Patents

Literature

59results about How to "Moderate response speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and preparation method thereof

ActiveCN105802460AHigh mechanical strengthAnti-corrosion and wear-resistantAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerEnd-group

The invention discloses a scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and a preparation method thereof. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is characterized by comprising an ingredient A and an ingredient B, wherein the ingredient A is prepolymers with NCO end groups obtained through the reaction between 30 to 40 mass percent of polyether polyol and 60 to 70 mass percent of polyisocyanates; the ingredient B is prepared from 30 to 40 mass percent polyaspartic acid ester, 60 to 70 mass percent of filling materials and a small number of auxiliary agents through high-speed dispersion grinding. In the use process, the prepared ingredient A and the prepared ingredient B are weighed according to the weight ratio of 1:4, and are then uniformly mixed; next, scraping coating construction is performed. The material has the characteristics of high mechanical intensity, corrosion resistance, wear resistance, good anti-seeping performance, aging resistance, proper reaction speed, no solvent, convenient construction and the like. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is particularly suitable for industrial and mining enterprise equipment and spare part anti-corrosion wear-resistant liners.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Grouting and hole-sealing material used for drilling of underground coal mine gas

InactiveCN105016677AAvoid the phenomenon of "air leakage"Accurate pH adjustmentSolid waste managementDrilling compositionPortland cementMetakaolin

The invention provides a grouting and hole-sealing material used for drilling of underground coal mine gas. The material comprises a dry grouting and hole-sealing material and water, wherein a weight ratio of the dry grouting and hole-sealing material to water is 1: 0.8-1.2; the dry grouting and hole-sealing material is composed of the following substances: Portland cement, fly ash, desulphurized gypsum, lime, aluminum powder paste, sodium chloride, metakaolin, and citric acid or sodium carbonate; and the substances composing the dry grouting-and-sealing material are required by weight as follows: 6 to 10 parts of the Portland cement, 0.5 to 3 parts of the fly ash, 0.5 to 3 parts of the desulfurized gypsum, 0.2 to 1 part of the lime, 0.0005 to 0.002 part of the aluminum powder paste, 0.05 to 0.15 part of the sodium chloride, 0.2 to 1.5 part of the metakaolin, and 0.0025 to 0.015 part of the citric acid or 0.005 to 0.03 part of the sodium carbonate. The grouting and hole-sealing material used fo drilling of underground coal mine gas provided by the invention has the advantages of adjustable coagulation time, improved air tightness of hole-sealing, improved hole-sealing efficiency and safety, lowered hole-sealing cost, simplified hole-sealing preparation work, etc.

Owner:HENAN TIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Thermofusion welding agent for welding copper covered steel grounded screen

ActiveCN101412167AHigh strengthReduce consumptionWelding/cutting media/materialsSoldering mediaDetonatorLow noise

The invention provides a hot-melt welding flux for copper-clad steel grounding net welding, which belongs to the field of metal welding. The prior hot-melt welding flux for copper-clad steel grounding net welding has the problems of violent reaction, huge heat release, high noise, poor corrosion resistance and the like. The hot-melt welding flux consists of hot-melt solder and detonator, wherein the hot-melt solder consists of the following materials in weight percentage: 30 to 40 percent of copper oxide powder, 8 to 11 percent of metal aluminum powder, 20 to 35 percent of metal copper powder, 5 to 10 percent of fluorite powder, 4 to 10 percent of tin powder and 5 to 10 percent of nickel powder. The hot-melt welding flux has the advantages of proper reaction speed, low heat release, low noise, good corrosion resistance and the like.

