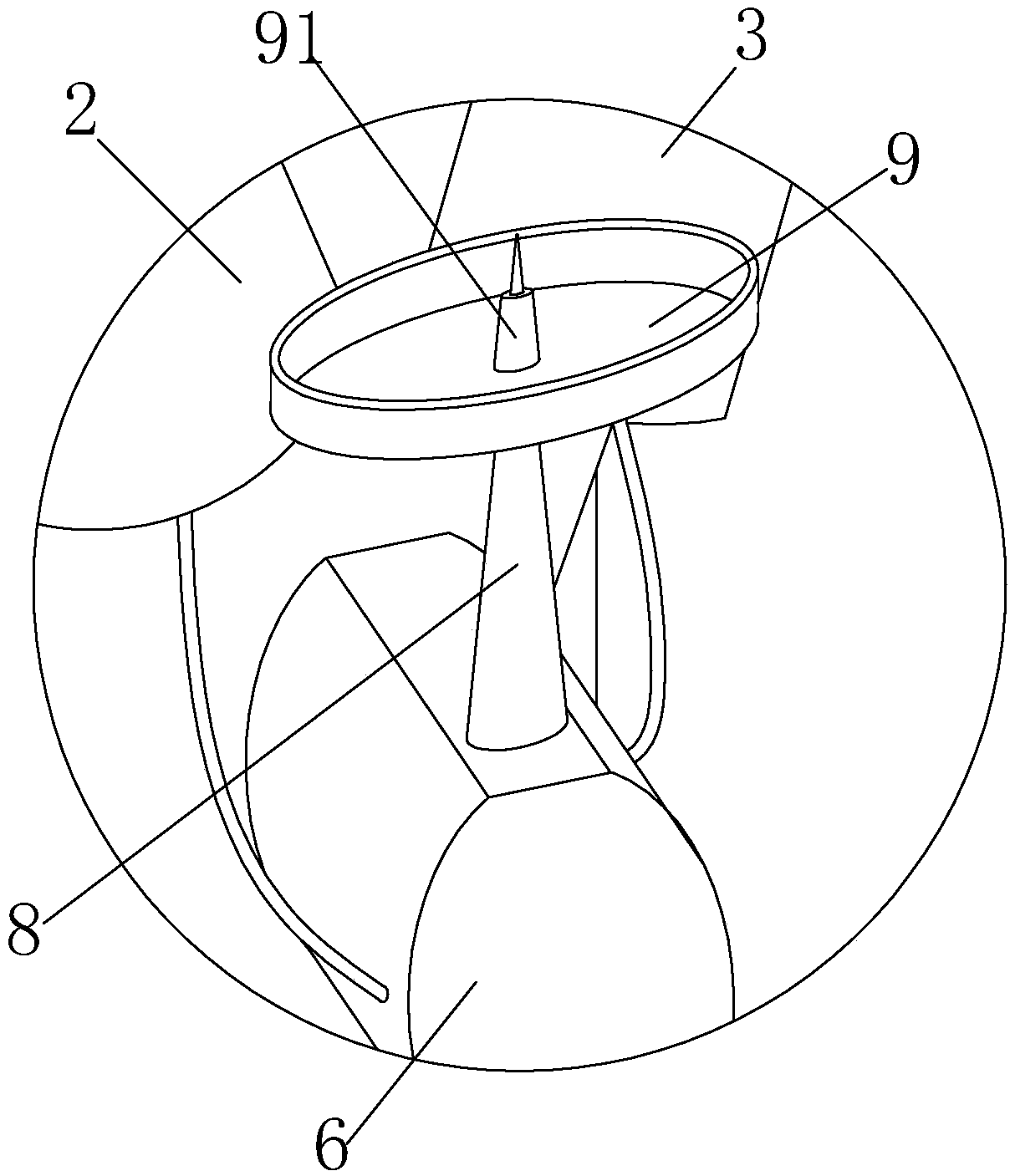

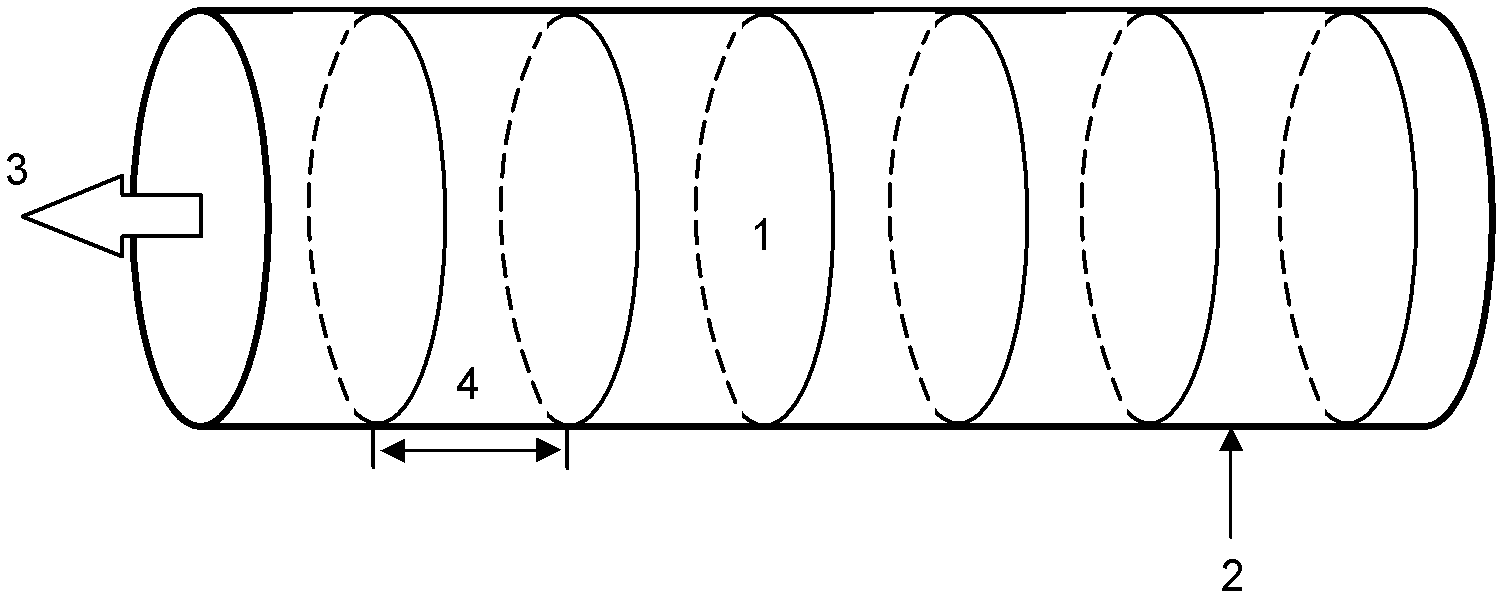

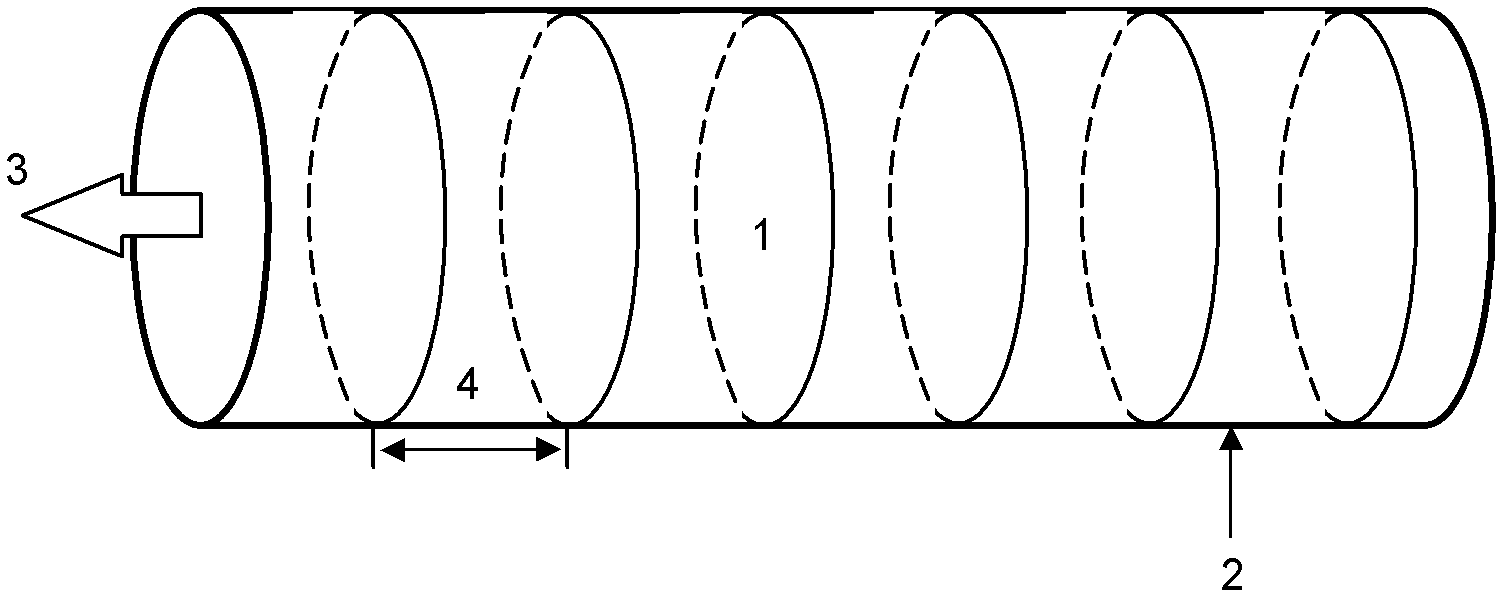

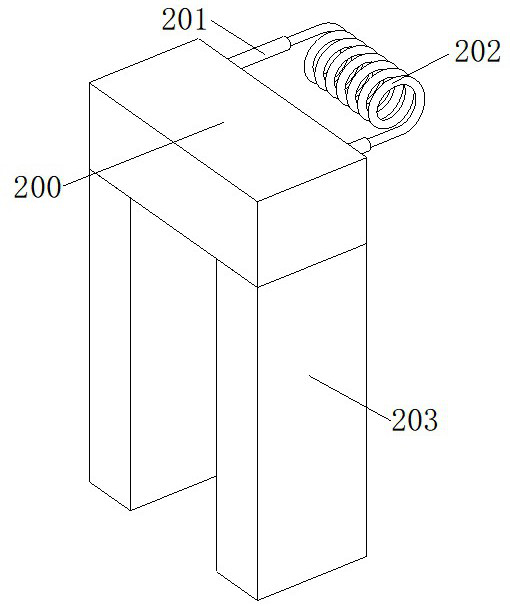

Hydraulic impact rotating cylinder fishway

ActiveCN111172953ARealize continuous fish passingImprove the effect of passing fishBarrages/weirsClimate change adaptationWater flowEnvironmental engineering

The invention discloses a hydraulic impact rotating cylinder fishway, and particularly relates to the technical field of river blocking building fish passing. The hydraulic impact rotating cylinder fishway comprises a gate foundation groove fixed to a riverbed at the bottom of an inlet of the fishway, a flow guide assembly is arranged at the inlet side of the gate foundation groove, a row of waterflow adjusting mechanisms and partition plate assemblies are arranged in the middle of the gate base groove in the water flowing direction in an alternative manner and divide the fishway into a leftpart and a right part, namely a slow flow area and a rapid flow area, an adjusting partition plate is arranged at an inlet of the rapid flow area, and the water flow adjusting mechanisms comprise vertical shafts, rotating cylinders and blades. According to the hydraulic impact rotating cylinder fishway, the water flow structure is improved through the rotating cylinders, the local flow field is effectively adjusted, the hydraulic impact rotating cylinder fishway is suitable for running of target fishes, the flowing speed is reduced, so that the physical strength recovery of the fishes in the upstream process is facilitated, and the fish passing effect is improved; and the overall structure is simple, too much maintenance is not needed, and the hydraulic impact rotating cylinder fishway iseconomically suitable for various hydraulic engineering and suitable for high-water-head dams.

