Plate spring base support pouring mold and pouring method

A leaf spring seat and mold technology, used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of reducing the speed of molten iron pouring, difficulty in setting buffers, and degrading product quality, reducing the flow rate of the pouring liquid, curing Good effect and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

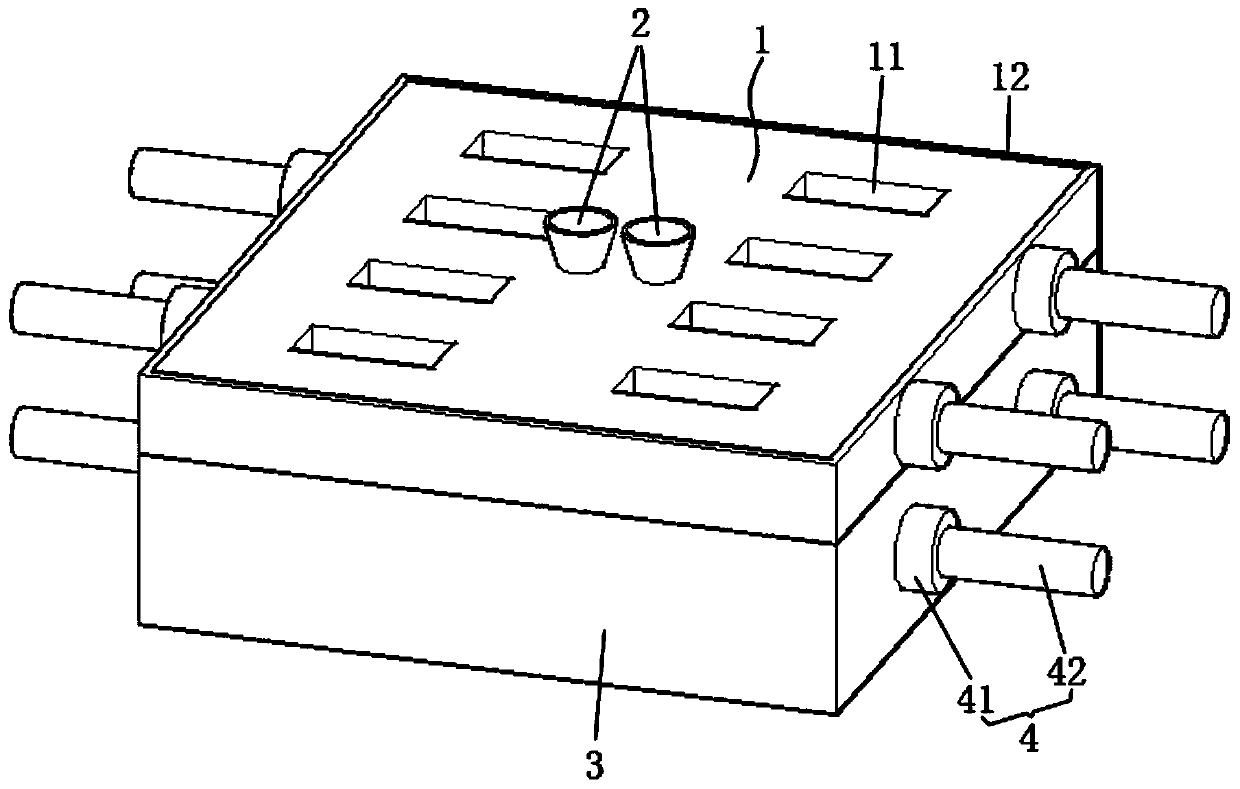

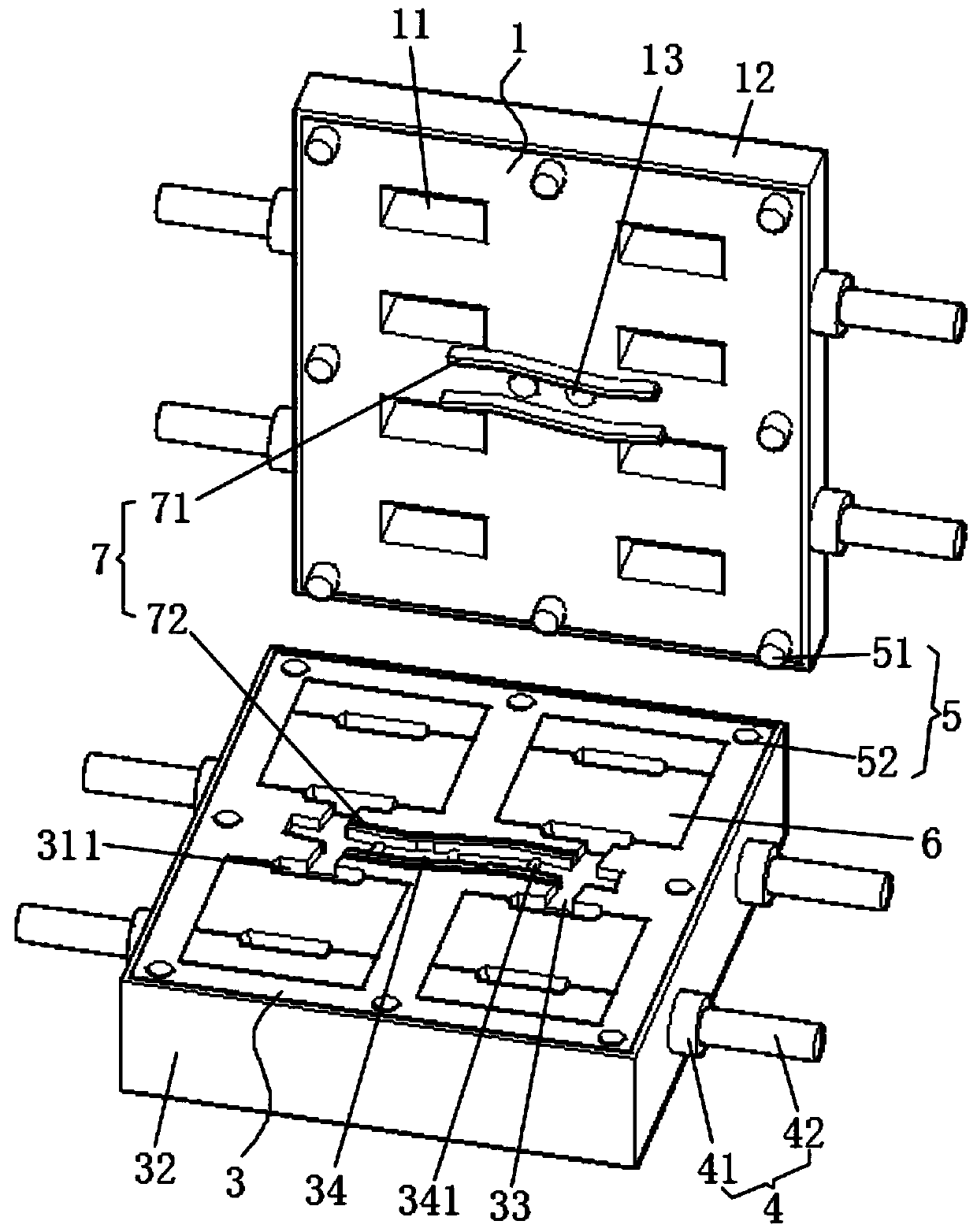

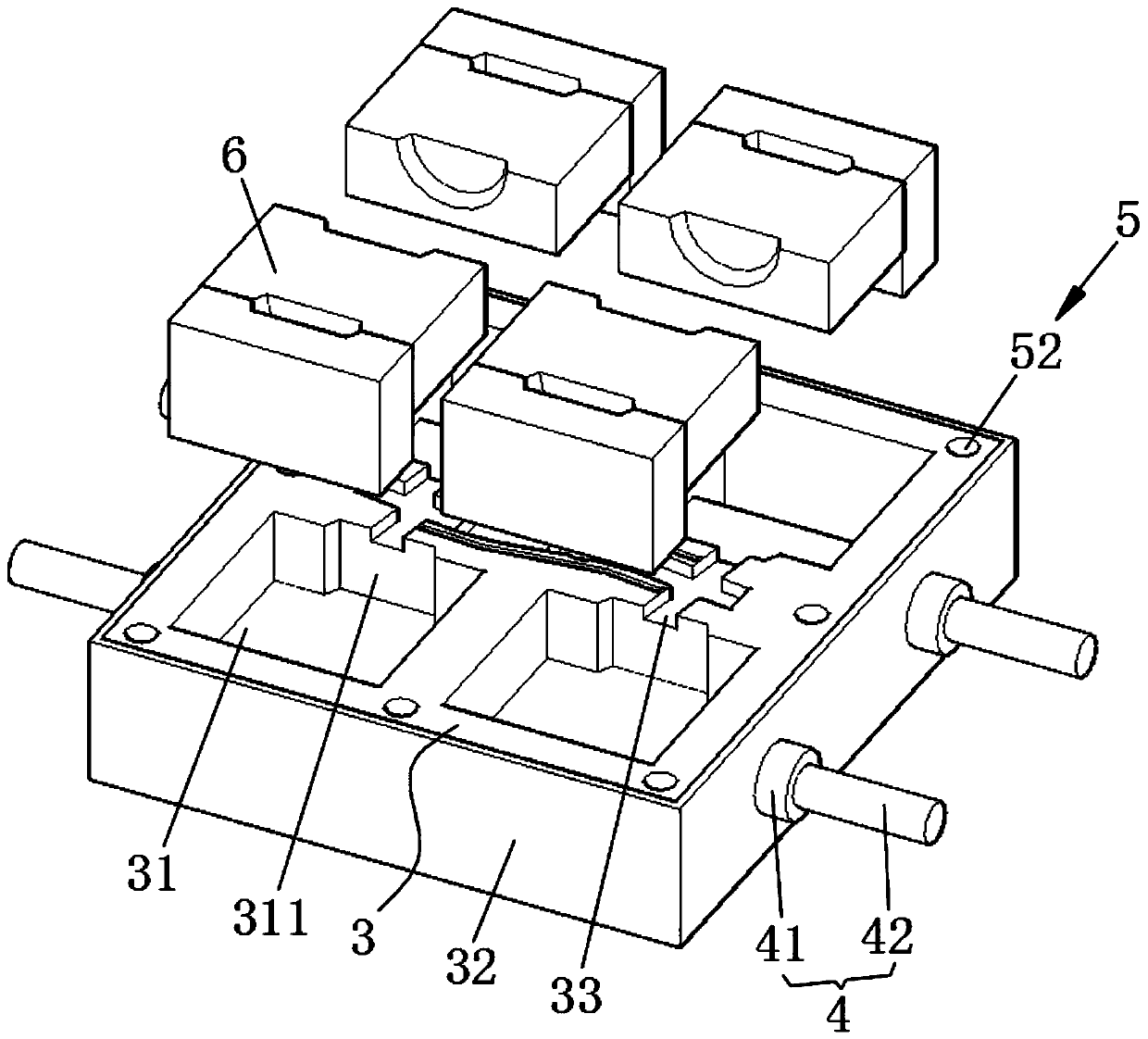

[0049] refer to figure 1 , the present embodiment discloses a casting mold for a leaf spring seat bracket, including an upper sand mold 1 , a pouring bucket 2 , a lower sand mold 3 , a bracket assembly 4 and a lost mold 6 .