Owner:CHINA ELECTRIC POWER RES INST +1

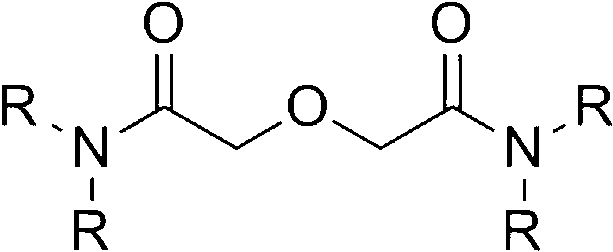

Liquid crystal medium composition

InactiveUS20130299741A1Increase contrastGood effectLiquid crystal compositionsUltraviolet lightsPolymer chemistry

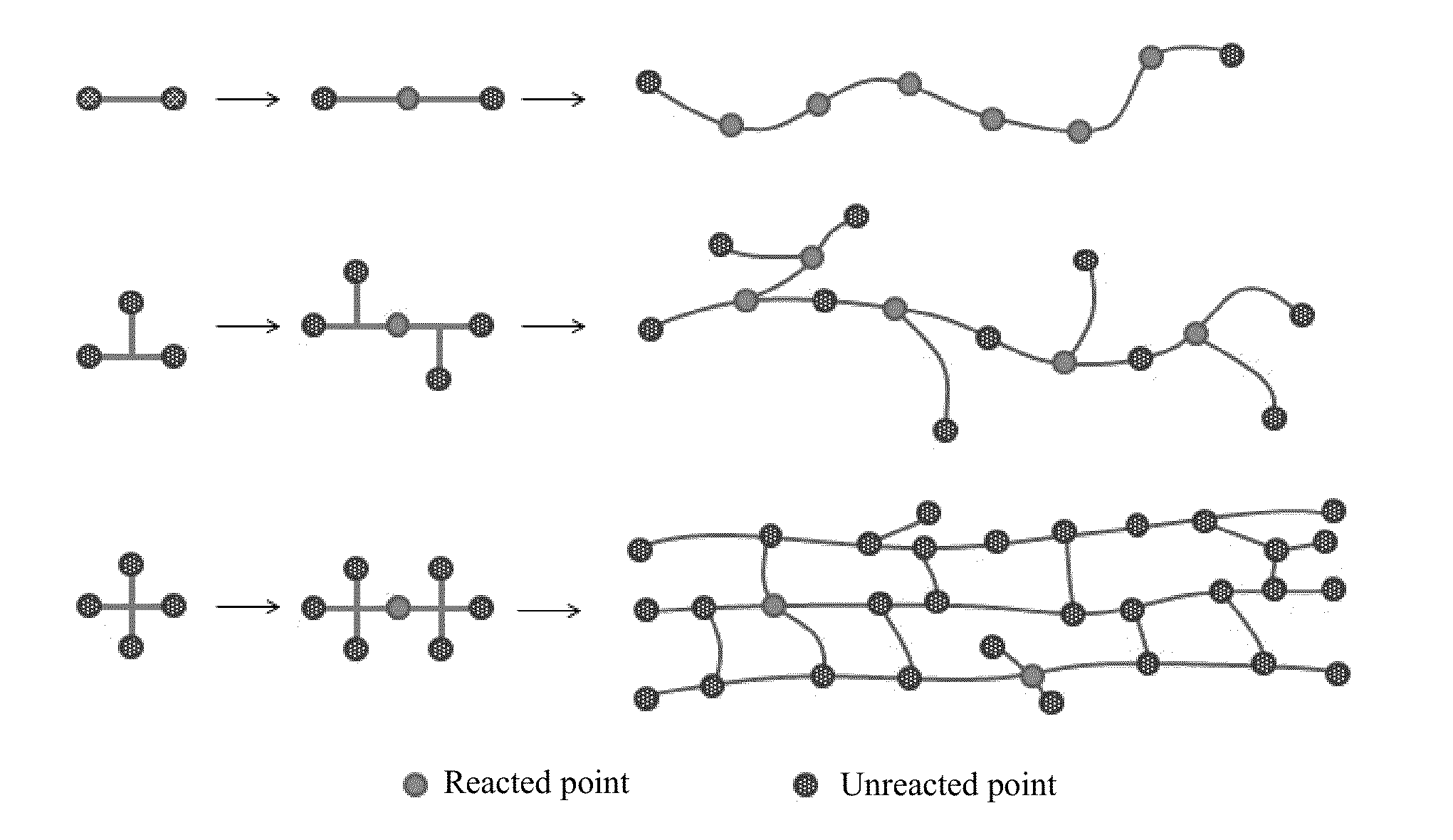

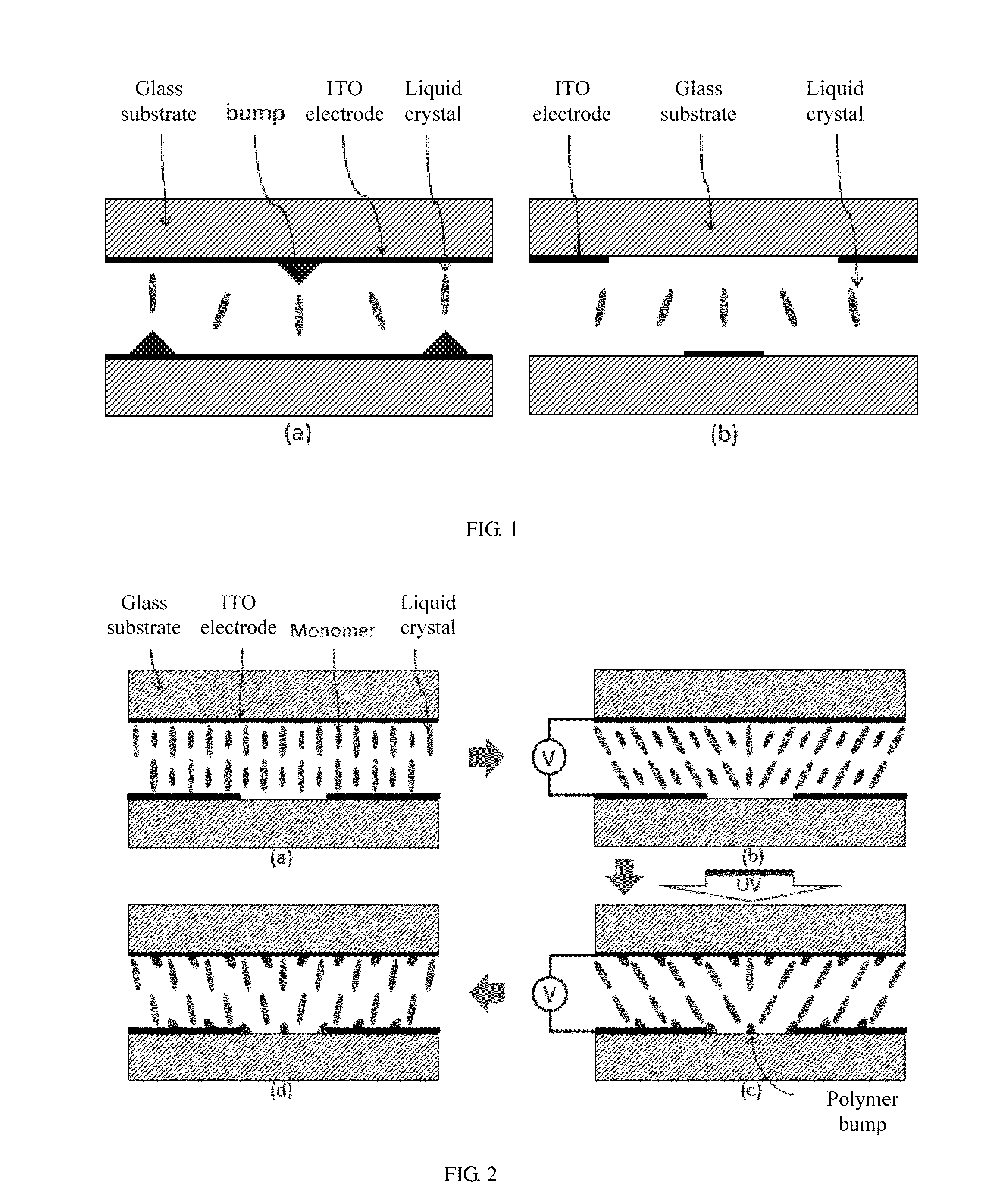

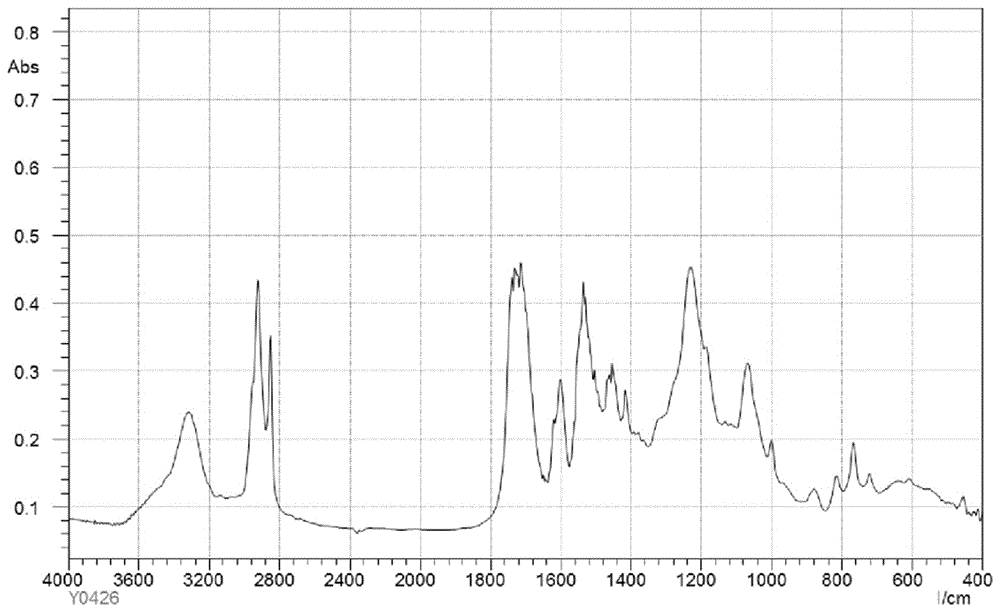

A liquid crystal medium composition includes negative type liquid crystal material, stabilizer, and reactive monomer capable of reacting when being irradiated by ultraviolet light; the amount of the reactive monomer is 5% to 85% by weight based on the total amount of the liquid crystal medium composition. The reactive monomer at least includes a single-polymerisable-group monomer having structure shown in the following Formula (1) and double-polymerisable-group monomer having structure shown in the following Formula (2), and the amount of the