Owner:CHONGQING JIAOTONG UNIVERSITY

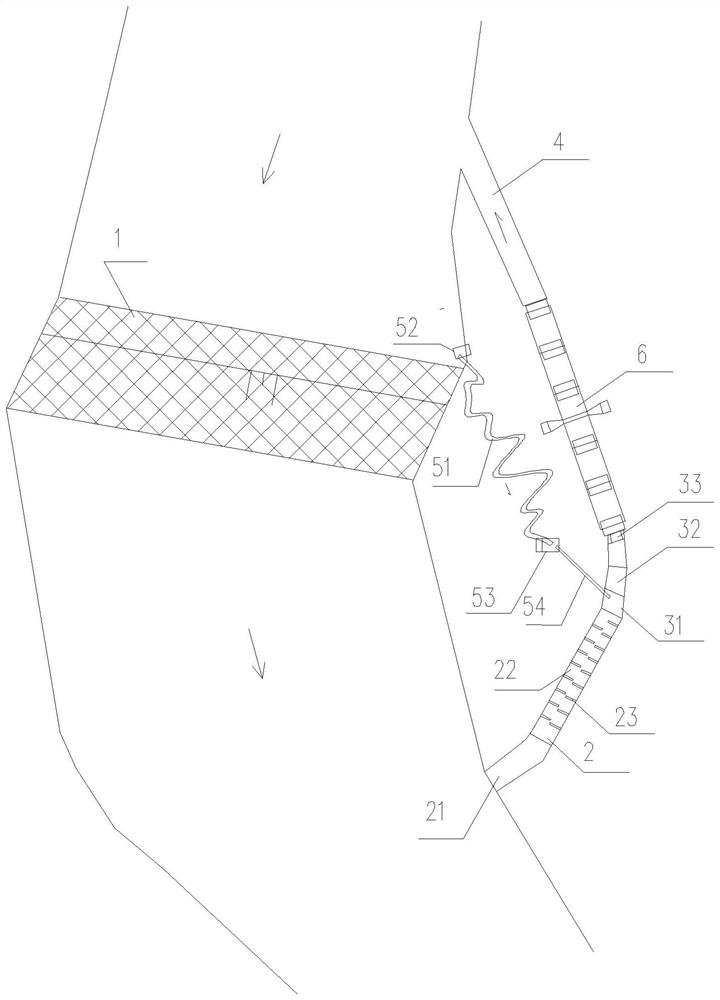

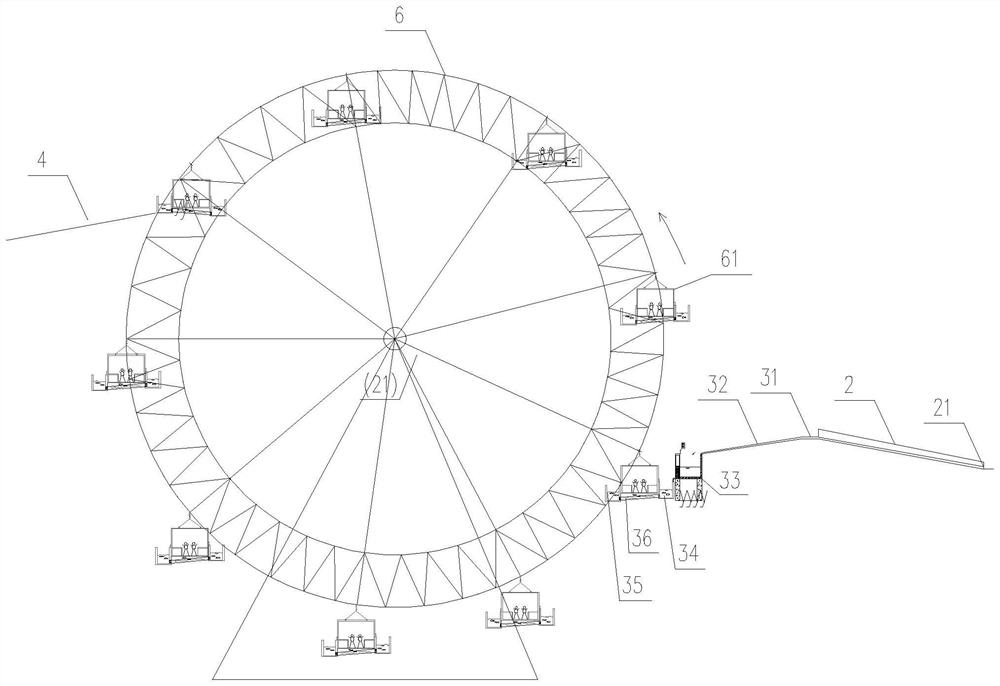

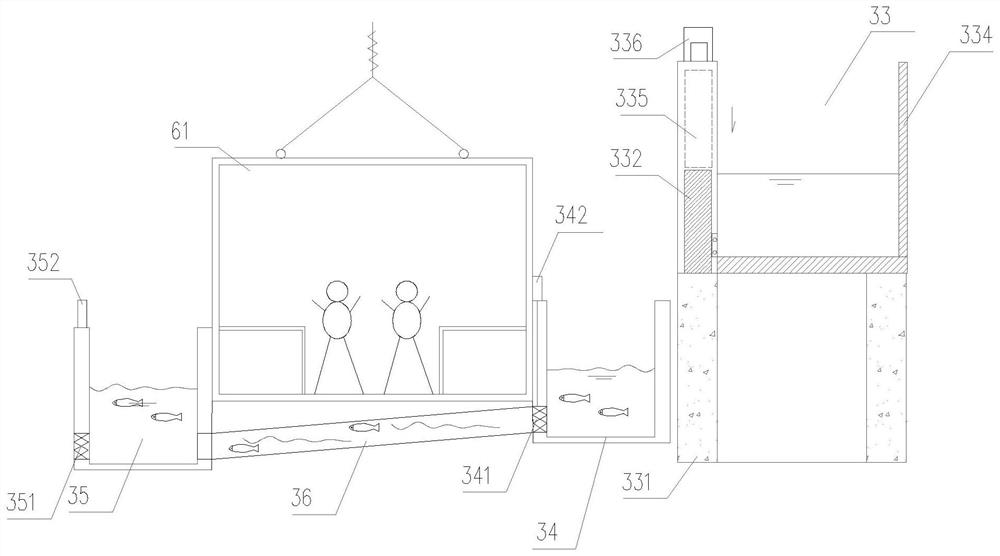

Fish passing system with tourism viewing function and fish passing method

ActiveCN114673124AImprove the effect of passing fishOvercome constraintsBarrages/weirsClimate change adaptationEnvironmental engineeringTransfer mechanism

The invention discloses a fish passing system with a tourism viewing function and a fish passing method, and belongs to the technical field of water conservancy and hydropower ecological protection. The system comprises a dam body, a ferris wheel, a water supplementing assembly and a master controller, a releasing slide way is arranged on the upstream of the dam body, one end of the releasing slide way extends into a dam body reservoir area water body, a fish passing transfer mechanism is arranged on the downstream of the dam body, and the fish passing transfer mechanism is connected with the water body on the downstream of the dam body through a fishway; the ferris wheel is located between the fish passing transfer mechanism and the releasing slide way, a plurality of manned fish lifting mechanisms are evenly distributed on the ferris wheel, one end of the water supplementing assembly extends into a dam body reservoir area water body, the other end of the water supplementing assembly is connected with the fish passing transfer mechanism, and the master controller is connected with the ferris wheel, the fish passing transfer mechanism and the manned fish lifting mechanisms. The ferris wheel is combined with the fish upstream tracing requirement, upstream and downstream fish population gene exchange of the high-water-head water conservancy project is promoted, meanwhile, the tourism and sightseeing value of the water conservancy project is improved, and the project investment is obviously reduced.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Device and system for electroplating thin sheets

The invention discloses a device and system for electroplating thin sheets. The device comprises an electroplating tank, flow-guiding devices and a first circulating device, wherein the electroplating tank is provided with a backflow channel, a conveying device for conveying electroplated thin sheets is arranged above the backflow channel; the flow-guiding devices are slantwise arranged at both sides of the electroplated thin sheets and located at the position higher than the uppermost ends of the electroplated thin sheets; electroplating metal liquid from an anode device space flows along the surface of the flow-guiding devices to the backflow channel in the electroplating tank at an uniform thickness from flow-guiding inlets; the liquid suction opening of the first circulating device is communicated with the backflow channel and the liquid discharging opening of the first circulating device is communicated with the anode device space. By virtue of the device for electroplating thin sheets disclosed by the invention, the uniform electroplating thickness of the electroplated thin sheets can be ensured, the quality of the electroplating is improved, the labor cost is saved and the production efficiency is improved.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

