Patents

Literature

168results about How to "Improve yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quaternized modified amino silicone oil softener and preparation and application thereof

InactiveCN101914206AAvoid yellowingImprove hydrophilicityVegetal fibresTetramethylammonium hydroxideDisiloxane

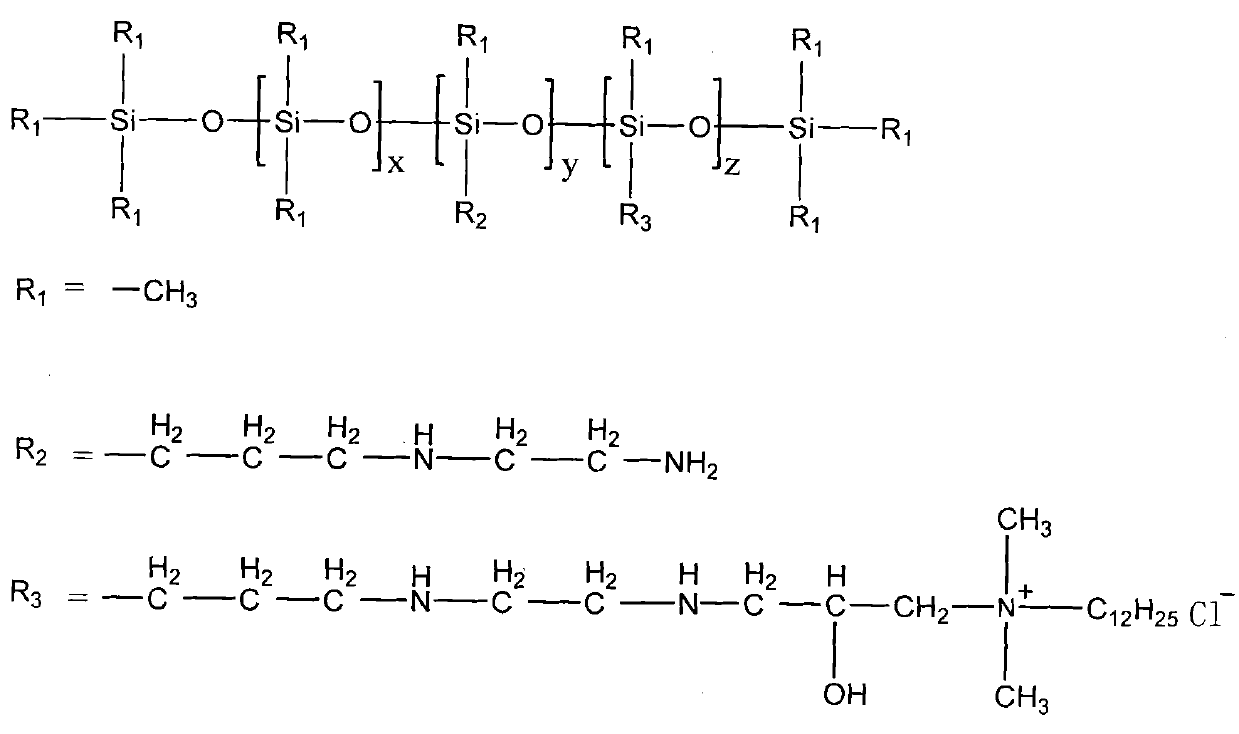

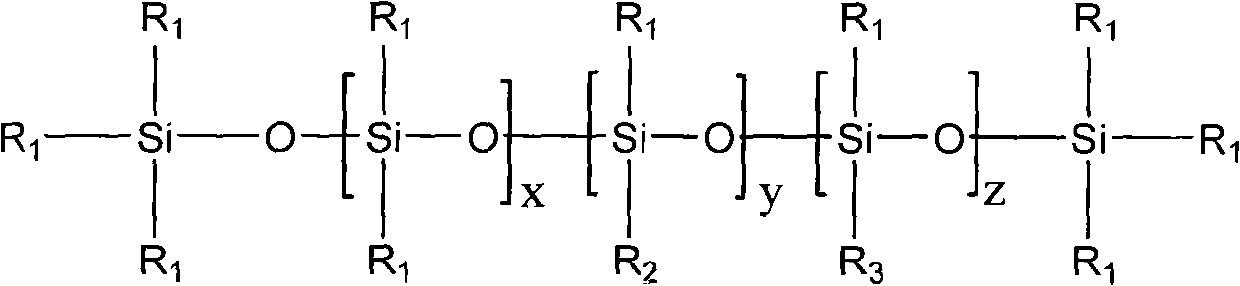

The invention relates to a quaternized modified amino silicone oil softener and preparation and application thereof. The softener comprises the following general formula in the specification. The preparation comprises the following steps of: (1) adding octamethylcy-clotetrasiloxane into a container, adding a coupling agent N-beta-(aminoethyl)-gamma-aminopropyl methyl dimethoxysilane into the container dropwise, adding a tetramethyl ammonium hydroxide catalyst and subsequently a capping agent hexamethyl disiloxane into the container, and then performing reduced pressure distillation to obtain amino silicon oil; (2) dissolving the amino silicon oil into a solvent, adding the mixture into epichlorohydrin, stirring and heating to react under the protection of nitrogen, and removing the solvent by steaming to obtain an intermediate product; and (3) uniformly mixing N,N-dimethyl-decanamide and the solvent to obtain a mixture, stirring with heating, adding the intermediate product dropwise into the mixture under the protection of nitrogen, performing a thermostatic reaction, and removing the solvent by steaming to obtain the product. The softener of the invention has high hydrophilicity and high stability; fabric processed by the softener has excellent soft handfeel, high hydrophilicity, low yellowing, antibacterial property and the like; and the softener is simple to prepare and is suitable for industrial production.

