A device and system for electroplating thin plates

A technology of electroplating plates and thin plates, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of low production efficiency, poor uniformity of coating thickness, high labor cost, etc., achieve high verticality, uniform coating thickness, and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

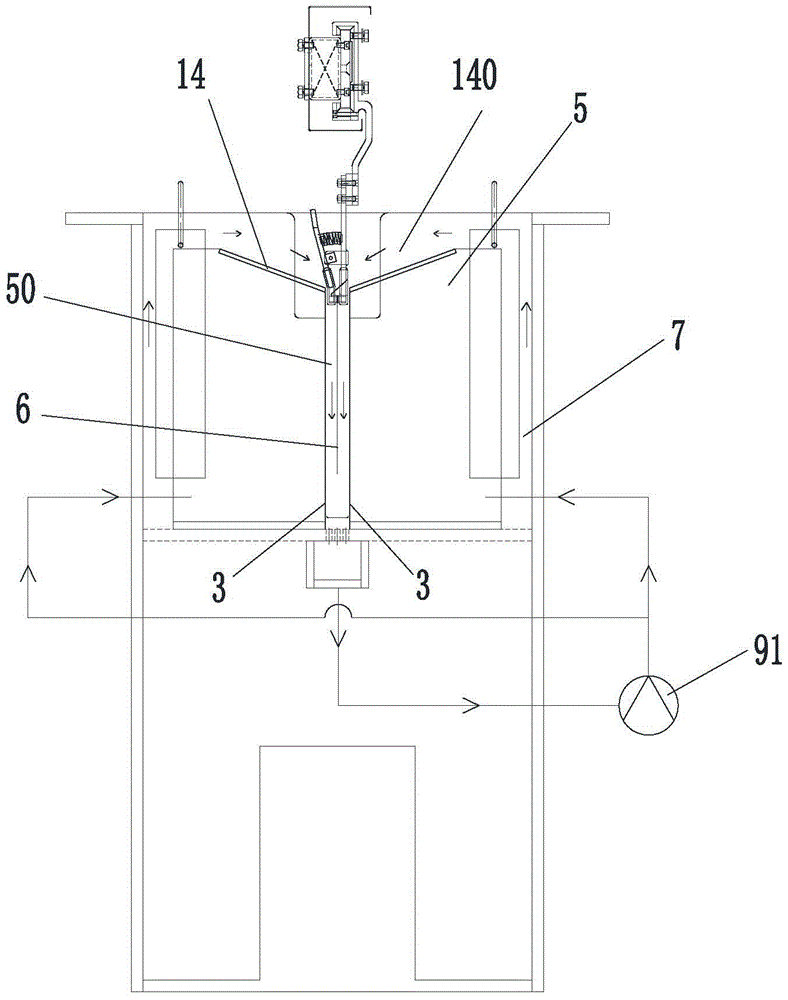

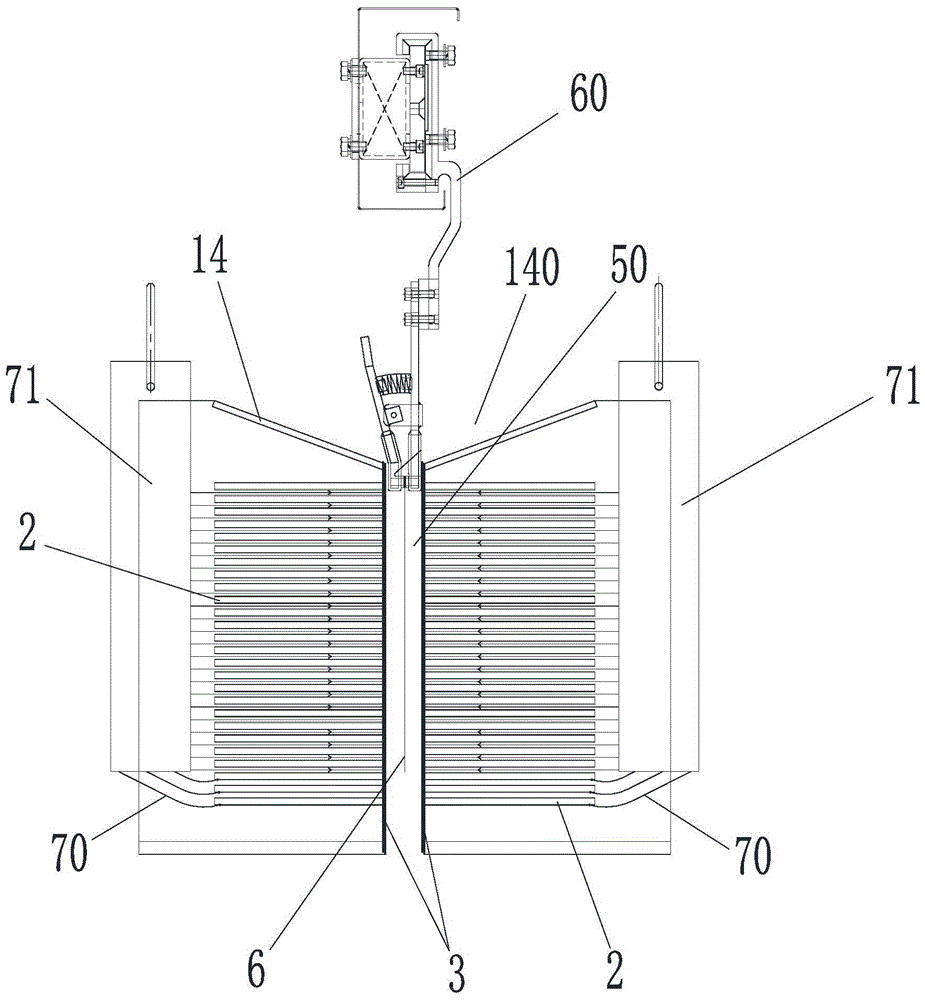

[0044] see figure 1 , a device for electroplating thin plates, which includes an electroplating tank 5, a return channel 50 is provided in the electroplating tank 5, and an electroplating plate 6 is electroplated in the return channel 50; guides are provided on both sides of the electroplating plate 6 A flow device, the deflector is a deflector 14, the deflector 14 is located higher than the uppermost end of the electroplating plate 6, and symmetrically arranged on both sides of the electroplating plate 6, formed on the upper end of the electroplating plate 6 The diversion inlet 140 whose cross-sectional area gradually decreases from top to bottom, the electroplating metal solution from the anode device space 7 (the anode device space 7 is the position for placing the anode device of the electroplating tank 5) along the The surface of the deflector 14 flows from the flow guide inlet 140 to the return channel 50 of the electroplating tank 5 with a uniform thickness, and the fir...

Embodiment 2

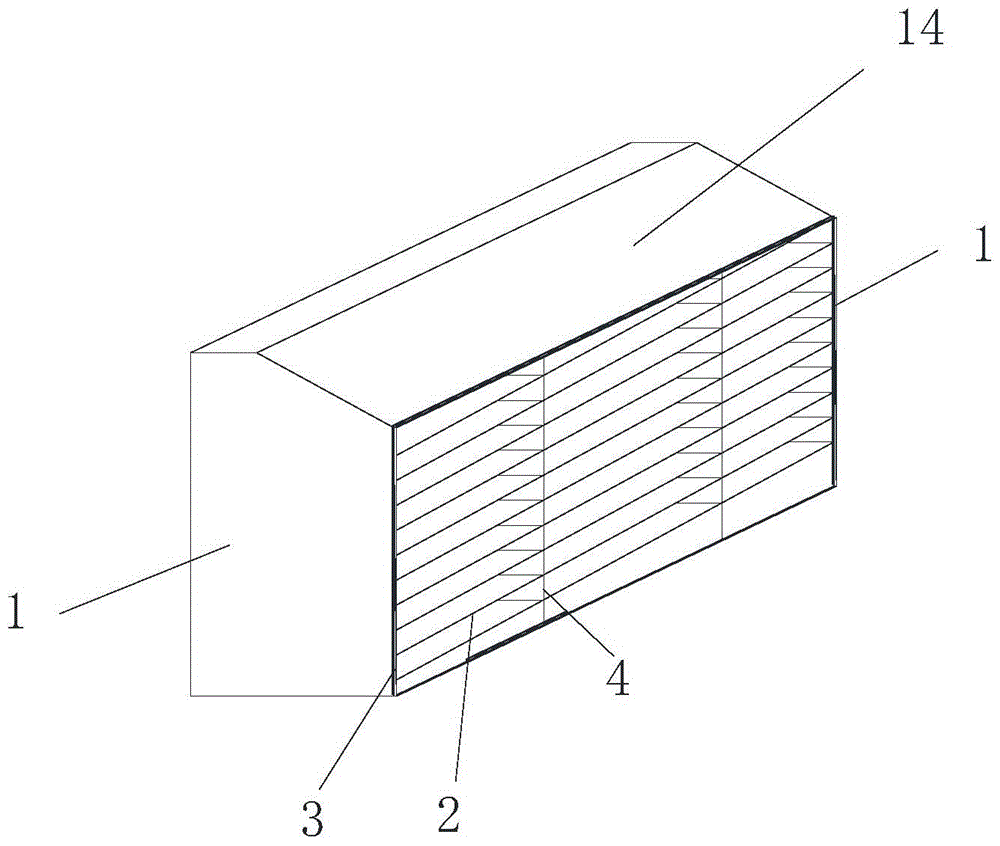

[0048] see figure 1 , in this embodiment, in order to prevent the plating layer below the electroplating plate 6 from being too thick, the current limiting device is provided with a second device for guiding the direction of the electric force lines in the electroplating metal