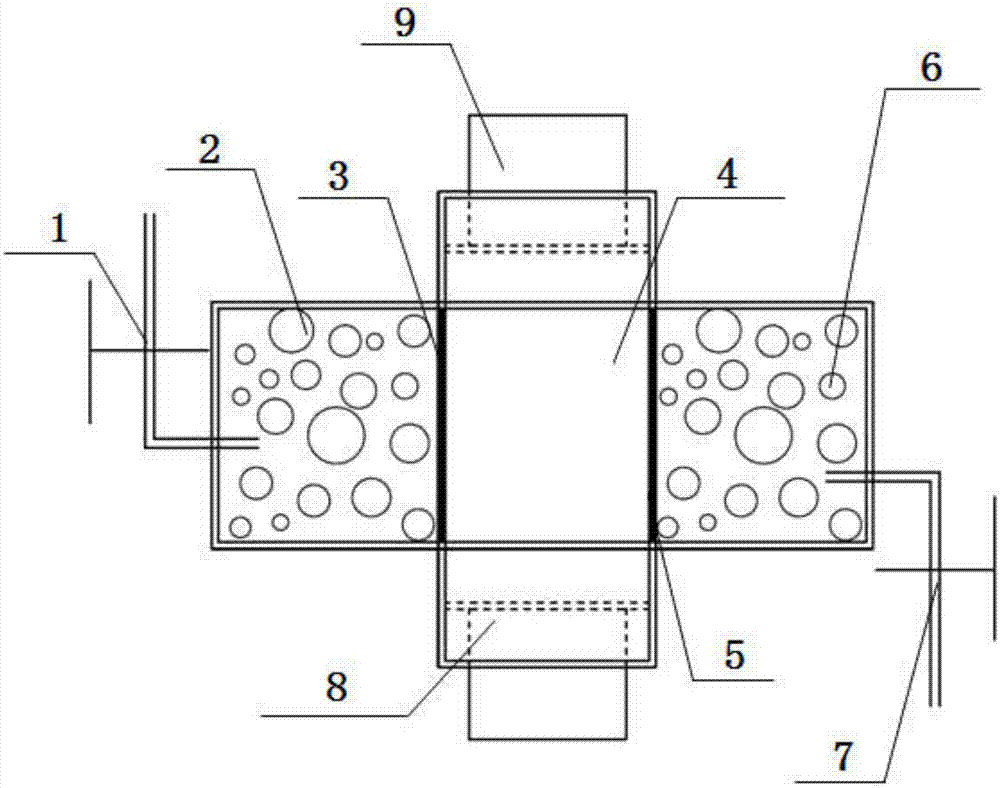

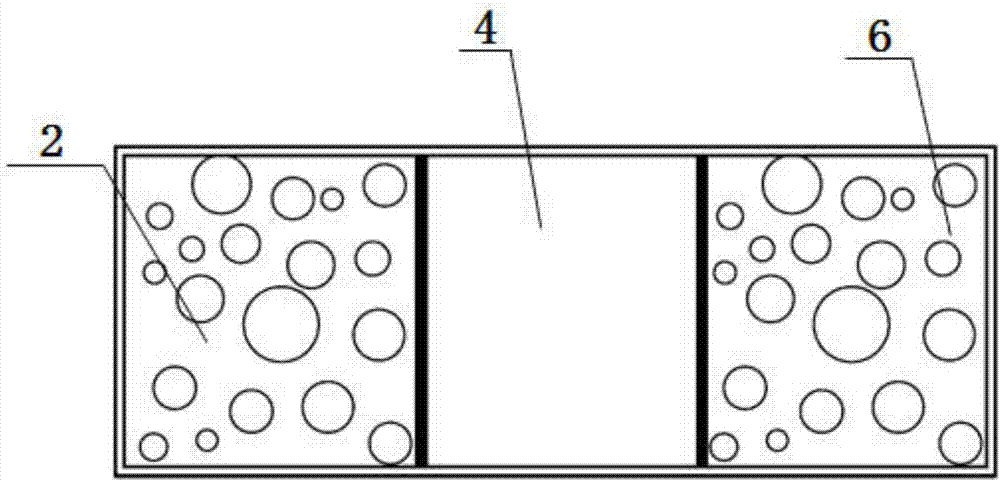

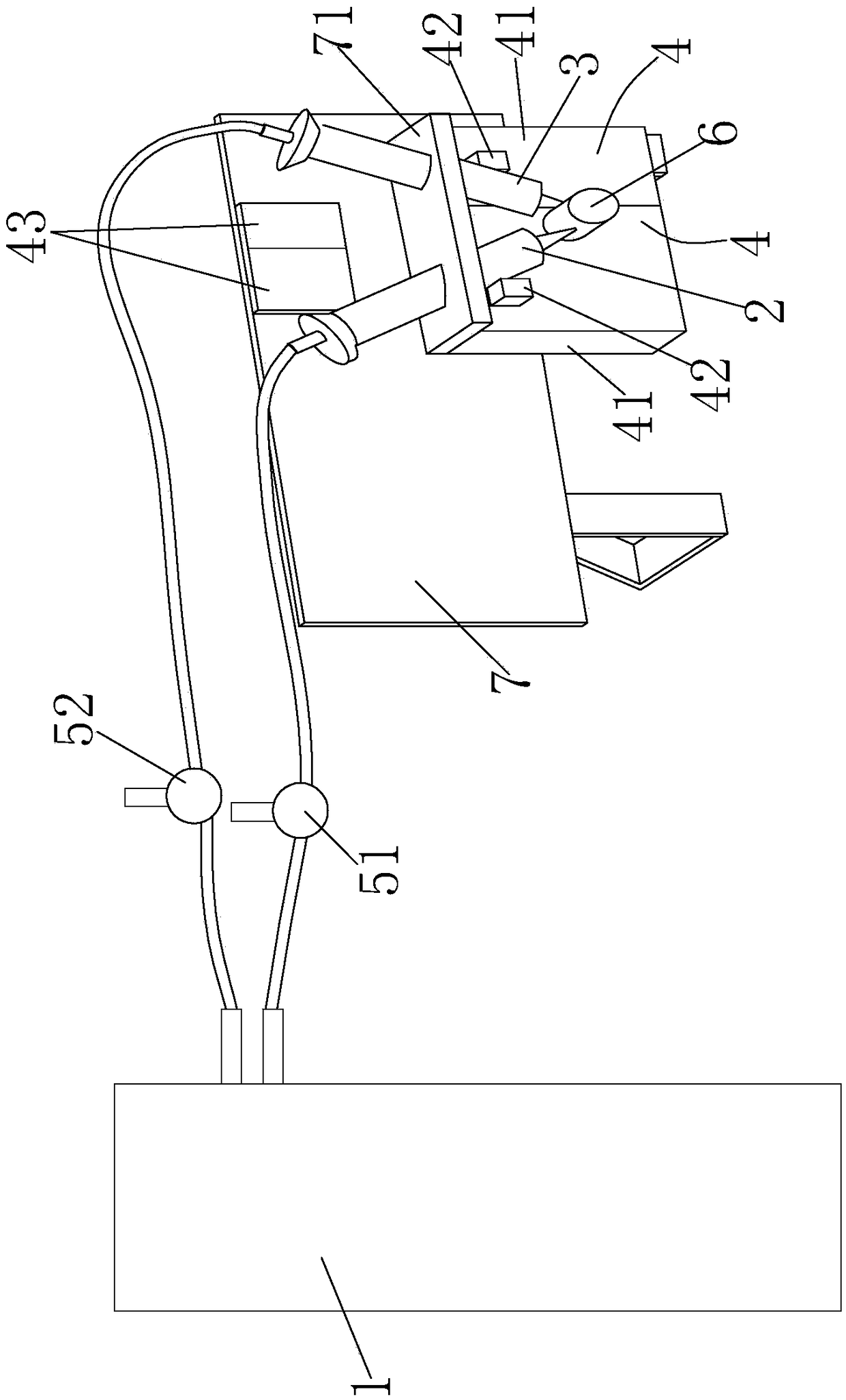

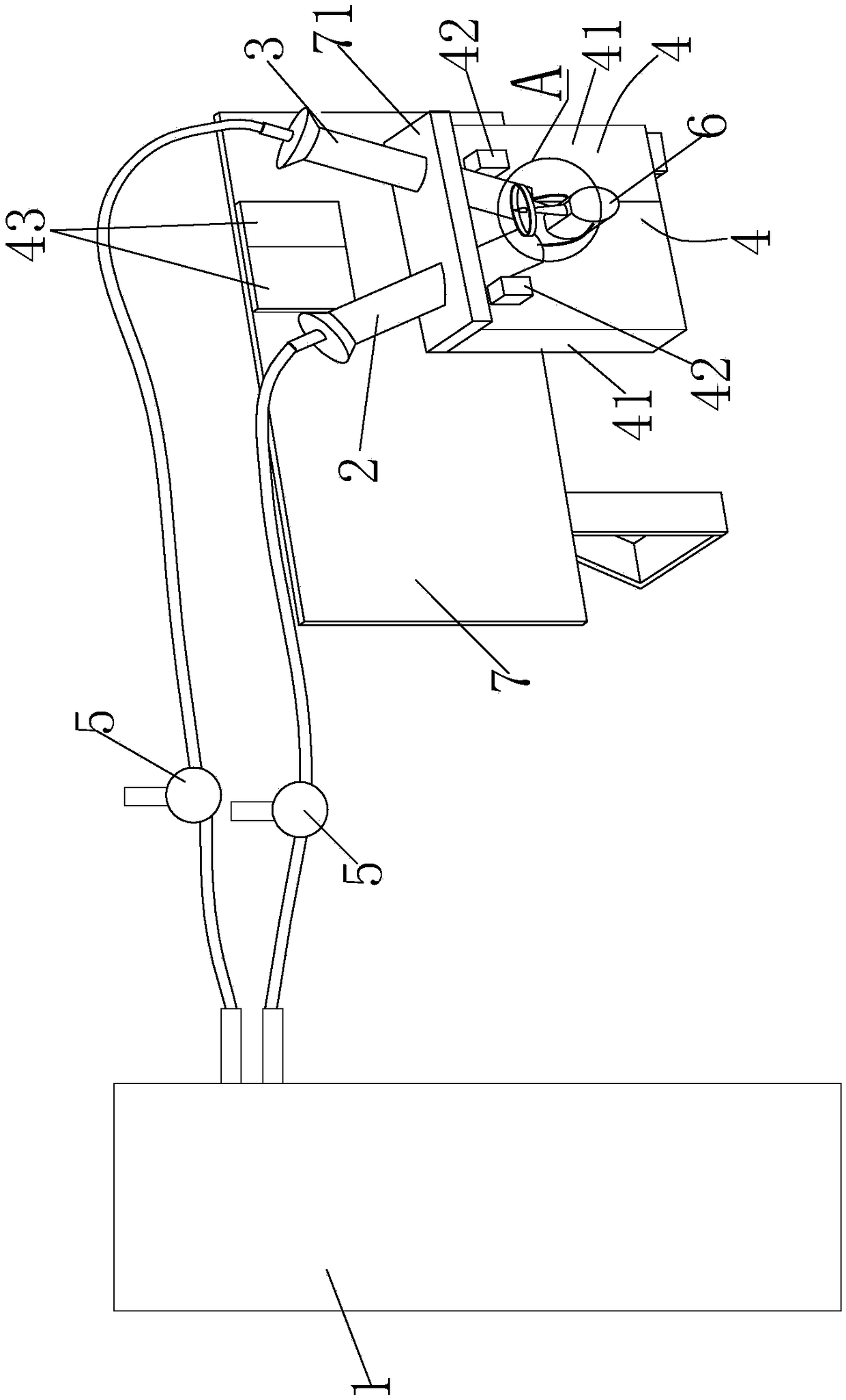

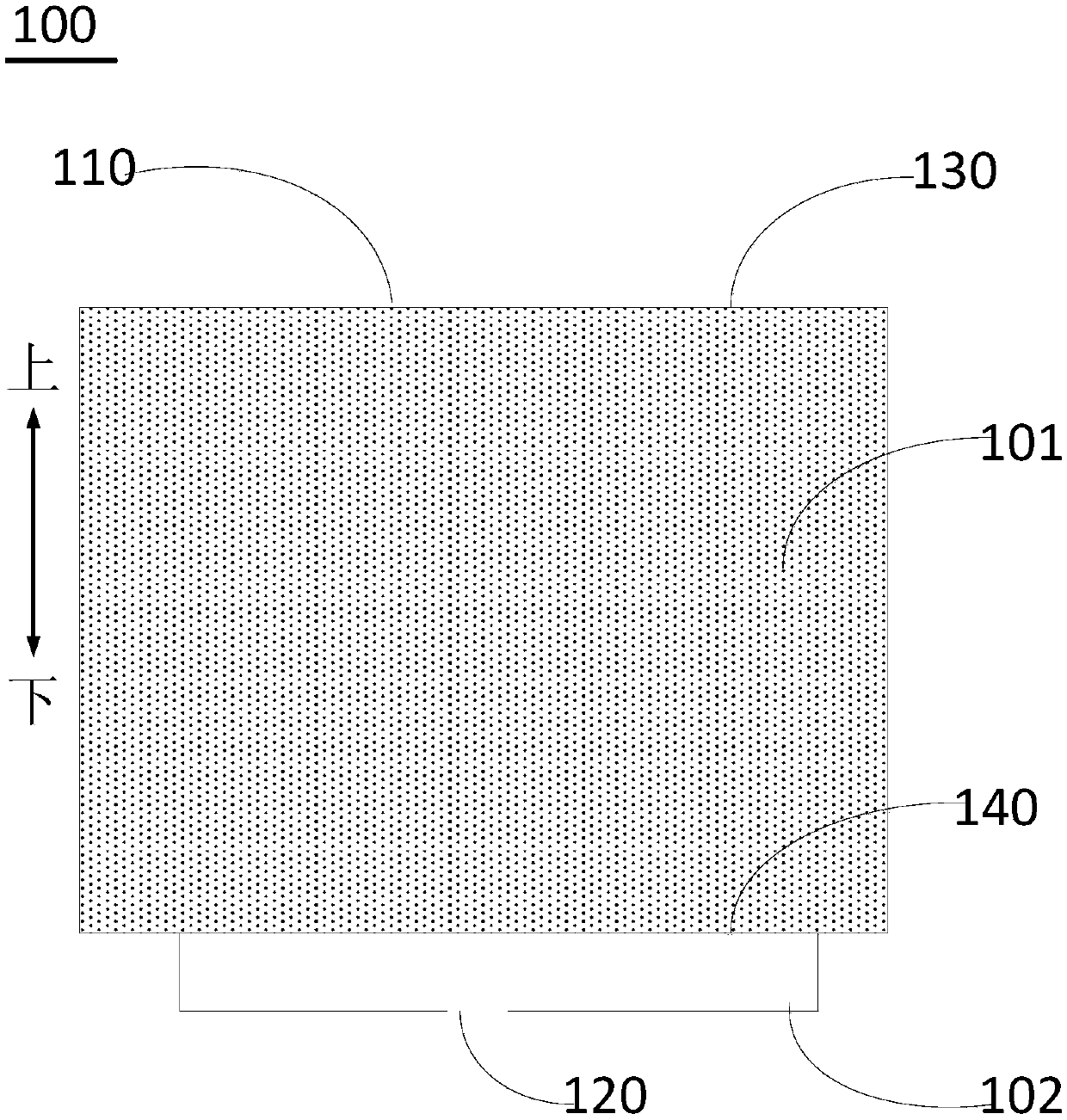

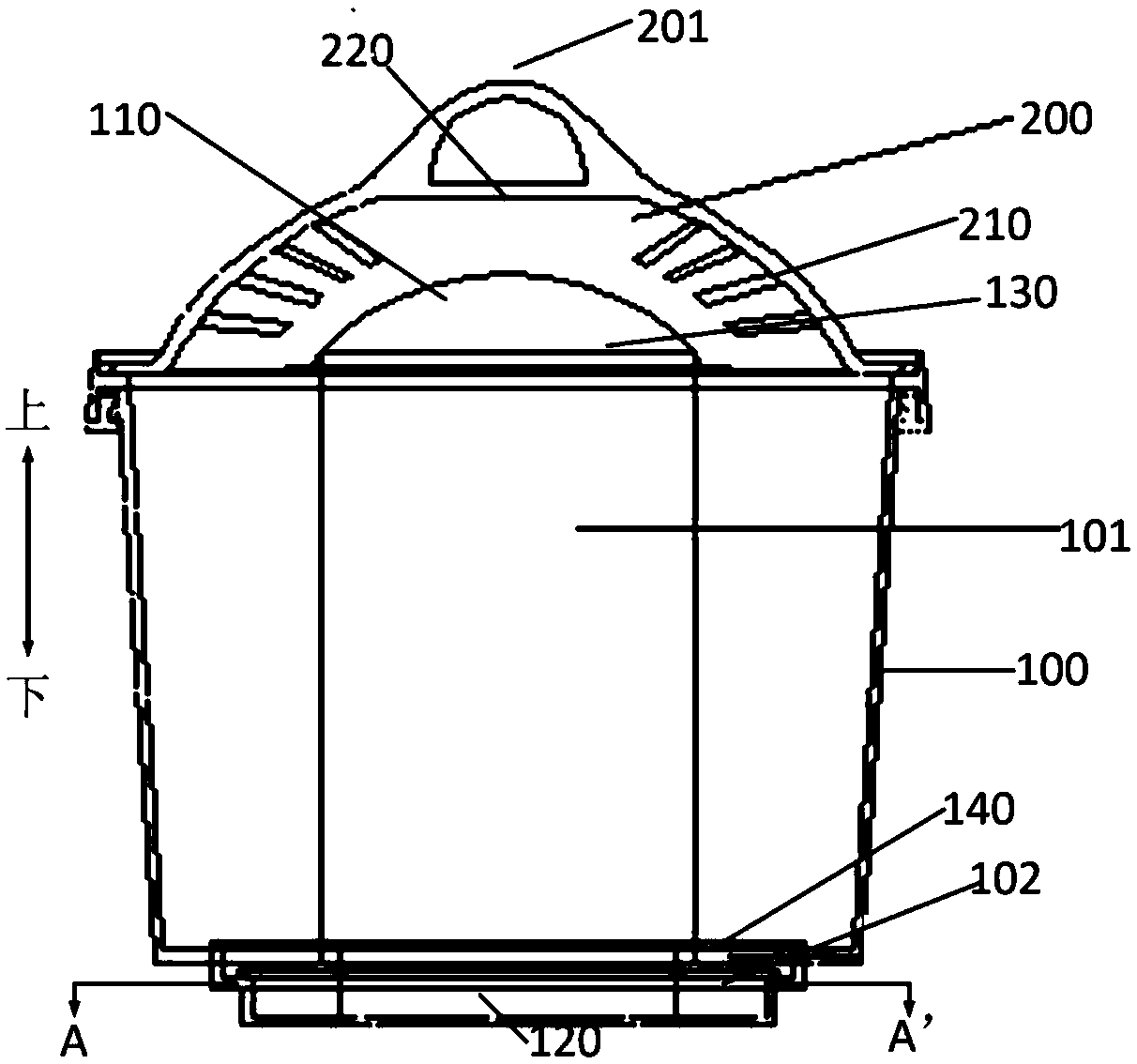

Device capable of applying compressive stress for permeability test and using method thereof

PendingCN107389520AMitigate Differential ErosionSimple structurePermeability/surface area analysisSoil scienceGeotechnical engineering

The invention discloses a device capable of applying a compressive stress for a permeability test and a using method thereof. The device comprises a water inlet, an upstream buffer zone, a soil sample chamber, a downstream buffer zone and a water outlet which are sequentially communicated from the left side to the right side, wherein a soil sample placing platform is fixed to the lower part of the soil sample chamber; a pressure loading platform capable of moving up and down along the inner wall of the soil sample chamber is arranged on the upper part of the soil sample chamber; the upstream buffer zone and the soil sample chamber are separated by the upstream water-permeable separating net; the soil sample chamber and the downstream buffer zone are separated by the downstream water-permeable separating net; the upstream buffer zone and the downstream buffer zone are filled with aggregate; the mesh apertures of the upstream water-permeable separating net and the downstream water-permeable separating net are smaller than the grain size of the aggregate. The device solves the problem that in the prior art, no relatively-pertinent test equipment for testing permeability deterioration of a porous medium in the presence of the compressive stress exists; the device can relatively really represent the permeability deterioration of the porous medium in the presence of the compressive stress, and can improve the test efficiency, reduce the test cost and enhance the test controllability.

Owner:YULIN UNIV

Method of mixing AB glue through isobaric temperature regulation

InactiveCN109395621AConstant viscosityPrecise control of glue volumeFlow mixersTransportation and packagingEngineeringAtmospheric pressure

The invention discloses a method of mixing AB glue through isobaric temperature regulation, which includes: A) providing an A glue tube and a B glue tube in same size and shape; B) providing a gas source, which communicates the upper ends of the A glue tube and the B glue tube, wherein the barometric pressures into the A glue tube and the B glue tube by the gas source are equal; C) regulating thetemperature of A glue in the A glue tube to be T1, constantly, with a group of constant temperature heating members, and regulating the temperature of B glue in the B glue tube to be T2, constantly, with another group of constant temperature heating members, so that the A glue and B glue are same in viscosity; D) turning on the gas source which communicates the A glue tube and the B glue tube, sothat the flow rates of the A glue, pushed from the A glue tube by air pressure, and the B glue, pushed from the B glue tube by equal air pressure, are equal; E) enabling the A glue and B glue to be mixed on a mixing component in a contact manner. The method, at constant temperature, stably controls the flow rates of the A glue and B glue by regulating the barometric pressures, thus accurately controlling the ratio of the A glue and B glue. A device is simple in structure and low in cost.