Owner:DONGHUA UNIV

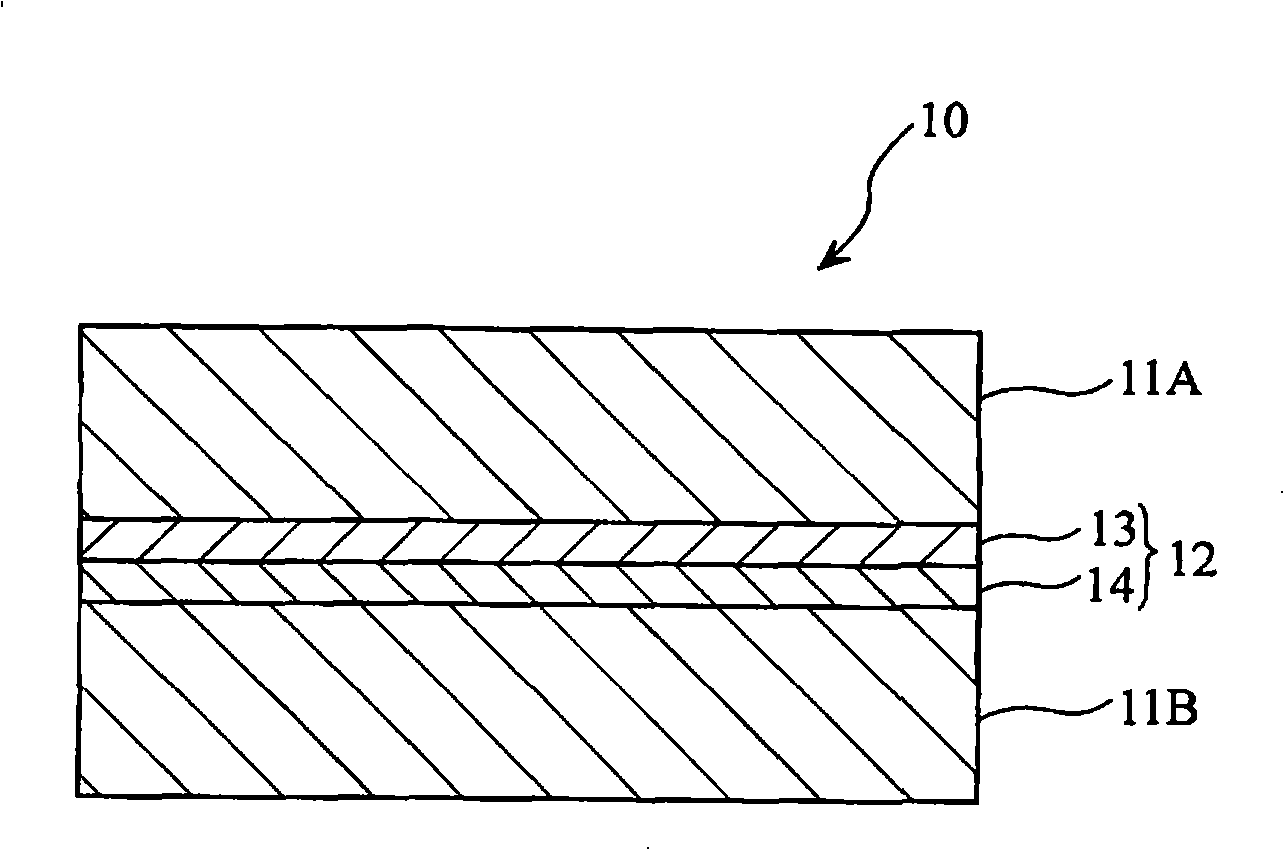

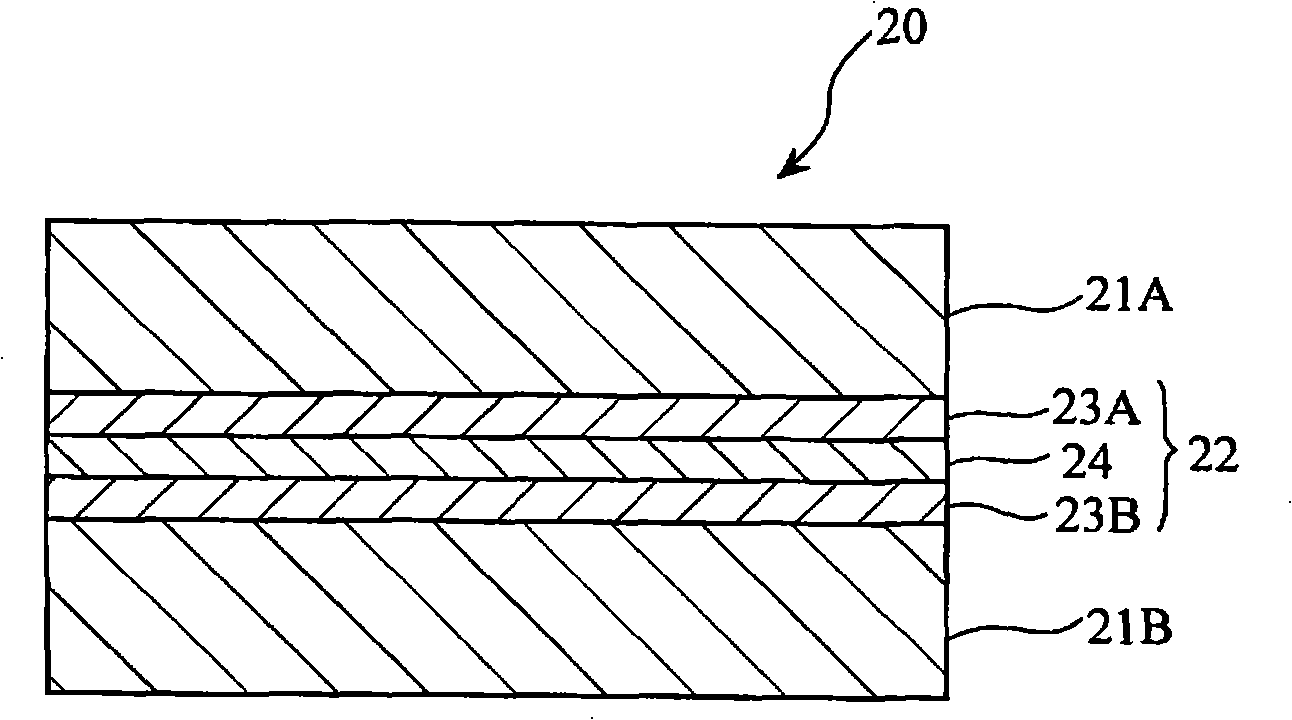

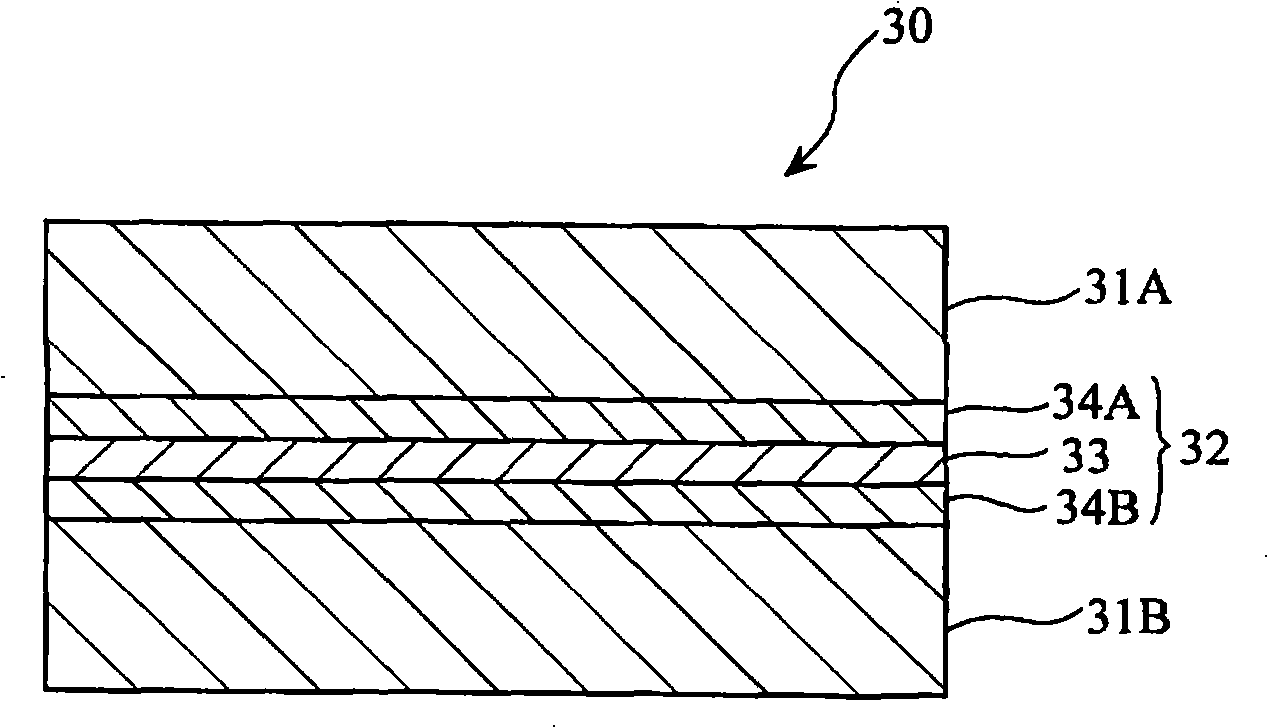

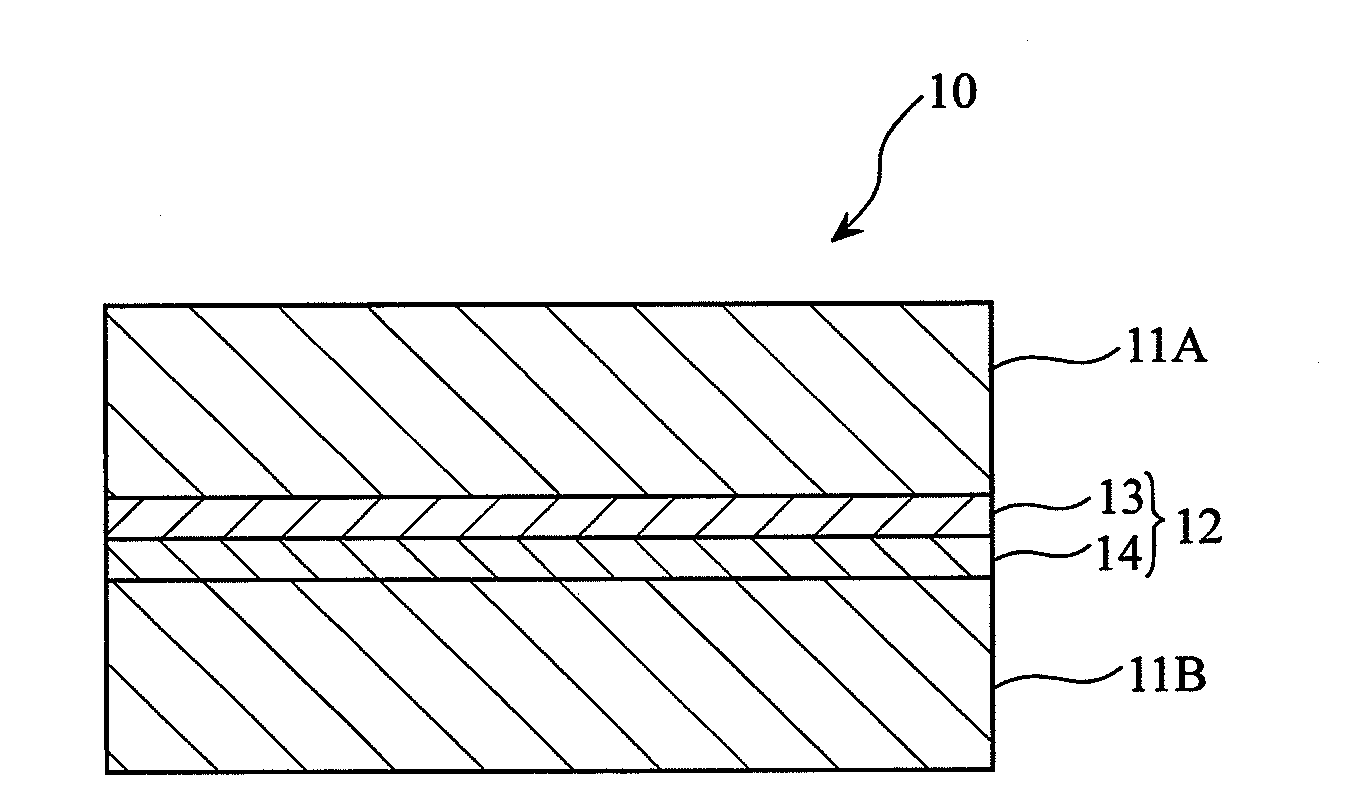

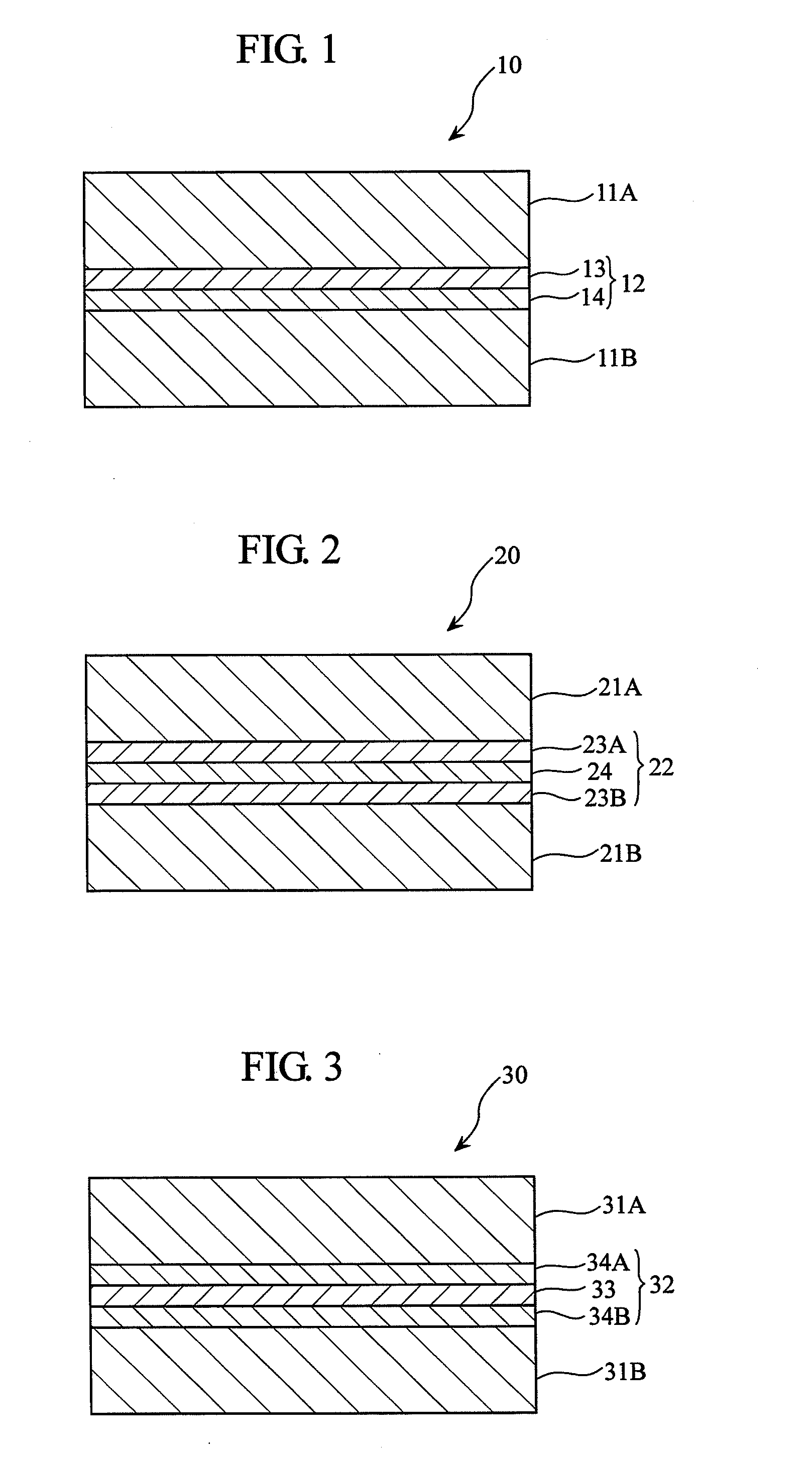

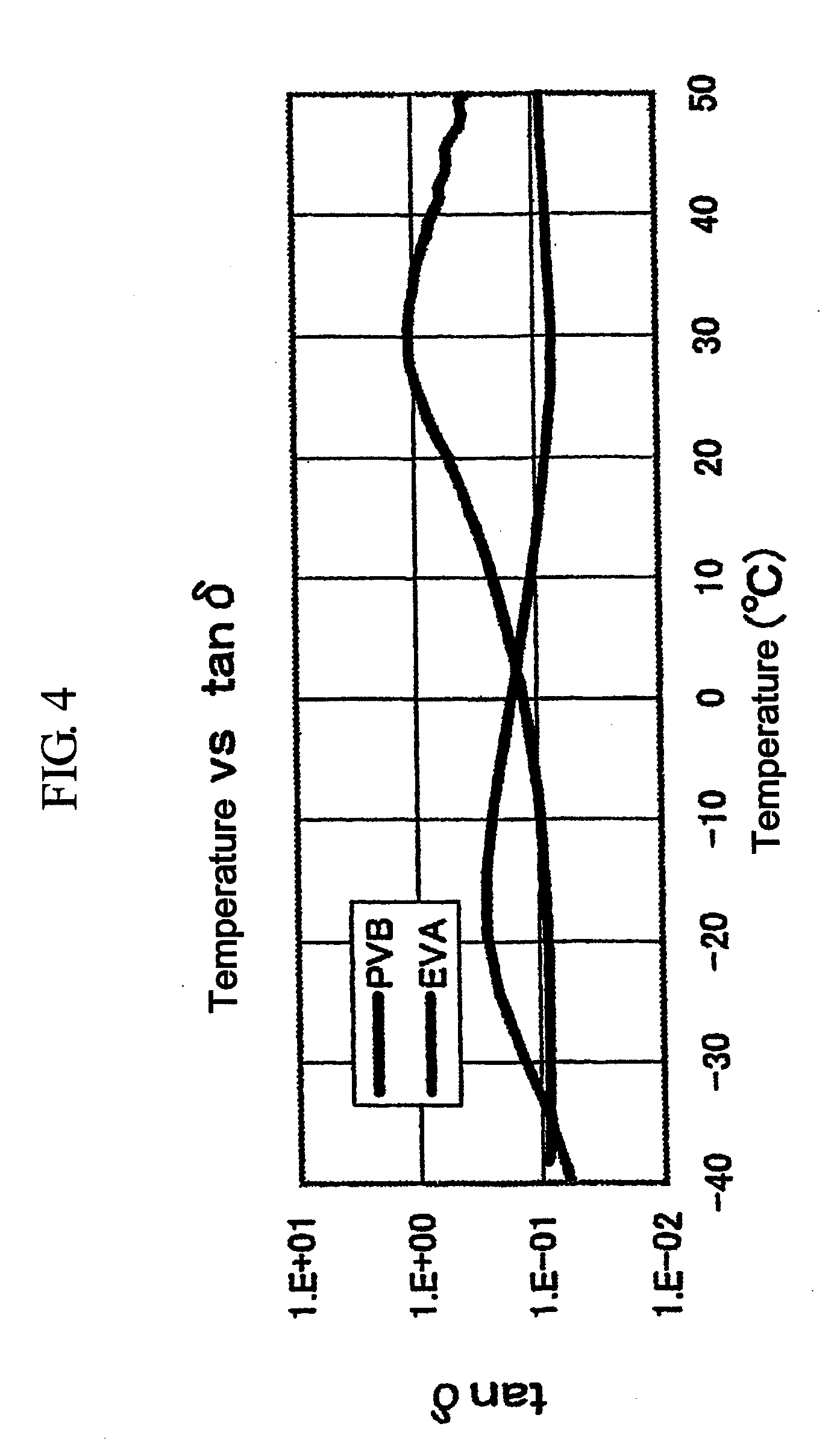

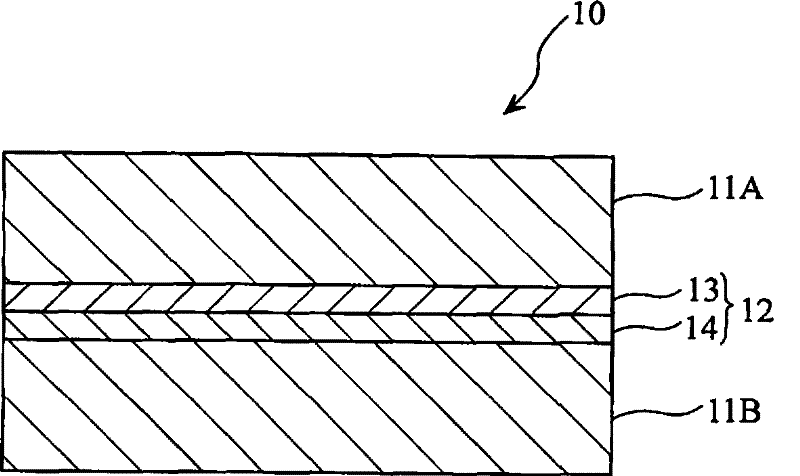

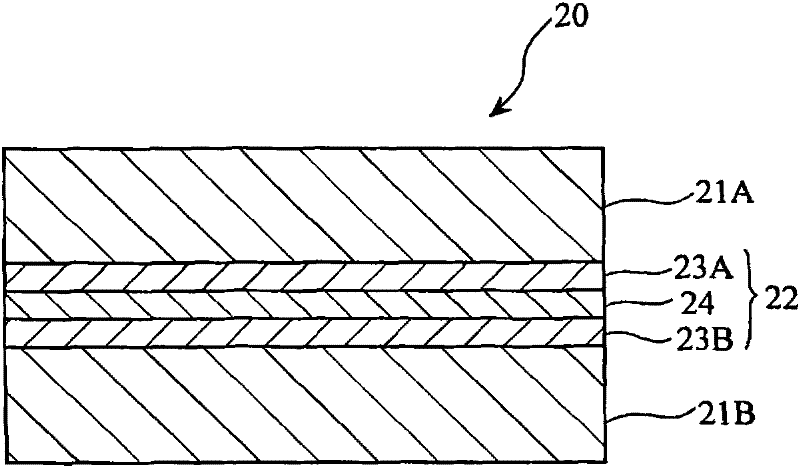

Intermediate film for laminated glass, laminated glass using the same, and method for production of the laminated glass

InactiveCN101410341AHigh transparencyGood penetration resistanceSynthetic resin layered productsGlass/slag layered productsWeather resistanceUv absorber

The object of the present invention is to provide an intermediate film for a laminated glass having excellent transparency, adhesion, impact resistance and penetration resistance as well as excellent light resistance and weather resistance, and scarcely turning yellow in a heating treatment during its preparation. An intermediate film for a laminated glass comprising a laminate consisting of a layer (PVB layer) of a composition comprising polyvinyl butyral and a layer (EVA layer) of a composition comprising ethylene / vinyl acetate copolymer containing an organic peroxide, wherein the composition comprising polyvinyl butyral contains a benzophenone compound as an ultraviolet absorber; a laminated glass; and a process for the preparation of the same.

Owner:BRIDGESTONE CORP

Intermediate film for laminated glass, laminated glass using the intermediate film, and process for the preparation of the laminated glass

InactiveUS20100233453A1High transparencyImprove penetration resistanceSynthetic resin layered productsLaminationPolyvinyl butyralWeather resistance

[Problem to be Solved]The object of the present invention is to provide an intermediate film for a laminated glass having excellent transparency, adhesion, impact resistance and penetration resistance as well as excellent light resistance and weather resistance, and scarcely turning yellow in a heating treatment during its preparation.[Means for Solving Problem]An intermediate film for a laminated glass comprising a laminate consisting of a layer (PVB layer) of a composition comprising polyvinyl butyral and a layer (EVA layer) of a composition comprising ethylene / vinyl acetate copolymer containing an organic peroxide, wherein the composition comprising polyvinyl butyral contains a benzophenone compound as an ultraviolet absorber; a laminated glass; and a process for the preparation of the same.

Owner:BRIDGESTONE CORP

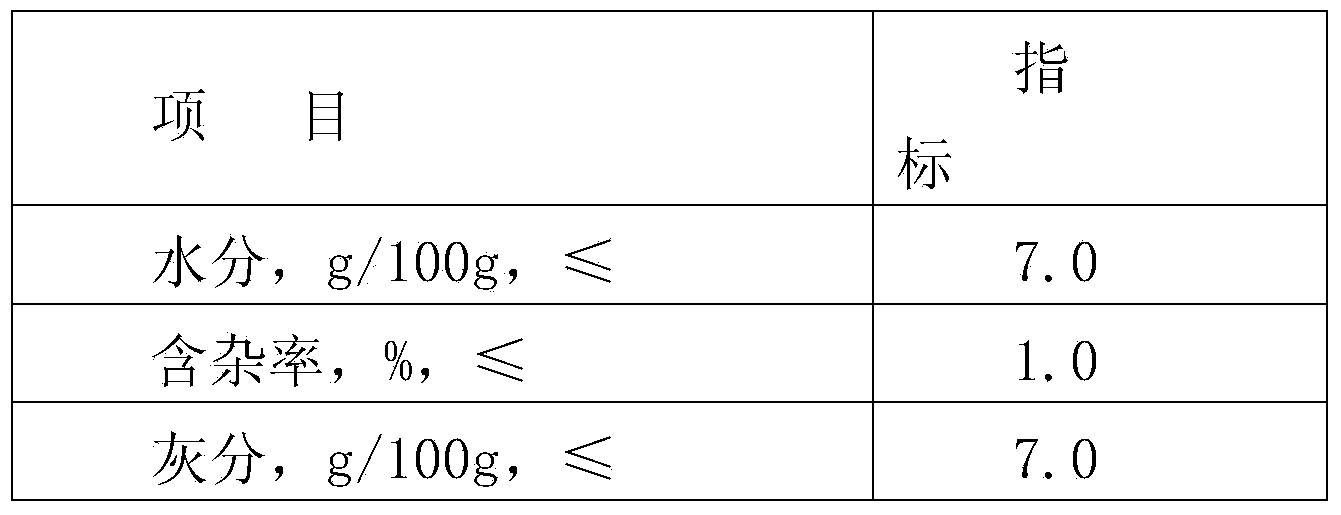

Method for preparing emulsion composite antioxidant

The invention relates to a method for preparing an emulsion composite antioxidant, which comprises the following steps: feeding materials in a mass part ratio that DLTDP:(Wingstay.L:1076) is equal to 4:2, wherein Wingstay.L:1076 is equal to 0.5-1.5:1.5-0.5, based on the total weight of a raw material A, namely 100 percent, adding 3 to 8 percent of stearic acid and 0.5 to 1.5 percent of C4 to C18 straight chain alcohol or branched chain alcohol or the mixture of the straight chain alcohol and the branched chain alcohol, heating to perform reaction with stirring at the speed of 300 to 400rpm, adding KOH when the temperature reaches 70 to 90 DEG C, and controlling the pH value to be between 7 and 11; adding deionized water to make the solid content of the whole system be 53 to 56 percent, adding 30 percent of deionized water, adjusting the stirring speed to be between 180 and 250rpm, adding the rest of deionized water, and naturally cooling to room temperature. By adopting the method, an aqueous emulsion of the composite antioxidant of which the solid content is 53 to 56 percent, the pH is 7 to 11 and the viscosity is less than or equal to 1,200mpa.s (BROOKFIELD PV-11+Pro) is synthesized, and has high oxidation resistance, low viscosity and good dispersity.

Owner:天津力生化工有限公司

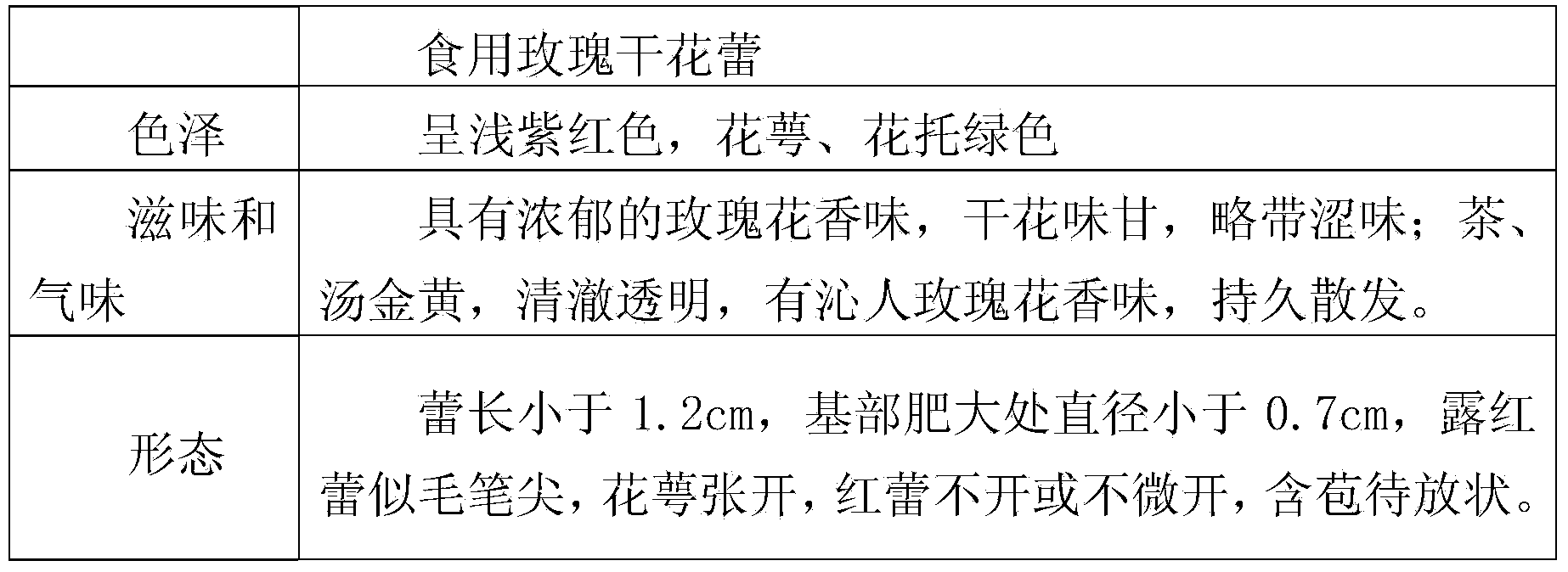

Comprehensive method for drying rosebuds through microwave vacuum and heated air circulation

ActiveCN103504448AEasy to useHumidity removalFood thermal treatmentFloral handlingEngineeringMicrowave

The invention discloses a method for drying rosebuds and belongs to the technical field of rosebud drying through microwave vacuum and heated air circulation. A comprehensive method for drying rosebuds through microwave vacuum and heated air circulation comprises the following steps: (1) feeding the rosebuds to a heated air circulation dryer for drying; (2) feeding the rosebuds obtained in the step (1) to a microwave vacuum drier for drying. According to the comprehensive method, the temperatures are low during the drying processes, the drying time is short, the product quality is high, meanwhile energy consumption is lowered, and the production efficiency is improved. Besides, microwaves can effectively sterilize the rosebuds and kill worms' eggs attached to the rosebuds, and are beneficial for prolonging product shelf lives.