liquid flowing from the anode device space 7 to the electroplating plate 6. The flow guide device, the second flow guide device is made of insulating material, and the second flow guide device is arranged on the side of the filter screen 3 away from the electroplating plate 6 . The second deflector includes an upright support plate 1, and partitions 2 arranged at intervals along the height direction of the support plate 1, and the deflector 14 and the filter screen 3 are fixedly arranged on the The upper end of the support plate 1 and the two ends of the partition plate 2 are fixedly connected to the support plate 1 respectively, the partition plates 2 are arranged in several layers, and a gap is formed ...

Embodiment 3

[0053] see Figure 5 , On the basis of the above-mentioned embodiment one or two, the device for electroplating thin plates also includes a liquid storage tank 8 for storing the electroplating metal solution. The electroplating metal solution can be stored in the liquid storage tank 8 at first, and then injected into the liquid storage tank 8 when necessary. Electroplating is carried out in the electroplating tank 5. The liquid storage tank 8 is arranged below the electroplating tank 5 or other adjacent positions, and the liquid storage tank 8 and the electroplating tank 5 are connected through a second circulation pump 92 . An overflow port is provided on the side wall of the electroplating tank 5, the overflow port is higher than the uppermost end of the deflector, and the overflow port communicates with the liquid storage tank. When working, the second circulation pump 92 starts to inject the electroplating metal solution into the electroplating tank 5, and simultaneously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com