Owner:浙江步丹工贸有限公司

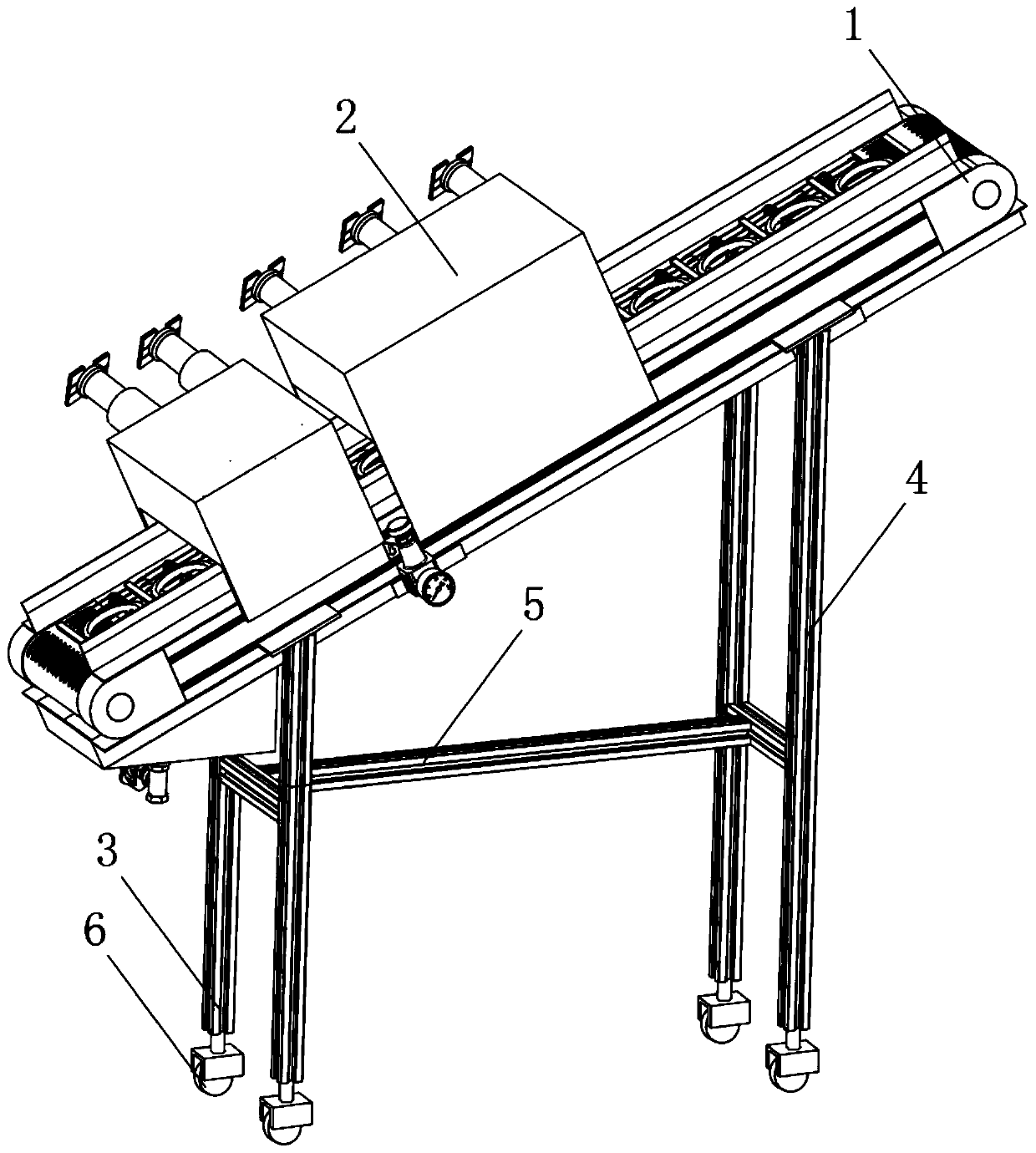

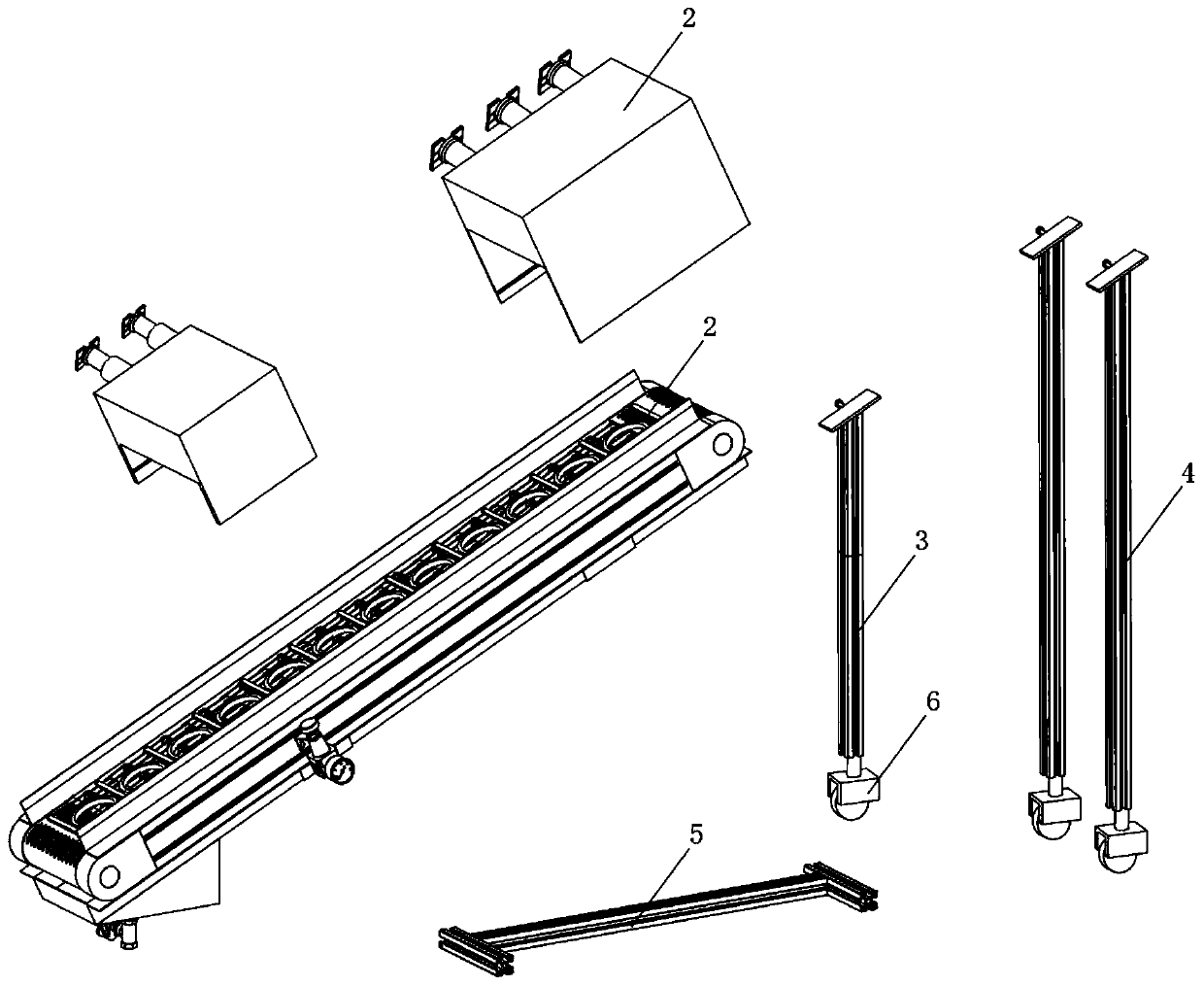

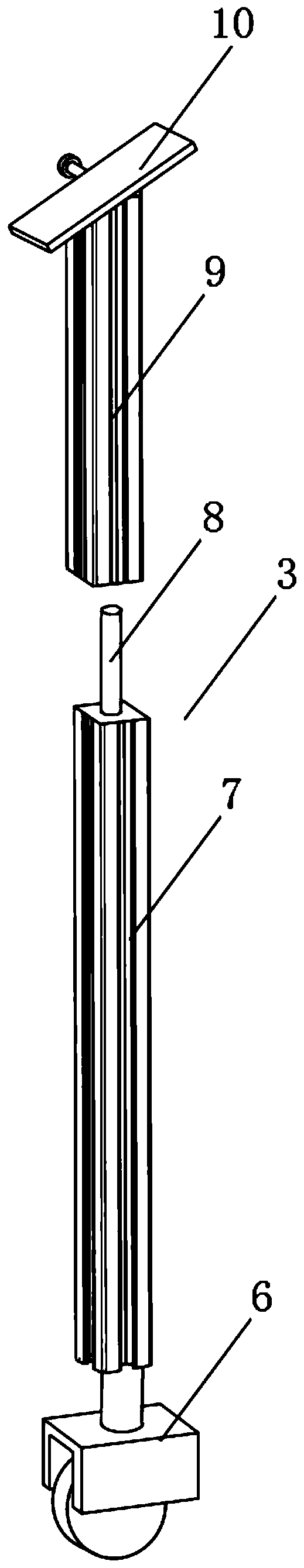

Greenhouse planting warm air equipment for seedling raising and heating and operation method thereof

ActiveCN110249865AReduce friction lossRegulatory activity is smoothClimate change adaptationGreenhouse cultivationGreenhouseEngineering

The invention discloses greenhouse planting warm air equipment for seedling raising and heating and an operation method thereof. The equipment comprises a supporting platform, sleeving discs, extending platforms and supporting rods, wherein the supporting platform is obliquely arranged, and the sleeving discs sleeve the supporting platform. The equipment has the advantages that the equipment movably blows warm air into a greenhouse, so that the coverage of an area into which the warm air is blown in the greenhouse is more uniform and comprehensive, the heating quality of the equipment for the greenhouse is improved, the working automation degree of the equipment is higher at the same time, and time and labor are saved when the equipment is used. The sleeving discs are connected into screw holes in the two ends of each mounting ring through the bottoms of two screw bolts respectively, the sleeving discs and the supporting platform are connected during mounting, and it is ensured that people can mount any sleeving disc of different sizes to heat greenhouses according to the actual heating demands of the greenhouses different in area, so that the use flexibility is guaranteed.