Owner:银谷芳香科技有限公司

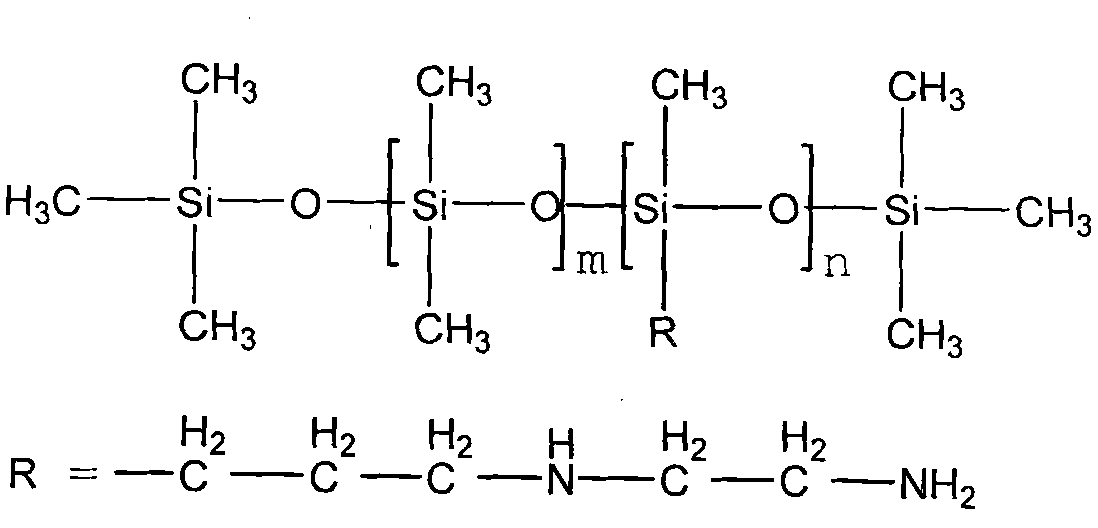

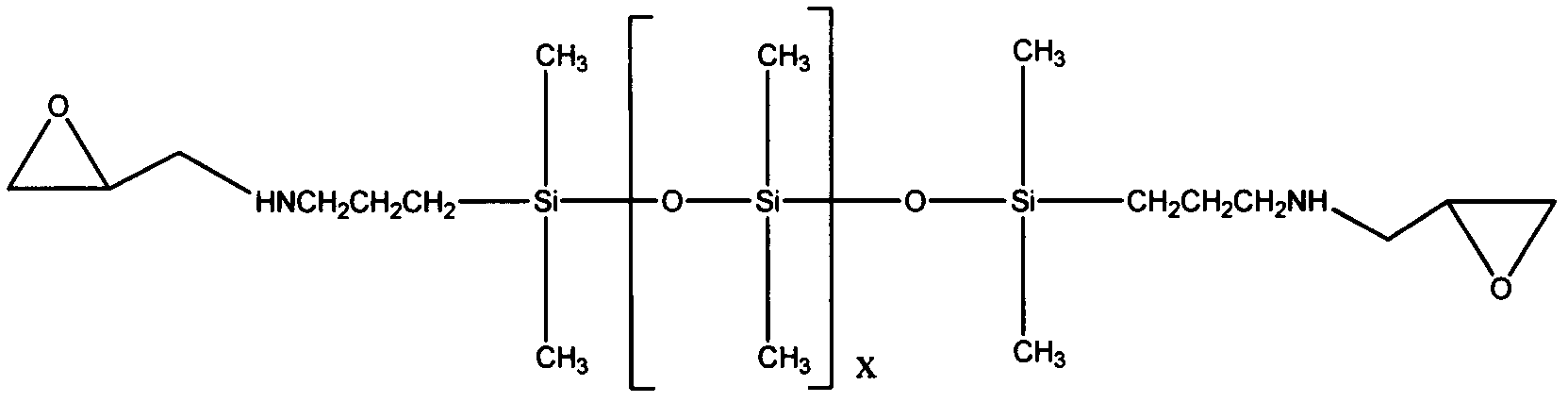

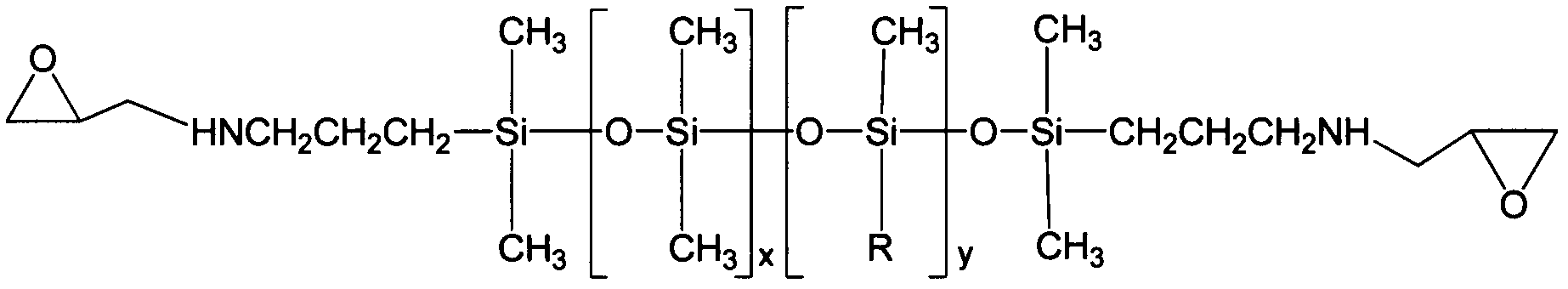

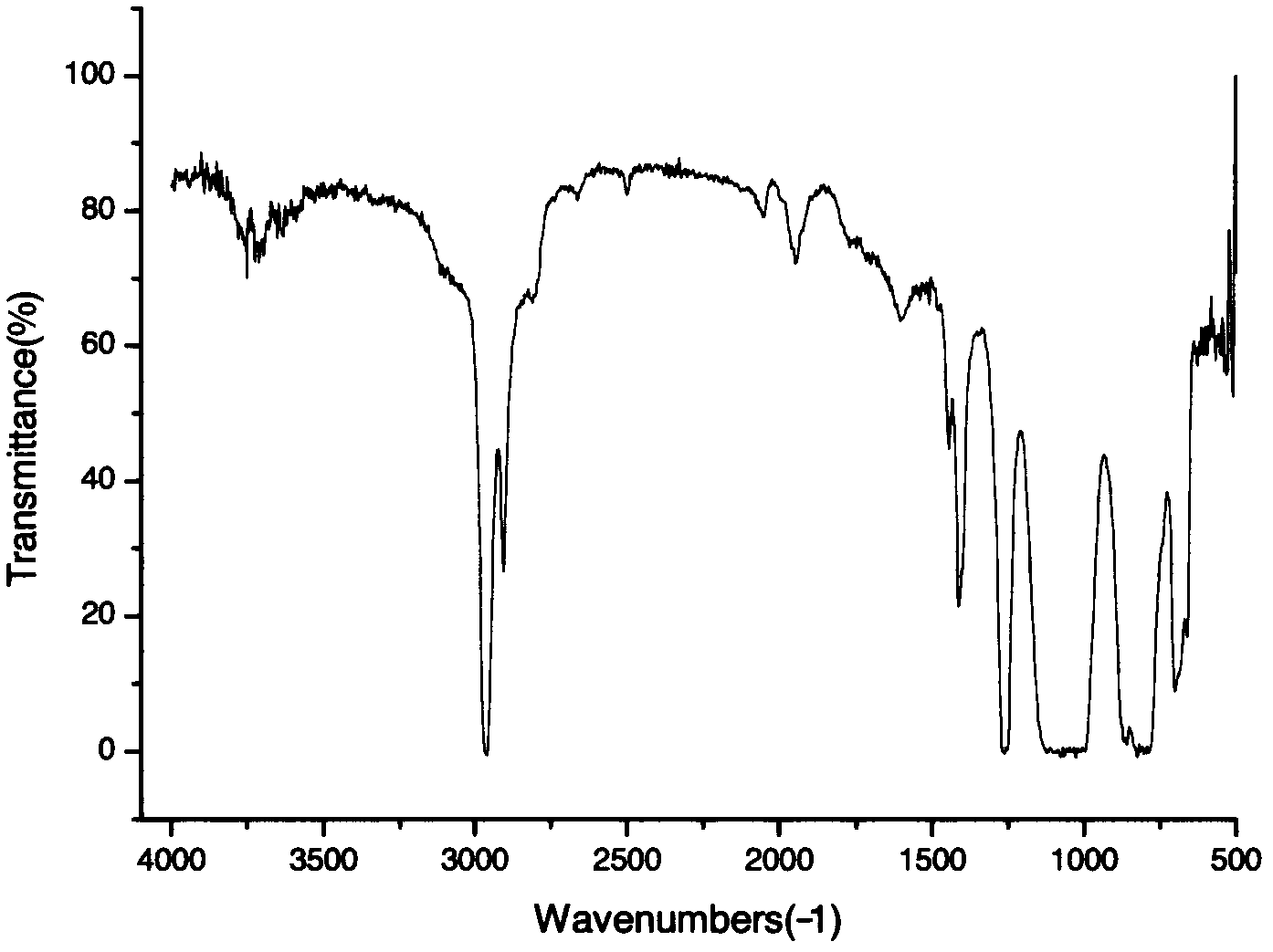

Preparation method of long-chain alkane and epoxy co-modified amino-terminated silicone oil

The invention relates to a preparation method of long-chain alkane and epoxy co-modified amino-terminated silicone oil. The structural formula of the long-chain alkane and epoxy co-modified amino-terminated silicone oil is represented by figure 1 in the specification. The preparation method of the modified silicone oil comprises the following steps: adding octamethylcyclotetrasiloxane, a long-chain alkane coupling agent and an amino-terminated silane end capping agent according to certain proportions, uniformly stirring, heating to 60-80DEG C, adding an alkaline catalyst, reacting under stirring for 0.5-1.5h, controlling the reaction temperature in a range of 90-140DEG C, carrying out a temperature maintenance reaction for a period of time, carrying out reduced pressure distillation to obtain a low-boiling-point substance which is modified silicone oil, dissolving the modified silicone oil in a solvent, reacting with epichlorohydrin at 50-100DEG C for 2-7h, and carrying out reduced pressure evaporation to remove the solvent in order to obtain the long-chain alkane and epoxy co-modified amino-terminated silicone oil. The long-chain alkane and epoxy co-modified amino-terminated silicone oil is mixed with an emulsifier and an acid, are added with deionized water in batch, and undergoes pH adjustment by the acid to about 7 in order to obtain an emulsion of the long-chain alkane and epoxy co-modified amino-terminated silicone oil. The long-chain alkane and epoxy co-modified amino-terminated silicone oil prepared in the invention overcomes the yellow disadvantage of amino silicone oil, and has the advantages of good lubrication property, good hydrophobicity and good fluffy feeling when the long-chain alkane and epoxy co-modified amino-terminated silicone oil is used for texture finishing.

Owner:JIANGNAN UNIV

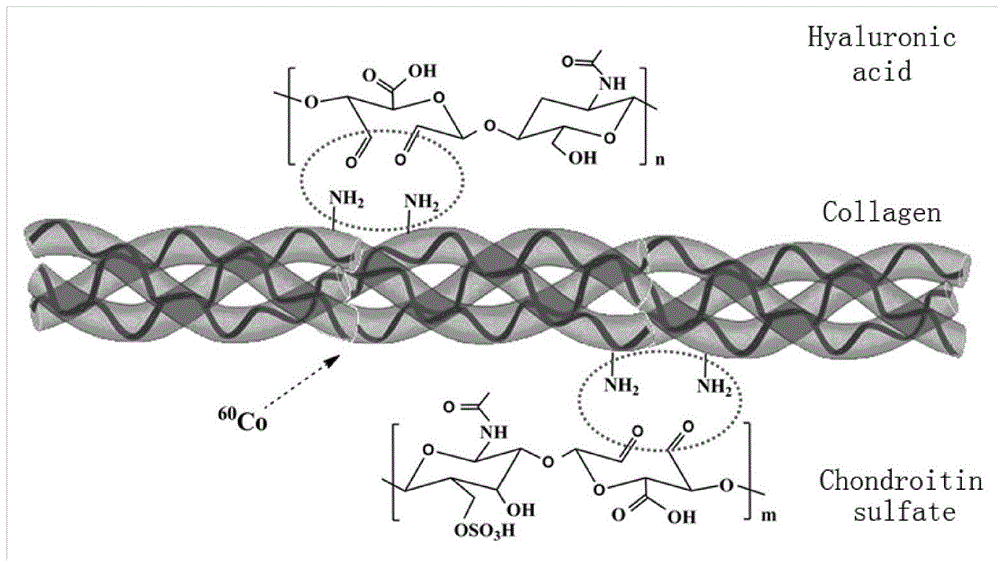

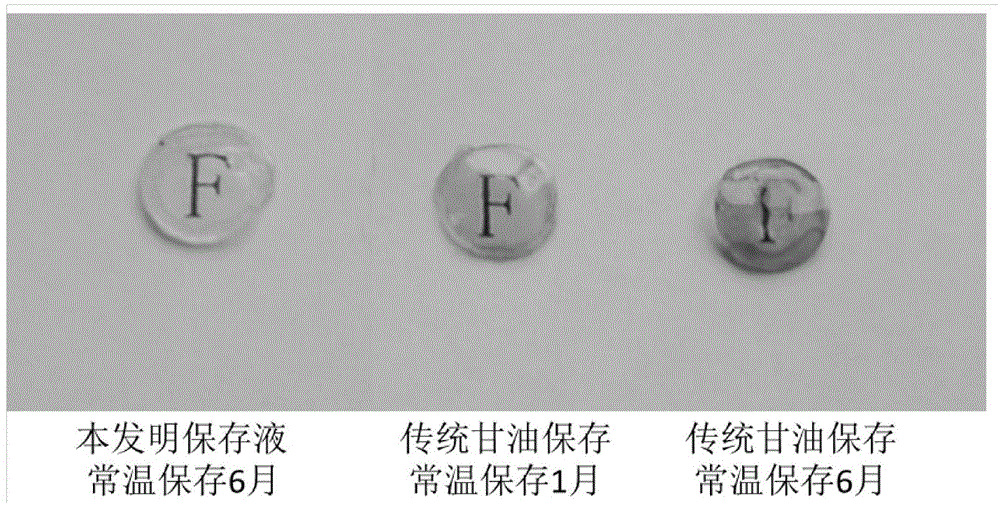

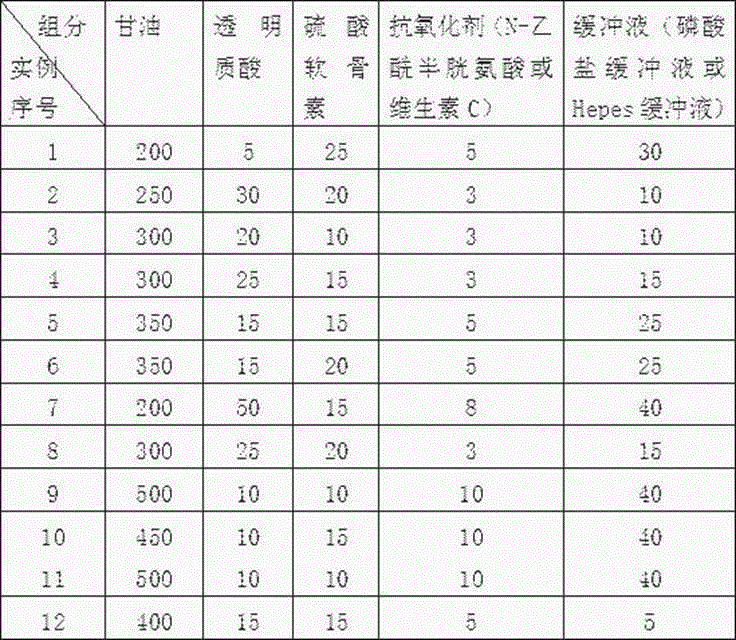

Lamellar corneal preserving solution

ActiveCN104094925AAvoid damageEfficient removalSenses disorderHydroxy compound active ingredientsOphthalmologyGlycerol

The invention discloses a lamellar corneal preserving solution which is characterized by comprising components as follows: glycerol with the concentration of 200-500g / L, hyaluronic acid with the concentration of 5-50g / L, chondroitin sulfate with the concentration of 10-25 g / L, antioxidant with the concentration of 1-10g / L and buffer salt solution with the concentration of 10-40 mmol / L and PH of 6.0-8.0. The lamellar corneal preserving solution is suitable for storage of a lamellar corneal material, can maintain original collagenous fiber structure and transparency of the cornea, and prevents the collagenous fiber of the cornea from being damaged due to irradiation sterilization treatment.

Owner:GUANGZHOU YOUDEQING BIOTECH

Fully-polished glazed ceramic tile and preparation method thereof

The invention discloses a fully-polished glazed ceramic tile and a preparation method thereof. The fully-polished glazed ceramic tile comprises a green body layer, a ground glaze layer, a printed layer and a fully-polished glazed layer from bottom to top; the fully-polished glazed layer is prepared from the following raw materials in parts by mass: 5-20 parts of potassium feldspar, 30-60 parts ofalbite, 4-15 parts of calcite, 6-12 parts of kaolin, 0-6 parts of calcined zinc oxide, 2-10 parts of quartz, 2-8 parts of calcined soil, 2-10 parts of zirconium silicate, 0.1-0.3 part of methyl and 0.3-0.6 part of a tripolymer. The preparation method has the advantages that an all-raw-meal formula is adopted, so that the production cost is lowered; the problem of yellowing caused after combinationof light-colored or white fully-polished glaze and ground glaze is solved, so that the product grade is improved; the whiteness of the light-colored or white fully-polished glaze is improved, and thecompetitiveness of the light-colored or white fully-polished glaze in the market is improved. Furthermore, the preparation method also improves the wear-resistant level and corrosion resistance of the product.

