Crystallization system and crystallization process for producing nickel sulfate by continuous method

A crystallization system, nickel sulfate technology, applied in nickel sulfate, crystallization separation, solution crystallization, etc., can solve the problems of high energy consumption, low production efficiency, and many control process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

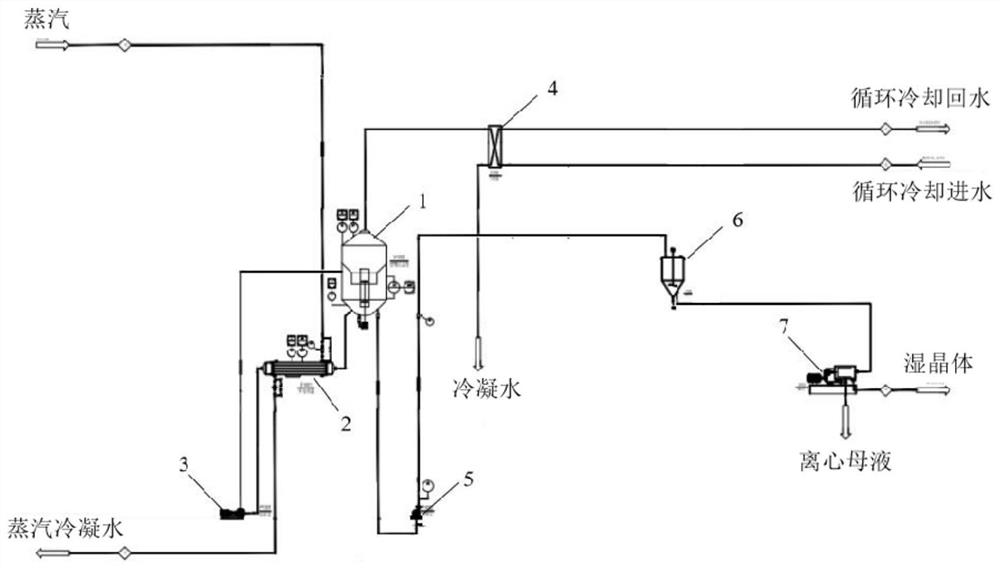

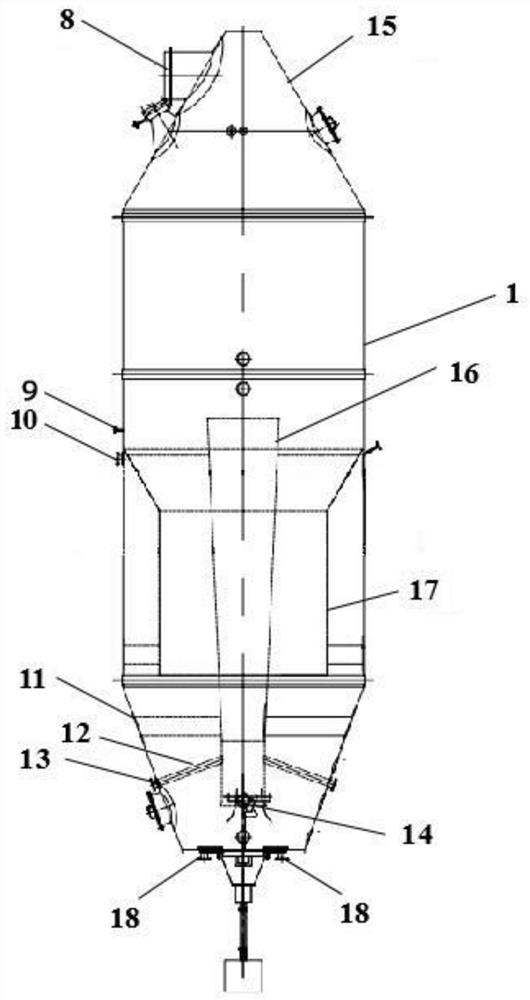

[0024] like figure 1 , figure 2 Shown, the crystallization system of a kind of continuous method production nickel sulfate that present embodiment describes, it comprises crystallizer 1, fine crystal eliminator 2, feed pump 3, heat exchanger 4, discharge pump 5, thickener 6 and a centrifuge 7; the crystallizer includes an upper cylinder 15, a middle cylinder 9 and a lower cylinder 11, the upper cylinder is provided with a steam outlet 8, and the steam outlet is connected to a heat exchanger; The liquid external circulation outlet 10, a straight cylinder baffle 17 is arranged in the middle cylinder, and a variable diameter guide cylinder 16 is arranged inside the straight cylinder baffle. The variable diameter guide cylinder is composed of a straight cylinder and a variable diameter cylinder, and the height of the straight cylinder is 0.25 to 0.5 times the height of the cylinder, and the maximum diameter of the variable diameter cylinder is 1 to 2 times the minimum diameter o...