[0050] A mold cavity 31 is uniformly opened on the side of the lower sand mold 3 that cooperates with the upper sand mold 1 . The lost mold 6 is placed in the mold cavity 36 . A sprue 34 is also provided at the middle position of the mating side of the lower sand mold 3 and the upper sand mold 1 . The sprue 34 is a non-linear straight path. A side of the mold cavity 31 close to the sprue 34 is provided with an inlet groove 311 communicating with the mold cavity 31 . The sprue 34 communicates with the plurality of inlet grooves 311 through branch channels 33 .

[0051] refer to figure 1 and Figure 5 , the upper sand mold 1 is arranged on the top of the lower sand mold 3 . A plurality of risers 11 are uniformly opened on the upper sand mold 1 . A p...

Embodiment 2

[0070] This embodiment also discloses a pouring method for the casting mold of the leaf spring seat bracket, which includes the following steps:

[0071] S1 makes the sand mold:

[0072] S1.1 mold set: directly socket the lower sand mold frame 32 on the mandrel, and position it well;

[0073] S1.2 Sand filling: fill sand into the downward sand mold frame 32 until it is full, and then compact it to obtain the lower sand mold 3 of the semi-finished product;

[0074] S1.3 Curing: Insert the carbon dioxide pipe into the lower sand mold 3, and pass carbon dioxide into the lower sand mold 3 for curing;

[0075] S1.4 Demoulding: Use a gantry crane to lift the lower sand mold 3 to make it fall off from the mandrel;

[0076] S1.5 Overturning: transport the lower sand mold 3 aside, and turn over the downward side;

[0077] S2 filling the lost foam 6: putting the prepared lost foam 6 into the cavity 31 of the lower sand mold 3;

[0078] S3 mold closing: close the pre-prepared upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com