Owner:CHONGQING WONDERFUL CERAMICS CO LTD +1

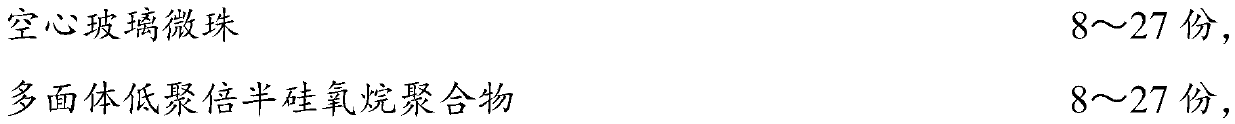

Intensive curing barn baking process for airflow alternate-operation flue-cured tobacco

ActiveCN102068028AReduce the plane temperature differenceReduce vertical temperature differenceTobacco preparationTobacco treatmentEcological environmentOperation mode

The invention relates to an intensive curing barn baking process for airflow alternate-operation flue-cured tobacco, belonging to the technical field of flue-cured tobacco preparation process. The intensive curing barn baking process for airflow alternate-operation flue-cured tobacco is the improvement on the existing intensive curing barn baking process. The improvement point is characterized inthat interval time for the alternate operation of airflow rise and airflow descending is as follows: in the low-temperature humidifying and yellowing stage: two airflow operation modes are provided, the time interval is 0.50 hour, and alternation is carried out once; in the stable-temperature dehumidifying and withering stage: two airflow operation modes are provided, the time interval is 0.50 hour, and alternation is carried out once; in the ventilating, dewatering and leaf-drying stage: two airflow operation modes are provided, the time interval is 0.75 hour, and alternation is carried out once; and in the temperature and moisture controlling and tendon drying stage: two airflow operation modes are provided, the time interval is 1.00 hour, and alternation is carried out once. Other baking operation technologies of the process are same with the conventional baking process. The intensive curing barn baking process can obviously improve the baking property of the tobacco loading chamber of the intensive curing barn, improve tobacco leaf baking quality, and improve the safety for baking the tobacco leaf. The intensive curing barn baking process is suitable for intensive baking underdifferent ecological environment conditions in the tobacco area in China.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

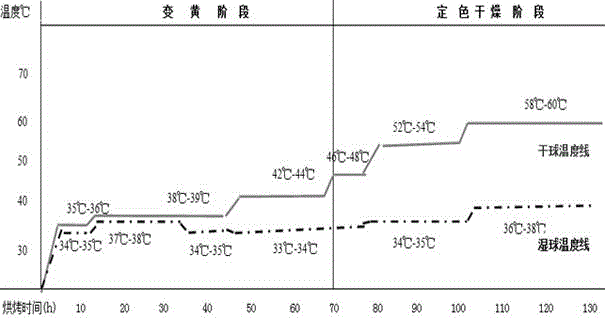

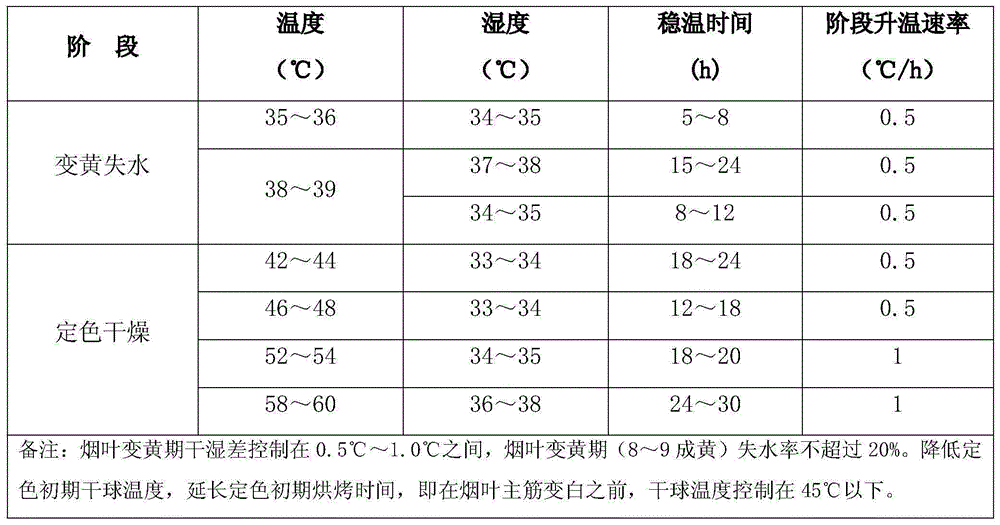

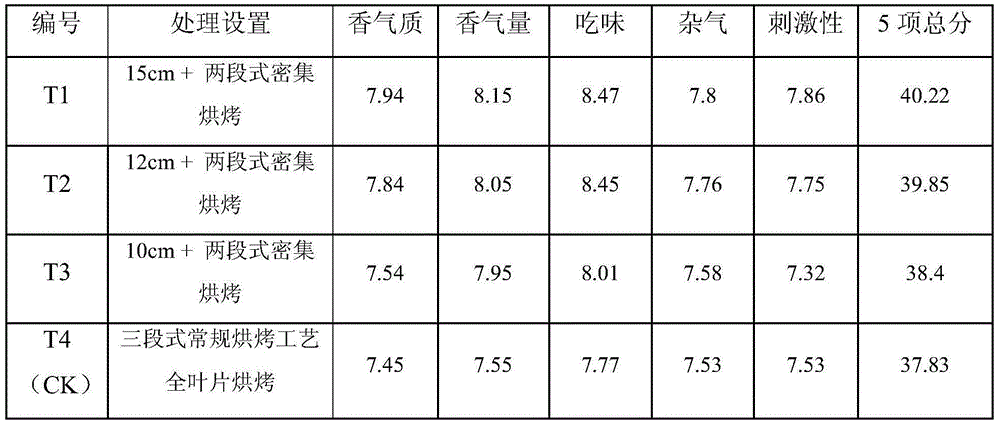

Two-stage type bulk curing process for flue-cured tobaccos

InactiveCN105105308AProcess OptimizationGood for yellowing and color fixingTobacco preparationFlueChemistry

The invention relates to a two-stage type bulk curing process for flue-cured tobaccos. A two-stage type curing process is adopted and comprises a yellowing stage and a color fixation and drying stage respectively; tobacco leaves are dried by using dry-bulb temperature of a color fixation later period; according to the curing process, 10-15cm of bases of the leaves are needed to be removed and then the tobacco leaves are filled and cured. The two-stage type bulk curing process for the flue-cured tobaccos has the following advantages that (1) the operability of the two-stage type curing process is stronger; (2) the process is more optimized and yellowing and color fixation of the tobacco leaves are facilitated; (3) stems are dried at low temperature, and the energy is saved; (4) the labor is saved and the cost is reduced; (5) the availability of the tobacco leaves is improved. According to the method provided by the invention, inapplicable leaf bases are treated before an agricultural curing link so that physical distribution cost and re-curing link cost are reduced and the availability of the tobacco leaves is more effectively improved.

Owner:GUIZHOU TOBACCO SCI RES INST

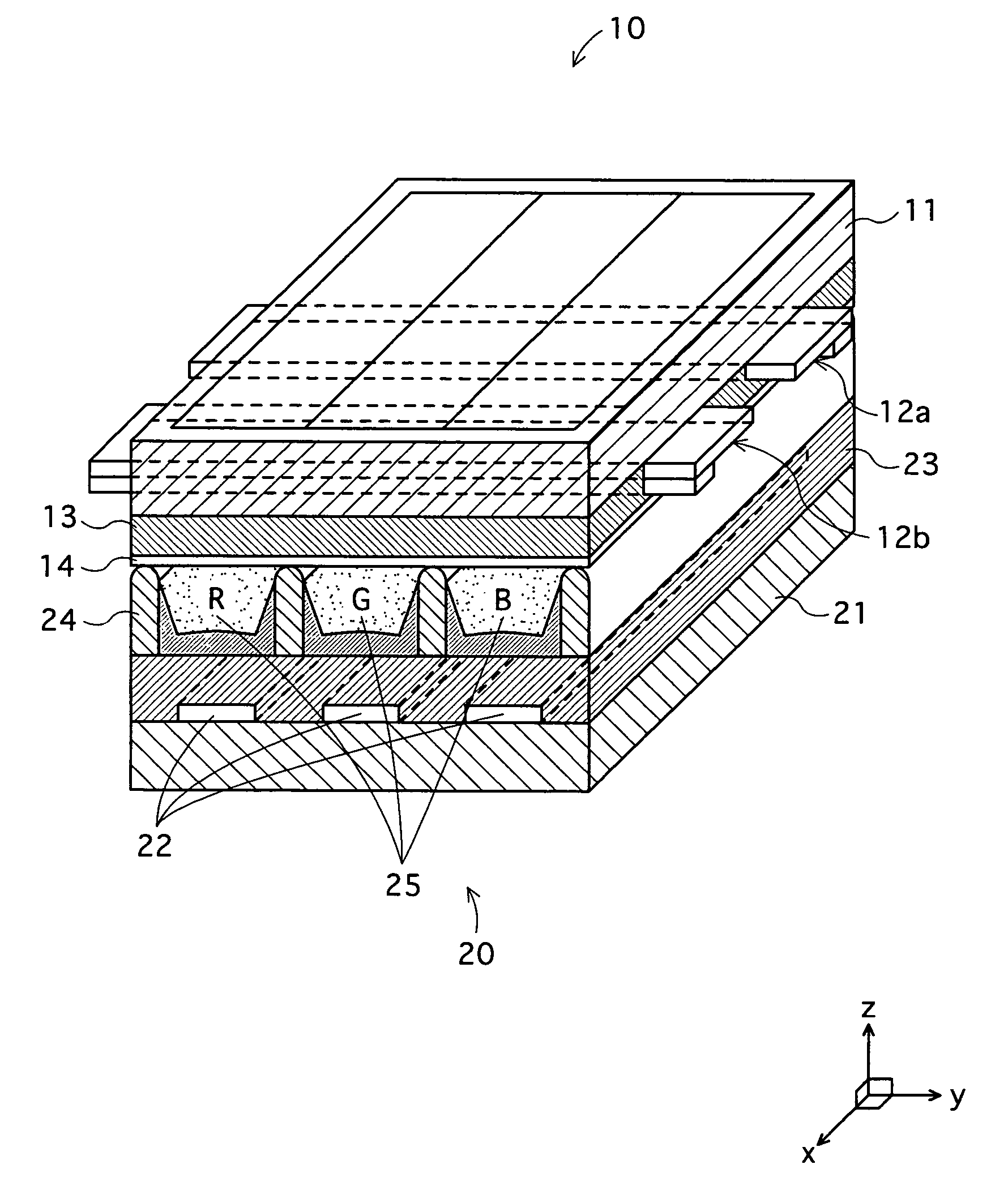

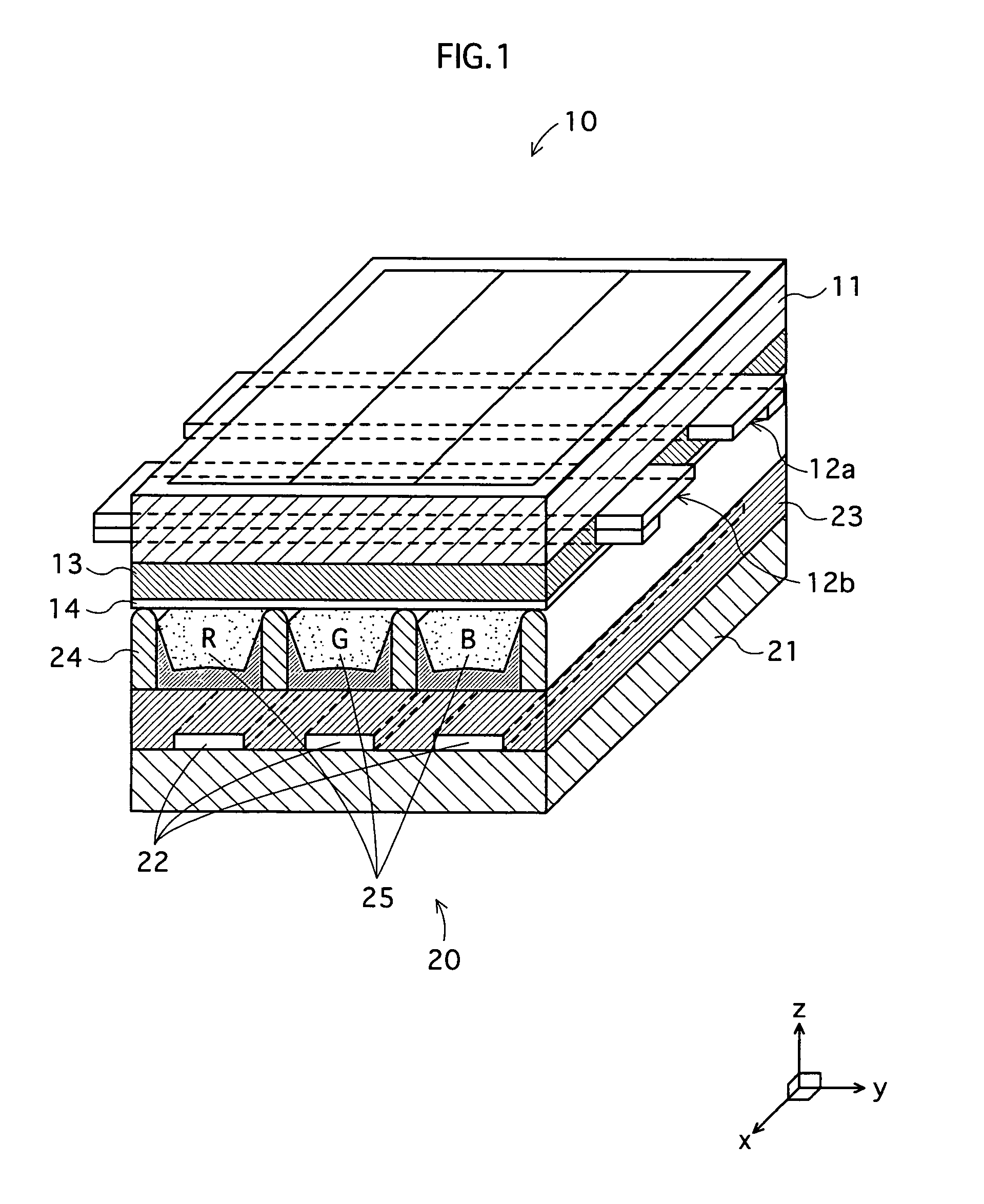

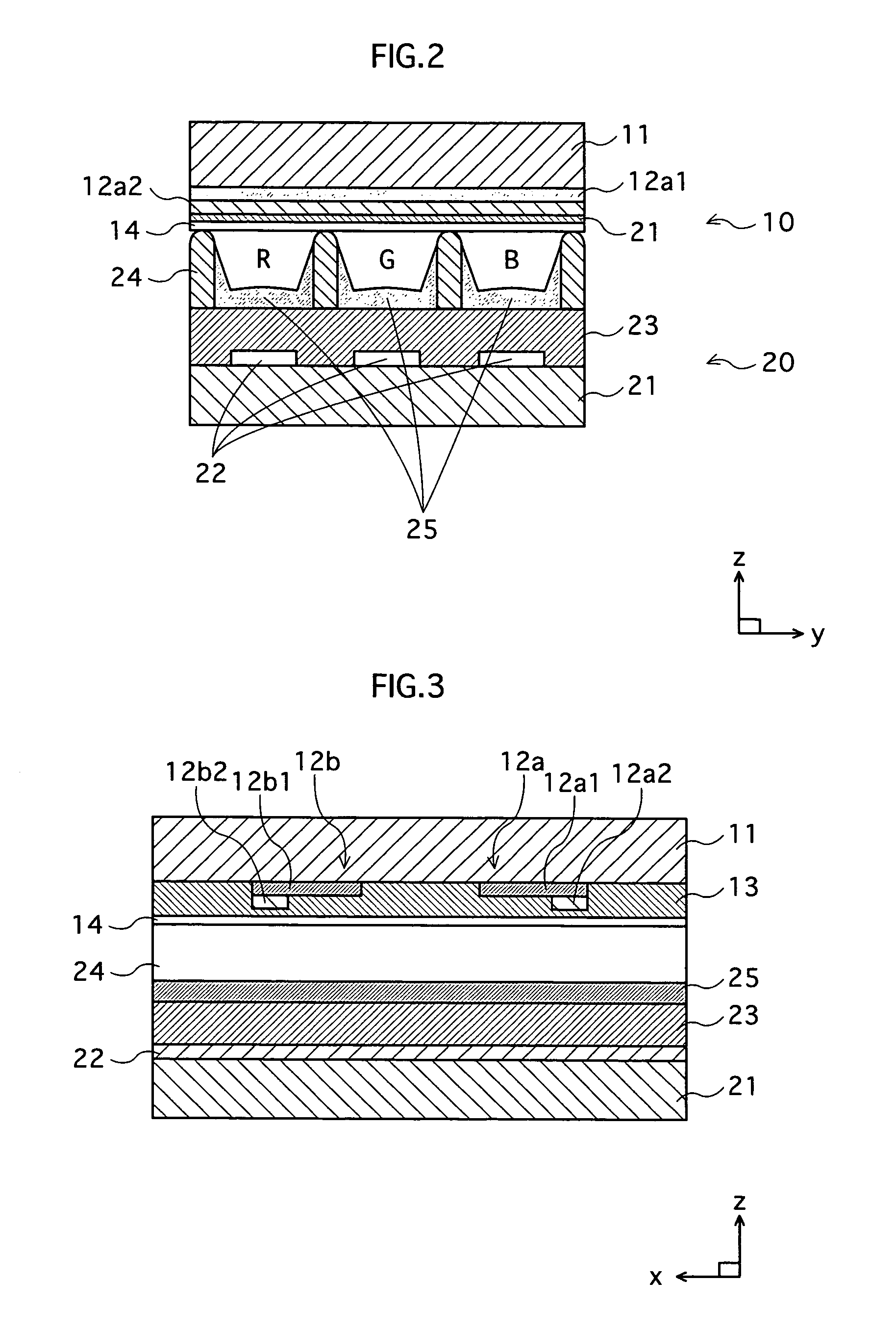

Plasma display panel and production method therefor

InactiveUS7057342B2Avoid yellowingImprove stress resistanceAddress electrodesSustain/scan electrodesOxidePlasma display

A plasma display panel capable of restricting the yellowing of a dielectric layer and the occurrence of dielectric breakdown, wherein glass constituting a dielectric layer uses glass containing a metal oxide MO2 capable of a trivalent or tetravalent-ion formation in glass. Accordingly, even when Ag is ionized from an electrode consisting essentially of Ag to diffuse to a dielectric layer, Ag does not aggregate to be formed into a colloid with an ionized state kept. Therefore, yellowing and dielectric breakdown caused by Ag turning to colloid can be restricted.