Embodiment 2

[0027] A kind of crystallization technique of continuous method production nickel sulfate, specifically comprises the steps:

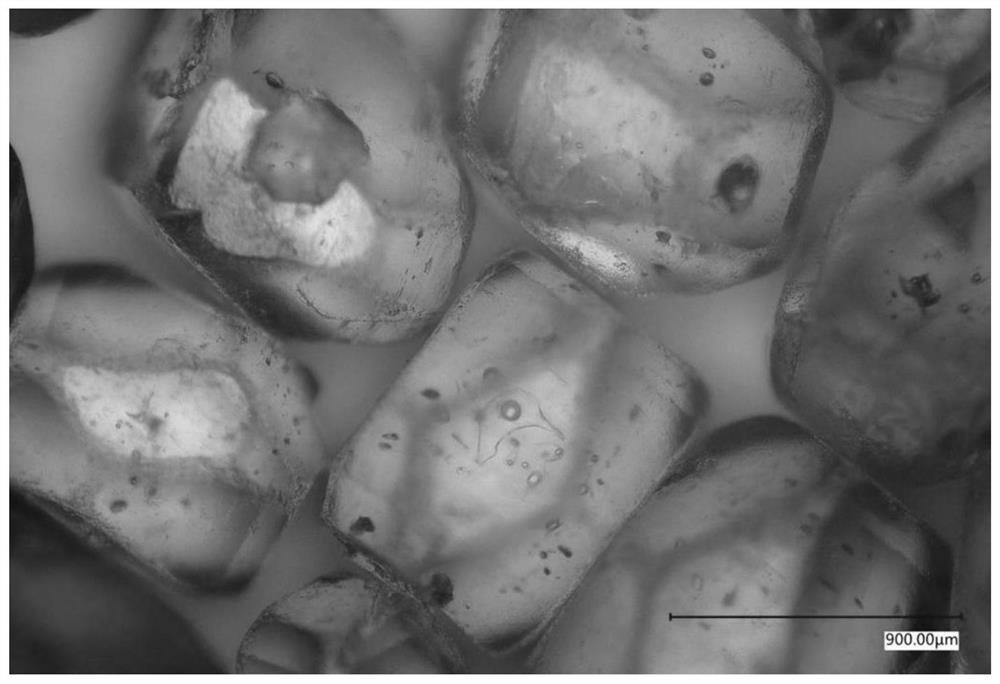

[0028]The dilute nickel sulfate solution is concentrated to near saturation by means of multi-effect evaporation, and the specific gravity of the nearly saturated nickel sulfate solution is maintained at 1.495-1.525kg / m3, and then enters the crystallizer draft tube at a flow rate of 32-40m3 / h; Under the action of the nickel sulfate solution, the nickel sulfate solution moves upward in the guide tube, and moves downward outside the guide tube, and the nearly saturated nickel sulfate solution directly contacts with the nickel sulfate solution at a temperature of 40-50°C in the crystallizer for heat and mass transfer. In the crystallization process, the nickel sulfate clear liquid in the crystallizer enters the fine crystal eliminator through the outlet of the clear liquid outer circulation, and heat exchange is performed in the fine grain eliminator to he...

Embodiment 3

[0030] A kind of crystallization technique of continuous method production nickel sulfate, specifically comprises the steps:

[0031] The dilute nickel sulfate solution is concentrated to near saturation by means of multi-effect evaporation, and the specific gravity of the nearly saturated nickel sulfate solution is maintained at 1.455-1.485kg / m3, and then enters the crystallizer draft tube at a flow rate of 32-40m3 / h; Under the action of the nickel sulfate solution, the nickel sulfate solution moves upward in the guide tube, and moves downward outside the guide tube, and the nearly saturated nickel sulfate solution directly contacts with the nickel sulfate solution at a temperature of 55-65°C in the crystallizer for heat and mass transfer. In the crystallization process, the nickel sulfate clear liquid in the crystallizer enters the fine crystal eliminator through the outlet of the clear liquid outer circulation, and heat exchange is performed in the fine grain eliminator to h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com