Owner:山东润鹏种苗有限公司

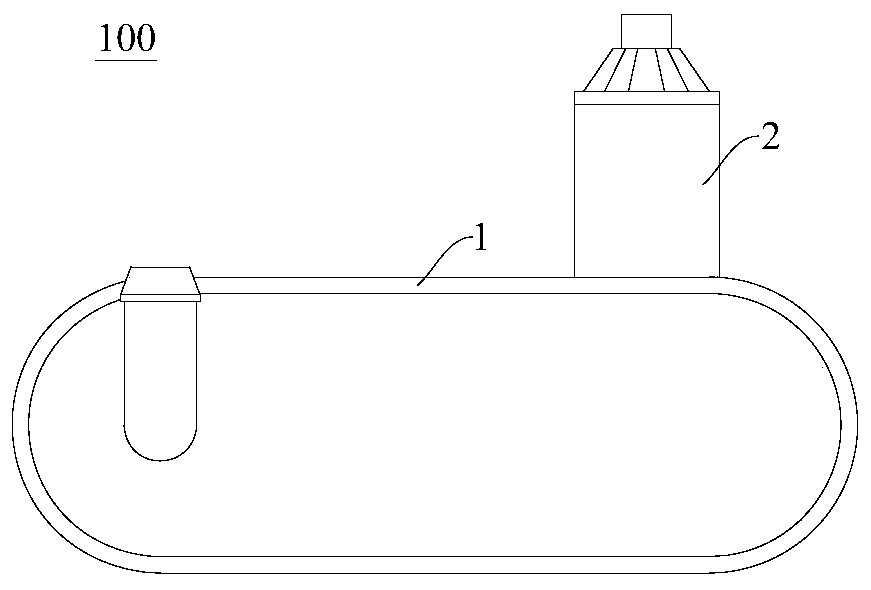

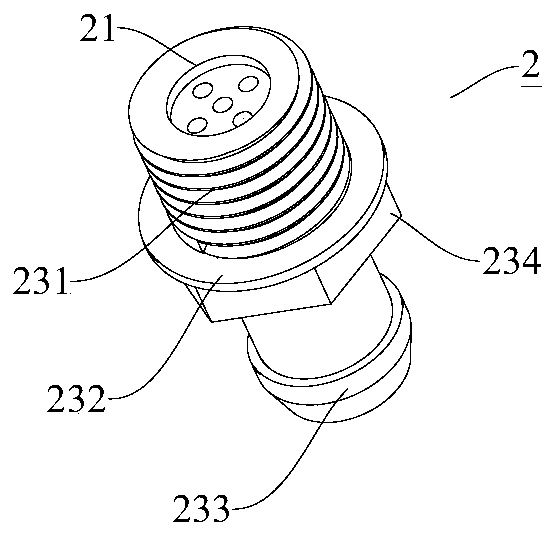

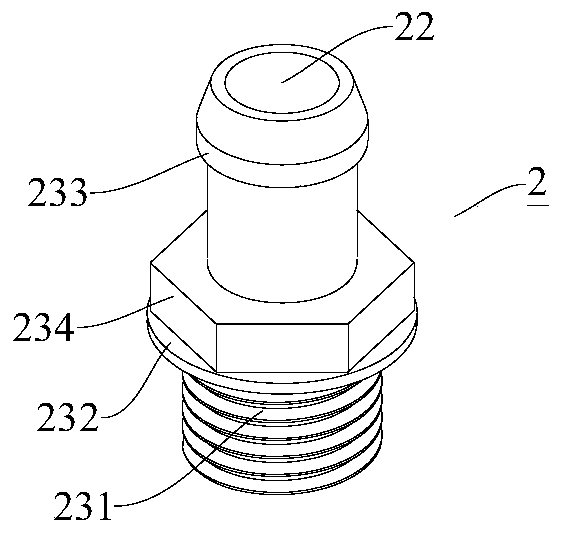

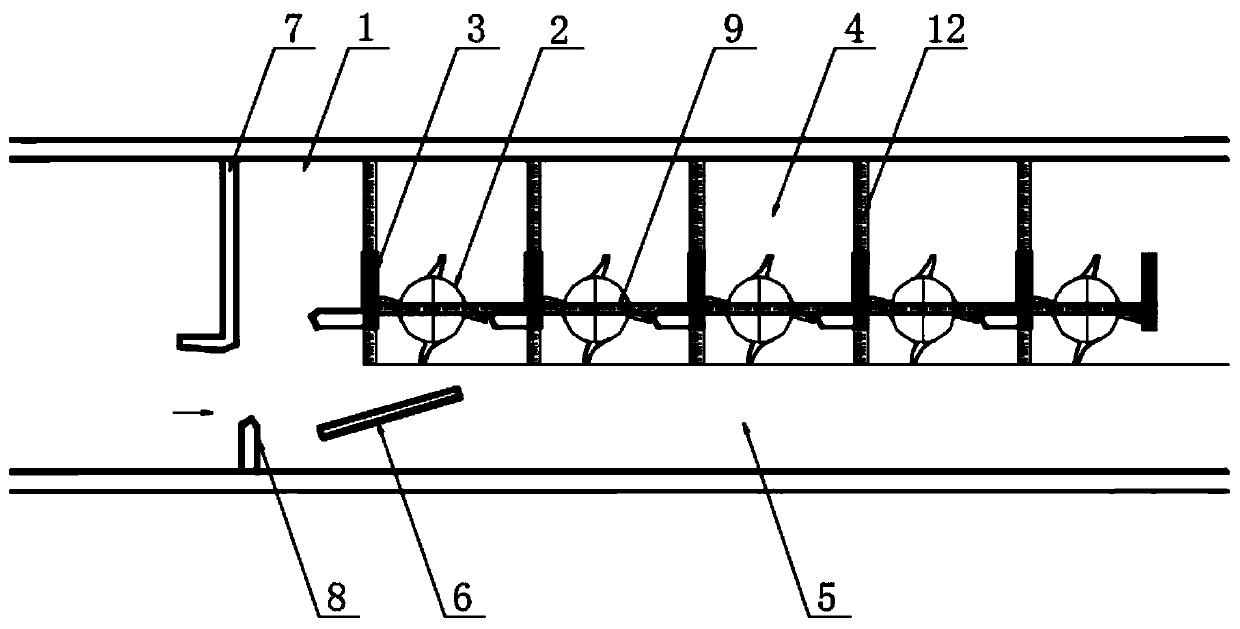

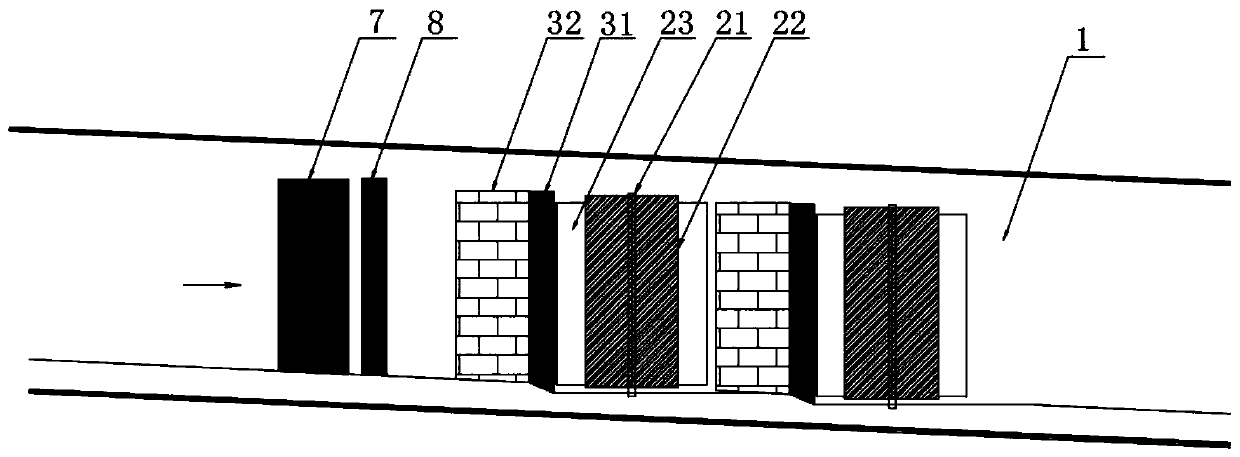

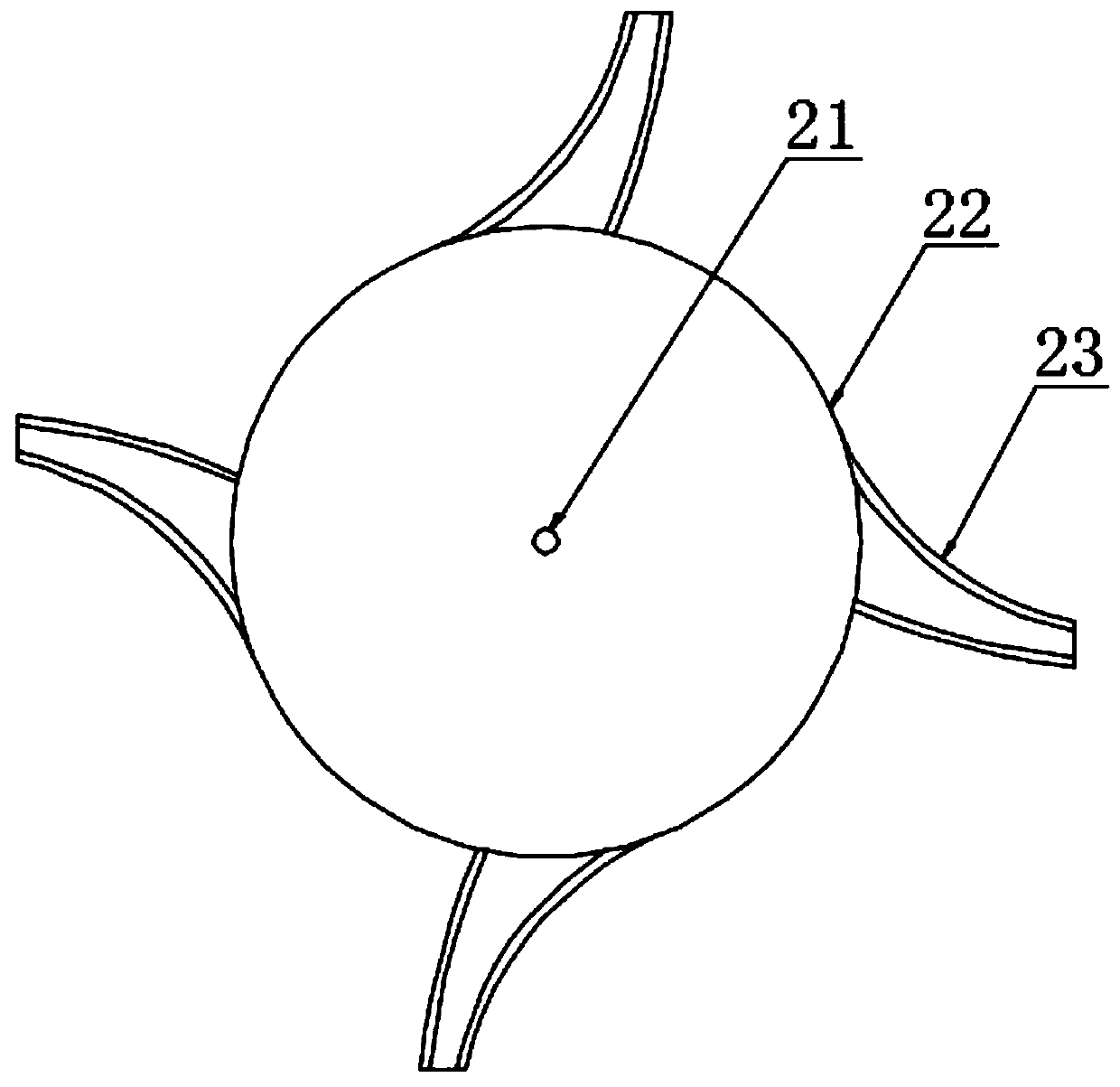

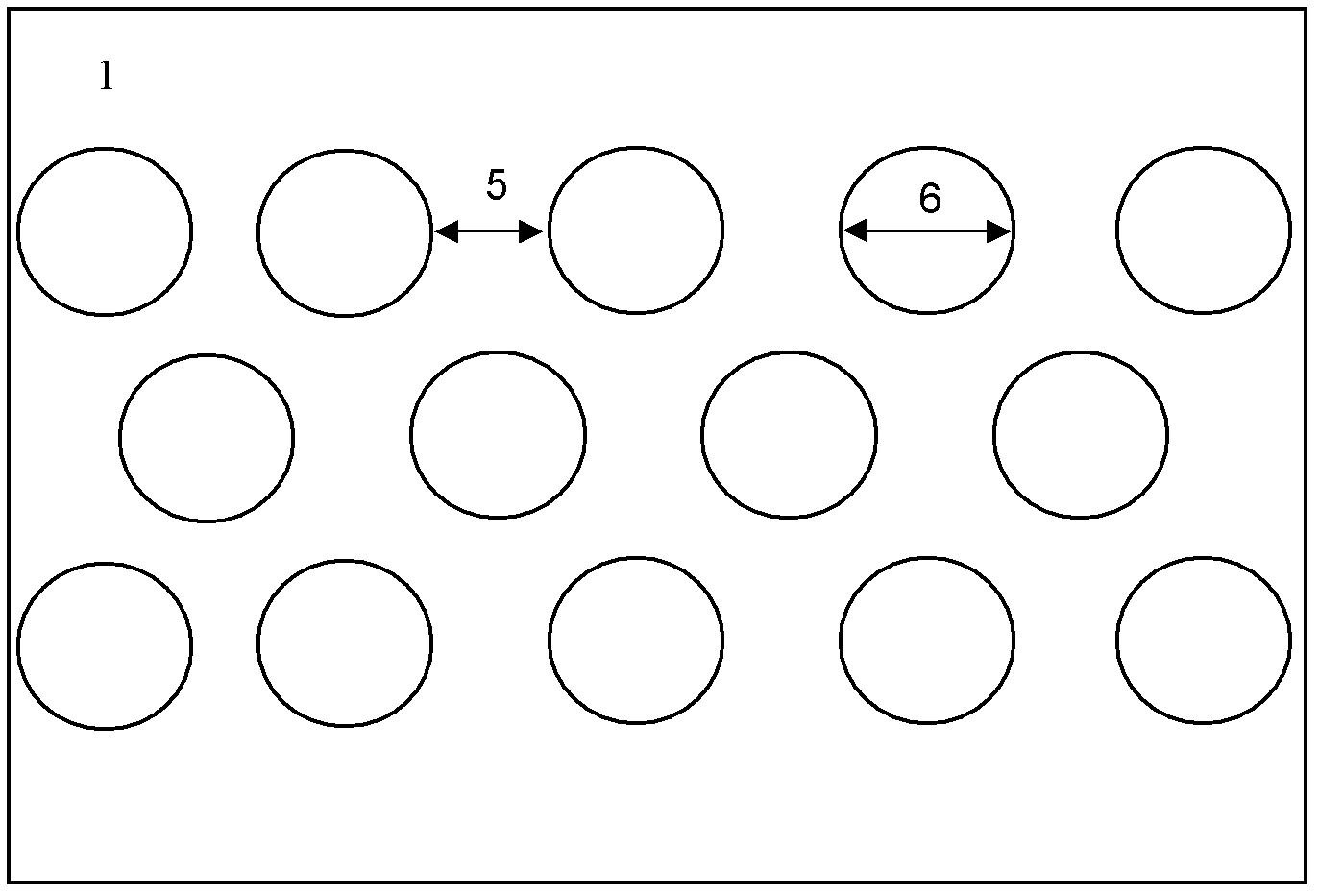

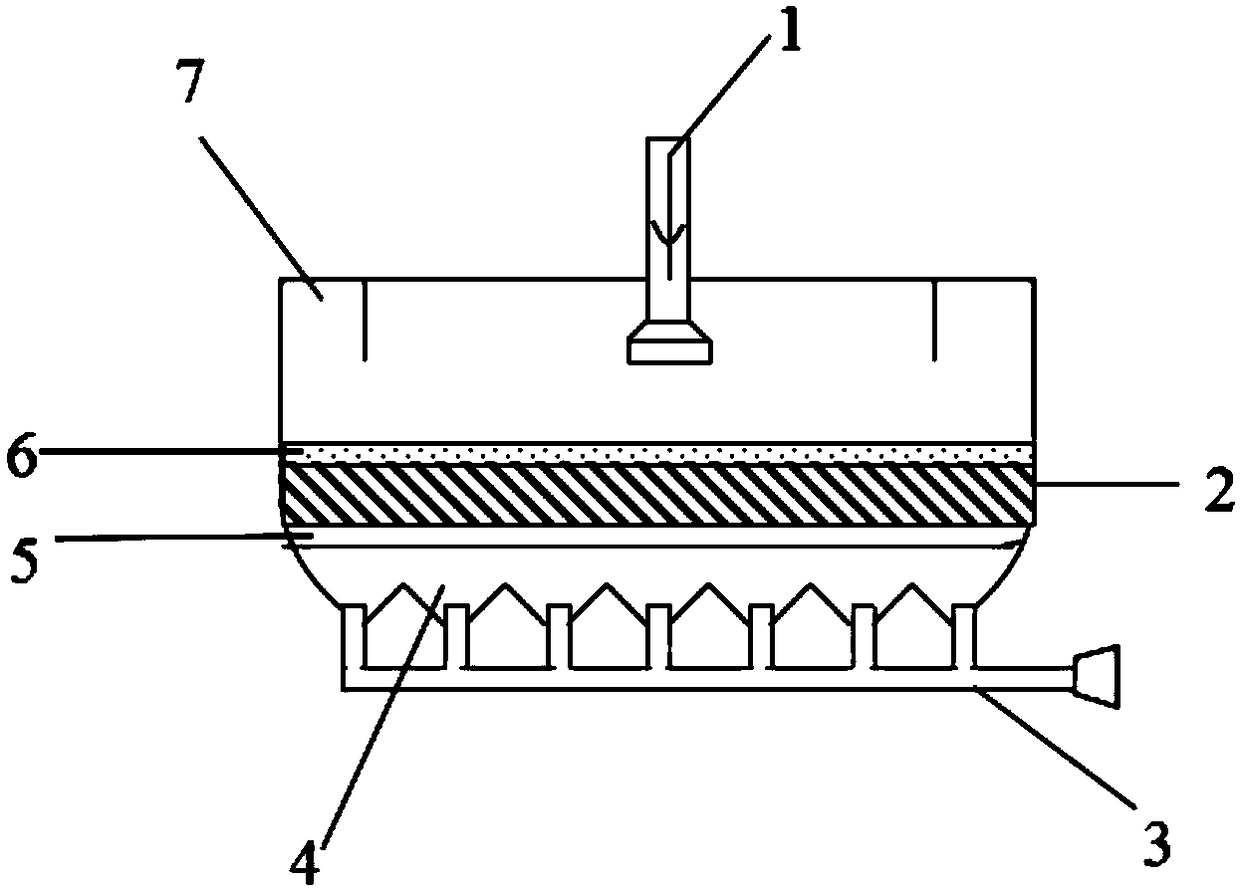

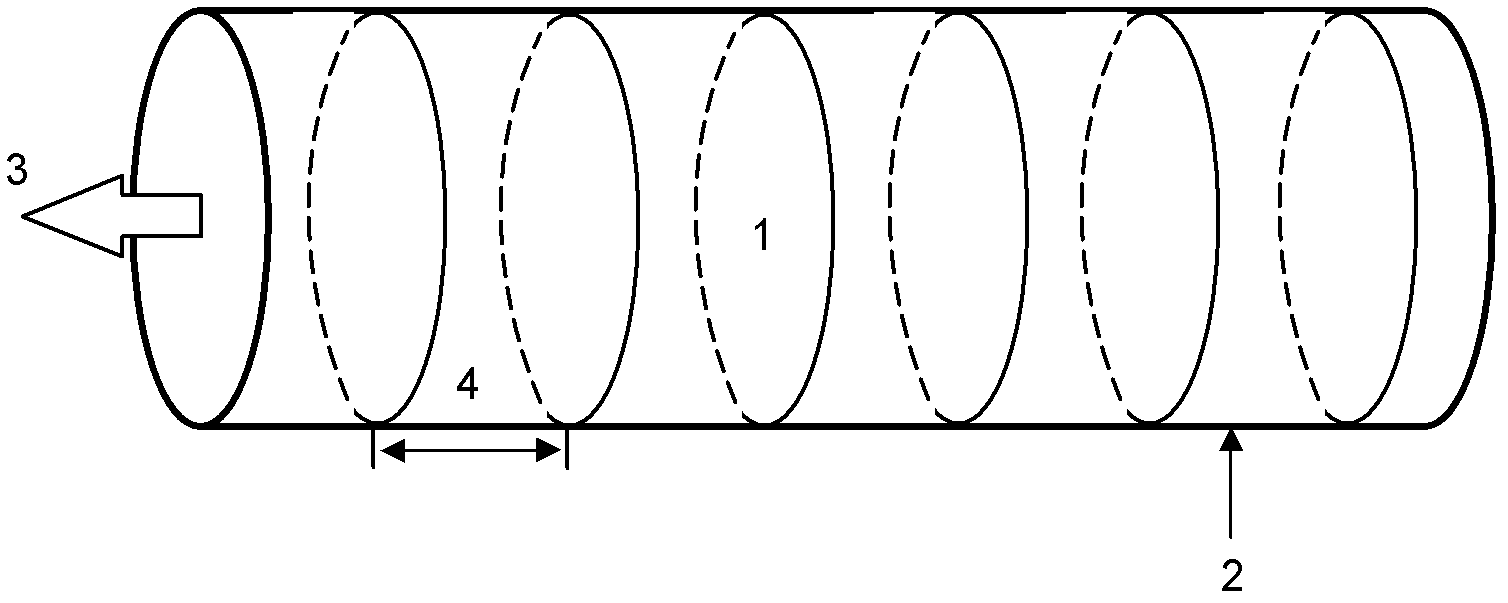

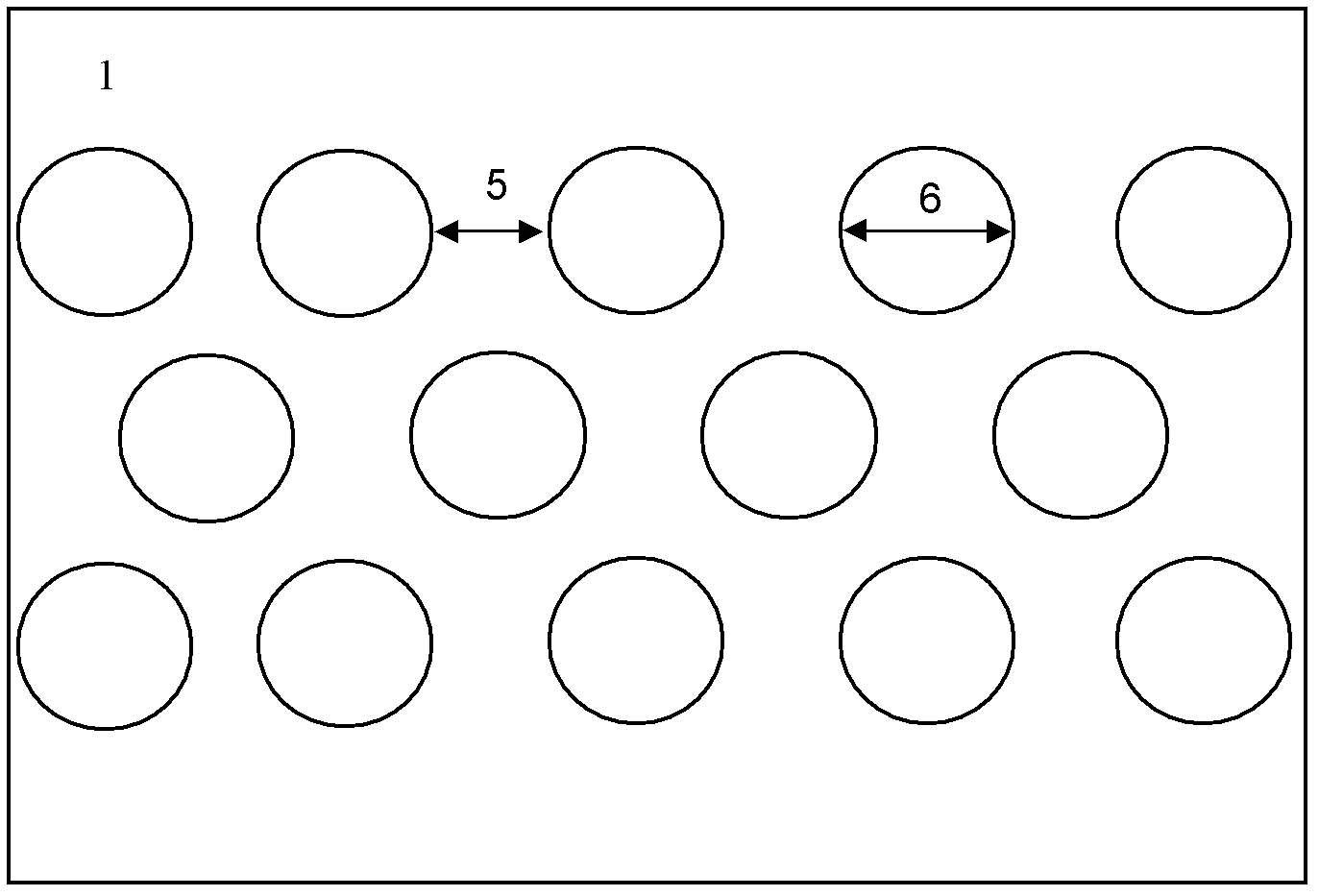

Killing apparatus for harmful microbody organisms in water, killing method, and water conveying engineering system

ActiveCN102424458ADoes not affect survivalEnsure safetyMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processWater sourceWater flow

The present invention provides a killing apparatus for harmful microbody organisms in water. The killing apparatus comprises an overflowing channel and hole plates arranged inside the overflowing channel. The hole plate crosses the overflowing channel along the overflowing cross-section direction, and forms a fixed connection with the inner wall of the overflowing channel, wherein no gap is remained between the hole plate and the inner wall of the overflowing channel. According to the present invention, with the pushing effect of the power system for pushing the flow of the water, the water flow passes through the hole plates with different specifications so as to generate different pulse waves, such that the harmful microbody organisms in the water can be effectively and selectively killed, wherein the body lengths of the harmful microbody organisms are in a certain body length range, therefore, the use requirements of the water source are met, the organisms living in the water are not damaged or damaged less so as to contribute to the use of the water source, wherein the body lengths of the organisms living in the water are not the same as the body lengths of the killed subjects. The present invention further relates to a killing method for the harmful microbody organisms in the water, and a water conveying engineering system applied by the killing apparatus and the killing method.

Owner:TSINGHUA UNIV

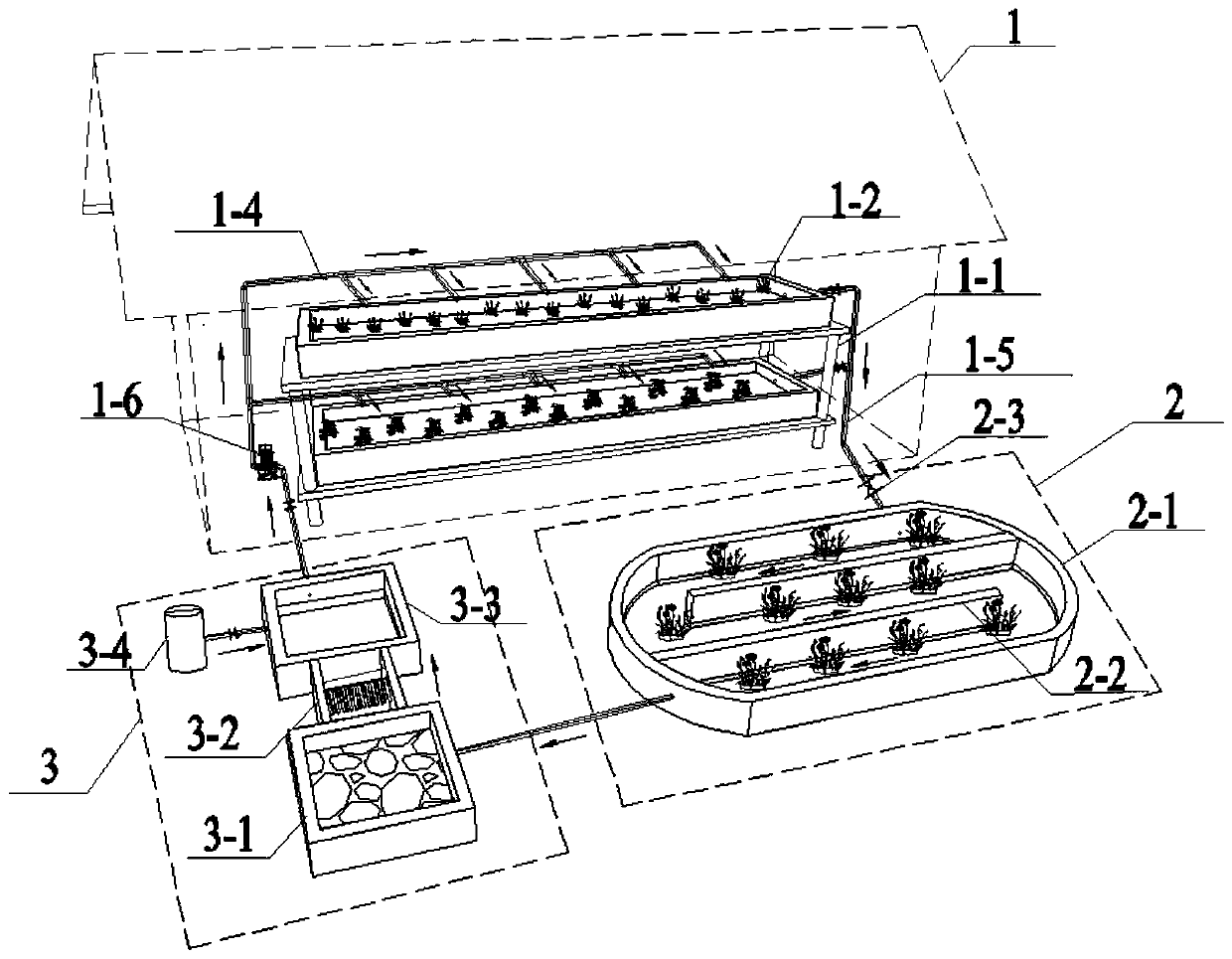

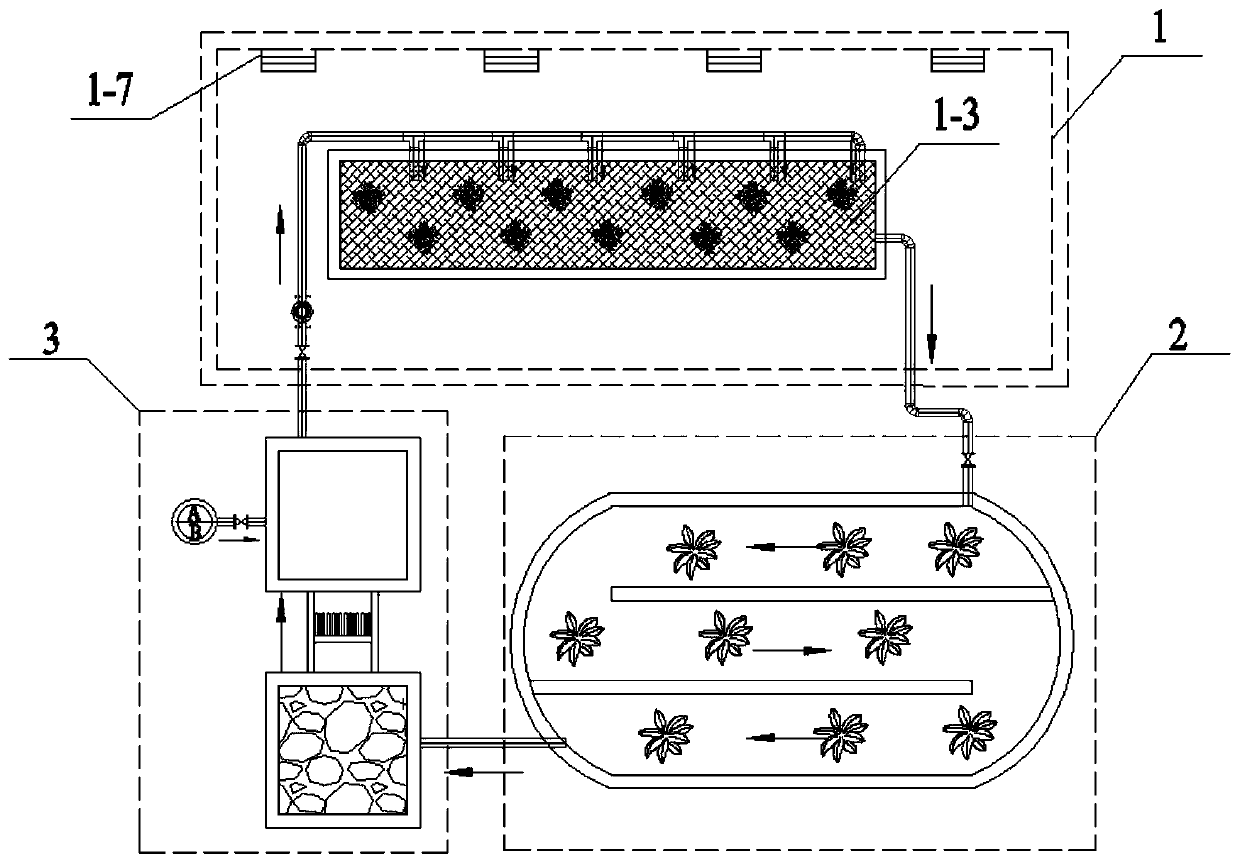