Owner:PANASONIC CORP

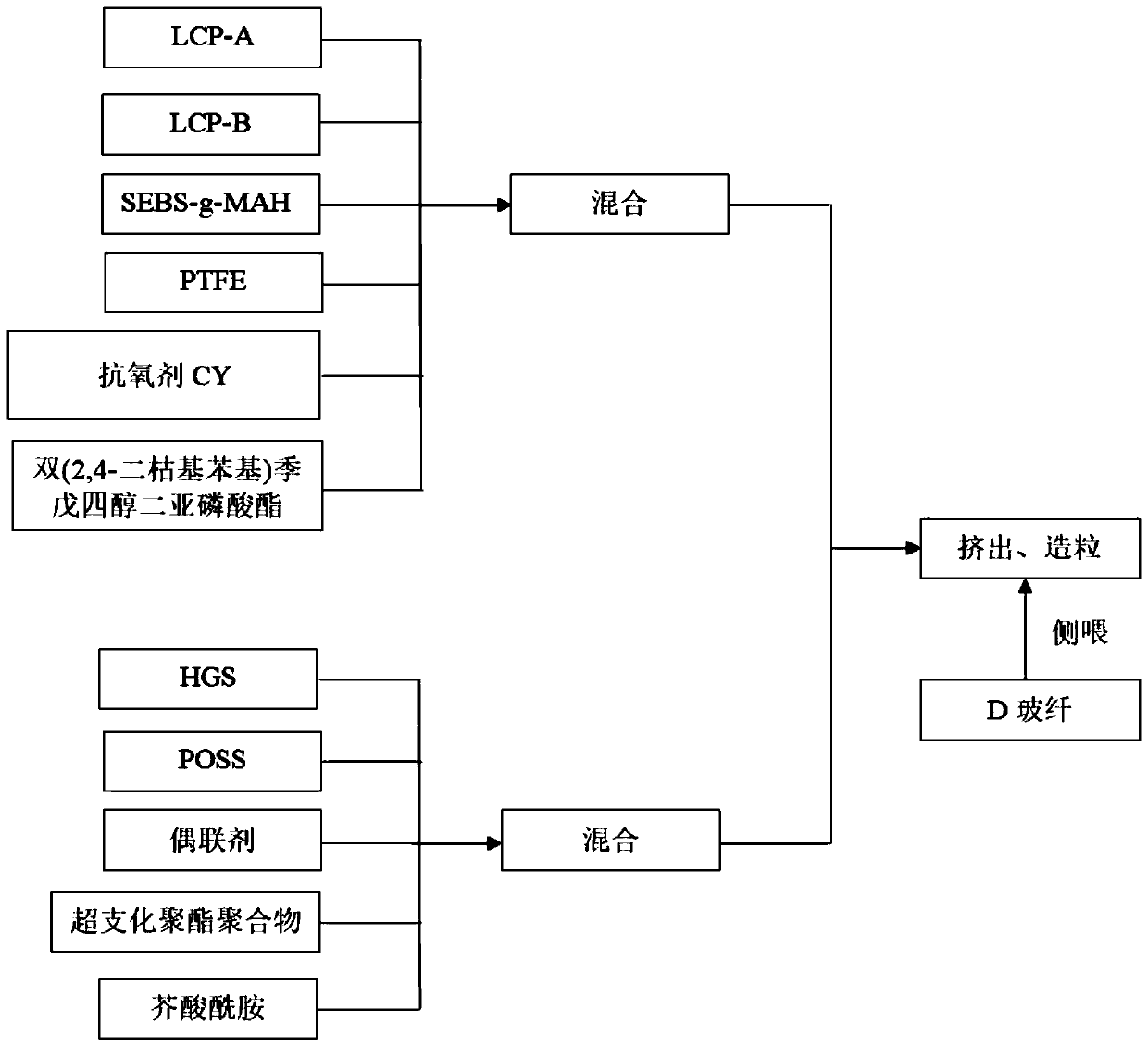

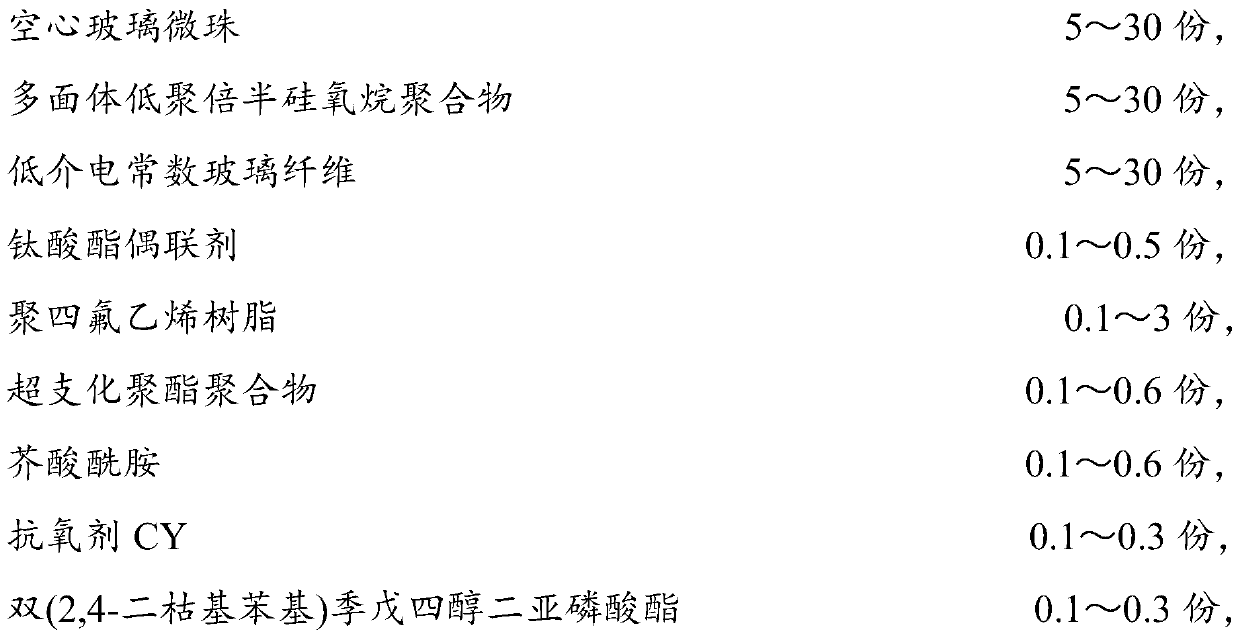

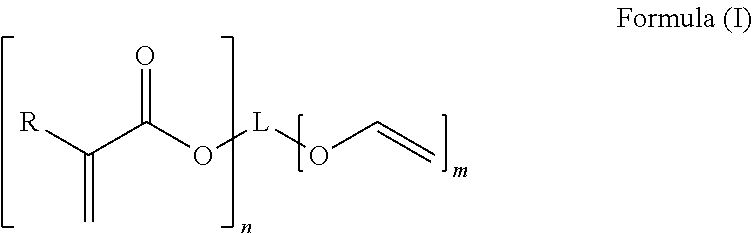

Liquid crystal polymer composition and preparation method thereof

InactiveCN111286176AImprove heat deflection temperatureEasy to processPolymer scienceRadio frequency

The invention relates to a liquid crystal polymer composition and a preparation method thereof. The liquid crystal polymer composition is prepared from the following raw materials: liquid crystal polymer A resin, liquid crystal polymer B resin, hydrogenated styrene-butadiene-styrene copolymer grafted maleic anhydride, hollow glass beads, a polyhedral oligomeric silsesquioxane polymer, low-dielectric-constant glass fibers, a titanate coupling agent, polytetrafluoroethylene resin, a hyperbranched polyester polymer, erucyl amide, an antioxidant CY, and bis(2,4-dicumyl phenyl) pentaerythritol diphosphite. The liquid crystal polymer composition has excellent mechanical properties, processability, thermal properties and low dielectric constant, and can be applied to shells, cladding and protective materials and the like of 5G base stations, micro base station systems, data communication terminals, antennas and radio frequency modules.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Roasting method of high-temperature droughty unripe tobacco leaves

ActiveCN103689782AReduce bake lossImprove roast qualityTobacco preparationIntermediate stageTobacco processor

The invention discloses a roasting method of high-temperature droughty unripe tobacco leaves. The roasting method comprises the following six steps: a yellowing early stage, a yellowing middle stage, a yellowing later stage, a color-fixing front stage, a color-fixing later stage and a stem drying stage. With the roasting method disclosed by the invention, roasting loss of high-temperature droughty unripe tobacco leaves is reduced by regulating roasting process parameters, and roasting quality of the tobacco leaves is improved. Moreover, a proportion of middle and upper grades of tobacco leaves is obviously increased, the proportion of variegated tobacco leaves is reduced, and the proportion of tobacco leaves which are greenish on middle upper parts is obviously lowered, and good effect is achieved.

Owner:LUZHOU CO LTD SICHUAN TOBACCO

Waterproof agent for fabrics and preparation method of waterproof agent

InactiveCN104611934AImprove yellowingImprove waterproof performanceFibre treatmentEpoxyPolymer science

The invention discloses a waterproof agent for fabrics. The waterproof agent comprises the following components: epoxy silicone oil modified vinyl / amino-functional silicone emulsion, carboxyl modified vinyl / amino silicon oil, amino-functional silicone emulsion, hydrogen-containing silicone emulsion and deionized water. The invention also relates to a preparation method of the waterproof agent for the fabrics; the method comprises the step of evenly mixing the epoxy silicone oil modified vinyl / amino-functional silicone emulsion, the carboxyl modified vinyl / amino silicon oil, the amino-functional silicone emulsion, the hydrogen-containing silicone emulsion and the deionized water at the mixing speed of 150-250r / min to obtain the waterproof agent for the fabrics. The waterproof agent for the fabrics is good in waterproofness, elasticity and hand feeling, has good softness, crease resistance and air permeability, and is non-toxic, odorless, free of skin irritation and harmless to the environment; furthermore, the preparation method of the waterproof agent for the fabrics is simple and easy to implement and high in safety during preparation, and does not cause environmental pollution.

Owner:SUZHOU CHENHENG WEAVING

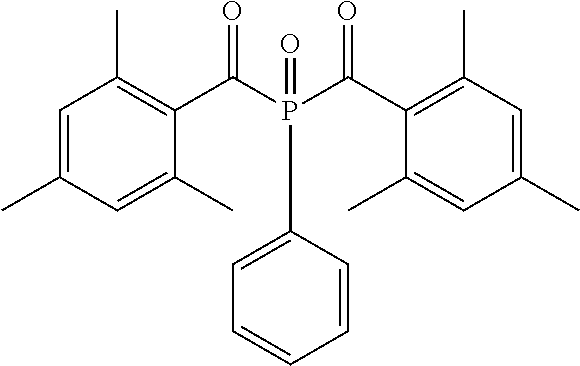

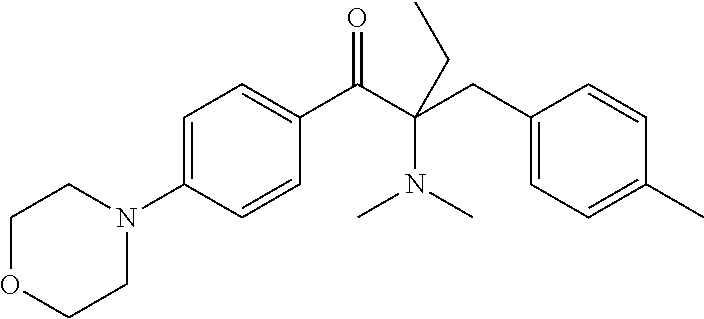

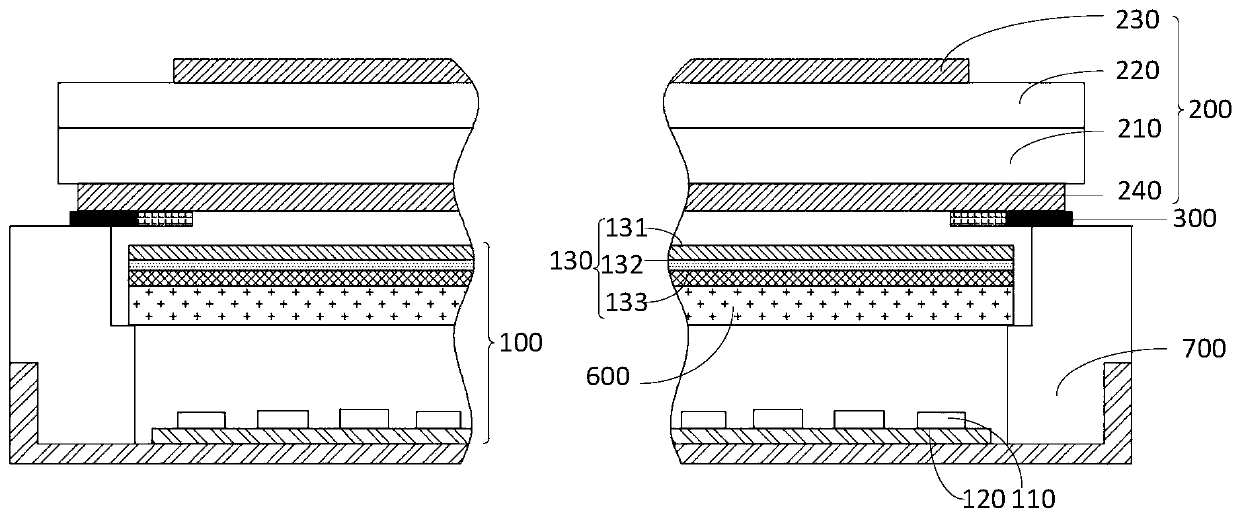

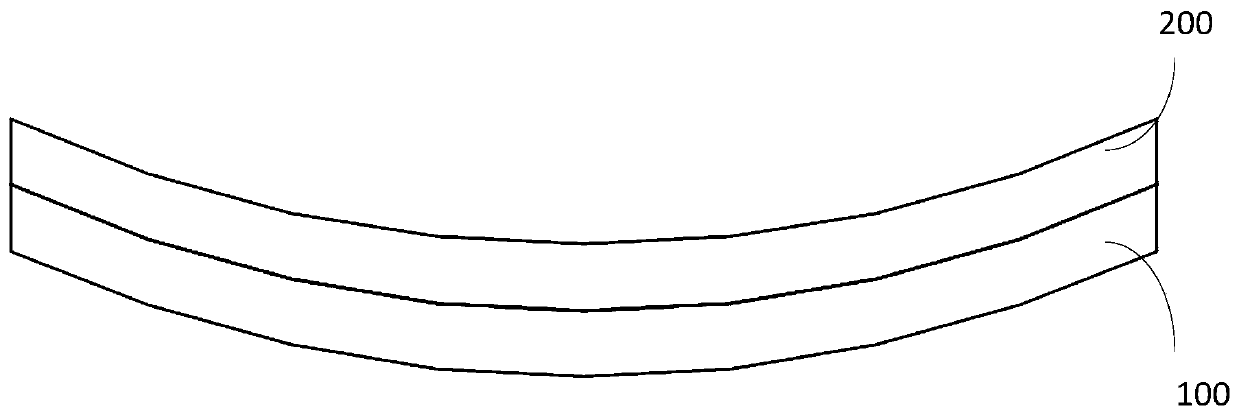

Display device

PendingCN110646981AImprove yellowingAvoid light leakageNon-linear opticsLiquid-crystal displayAdhesive belt

The invention relates to the field of optical devices, and discloses a display device. The display device comprises a backlight module, a liquid crystal display panel and an optical structure, whereinthe liquid crystal display panel comprises a display area and a non-display area; the optical structure is positioned between the liquid crystal display panel and the backlight module, and the orthographic projection of the optical structure is at least partially overlapped with the orthographic projection of the non-display area in the direction perpendicular to the liquid crystal display panel;the optical structure comprises a shading adhesive tape, and the orthographic projection of the shading adhesive tape on the liquid crystal display panel is positioned in the non-display area; the optical structure further comprises a light processing layer, and the light processing layer is used for converting light in at least a part of the backlight module, which is irradiated to the edge partof the display area of the liquid crystal display panel, into blue light; in the light propagation path, the blue light and yellowish light produce a color mixing effect, and a person can see white light when observing the display device, so that the phenomenon that the display image of the liquid crystal display panel is yellow in the prior art is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

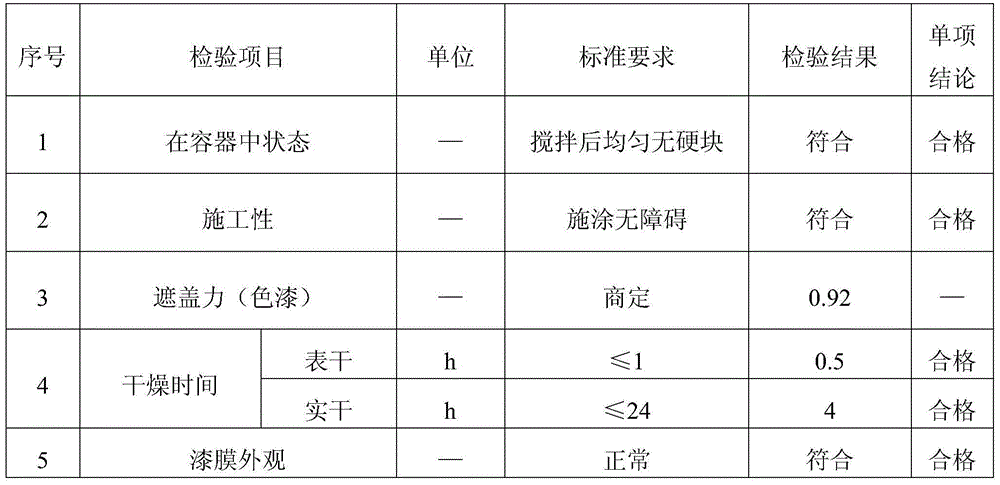

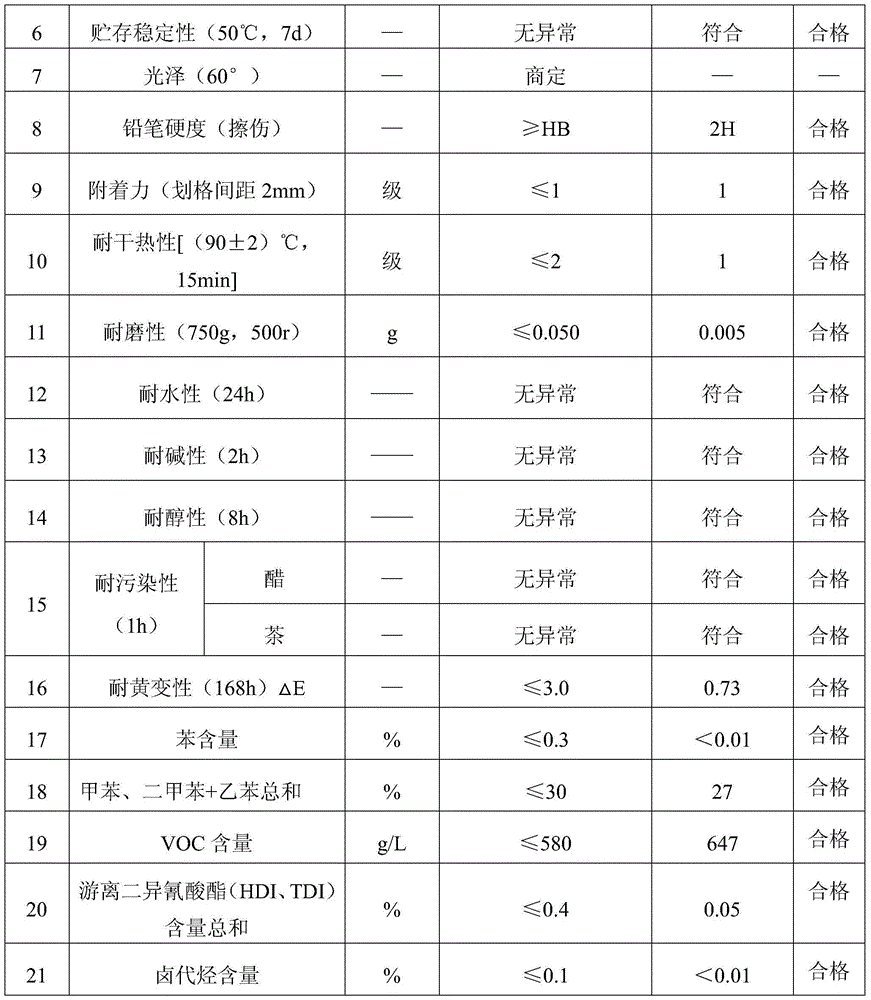

Matte black finishing paint and preparation method thereof

ActiveCN104962151AIncrease coverageStrong adhesionPolyurea/polyurethane coatingsWaxMethyl isobutyl ketone

The invention relates to coating for wooden furniture and discloses matte black finishing paint with high yellowing resistance and high hardness. The matte black finishing paint is prepared by mixing a component A, a component B and a component C according to the weight ratio of 1:0.5:0.5-0.6, wherein the component A is prepared from the following materials by weight percent: 63-70 percent of acrylic resin, 15-20 percent of black paste, 0.6-1 percent of dispersing agent, 1.5-2 percent of polyamide wax paste, 0.5-1 percent of leveling agent EFKA-3777, 0.05-0.1 percent of leveling agent EFKA-3600, 0.05-0.1 percent of defoaming agent, 1-2.5 percent of methyl isobutyl ketone, 0.3-0.5 percent of wax powder, 3.5-4.8 percent of extinction powder, 1.5-2 percent of n-butyl acetate and 4-6 percent of cellulose acetate solution; the component B is a curing-agent component; and the component C is a diluting-agent component. The invention also discloses a preparation method of the matte black finishing paint. The matte black finishing paint has high hardness and high yellowing resistance.