single-polymerisable-group monomer is 5% to 85% by mole based on the total amount of the reactive monomer. The single-polymerisable-group monomer or the multiple-polymerisable-group monomer is capable of being irradiated by ultraviolet light to allow for the polymerization reaction to form the polymer. Additionally, the reaction speed is moderate to prevent the polymer from being oversized and loosely piled up for high reaction speed.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Preparation method and application of phosphate inorganic casting binder suspension curing agent

InactiveCN101941045AHigh solid contentHigh solid content (>60%)Foundry mouldsFoundry coresOrganic acidPhosphate

The invention discloses a phosphate inorganic casting binder suspension curing agent and a preparation method thereof. The preparation method comprises the following steps of: adding organic resin to an alcoholic solvent; stirring to be fully dissolved and adding organic acid; stirring to be fully dissolved and then adding powder magnesia; and evenly stirring and dispersing to prepare the suspension curing agent. The invention also discloses the application of the curing agent to the foundry industry. The preparation method of the phosphate inorganic casting binder suspension curing agent is simple and adopts easily obtained raw materials with lower cost. The curing agent has the excellent performances of high efficiency, suspension rate and solid content, free toxicity, moderate reaction speed with the binder, and the like; a casting sand mould bonded by utilizing the curing of the curing agent and the organic binder has high sintering strength and stable sintering performance without a dust flying phenomenon in a sand-mixing process or generating dust pollution and is easy to popularize and apply in the foundry industry.

