Inclined-plate sedimentation tank for sewage treatment

A technology for sloping plate sedimentation and sewage treatment, applied in the field of sedimentation tanks, can solve the problems of poor sedimentation effect and sludge discharge effect, and excessively fast sedimentation material flow rate, so as to improve the sedimentation effect and sedimentation rate, the flow rate is moderate, and the sludge discharge rate is improved. Effect and effect of sludge discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

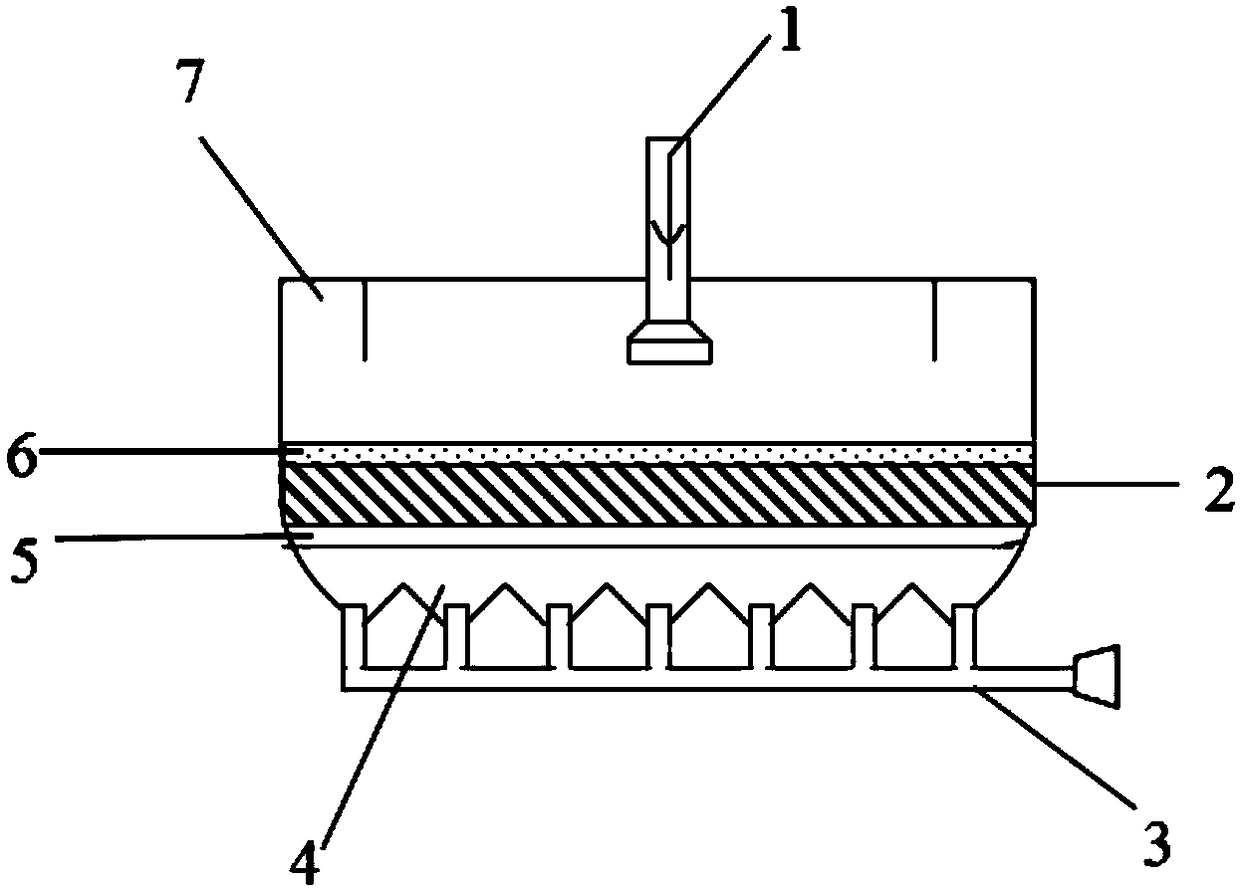

[0014] Such as figure 1 As shown, the inclined plate sedimentation tank used for sewage treatment includes a feed inlet 1, an overflow port 7, several inclined plates 2, a transition layer 6, a spoiler 5, a mud discharge pipe 3 and a sludge bucket 4; The sedimentation tank is made of steel, concrete or glass fiber reinforced plastics. At least 6 sludge buckets 4 are arranged at the lower end of the sedimentation tank. The bottom of the sludge bucket 4 is provided with a sludge discharge pipe 3. flow layer 5, the surface of the flow blocking layer 5 is provided with some slant plates 2 made of glass fiber reinforced plastics, the distance between the adjacent slant plates 2 is 6-12cm, and the installation angle of the slant plates 2 is 45°-50° , the upper end of the sloping plate 2 is provided with a slow-flow layer 6, and the two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com