Owner:广东花王涂料有限公司

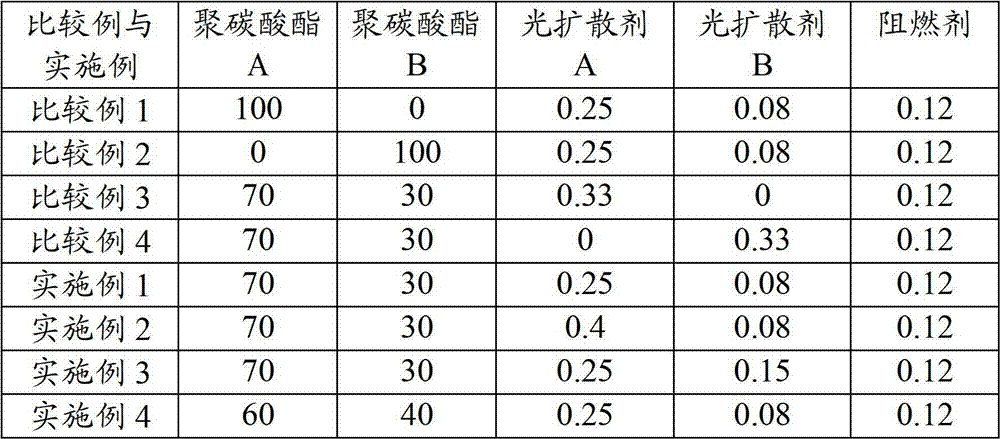

Light-diffusion environment-friendly and inflaming retarding polycarbonate based composition for LED (Light-Emitting Diode) illumination and preparation method thereof

ActiveCN102731985AImprove mechanical propertiesEasy to processPoint-like light sourceSemiconductor devices for light sourcesAntioxidantOptical transmittance

The invention discloses a light-diffusion environment-friendly and inflaming retarding polycarbonate based composition for LED (Light-Emitting Diode) illumination and a preparation method thereof. The composition is prepared from the following raw materials in parts by weight of: 50-90 parts of diphenol A aromatic polycarbonate A, 1-40 parts of diphenol A aromatic polycarbonate B, 0.005-2 parts of light dispersant A, 0.05-1 part of light dispersant B, 0.01-2 parts of fire retardant, 0-2 parts of antioxidant A, 0-2 parts of antioxidant B and 0-2 parts of antioxidant C. The composition disclosed by the invention has excellent mechanical property and machining performance, has higher light transmittance and haze, and has a good inflaming retarding effect.

Owner:SINOPLAST NEW MATERIAL

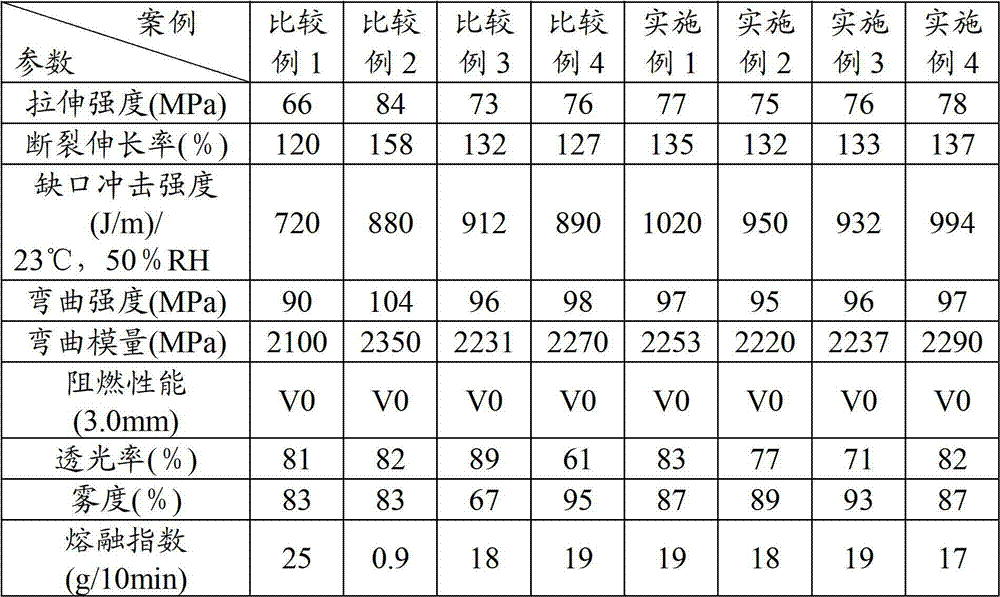

Liquid crystal display

InactiveUS20160195768A1Improve yellowish phenomenonImprove yellowingLiquid crystal compositionsNon-linear opticsLiquid-crystal displayLiquid crystal

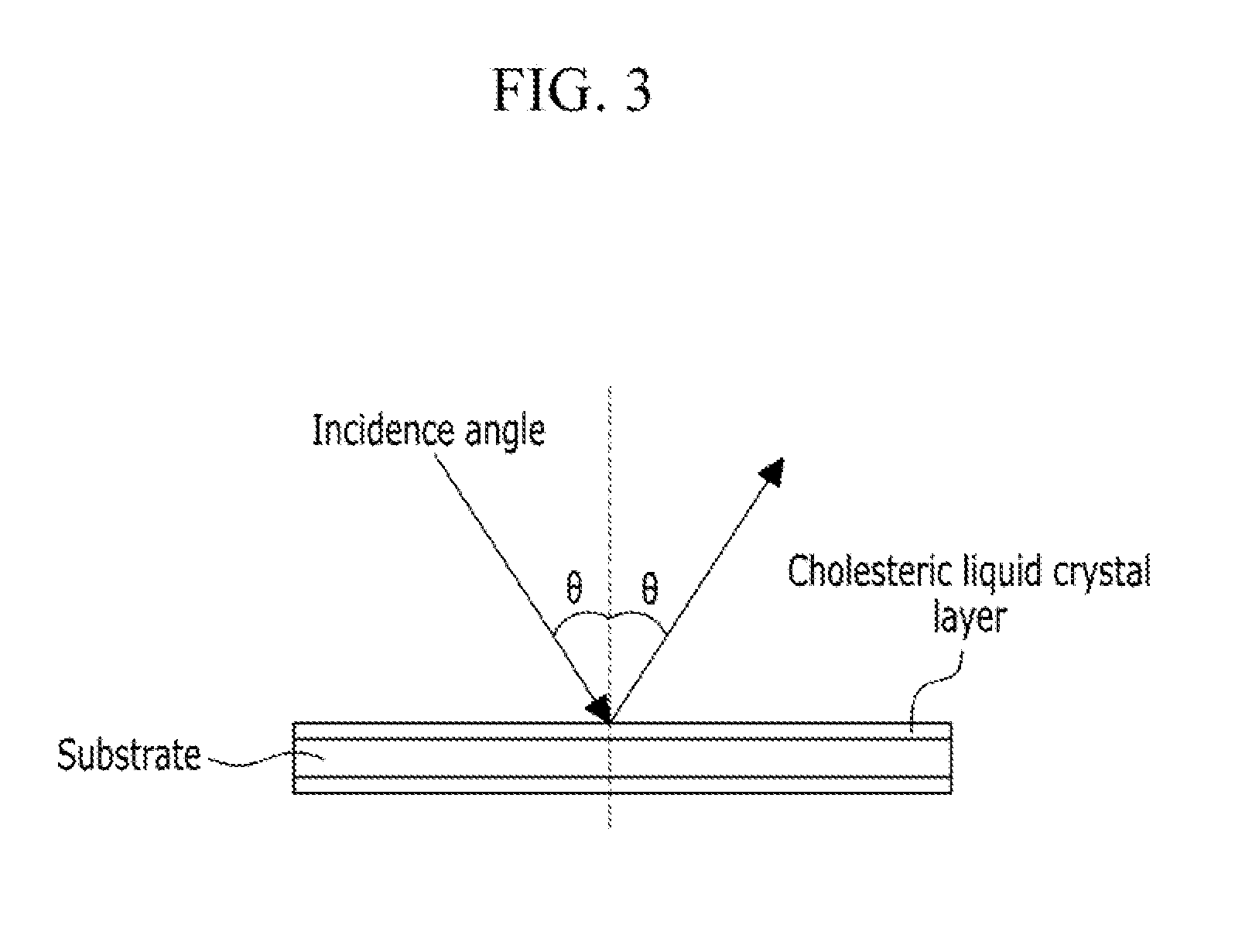

A liquid crystal display (LCD) includes: a liquid crystal panel; a backlight unit for supplying light to the liquid crystal panel; and a wavelength-converting reflector disposed between the liquid crystal panel and the backlight unit. Light reflected from the wavelength-converting reflector has a shorter wavelength as a reflection angle increases.

Owner:SAMSUNG DISPLAY CO LTD

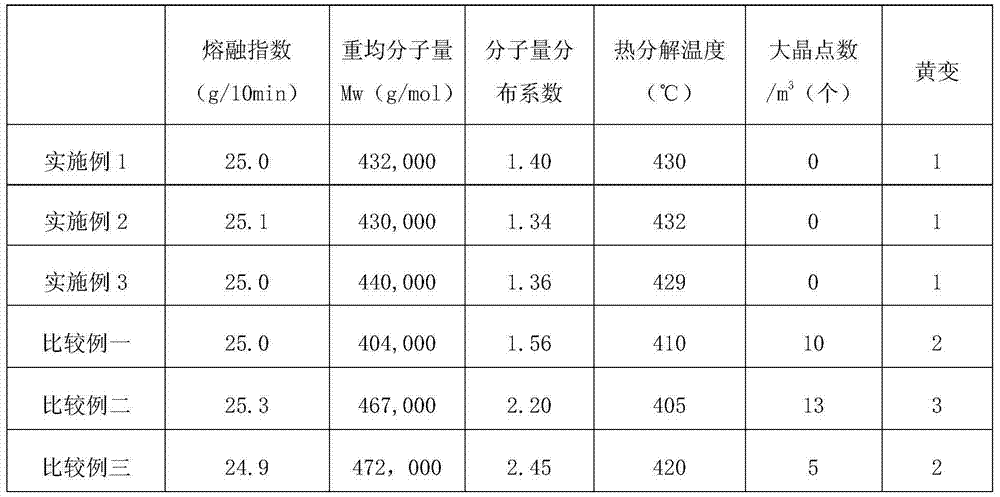

Preparation method of polyvinylidene fluoride resin for solar backboard film

The invention relates to a preparation method of polyvinylidene fluoride resin for a solar backboard film. According to the method, an initiator for polymerization is an organic lipoperoxide initiator being low in reaction activation energy, and an adjustor for polymerization is low molecular weight ester with high adjusting efficiency, wherein the concentration of the initiator is 10-30% and the concentration of the adjustor is 5-30%. The continuous feeding manner is adopted, the polymerization condition is mild, the temperature is 64.5-66.5 DEG C, the pressure of a kettle is 2.95-3.15MPa, the end group of a polymerization product is stable and the molecular weight of the polymerization product is controllable in size, and the distribution coefficient is narrow. The obtained polyvinylidene fluoride product cannot be yellowed, is free from big crystal points and can satisfy the demand on technical indexes of the solar backboard film.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

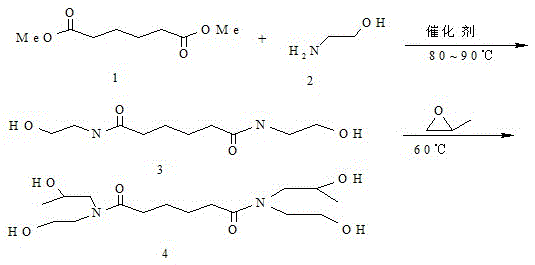

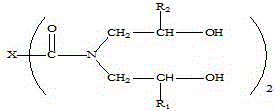

Beta-hydroxyalkylamide and preparation method thereof

ActiveCN105541654AStable storageHigh reactivityOrganic compound preparationCarboxylic acid amides preparationPolymer scienceEthanolamines

The invention discloses beta-hydroxyalkylamide and a preparation method thereof, relates to a curing agent and a preparation method thereof and provides a preparation method of N,N'-bis(beta-hydroxyethyl)-N,N'bis(beta-hydroxypropyl) adipamide. Dimethyl adipate, ethanolamine and propylene oxide are taken as raw materials for synthesis of N,N'-bis(beta-hydroxyethyl)-N,N'bis(beta-hydroxypropyl) adipamide. The synthetic method of N,N'-bis(beta-hydroxyethyl)-N,N'bis(beta-hydroxypropyl) adipamide comprises two steps: (1) synthesis of N,N'-bis(beta-hydroxyethyl) adipamide; (2) addition reaction. A product obtained with the method has high purity and good performance, and an obtained intermediate product is an important organic intermediate. The method has the advantages that the molecular reaction activity is reduced, the reaction speed is reduced, so that the viscosity of a coating film is improved, and an anti-pinhole effect is enhanced; the synthesis is simple, severe conditions such as high pressure, high vacuum and the like are avoided, the production cost is lower, and industrialization is facilitated.

Owner:NANJING JINHAO MEDICAL TECH CO LTD

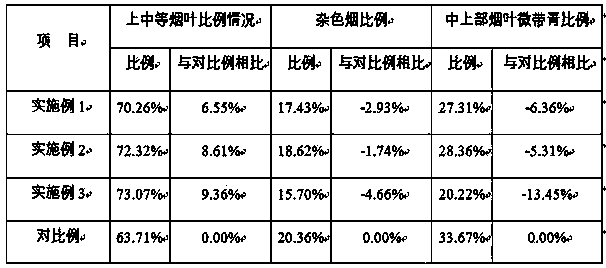

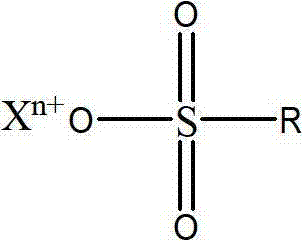

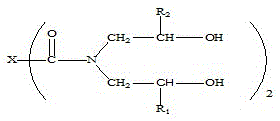

Anti-wrinkle finishing agent for cotton fabrics, and preparation method and application thereof

InactiveCN105986482AImprove stabilityNo pollution in the processVegetal fibresIsophorone diisocyanateChemistry

The invention discloses an anti-wrinkle finishing agent for cotton fabrics, and a preparation method and an application thereof. The anti-wrinkle finishing agent is aqueous polyurethane which is formed by polymerizing the unit represented in the chemical structural formula (I). The preparation method includes the steps of polymerizing a polyether flexible chain segment with excessive isophorone diisocyanate, and terminating excessive isocyanate groups to prepare the terminated aqueous polyurethane. The anti-wrinkle finishing agent has very good effects on the cotton fabrics and effectively solves the problems that an anti-wrinkle finishing agent in the prior art releases formaldehyde, reduces strength of the fabrics and yellows the fabrics, and furthermore, the cotton fabric is improved in washability.