Owner:HUBEI UNIV OF TECH

Moisture permeation and water proofing fabric, and preparation process thereof

InactiveCN102619092ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentCoated surfaceMoisture permeation

The present invention discloses a moisture permeation and water proofing fabric, and a preparation process thereof. According to the fabric, a prime coat comprises: a polyurethane resin, butanone, toluene, water, 1,6-diisocyanatohexane and N-methylethanolamine; a first surface coating and a second surface coating comprise a polyurethane resin, butanone, toluene, water and N-methylethanolamine. The preparation process comprises: mixing 1,6-diisocyanatohexane and a main resin; mixing water and butanone to form a solvent; adding the solvent to the main resin mixing solution in at least 6 times; filtering the resulting mixed solution with a nylon net to obtain a filtered main resin solution; carrying out a deaeration treatment to form a prime coat slurry; blending a surface coating slurry with a matching solution viscosity of 3500-6000 mpas; coating the prime coat slurry on the surface of the base cloth to form the prime coat, and drying; coating the surface coating slurry on the surface of the prime coat in 2 times to form the surface coatings, and drying. In the prior art, micropores in the hydrophilic moisture permeation processing coating fabric are not uniform, and are easily expanded when contacting the water. With the present invention, the disadvantages in the prior art are solved, and the moisture permeation performance of the fabric is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

