Preparation method of anti-aging moisture-curing vinyl resin

A vinyl resin and moisture curing technology, which is applied in the field of preparation of anti-aging moisture curing vinyl resin, can solve the problems of insufficient resin curing degree, difficult resin curing, soft resin without hardness, etc., and achieve high strength and stable dispersion The effect of improving sex and increasing water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

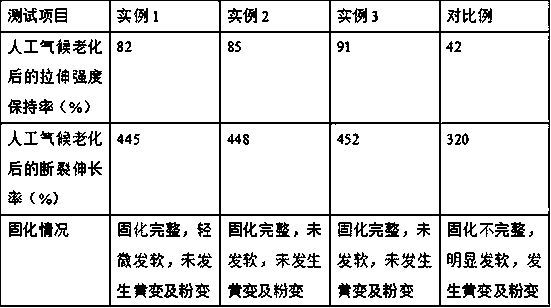

Examples

example 1

[0028] Take 16g of 3-aminophenol, 10g of ethyl acetoacetate, 17g of zinc chloride and 70mL of absolute ethanol, place them in a three-necked flask with a stirrer and a condensing reflux tube, heat up to 70°C under nitrogen protection, and start the stirrer Insulate and stir at a speed of 400r / min, condense and reflux for 14 hours, and naturally cool to room temperature to obtain a reaction solution; add 60mL of hydrochloric acid with a mass fraction of 10% to the reaction solution, stir and mix for 10min, filter and remove the filtrate to obtain a solid product, and use distilled water After washing the solid product 3 times, put it in an oven, heat it up to 60°C, and dry it for 8 hours to obtain a dry product. Recrystallize the dry product with 70 mL of isopropanol to obtain coumarin crystals; take 8 g of coumarin crystals , 10g of 2,3-epoxypropyltrimethylammonium chloride and 40mL of hydrochloric acid with a mass fraction of 20% were placed in a three-necked flask with a stir...

example 2

[0030] Take 20g of 3-aminophenol, 12g of ethyl acetoacetate, 20g of zinc chloride and 80mL of absolute ethanol, place them in a three-necked flask with a stirrer and a condensing reflux tube, heat up to 80°C under nitrogen protection, and start the stirrer Insulate and stir at a speed of 450r / min, condense and reflux for 16 hours, and naturally cool to room temperature to obtain a reaction solution; add 80 mL of hydrochloric acid with a mass fraction of 10% to the reaction solution, stir and mix for 15 minutes, filter and remove the filtrate to obtain a solid product, and use distilled water After washing the solid product 4 times, put it in an oven, heat it up to 70°C, and dry it for 9 hours to obtain a dry product. Recrystallize the dry product with 75 mL of isopropanol to obtain coumarin crystals; take 10 g of coumarin crystals , 12g of 2,3-epoxypropyltrimethylammonium chloride and 50mL of hydrochloric acid with a mass fraction of 20% were placed in a three-necked flask with...

example 3

[0032] Take 18g of 3-aminophenol, 11g of ethyl acetoacetate, 18g of zinc chloride and 75mL of absolute ethanol, place them in a three-necked flask with a stirrer and a condensing reflux tube, heat up to 75°C under nitrogen protection, and start the stirrer Insulate and stir at a speed of 430r / min, condense and reflux for 15 hours, and naturally cool to room temperature to obtain a reaction solution; add 75mL of hydrochloric acid with a mass fraction of 10% to the reaction solution, stir and mix for 13 minutes, filter and remove the filtrate to obtain a solid product, and use distilled water After washing the solid product 4 times, put it in an oven, heat it up to 65°C, and dry it for 9 hours to obtain a dry product. Recrystallize the dry product with 73 mL of isopropanol to obtain coumarin crystals; take 9 g of coumarin crystals , 11g of 2,3-epoxypropyltrimethylammonium chloride and 45mL of hydrochloric acid with a mass fraction of 20% were placed in a three-necked flask with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com