Owner:JIANGSU LIANFA TEXTILE

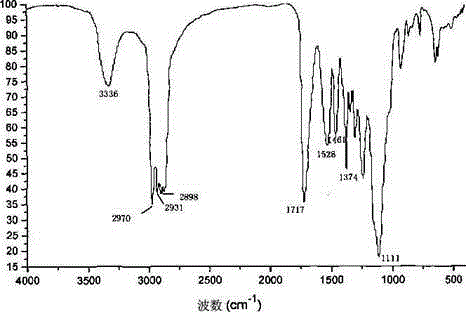

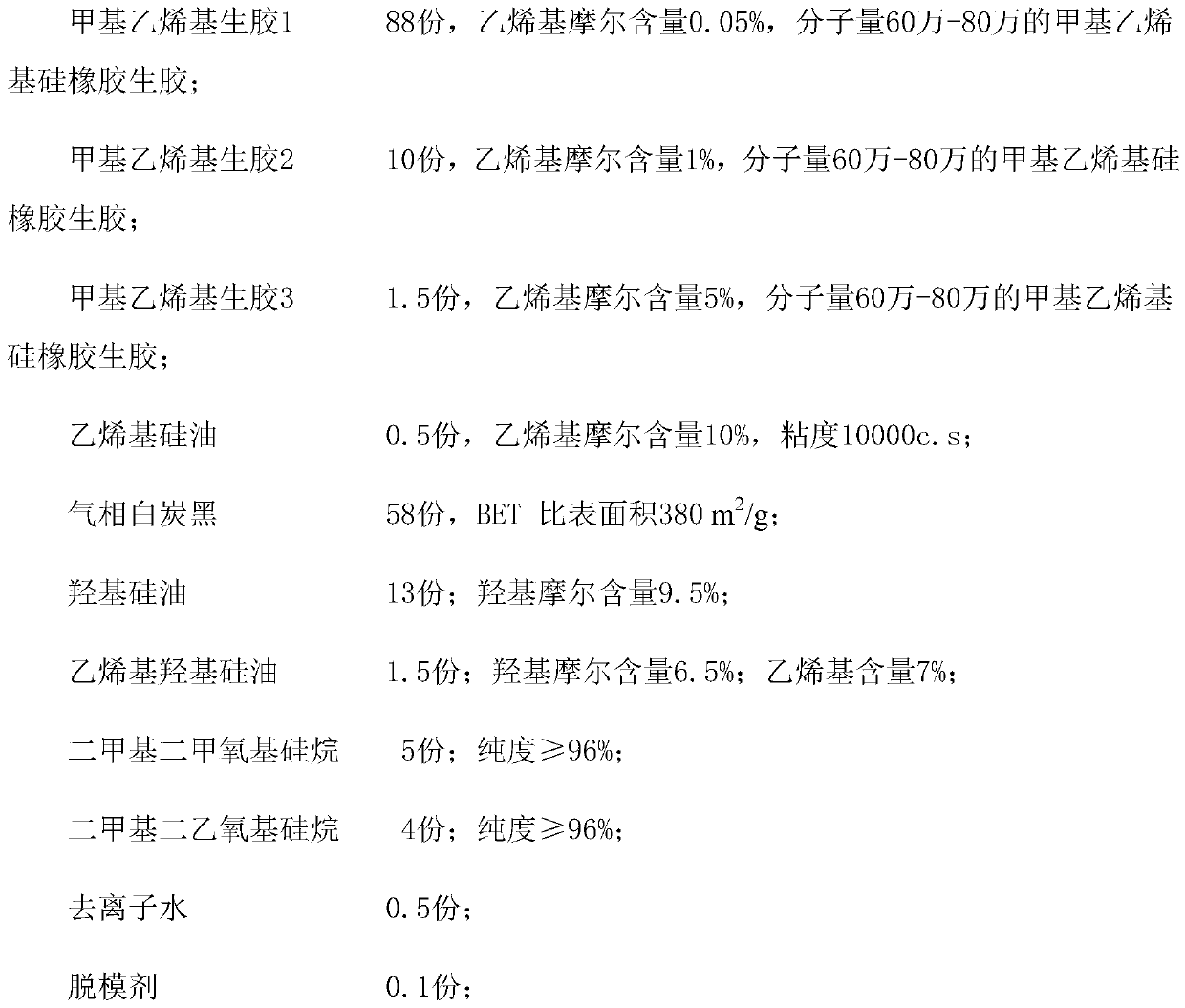

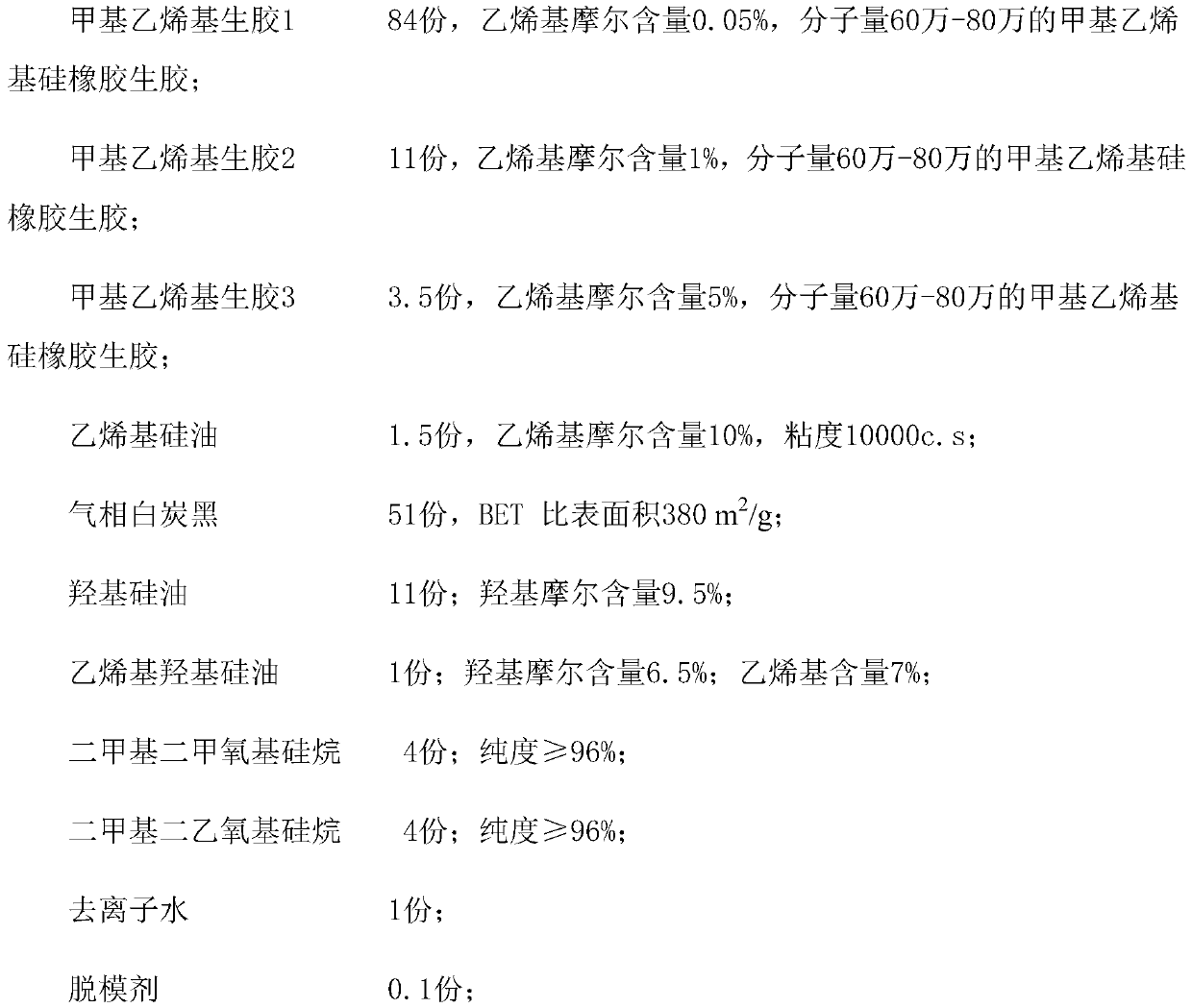

Silicone rubber masterbatch, silicone rubber and preparation method of silicone rubber

The invention belongs to the field of silicone rubber, and discloses silicone rubber masterbatch. The silicone rubber masterbatch comprises the following components in parts by weight of: 80-90 partsof polysiloxanes di-Me Me vinyl vinyl group-terminated crude rubber of which the vinyl mol content is 0.03%-0.23% and the molecular weight is 600-800 thousands, 7-16 parts of the polysiloxanes di-Me Me vinyl vinyl group-terminated crude rubber of which the vinyl mol content is 1%-5% and the molecular weight is 600-800 thousands, 1.5-5 parts of the polysiloxanes di-Me Me vinyl vinyl group-terminated crude rubber of which the vinyl mol content is 3%-10% and the molecular weight is 600-800 thousands, 0.5-1.5 parts of of silicone oil of which the vinyl mol content is 5%-30% and the stickiness is 10-100 thousands, 51-63 parts of fumed silica, 10-13 parts of hydroxyl silicone oil, 1-2 parts of vinyl hydroxyl silicone oil, 4-7 parts of dimethyl dimethoxy silicane, 4-5 parts of dirthoxydimethylsilane, 0.5-1 part of pure water; and 0.1-0.2 part of a demoulding agent. The silicone rubber obtained from the silicone rubber masterbatch can meet the requirements of medical throat hood pipes for goodshaping bending degree, good appearance transparency, freedom from bubbles, freedom from gelatin of products, and good ageing performance after being used for a long term. Besides, the invention further provides a preparation method of the silicone rubber.

Owner:XINAN TIANYU SILICONE CO LTD

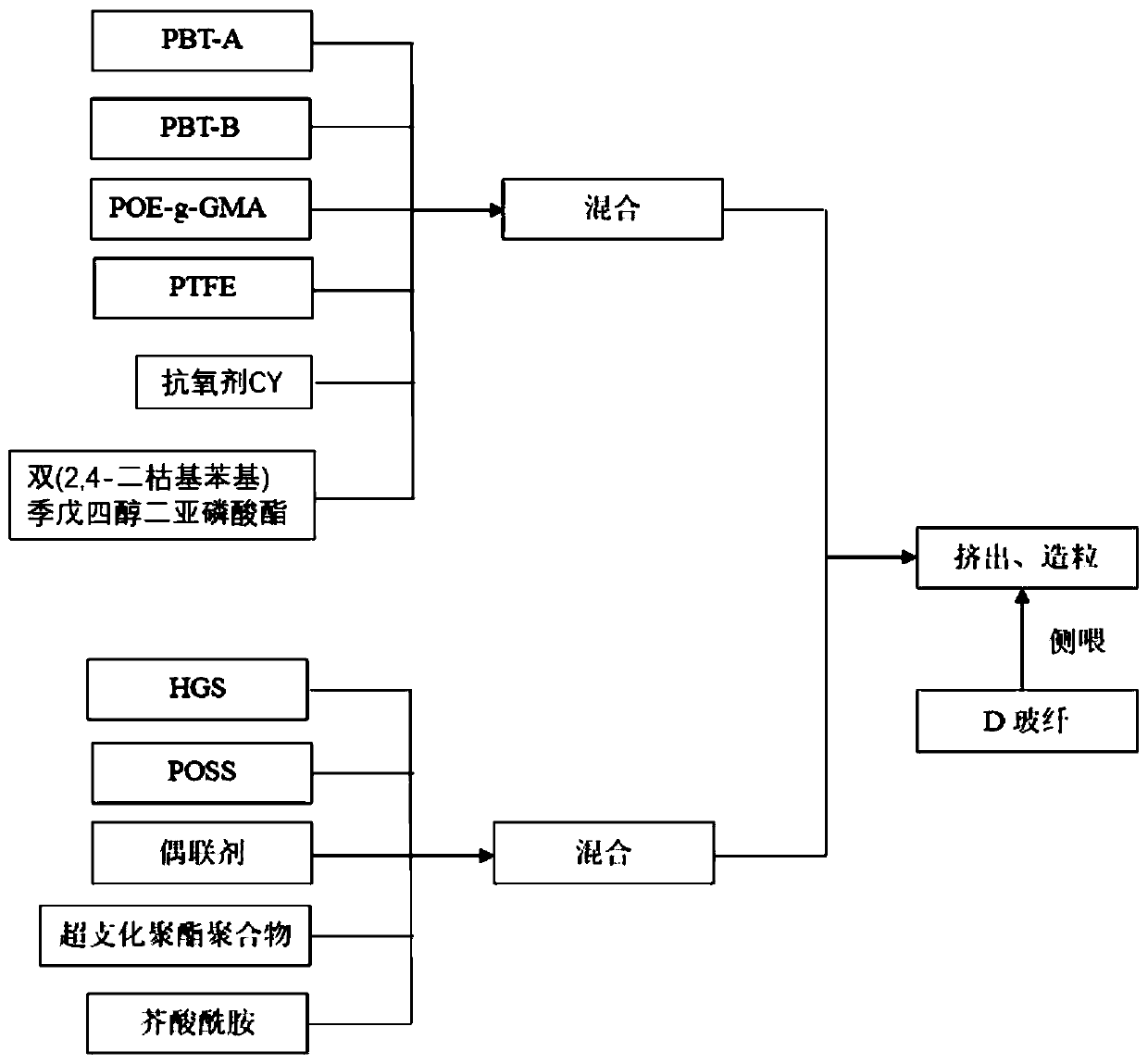

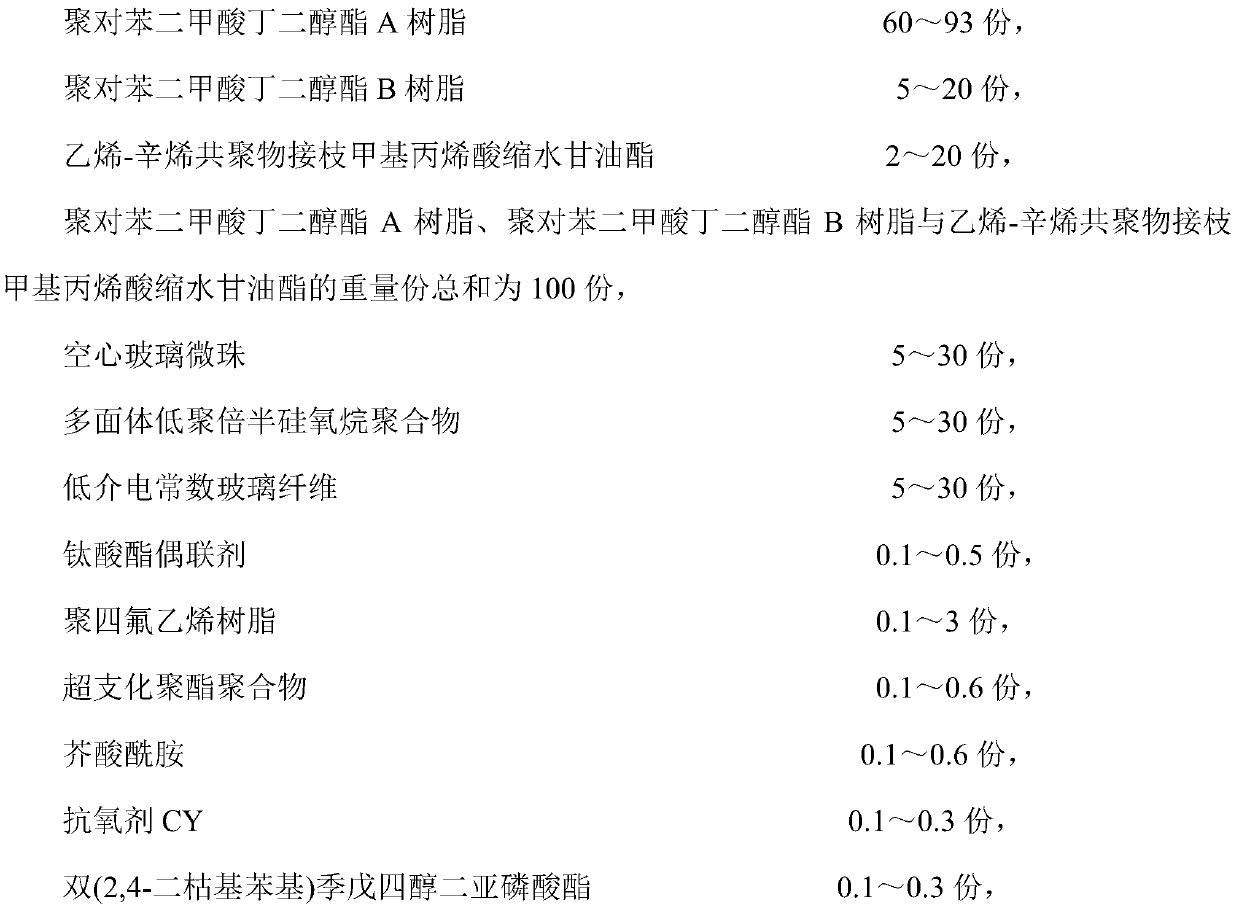

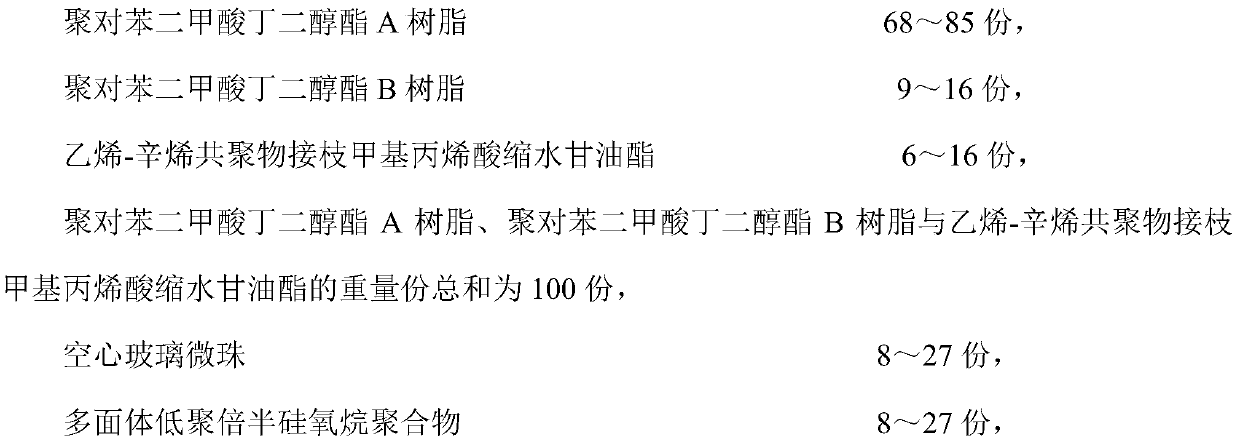

Reinforced polybutylene terephthalate composition and preparation method thereof

InactiveCN111410823ALow dielectric constantEasy to processPolytetramethylene terephthalatePolymer science

The invention relates to a reinforced polybutylene terephthalate composition and a preparation method thereof. The reinforced polybutylene terephthalate composition is prepared from the following rawmaterials: polybutylene terephthalate resin A, polybutylene terephthalate resin B, ethylene-octene copolymer grafted glycidyl methacrylate, hollow glass beads, polyhedral oligomeric silsesquioxane polymer, low dielectric constant glass fiber, a titanate coupling agent, polytetrafluoroethylene resin, a hyperbranched polyester polymer, erucyl amide, an antioxidant CY and bis(2, 4-diquylphenyl)pentaerythritol diphosphate. The reinforced polybutylene terephthalate composition has excellent mechanical properties and processability and a low dielectric constant, and can be applied to shells, cladding and protective materials and the like of 5G base stations, micro base station systems, data communication terminals, antennas and radio frequency modules.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

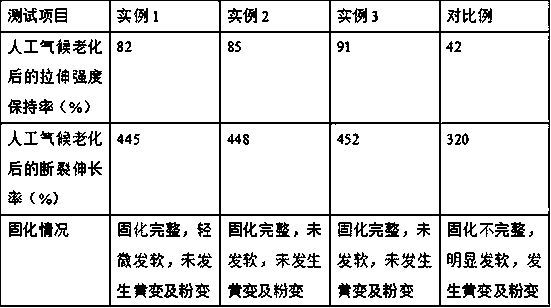

Preparation method of anti-aging moisture-curing vinyl resin

The invention discloses a preparation method of anti-aging moisture-curing vinyl resin and belongs to the technical field of resin preparation. Cumarin prepared in the method is high in fluorescence quantum yield and stability, so that impact of ultraviolet radiation on the vinyl resin is lowered. In addition, cumarin has high antioxidation performance, and increase of crosslinking degree lowers aging degradation ability of the vinyl resin, so that the defect that the vinyl resin is prone to yellowing and pinking is improved, and anti-aging effect is realized. A PAE intermediate can polymerizeand generate a PAE emulsion during preparation of the vinyl resin and can be in covalent bond combining with hydroxyl in epoxy resin to form a crosslinked structure in the vinyl resin, so that dispersion stability of the PAE emulsion during curing is improved; after the PAE emulsion is modified through diethanol amine, molecular weight of PAE is lowered, which leads to decrease of viscosity of the emulsion, so that water loss of the vinyl resin in a humid condition during curing is intensified, the vinyl resin can maintain high strength after curing without being softened, and the vinyl resinhas wide application prospect.