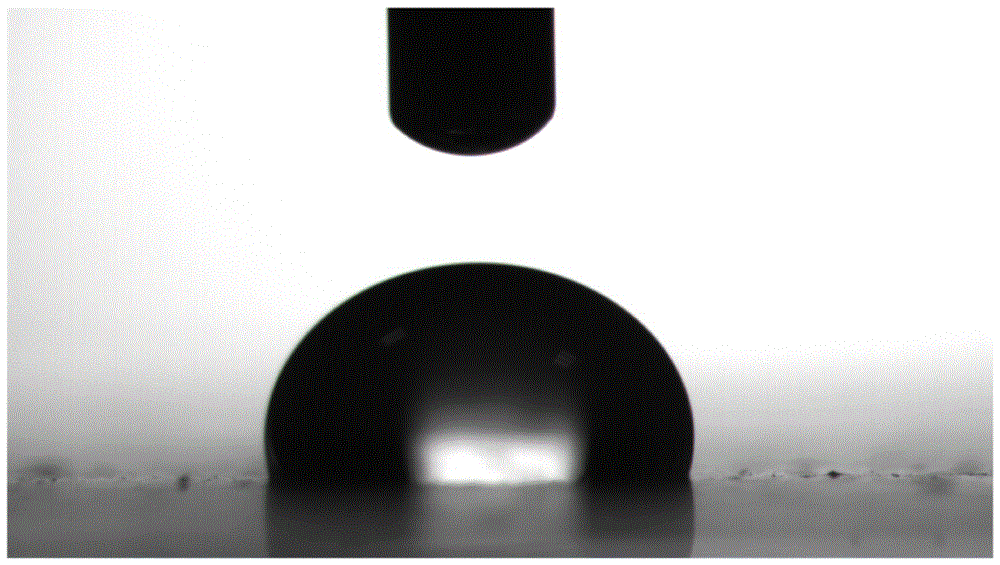

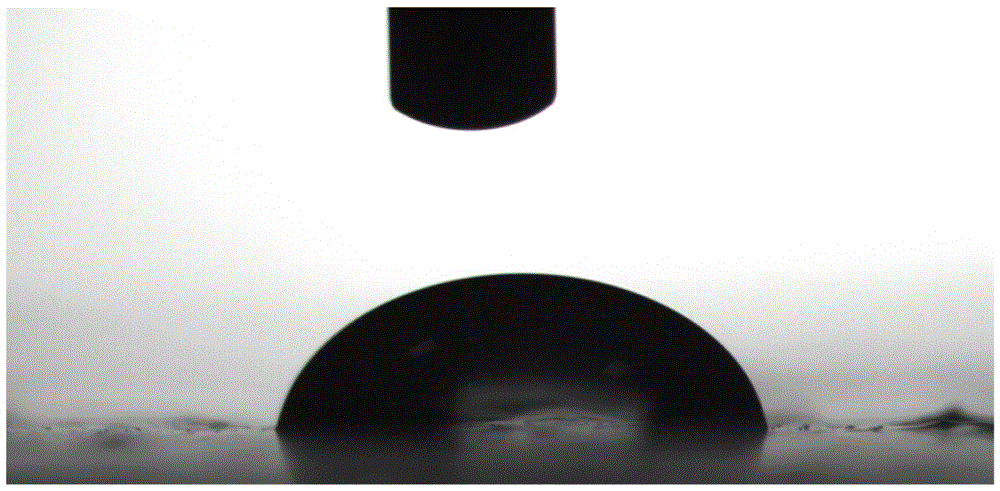

Preparation method of waterborne polyurethane with hyperbranched structure silicone oil side chain

The invention provides a hyperbranched silicone oil side chain modified waterborne polyurethane polymer and a preparation method thereof. The preparation method of the polymer comprises the following steps: making 100 parts of polyether polyol and 10 parts of hyperbranched amino silicone oil react with 20 to 80 parts of diisocyanate to obtain a polyurethane prepolymer which contains a hyperbranched silicone oil side chain and is blocked by an isocyanate group; adding 2 to 19 parts of small molecular polyol chain extender into the prepolymer and 0.1 to 10 parts of amino-containing small molecular dihydric alcohol for chain extension, and performing quaternization and further emulsification to obtain hyperbranched silicone oil side chain modified polyurethane polymer emulsion. In the hyperbranched silicone oil side chain modified waterborne polyurethane emulsion, a hyperbranched siloxane chain segment is adopted, so that the water contact angle is increased, and the water absorption of polyurethane is lowered; the emulsion can be used as a fluorine-free waterproof agent to be applied to chemical fiber cloth or cotton; the preparation method is simple in process, the reaction speed is moderate and the operating conditions are easy to control; the product belongs to a water-based emulsion, and conforms to the development direction of environmental friendliness.

Owner:WACKER DYMATIC SILICONES SHUNDE CO LTD FOSHAN

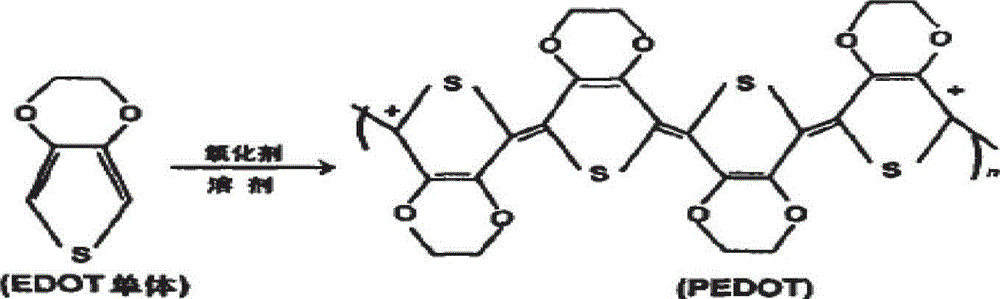

Method for preparing iron p-toluenesulfonate and solution thereof

ActiveCN102911089AFerric hydroxide is activeHigh puritySulfonic acids salts preparationReaction intermediateP-toluenesulfonate