Submerged plant seedling cultivation system

ActiveCN110122123AImprove survival rateShorten the breeding cycleWater/sewage treatment by irradiationLiquid fertiliser distributionNutrientBiology

The invention discloses a submerged plant seedling cultivation system. The system comprises a greenhouse and a seedling breeding system arranged in the greenhouse, wherein the seedling breeding systemcomprises a load bearing frame and multiple layers of planters arranged on the load bearing frame, seedling substrates are arranged at the bottoms of the planters, a water supply pipe is connected with a water supply pump, a light control device is arranged above the planters, a plurality of water supply branch pipes are sequentially distributed at the side parts of the planters, each water supply branch pipe is communicated with the water supply pipe, a drainage pipe is communicated with the end parts of the planters, and a temperature control device is arranged in the greenhouse. The systemalso comprises a seedling hardening system and a water treatment system outside the greenhouse. Cyclic utilization of water resources and nutrients in the water resources is realized, the system is saving and environmentally friendly, and the seedling cultivation cost is reduced.

Owner:WUHAN ZHONGKE HYDROBOLOGY ENVIRONMENTAL ENG

Filter material, filter element, and water purification cup

PendingCN110615499AEfficient removalGood effect in removing heavy metal pollutantsWater contaminantsWater/sewage treatment by ion-exchangeTetrachloroethyleneFilter material

The invention provides a filter material, a filter element, and a water purification cup. The filter material comprises: carbon particles; and resin, wherein the particle size of the resin is 300-1600[mu]m. Therefore, the particle size of the resin in the filter material is within the range, so that the flow velocity of water is relatively proper, removal of heavy metal pollutants (such as copperand cadmium), industrial pollutants (such as tetrachloroethylene), residual chlorine and calcium and magnesium ions in the water is facilitated, and a relatively good water purification effect can beachieved.