Owner:长兴合成树脂(常熟)有限公司

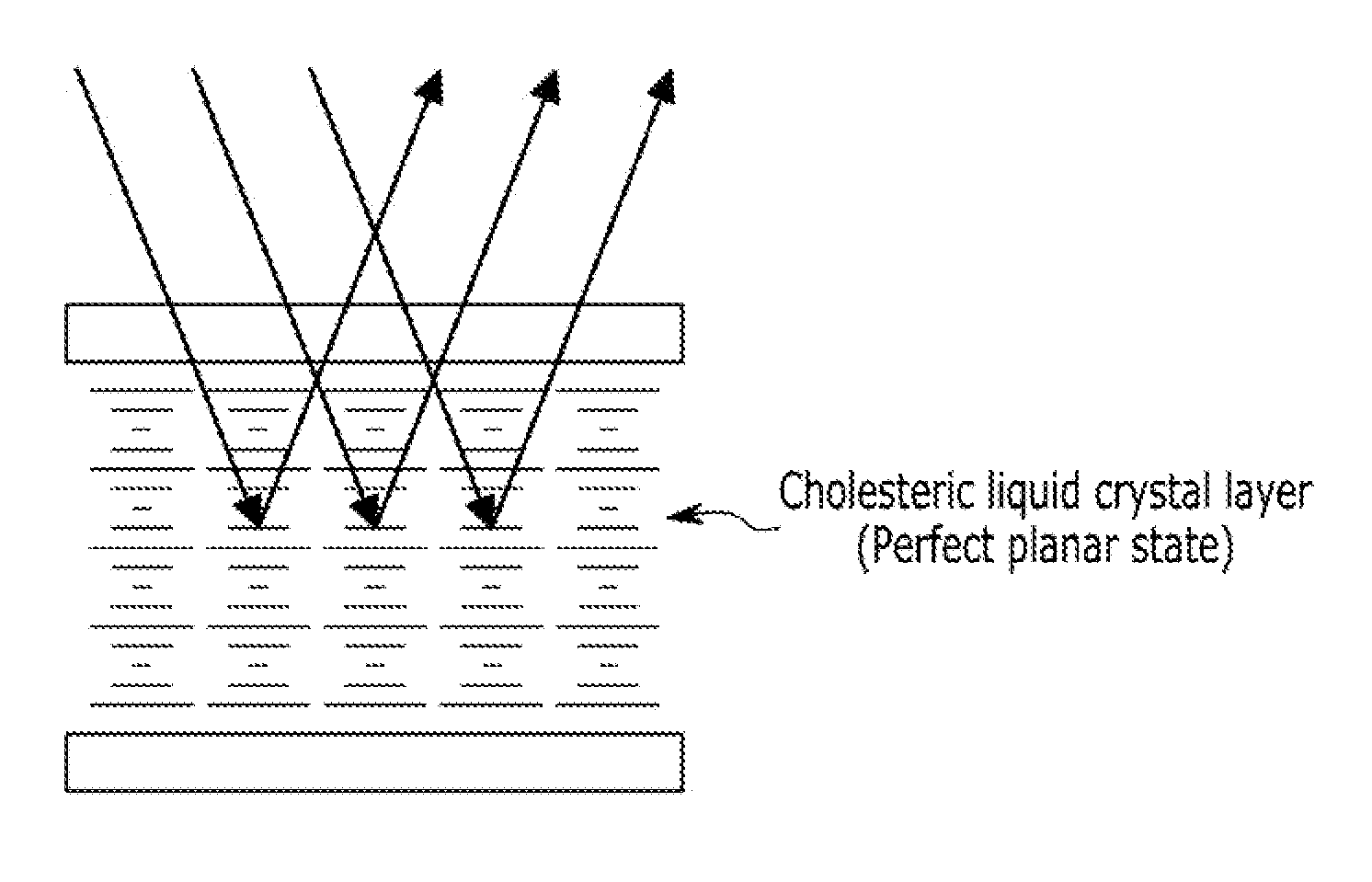

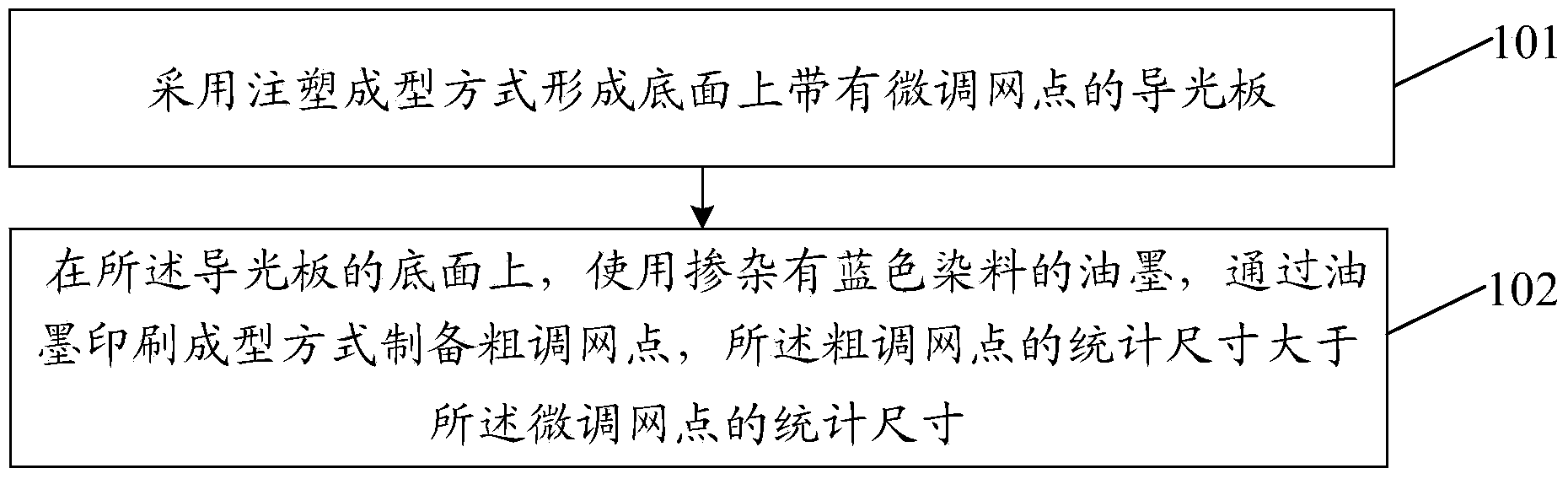

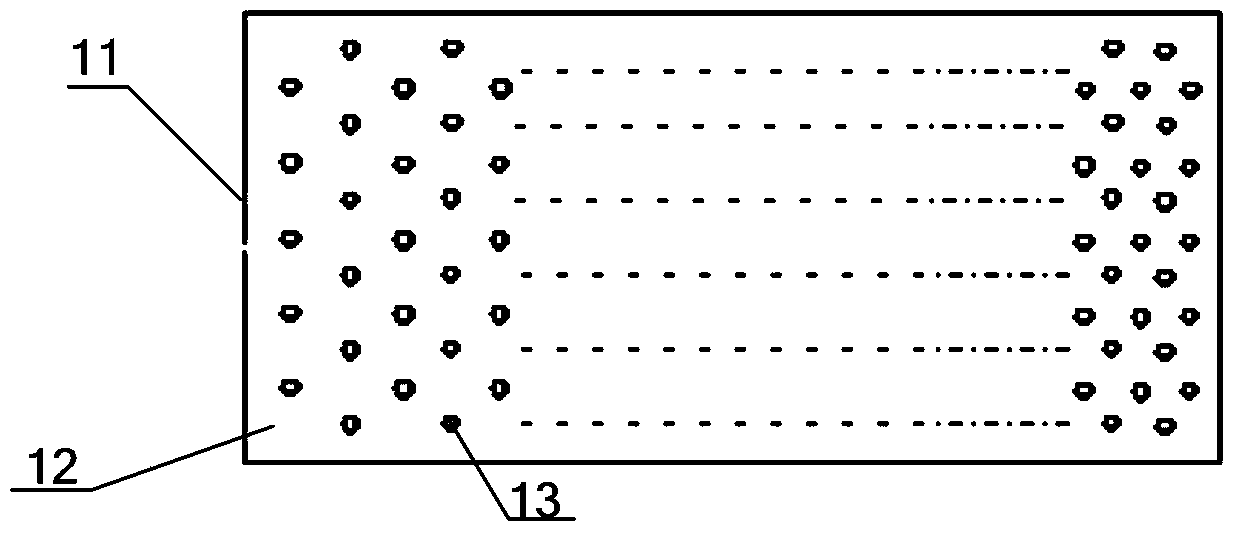

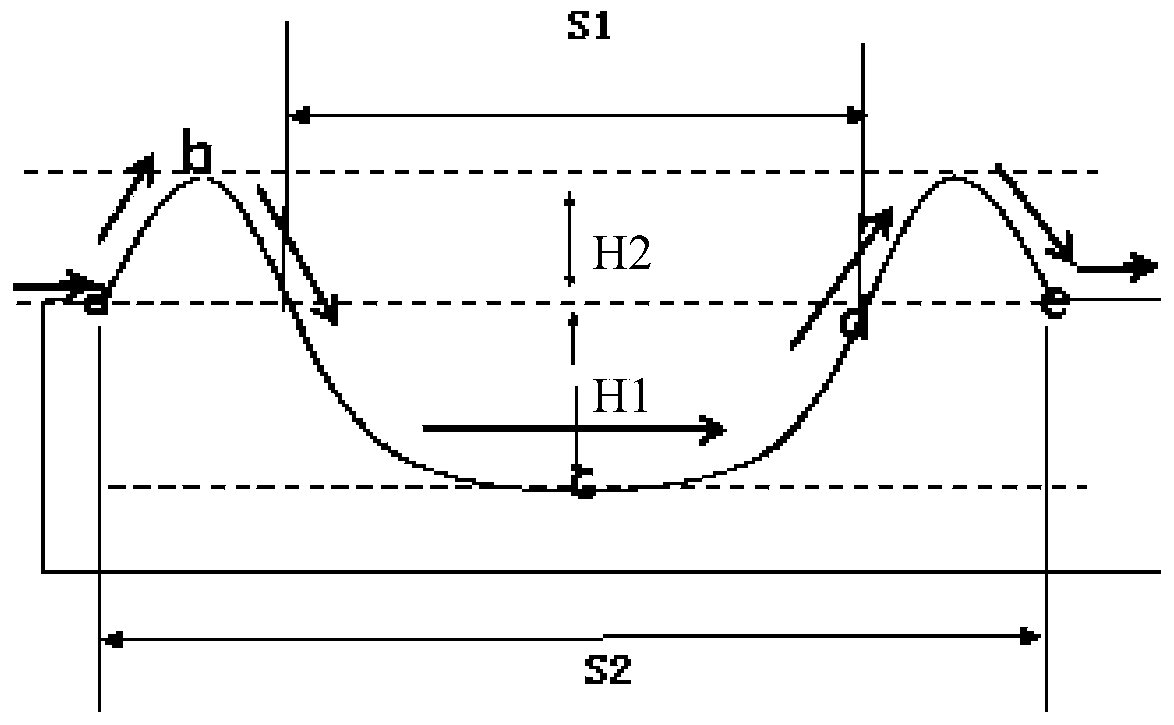

Preparation method of light guide plate, light guide plate, backlight module and display device

InactiveCN103728688AIncrease brightnessImprove uniformityOther printing apparatusOptical light guidesLight guideDisplay device

The embodiment of the invention discloses a preparation method of a light guide plate, the light guide plate, a backlight module and a display device, and relates to the field of display. The preparation method of the light guide plate, the light guide plate, the backlight module and the display device can effectively improve bad yellowing of a back light source and improve the brightness and evenness of outgoing light of the light guide plate. The preparation method of the light guide plate comprises the steps that the light guide plate with fine adjusting lattice points on the bottom face is formed by adopting an injection molding mode, and the bottom face is opposite to a light outgoing surface of the light guide plate; on the bottom face of the light guide plate, rough adjusting lattice points are prepared through an ink printing forming mode by using ink mingled with blue dyestuff, and the average size of the rough adjusting lattice points is larger than that of the fine adjusting lattice points.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

Intermediate film for laminated glass, laminated glass using the same, and method for production of the laminated glass

InactiveCN101410341BHigh transparencyGood penetration resistanceSynthetic resin layered productsGlass/slag layered productsWeather resistanceUv absorber

Owner:BRIDGESTONE CORP

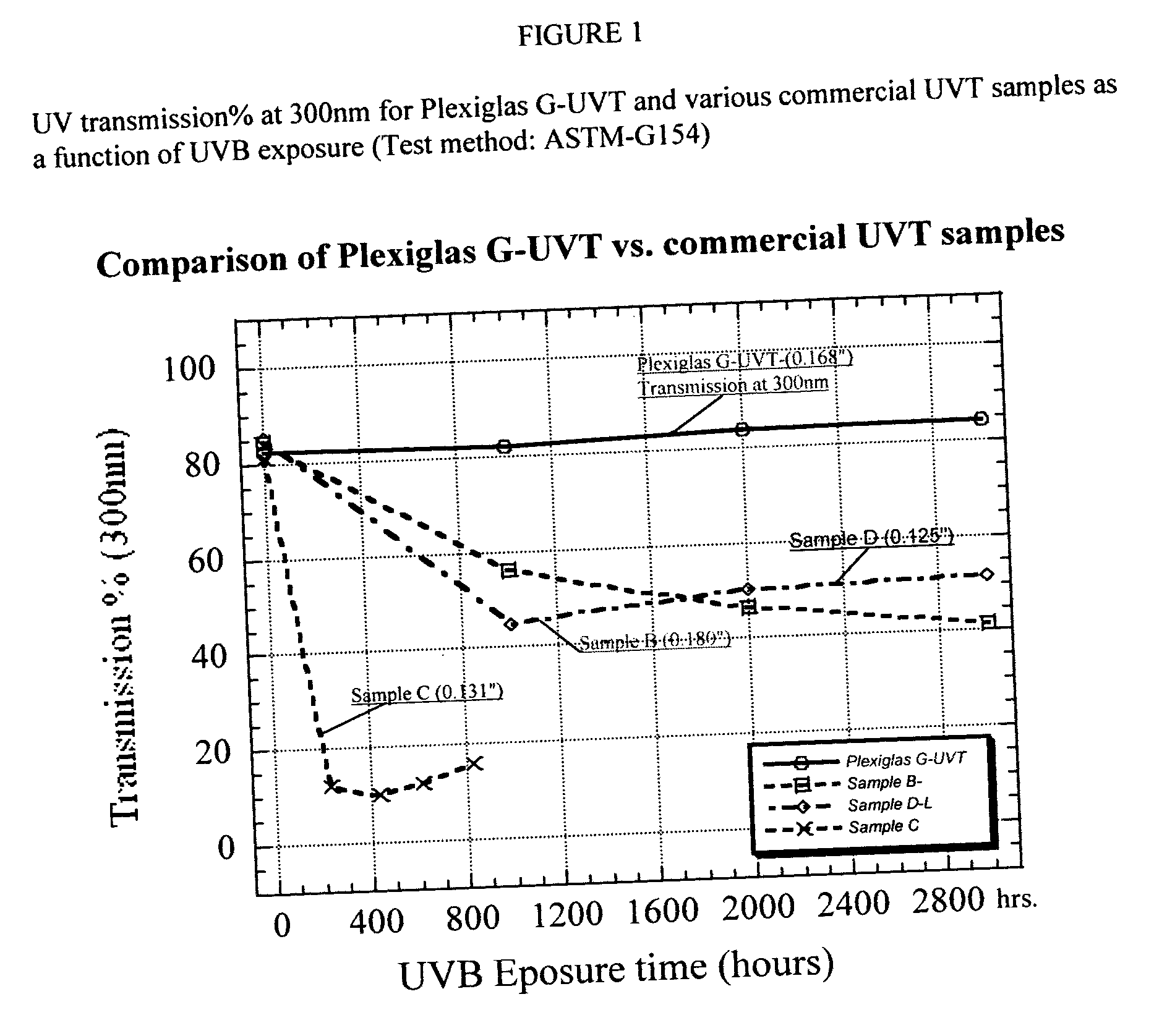

Stabilized UV transparent acrylic composition

ActiveUS20060069189A1Resists deteriorationImprove the level ofSynthetic resin layered productsUltravioletCompound (substance)

This invention relates to a UV stabilized transparent acrylic composition. More specifically the acrylic composition is stabilized with a carboxylic acid compound, which prevents or delays deterioration of the acrylic composition from high intensity UV radiation. The carboxylic acid compound is preferably an alpha hydroxylcarboxylic acid compound. The delay or prevention of deterioration results in the transmission of more UV radiation through the acrylic composition for longer periods of time. The composition is especially useful for tanning and other applications requiring transmission of high levels of UV radiation and resistance to discoloration. It is also useful in optical cable, LCD displays, acrylic storage media, and in HID devices.

Owner:TRINSEO EURO GMBH

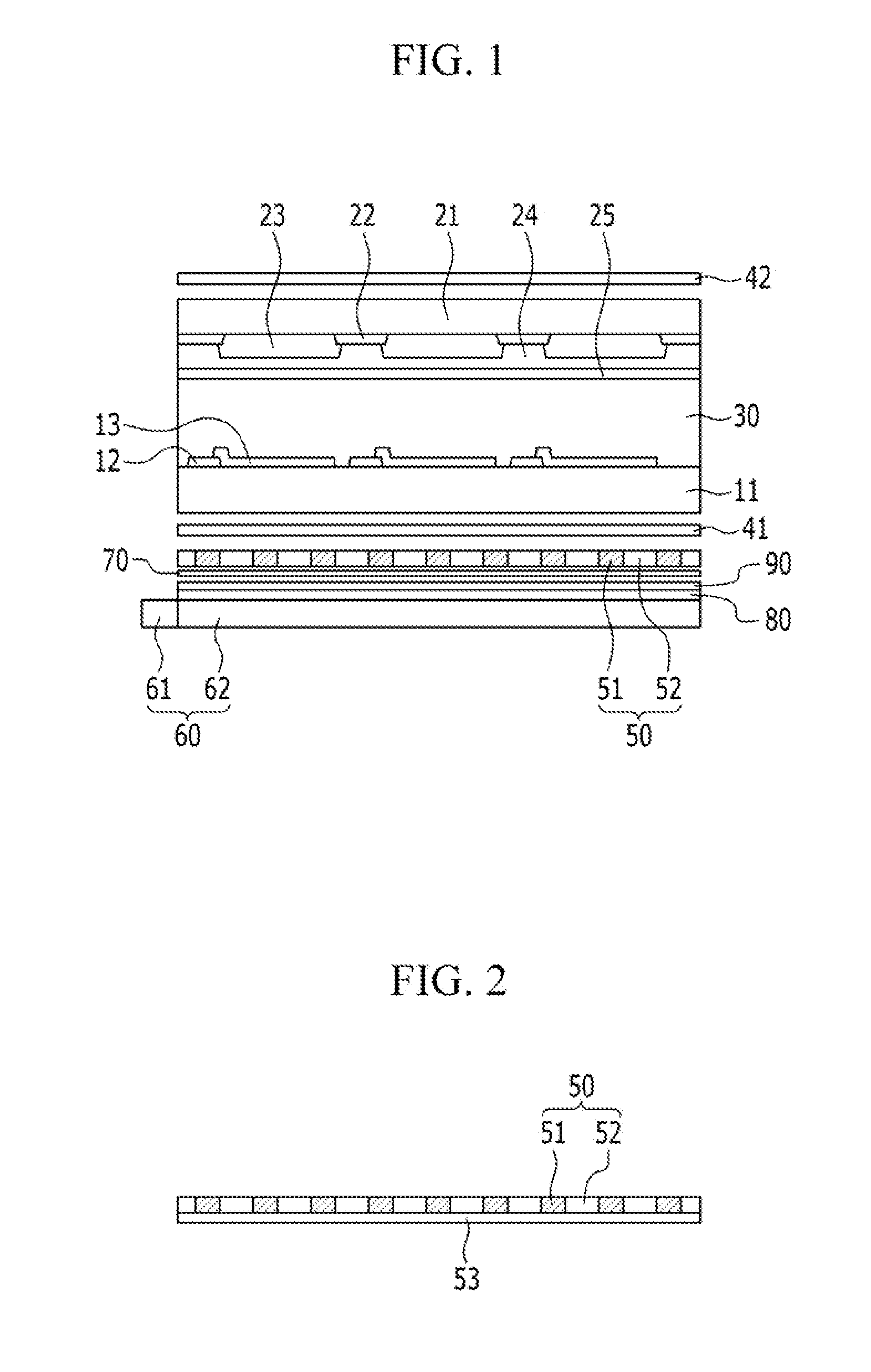

Anti-Ultraviolet Reflector

InactiveUS20070037000A1Improve yellowing issueImprove yellowingSynthetic resin layered productsPretreated surfacesPoint light sourceBisphenol-A-polycarbonate

Disclosed is an anti-UV reflector for distributing a light from a point light source or a linear light uniformly over a target. The anti-UV reflector mainly includes a light reflecting polymeric substrate and a protecting layer of anti-UV material provided on the polycarbonate substrate for reducing yellowing in the polycarbonate substrate. When a light from a point light source or a linear light illuminates the anti-UV reflector, UV radiation in the light is filtered or absorbed by the protecting layer thereby reducing yellowing in the polyearbonate substrate.

Owner:CHI MEI CORP

Composite microbial preparation, preparation method and application

ActiveCN113122477AIncrease contentPrevention and control of anthraxBiocidePlant growth regulatorsBacilliTrichoderma harzianum

The invention discloses a composite microbial preparation, which comprises a bacillus subtilis JNKC001 bacterial liquid, a trichoderma harzianum JNHC bacterial liquid and an auxiliary agent, and the ratio of the total bacterial count of the trichoderma harzianum to the total bacterial count of the bacillus subtilis in the prepared composite microbial preparation is (1-3):(100-300). The compound microbial preparation can effectively improve the content of chlorophyll in citrus leaves; the citrus anthracnose is effectively prevented and controlled; the content of soluble solids in the citrus is increased; the Vc content of the citrus is increased; and the composite microbial preparation has good growth promoting and yield promoting effects on the citrus.

Owner:金禾佳农(北京)生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com