Preparation method of polyvinylidene fluoride resin for solar backboard film

A technology of polyvinylidene fluoride resin and solar backsheet film, which is applied in the field of polymerization to achieve the effects of narrow molecular weight distribution, stable end groups, and mild polymerization conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

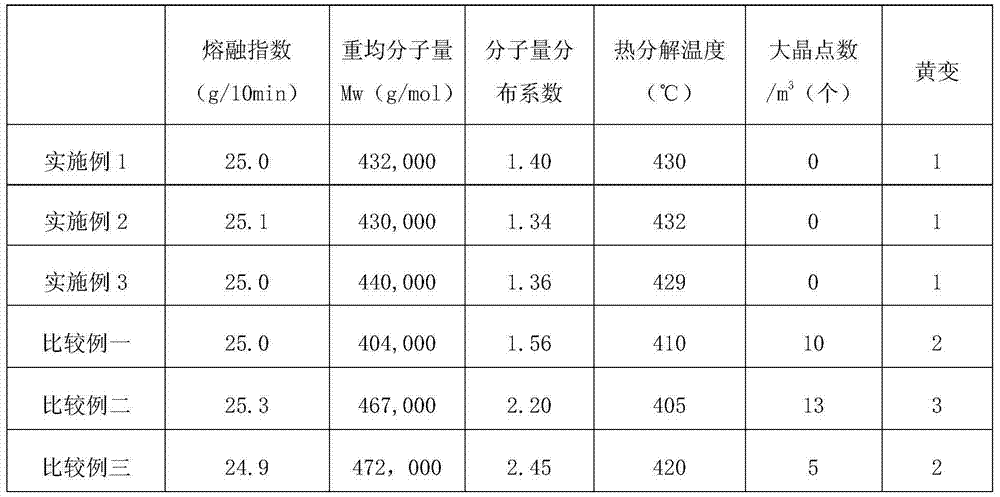

Examples

Embodiment 1

[0031] In a 10L horizontal reaction kettle, add 6L of deionized water, 40g of ammonium perfluorooctanoate solution with a mass concentration of 30%, and 100g of paraffin as an anti-sticking kettle agent. Then, the temperature of the polymerization kettle was increased, and the pressure was increased by charging the vinylidene fluoride monomer into the polymerization kettle. When the pressure of the polymer kettle reached 3.0 MPa, and the temperature of the kettle reached 65 °C, 15g of initial initiator was quickly injected with a metering pump in 20 minutes. solution, the initiator is a 15% mass concentration of tert-amyl peroxyneodecanoate solution; start the polymerization reaction, after 15min, inject 200g, mass concentration 10% molecular weight regulator ethyl propionate solution at a constant speed with a metering pump, and 15g of tert-amyl peroxyneodecanoate solution with a mass concentration of 15% (additional initiator), the molecular weight regulator and the additiona...

Embodiment 2

[0034] As described in Example 1, the difference is that the initiator concentration is 10wt%, the first addition amount is 20g, and the second addition amount is 30g; the concentration of the regulator ethyl propionate solution is 5wt%, and the addition amount is 400g.

Embodiment 3

[0036] As described in Example 1, the difference is that the molecular weight modifier is changed to ethyl acetate. The concentration and dosage are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com