Owner:FOSHAN MIDEA CHUNGHO WATER PURIFICATION MFG

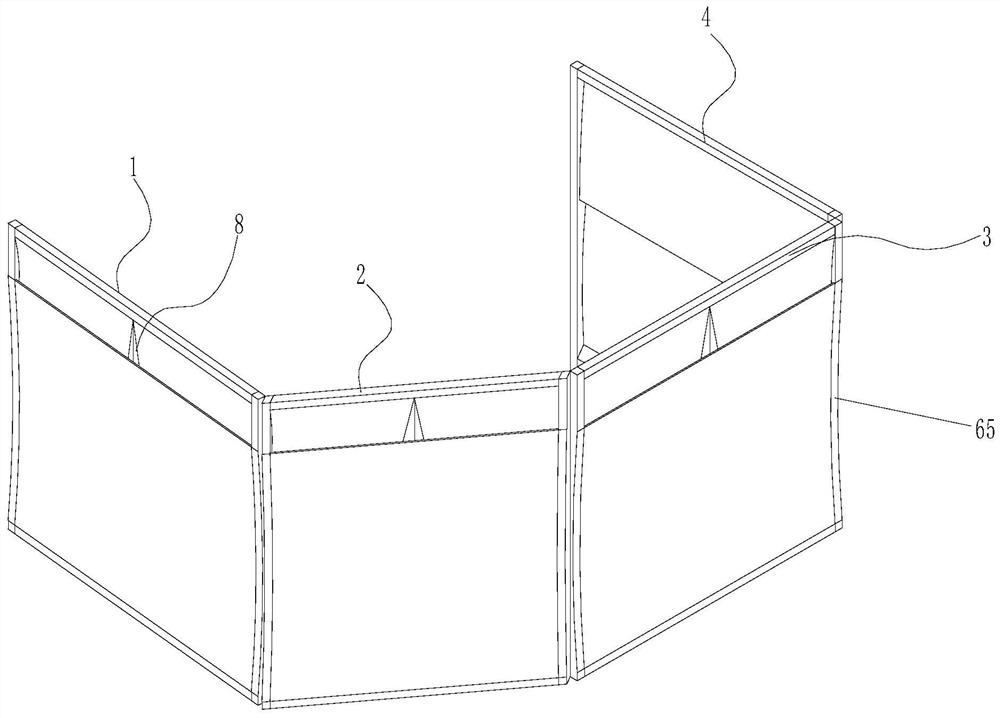

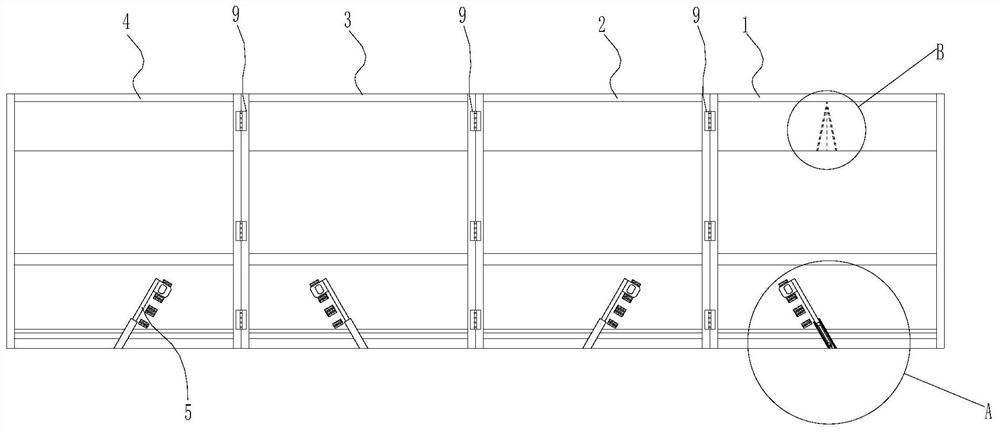

A Turnable Portable Folding Pile Windshield

ActiveCN112192097BImprove placement constraintsAvoid rollover and other adverse conditionsWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsStructural engineering

The invention discloses a turnable portable folding windshield for pile connection, which comprises: a first baffle; a second baffle, one side of which is rotatably connected to one side of the first baffle; The other side of the second baffle is rotatably connected; one side of the fourth baffle is rotatably connected to the other side of the third baffle; the fixing mechanism is multiple and corresponds to each baffle one by one and is fixedly arranged on each baffle The lower end of the plate; the first baffle plate, the second baffle plate, the third baffle plate and the fourth baffle plate all include a connecting frame of a rectangular frame structure and a connecting plate fixed in the rectangular frame structure of the connecting frame, and the connecting plate The upper end of the second air guide plate and the connecting frame form an air guide window, and an air guide channel is formed between the first air guide plate and the second air guide plate. Guide to dissipate the irritating gas generated during the welding process without interfering with the welding operation.

Owner:中建四局建设发展有限公司 +1

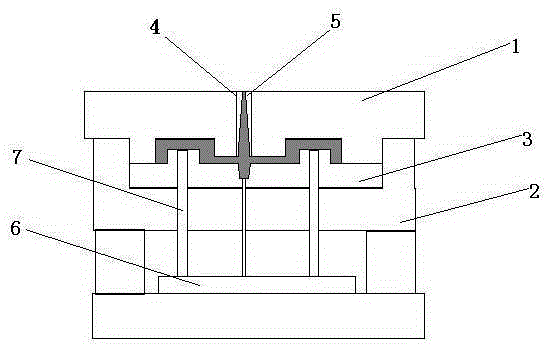

Temperature-controllable injection mold

The invention discloses a temperature-controllable injection mold. The temperature-controllable injection mold comprises a movable mold body and a fixed mold body. The movable mold body comprises a movable mold plate, a mold core installed on the movable mold plate and an ejecting mechanism. A cavity formed after the movable mold plate, the fixed mold body and the mold core are closed serves as a mold cavity. A main runner hole communicated with the mold cavity is formed in the fixed mold body. A main runner pipe is tightly installed in the main runner hole. The main runner pipe is a long hollow pipe. An inlet is formed in one end of the main runner pipe, and an outlet is formed in the other end of the main runner pipe. Electric heating elements and temperature sensing elements are arranged in the fixed mold body and the movable mold plate. According to the temperature-controllable injection mold, real-time monitoring and rapid stability compensation of the temperature of the mold can be achieved in the injection molding process, and the main runner pipe can be replaced according to requirements so that injection molding of materials with different injection molding requirements can be conducted on one mold; the injection mold is simple in structure, durable and suitable for the injection molding process.

Owner:SUZHOU YUANSHUO PRECISION MOLD

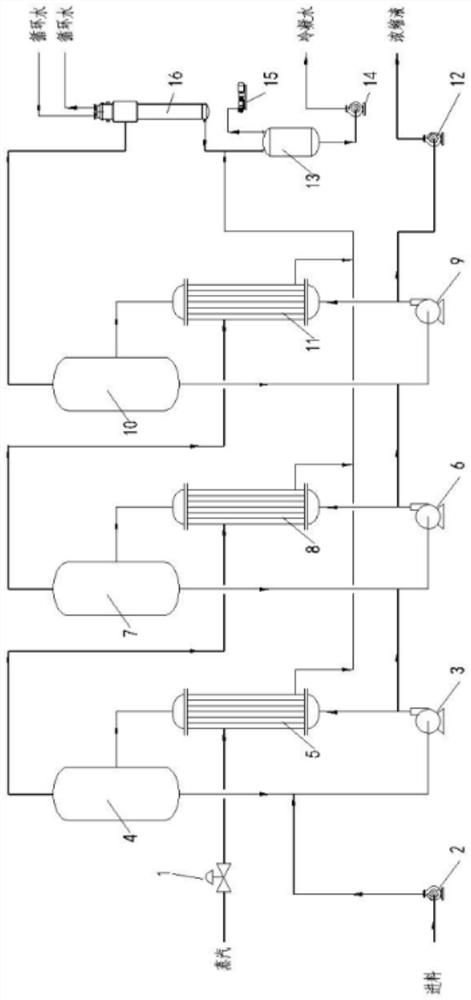

Anti-scaling triple-effect evaporation device

InactiveCN111792686ATake advantage ofLow costSpecific water treatment objectivesScale removal and water softeningCirculator pumpEngineering

The invention relates to an anti-scaling triple-effect evaporation device. The device comprises a feeding pump, a first-effect separator, a first-effect forced circulation pump, a first-effect heat exchanger, a second-effect separator, a second-effect forced circulation pump, a second-effect heat exchanger, a third-effect separator, a third-effect forced circulation pump, a third-effect heat exchanger, a discharging pump, a condenser and a condensed water tank. In the device, a first-effect evaporation unit is composed of the first-effect separator, the first-effect forced circulation pump, the first-effect heat exchanger and a pipeline, a second-effect evaporation unit is composed of the second-effect separator, the second-effect forced circulation pump, the second-effect heat exchanger and a pipeline, and a third-effect evaporation unit is composed of the third-effect separator, the third-effect forced circulation pump, the third-effect heat exchanger and a pipeline. Enough circulation flow velocity and material circulation amount in the three evaporation units are guaranteed through the set of forced circulation pumps, so that the anti-scaling purpose is achieved; and meanwhile,secondary steam of the first-effect evaporation unit and secondary steam of the second-effect evaporation unit are adopted as heat sources of the second-effect evaporation unit and the third-effect evaporation unit respectively, so heat energy is fully utilized.

