Heat treatment equipment for production of high-ductility ribbed steel bars

A heat treatment equipment and technology of ribbed steel bars, which are applied in the field of metal processing, can solve the problems of short cooling water flow, inability to have multiple heat treatments of steel bars at the same time, and rapid drying of cooling water, so as to achieve perfect cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

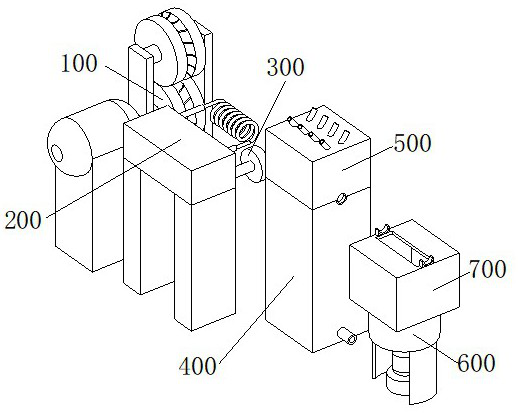

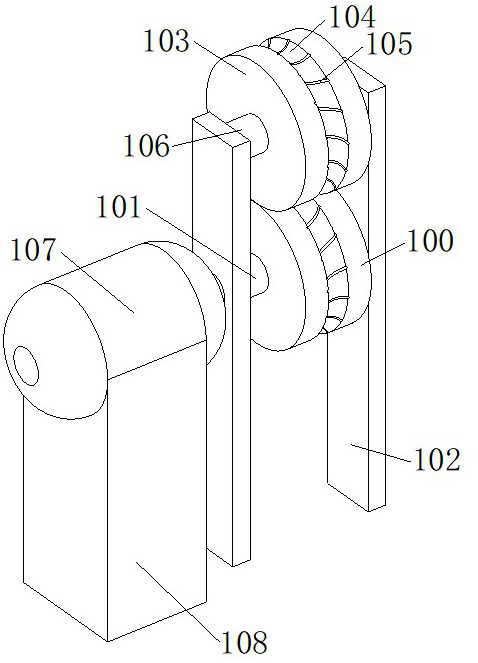

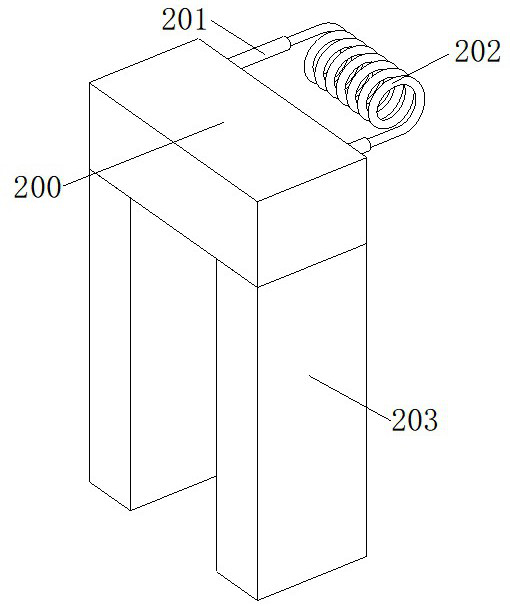

[0036] see Figure 1-8 As shown, the present invention is a heat treatment equipment for the production of high-ductility ribbed steel bars, including a main extrusion roll 100, a power supply module 200, a top cover 500 and an air outlet box 700, and an auxiliary extrusion roll is arranged on the top of the main extrusion roll 100 103, the main extrusion roller 100 cooperates with the auxiliary extrusion roller 103 when driven by the servo motor 107, and squeezes the ribs of the steel bar to be processed. The middle of the main extrusion roller 100 and the auxiliary extrusion roller 103 are all A steel bar extruding groove 104 is provided. When the steel bar is being squeezed, it moves in the steel bar extruding groove 104, so that the steel bar is transported to the induction heater 202 on the power module 200. The main extrusion of the inner wall of the steel bar extruding groove 104 Both the pressure roller 100 and the auxiliary extrusion roller 103 are provided with rib e...

Embodiment 2

[0045] Based on the heat treatment equipment for the production of high-ductility ribbed steel bars described in Embodiment 1, when the required heat treatment is performed on the steel bars, the rotation speed of the servo motor 107 that drives the main extrusion roller 100 is adjusted so that the speed at which the steel bars pass through the induction heater 202 changes. , so that the temperature of the heat treatment of the steel bar and the cooling time of the water tank 400 and the top cover 500 are changed, so that the temperature of the heat treatment of the steel bars with different components is different, and the driving speed of the same steel bar can be changed by the servo motor 107. The temperature after the induction heater 202 is heated is different, the time length for cooling after heating is different, and different heat treatments are performed. In addition, the liquid that is transported into the top cover 500 in the water inlet pipe 502 on the top cover 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com