The invention discloses a method for preparing iron p-toluenesulfonate and a solution thereof. The method for preparing the iron p-toluenesulfonate includes the steps that (1) a sodium hydroxide solution and an ammonium ferric sulfate solution are prepared; (2) the sodium hydroxide solution is added in the ammonium ferric sulfate solution, the final potential of hydrogen (pH) value of reaction is 7.0 to 9.0, and iron hydroxide precipitation is obtained; (3) the iron hydroxide precipitation is washed, placed in a filter bag and suspended to be dried at room temperature until the iron hydroxide precipitation which is colloid and contains a small amount of water is formed; (4) iron hydroxide which is suspended to be dried is reacted with a p-toluene sulfonic acid to generate an iron p-toluenesulfonate solution; (5) the iron p-toluenesulfonate solution is filtered and concentrated to be viscous, and discharging-cooling and crystallization are performed; and (6) crystals are crushed and dried to obtain the product. The method for preparing the iron p-toluenesulfonate and the solution thereof has the advantages that the activity of the reaction intermediate iron hydroxide is good, the reaction with the p-toluene sulfonic acid is complete, the process is simple, the energy consumption and the cost are low, and the environmental pollution is small.

Owner:广州化学试剂厂

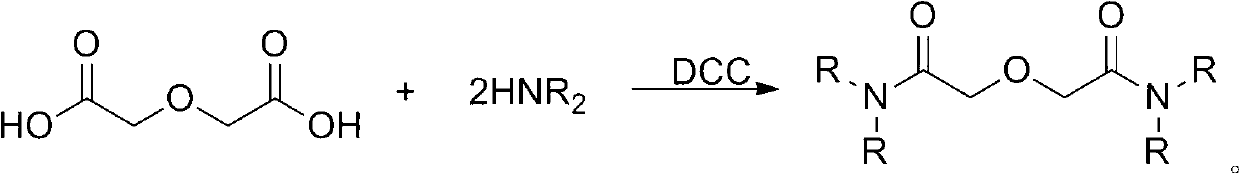

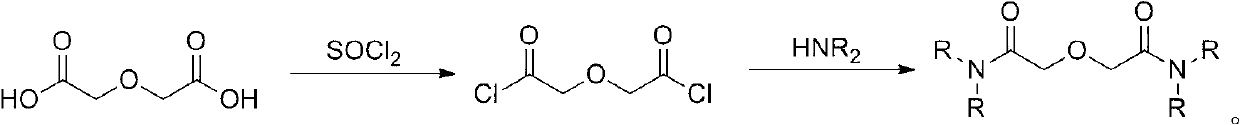

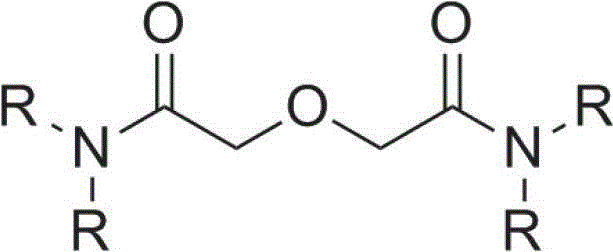

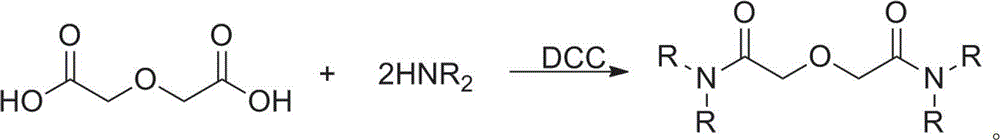

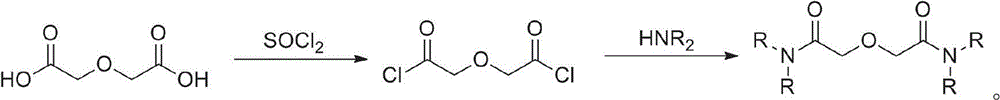

Method for synthesizing diamide podand extraction agent

ActiveCN102993042AEasy to purifyMild reaction conditionsOrganic compound preparationCarboxylic acid amides preparationLiquid wasteFuel reprocessing

