Method of mixing AB glue through isobaric temperature regulation

A technology of temperature adjustment and equal pressure, which is applied in the direction of mixers, fluid mixers, chemical instruments and methods, etc., can solve problems such as poor bonding effect, difficult to control the ratio stably, and affect product quality, so as to achieve convenient use and high flow rate. always the same effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment discloses a method of mixing AB glue with constant pressure and temperature adjustment. The commercially available AB glue is purchased from Dongguan Yantai Adhesive Co., Ltd., and the production model is TA-860. Clean the moisture, dust, oil stains, rust spots and other dirt on the surface of the bonded object, and keep it clean, dry and smooth. When using, mix and stir components A and B according to the ratio of 1:1, and apply it on the surface of the adherend. When bonding, it can be rotated and matched as much as possible. The glue is initially solidified in 3-6 minutes, and the usable strength can be reached in 1 hour. 24 hours to reach optimal strength. Can be used at -60°C to +110°C. (do not mix a large amount of glue at one time)

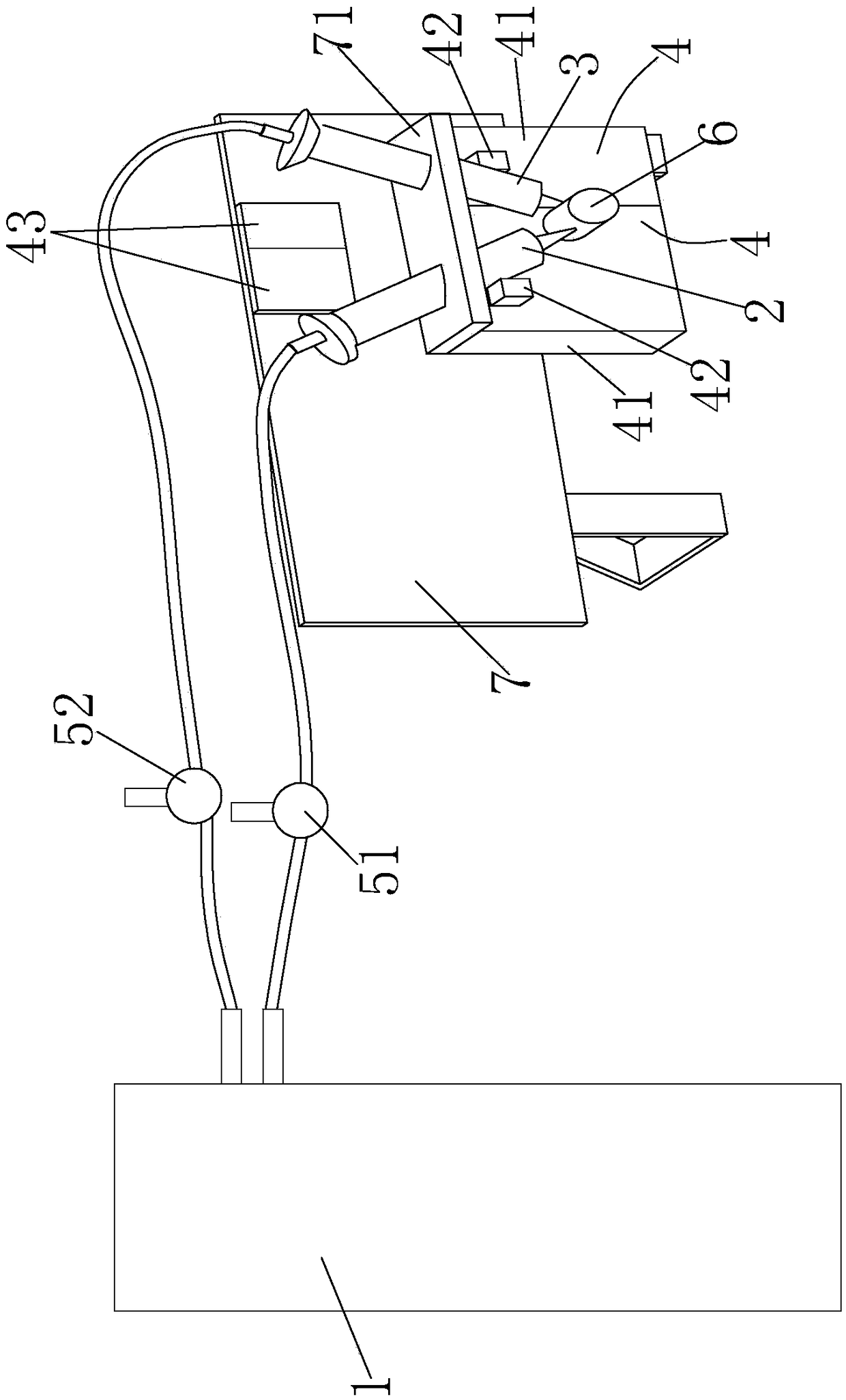

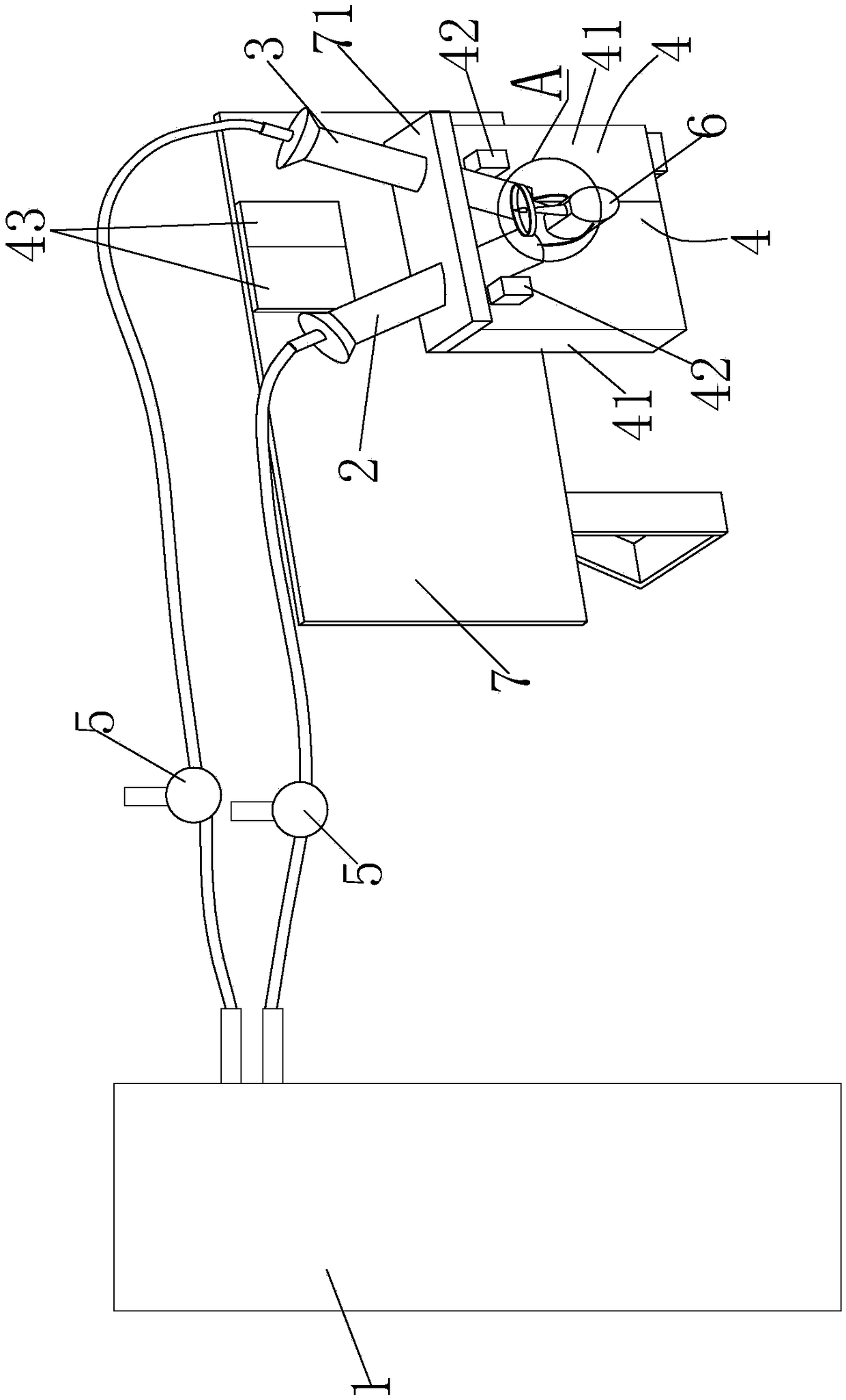

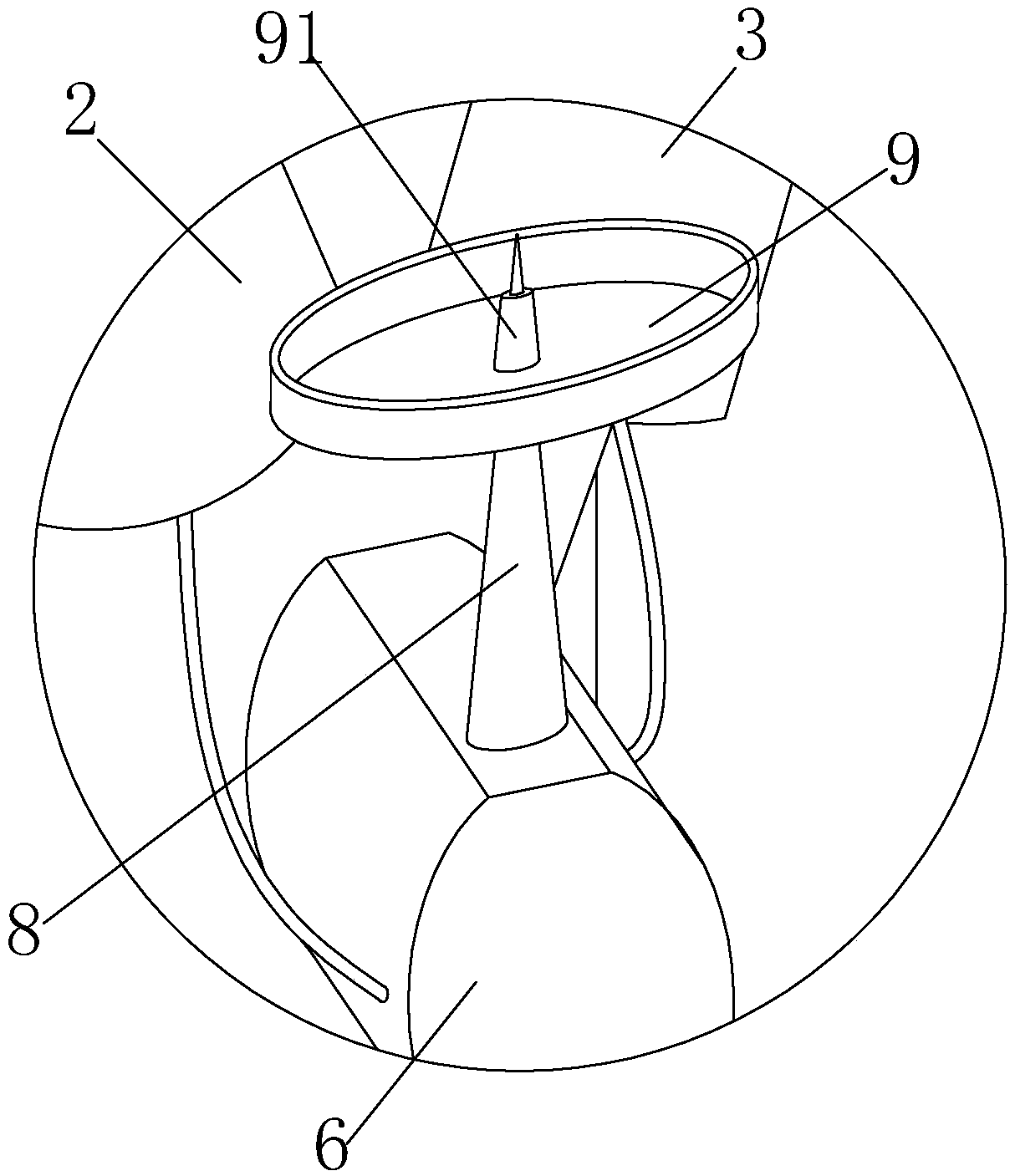

[0033] A method of isobaric and temperature-adjusting mixed AB glue, used to realize the device of the present embodiment such as Figures 1 to 4 shown, including the following steps:

[0034] A. Provide an A rubb...

Embodiment 2

[0049] The main difference between this embodiment and embodiment 1 is that the constant heating temperature of A glue is T 1 , the constant heating temperature of glue B is T 2, the air pressure in the A rubber hose 2 and the B rubber hose 3 is P, and the flow rate V of the A glue and the B glue 1 And the flow rate V of AB glue 2 , see Table 1 for details.

Embodiment 3

[0051] The main difference between this embodiment and embodiment 1 is that the constant heating temperature of A glue is T 1 , the constant heating temperature of glue B is T 2 , the air pressure in the A rubber hose 2 and the B rubber hose 3 is P, and the flow rate V of the A glue and the B glue 1 And the flow rate V of AB glue 2 , see Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com