Cavitation piece of micro-bubble generator, micro-bubble generator and washing device

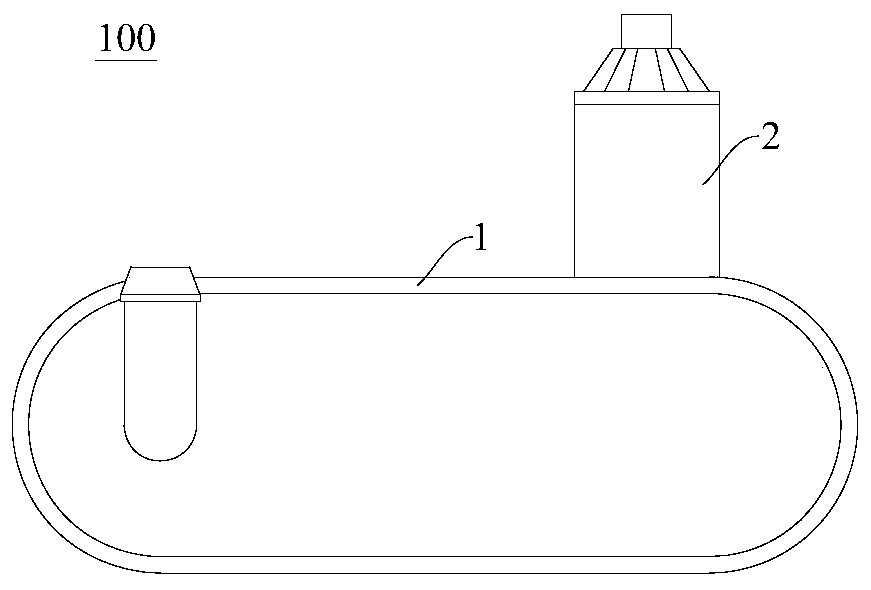

A technology of micro-bubble generator and chemical parts, which is applied to washing devices, other washing machines, fluid mixers, etc., can solve the problems of inconvenient installation, manufacturing, unreasonable structure, large occupied volume, etc., and achieves convenient processing and manufacturing effect. Good, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Such as Image 6 As shown, under the premise of the same structure, changing the diameter d1 of the throat 252 of the cavitation element 2, the microbubble water obtained by the cavitation element 2 is different under each parameter selection range. When the diameter d1 of the throat pipe 252 is selected as 0.2-0.5mm, the water changes from transparent color to rich floating white color, thus it can be inferred that the content of microbubbles in the water is high. When the diameter d1 of the throat pipe 252 is selected to be 0.5-2mm, the water will keep a rich floating white color. From this, it can be inferred that the content of microbubbles in the water is still high, and the water velocity of the cavitation part 2 is applicable in this interval. When the diameter d1 of the throat pipe 252 is chosen to be less than 0.2mm, the flow rate of the water flow through the cavitation element 2 is too small, which is no longer applicable. However, when the diameter d1 of t...

Embodiment 2

[0077] Such as Figure 7 As shown, under the premise of the same structure, changing the multiple of the diameter d2 of the end of the tapered section 251 and the diameter d1 of the throat pipe 252 in the cavitation part 2, the experiment found that under the conditions of different multiples, the water production of the cavitation part 2 The microbubble content is different. When the multiple of the end diameter d2 of the tapering section 251 and the diameter d1 of the throat 252 is less than 1.05, the water is clear, and it can be inferred that the microbubble content in the water is too small. And when the diameter multiple is 1.05-1.3, it can be inferred from the color of the water that the content of microbubbles in the water increases significantly. Especially when the diameter multiple exceeds 1.3, the prepared water is rich and floating white, indicating that the content of microbubbles in the water is very high.

[0078] Under the same structural premise, similar ex...

Embodiment 3

[0080] Such as Figure 8 As shown, changing the cavitation element 2 under the same structural premise, it can be seen that when the ratio of the length L2 of the divergent section 253 to the length L1 of the tapered section 251 changes, the bubble-making effect will also change significantly.

[0081] After the bubbles are generated in the throat pipe 252, if the gradient of the diverging section 253 changes too much, the generated bubbles are very easy to burst. Therefore, if the length ratio of the diverging section 253 and the tapering section 251 is less than or even equal to 1:1, a large number of bubbles will Immediately after it is produced, it is destroyed, so the concentration of air bubbles in the water is not high. When the length ratio of the diverging section 253 and the converging section 251 is between 1-4, the produced water is rich and floating white, and the air bubble content in the water is very high. When the length ratio of the diverging section 253 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com