Owner:SHANGHAI JIANGZHE ENVIRONMENT ENG TECH CO LTD

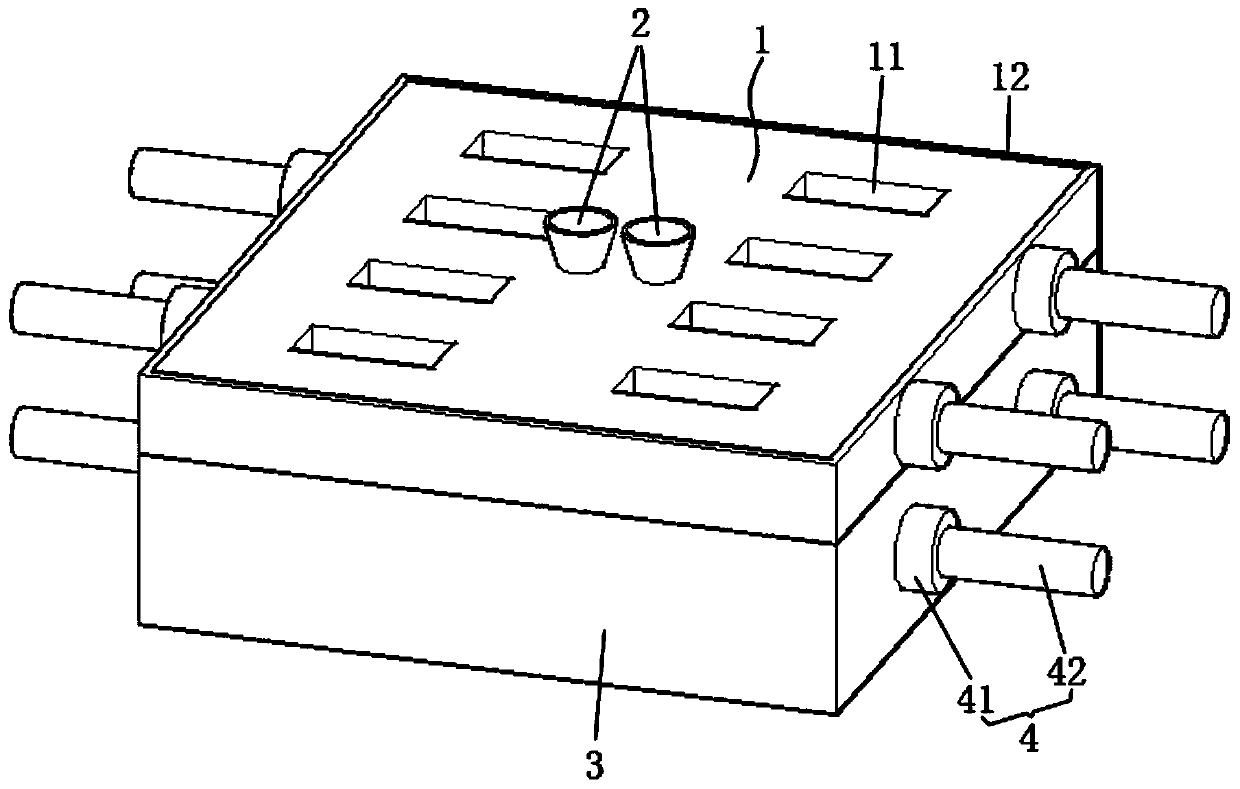

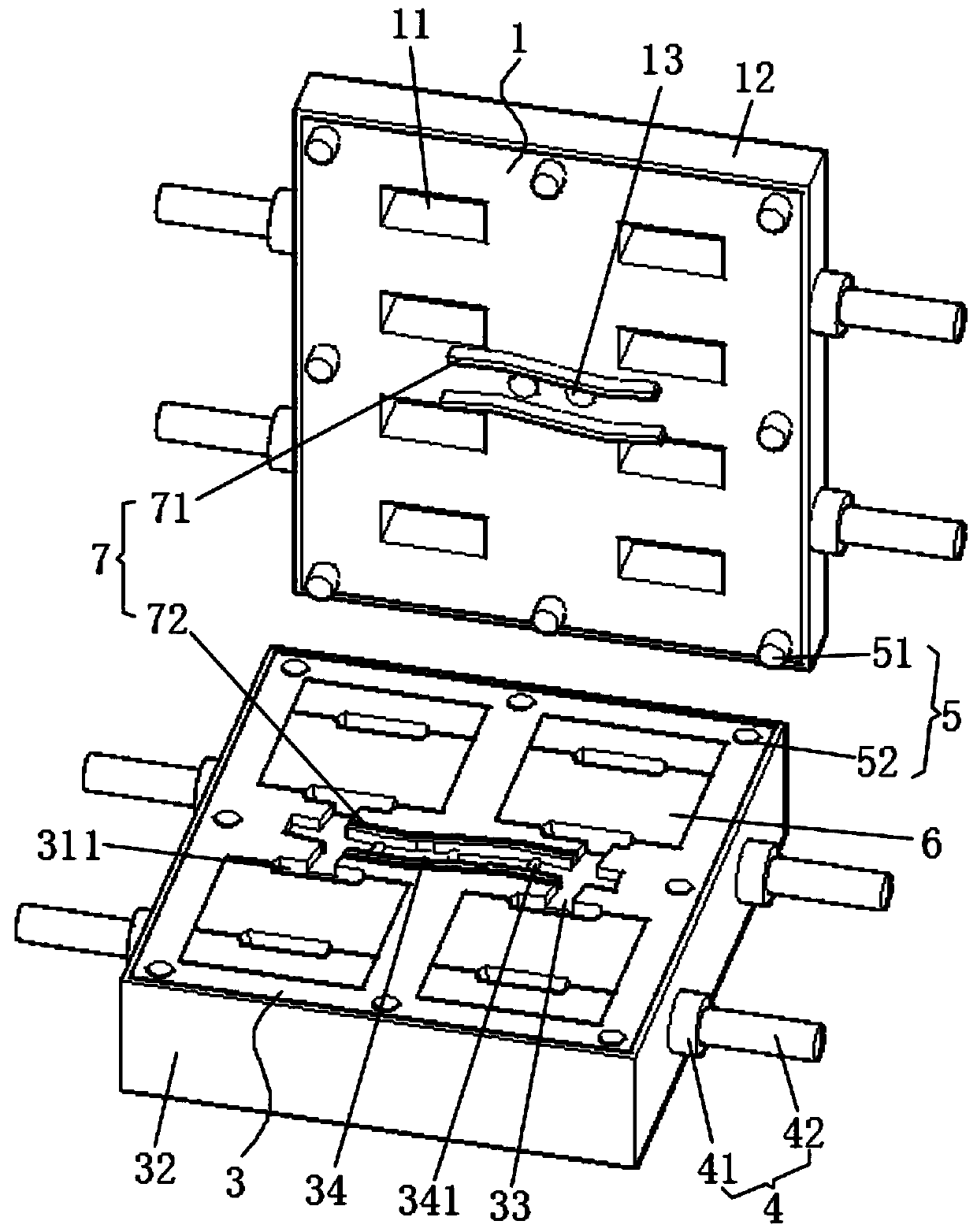

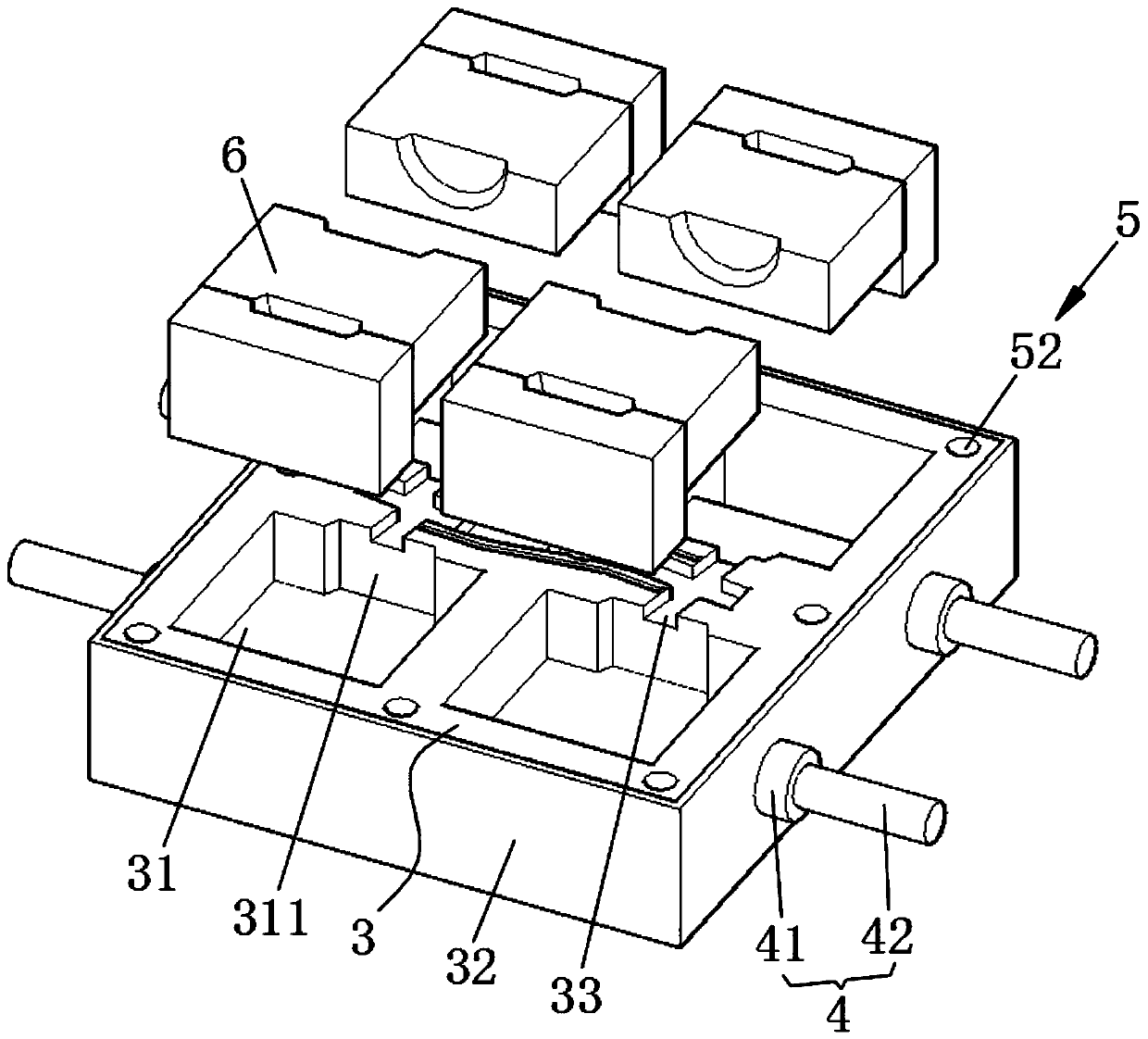

Plate spring base support pouring mold and pouring method

PendingCN110860653AReduce flow rateSimplify pouring processFoundry mouldsFoundry coresStructural engineeringMechanical engineering

The invention discloses a plate spring base support pouring mold and a pouring method. The plate spring base support pouring mold comprises an upper sand mold, pouring hoppers, a lower sand mold, support assemblies and pieces of lost foam. An upper sand mold frame sleeves the upper sand mold, and a lower sand mold frame sleeves the lower sand mold. Mold cavities are evenly formed in the face, matched with the upper sand mold, of the lower sand mold, and the pieces of lost foam are placed in the mold cavities. A pouring channel is further formed in the middle of the face, matched with the uppersand mold, of the lower sand mold, and is a nonlinear straight channel. According to the plate spring base support pouring mold and the pouring method, the flow velocity of the poured liquid is moderate, bubbles are timely discharged, finished products are complete, and the yield is high. The pouring technology is simple, the operation is easy, carbon dioxide is used for conducting curing operation, and the curing effect is good. In addition, the multiple products can be formed by the one-time pouring operation, and the production efficiency is improved.

Owner:ANHUI SHUANGLIN MACHINERY MFG CO LTD

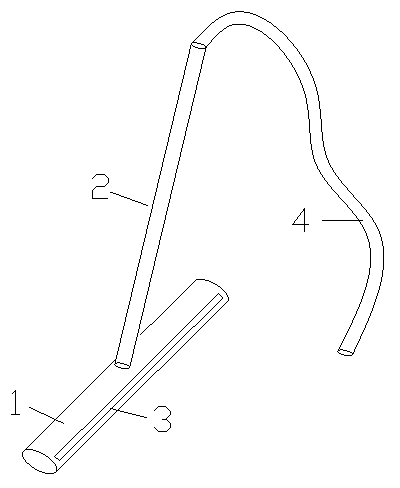

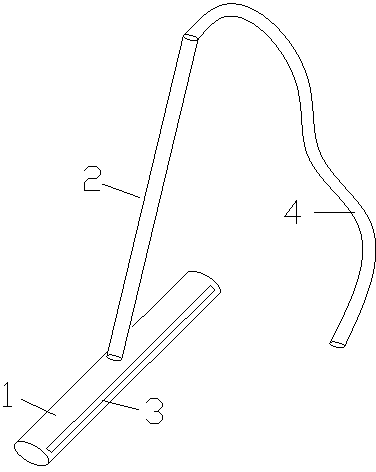

Handheld bottom suction device for artificial sea worm breeding

InactiveCN103380754AReduce usageResidue reductionPisciculture and aquariaPolyvinyl chlorideEngineering

A handheld bottom suction device for artificial sea worm breeding is a T-shaped bottom suction device consisting of a horizontal polyvinyl chloride (pvc) hard pipe, a vertical pvc hard pipe and a hose. The head portion of the T-shaped bottom suction device consists of the horizontal pvc hard pipe with two clised ends, wherein the inner diameter of the horizontal pvc hard pipe is 100cm, the side of the horizontal pvc hard pipe is provided with a water intake gap with the 1cm width and the length identical to the length of the pvc hard pipe. A round hole with 50cm diameter is formed in the position of a 135-degree circular arc formed by the horizontal pvc hard pipe and the water intake gap and connected with the vertical pvc hard pipe with 50cm outer diameter. The tail portion of the T-shaped bottom suction device is composed of the hose connected with the tail end of the vertical pvc hard pipe. The problems including bottom cleaning and pond reversing in the sea worm breeding process is solved, and the handheld bottom suction device is used for sea worm breeding and cultivation.

Owner:QINGDAO HENGSHENGYUAN ECOLOGICAL AGRI

Heat treatment equipment for production of high-ductility ribbed steel bars

PendingCN113430345ACooling effect is perfectImprove cooling effectDrying gas arrangementsInduction heaterManufacturing engineering

The invention discloses heat treatment equipment for production of high-ductility ribbed steel bars, and relates to the technical field of metal processing. The equipment comprises a main extrusion roller, a power module, a top cover and an air outlet box, an auxiliary extrusion roller is arranged at the top of the main extrusion roller, an induction heater is fixed to the front side of the power module, a water inlet pipe is fixed to the top of the top cover, and an air outlet is transversely formed in the center of the top of the air outlet box. Through the arrangement of the main extrusion roller, the power module, the top cover and the air outlet box, the problems that existing heat treatment equipment for high-ductility ribbed steel bar production cannot have multiple heat treatment functions on steel bars at the same time, the passing time of cooling water flow on the steel bars is too short, and cooling water on the steel bars cannot be quickly blow-dried are solved; and multiple heat treatments of the reinforcing steel bars can be carried out on the same equipment, the cooling effect of the reinforcing steel bars after heat treatment is good, and the reinforcing steel bars can be rapidly dried to prevent corrosion of the reinforcing steel bars.

Owner:河南省鼎鼎实业有限公司

Inclined-plate sedimentation tank for sewage treatment

InactiveCN108939621AImprove precipitation effectIncrease speedSettling tanks feed/dischargeSedimentation settling tanksSludgeDischarge rate

The invention discloses an inclined-plate sedimentation tank for sewage treatment. The inclined-plate sedimentation tank comprises a feeding port, overflow ports, a plurality of inclined plates, a transition layer, a flow blocking plate, a sludge discharging pipe and a plurality of sludge hoppers; the plurality of sludge hoppers are arranged at the lower end of the sedimentation tank; a sludge discharge pipe is arranged at the bottoms of the sludge hoppers; the flow blocking layer is arranged above the sludge hoppers; the surface of the flow blocking layer is provided with the plurality of inclined plates; a slow flow layer is arranged on the upper ends of the inclined plates; each of two ends of the sedimentation tank is provided with one overflow port; and the feeding ports penetrate through the sedimentation tank and are located above the slow flow layer. According to the inclined-plate sedimentation tank provided by the invention, the inclined plates, the flow slowing layer and theflow blocking layer are effectively combined, so that the flow speed of a sedimentation material is moderate, and the sedimentation effect and the sedimentation rate of the sedimentation tank are effectively improved. The sludge discharge pipe is arranged at the bottoms of the sludge hoppers, so that the sludge discharging effect and the sludge discharging rate of the sedimentation tank are effectively improved.

Owner:贺利兵

Killing apparatus for harmful microbody organisms in water, killing method, and water conveying engineering system

ActiveCN102424458BDoes not affect survivalEnsure safetyMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processWater sourceWater flow

The present invention provides a killing apparatus for harmful microbody organisms in water. The killing apparatus comprises an overflowing channel and hole plates arranged inside the overflowing channel. The hole plate crosses the overflowing channel along the overflowing cross-section direction, and forms a fixed connection with the inner wall of the overflowing channel, wherein no gap is remained between the hole plate and the inner wall of the overflowing channel. According to the present invention, with the pushing effect of the power system for pushing the flow of the water, the water flow passes through the hole plates with different specifications so as to generate different pulse waves, such that the harmful microbody organisms in the water can be effectively and selectively killed, wherein the body lengths of the harmful microbody organisms are in a certain body length range, therefore, the use requirements of the water source are met, the organisms living in the water are not damaged or damaged less so as to contribute to the use of the water source, wherein the body lengths of the organisms living in the water are not the same as the body lengths of the killed subjects. The present invention further relates to a killing method for the harmful microbody organisms in the water, and a water conveying engineering system applied by the killing apparatus and the killing method.

Owner:TSINGHUA UNIV

Double ventilating regulator and burner nozzle of low NOx combustor system

InactiveCN1789811AConvenient continuous adjustmentEasy to adjustPulverulent fuel combustion burnersCombustion apparatusCombustorLow nitrogen

This invention relates to double ventilate adjustor and burst spray mouth in the low nitrogen oxidation burst device system, wherein, The said ventilate adjustor comprises one pair of supportive board suspension rack to guide burst air into shell entrance composed of one block gate with one pair of parallel edges, rivet structure and block gate rotation axis; The said spray mouth comprises ring channel to exit connected to the powder mineral burst area and the ring channel is between the inside column part and shell parts; the burst flow area device comprise one shade part, one secondary parts at certain angle to the first one.

Owner:钟兰狄

A device and system for electroplating thin plates

The invention discloses a device and system for electroplating thin sheets. The device comprises an electroplating tank, flow-guiding devices and a first circulating device, wherein the electroplating tank is provided with a backflow channel, a conveying device for conveying electroplated thin sheets is arranged above the backflow channel; the flow-guiding devices are slantwise arranged at both sides of the electroplated thin sheets and located at the position higher than the uppermost ends of the electroplated thin sheets; electroplating metal liquid from an anode device space flows along the surface of the flow-guiding devices to the backflow channel in the electroplating tank at an uniform thickness from flow-guiding inlets; the liquid suction opening of the first circulating device is communicated with the backflow channel and the liquid discharging opening of the first circulating device is communicated with the anode device space. By virtue of the device for electroplating thin sheets disclosed by the invention, the uniform electroplating thickness of the electroplated thin sheets can be ensured, the quality of the electroplating is improved, the labor cost is saved and the production efficiency is improved.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Technology for long-distance direct injection of pulverized coal

InactiveCN103849700AAvoid blockingReduced coal injectionBlast furnace detailsCharge manipulationProduct gasEngineering

The invention discloses a technology for long-distance direct injection of pulverized coal. The technology comprises the following steps of a, fluidization mixing, wherein a part of conveyed gas is injected into an injection tank from the middle of the injection tank, a cone end of the injection tank needs enough fluidization equipment, a fluidization process is carried out at the bottom of the injection tank and the materials are discharged from an upper part of the injection tank, b, pulverized coal conveying, wherein a gas tangential-feeding-type mixer is adopted, a flow rate is controlled by pipe diameter grading adjustment comprising that when a pipe flow rate is more than 3m / s, the pipe diameter is increased so that the pipe flow rate is greater than or equal to a lowest flow rate of pulverized coal conveying, c, pulverized coal distribution, wherein an equal-head loss tubing design is adopted so that the total length of each pipe is equal and the number of elbows of each pipe is same, and a branch pipe conveying flow rate is controlled in a way that when a coal injection amount is greater than 1t / h, more spray guns are used and when the coal injection amount is reduced, the used spray guns are reduced, and d, pipe blocking prevention and elimination, wherein a flowing state in the current pipe is determined by a detector on the pulverized coal pipe, a pulverized coal flowing rate in the pipe is controlled to more than 3m / s, the pipe is automatically cleaned according to the determination result of the detector when the pulverized coal flowing rate is less than 3m / s, remote and manual blocking elimination devices needs to be arranged on the way of the pulverized coal pipe so that when the blocking situation is not serious, a remote blocking-elimination process is carried out on an operation screen and when the blocking situation is serious, a manual pipe sectionalized-cleaning process is carried out on site. The technology can be widely used as a method for long-distance direct pulverized coal injection of iron-making production.

Owner:XI LIN IRON & STEEL GRP

Handheld bottom suction apparatus for intensively cultivating Penaeus Vanmamei

InactiveCN104304158AReduce usageResidue reductionPisciculture and aquariaPolyvinyl chlorideEngineering

The invention discloses a handheld bottom suction apparatus for intensively cultivating Penaeus Vanmamei, and the handheld bottom suction apparatus is the T-shaped one composed of a horizontal PVC (polyvinyl chloride) hard tube, a vertical PVC hard tube and a flexible tube. The head of the T-shaped bottom suction apparatus is composed of the horizontal PVC hard tube with two sealed ends and the inner diameter of 100cm, and the side of the horizontal PVC hard tube is provided with a water feeding seam with the width of 1cm and the same length as the PVC hard tube. The 135 degrees arc position formed between horizontal PVC hard tube and the water feeding seam is provided with a circular hole with the diameter of 50cm, and the circular hole is connected with the vertical PVC hard tube with the outer diameter of 50cm. The tail of the T-shaped bottom suction apparatus is connected with the tail end of the vertical PVC hard tube by the flexible tube. The handheld bottom suction apparatus can solve the bottom-clearing problem when the Penaeus Vanmamei is cultivated by an improved sea slug nursery pond, and the handheld bottom suction apparatus is used to intensively cultivate the Penaeus Vanmamei.

Owner:QINGDAO HENGSHENGYUAN ECOLOGICAL AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com