The invention discloses a method for synthesizing diamide podand extraction agent, wherein chloro-carbonic ester and diglycolic anhydride react to generate mixed anhydride under the action of tertiary amine, and then the reaction is performed with amine to generate the diamide podand extraction agent. The method has mild reaction condition, can be performed at a low temperature, and has high reaction speed and short consumed time; the product purification operation is simple and easy; the obtained diamide podand extraction agent can meet the extraction purity requirement, and is beneficial to establishing flow that the diamide podand is used for treating high-level liquid waste in spent fuel reprocessing plant; the used chloro-carbonic ester is easy to prepare and has a low price, therefore, the cost for preparation of a great amount of extraction agent is greatly reduced; and besides, the yield of the extraction agent is high, so that the method is very suitable for industrial production and application.

Owner:SICHUAN UNIV

Hydrogen-making method by utilizing catalytic cracked regenerated flue gas

InactiveCN1169707CIncrease contentSolve the pollution of the environmentHydrogenChemical recyclingHydrogenFlue gas

The method for making hydrogen by utilizing catalytic cracking regenerated flue gas includes the following steps: (1). contacting hydrocarbon oil raw material with catalytic cracking catalyst and making them produce reaction; (2). separating reaction oil vapour and catalyst of carbon deposit, feeding oil vapour into subsequent separation system, and stripping the catalyst of carbon deposit and feeding it into first regenerator; (3). in first regenerator contacting the catalyst of carbon deposit with oxygen-containing gas for 2-2.5 sec. at 500-660 deg.C and empty bed gas speed of 0.2-0.8 m / s, feeding regenerated flue gas into subsquent hydrogen-making process; (4). separating CO from regenerated flue gas, making CO and water vapour produce conversion reaction and separating hydrogen from the obtained gas product.

Owner:CHINA PETROLEUM & CHEM CORP +1

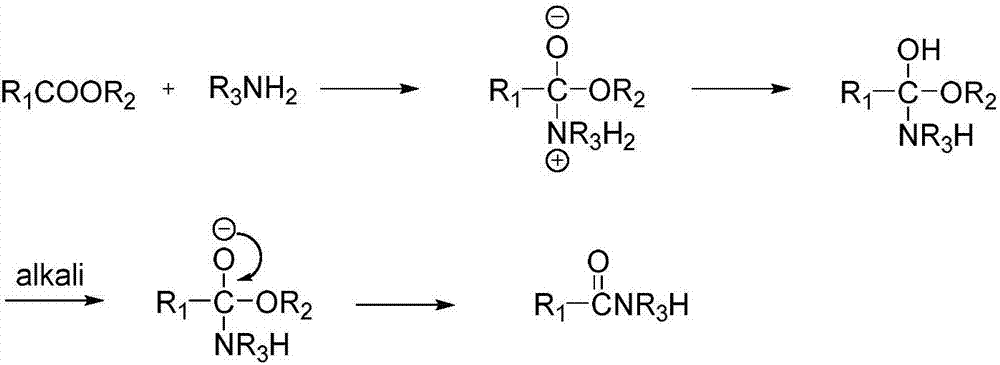

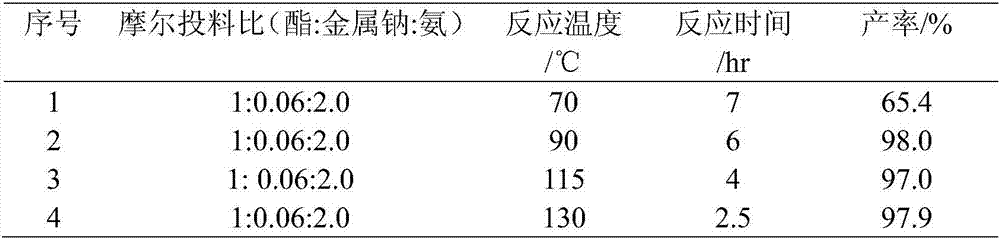

Method for preparing amide by metallic sodium catalyzed ester ammonolysis reaction

InactiveCN106928083ALow costEasy to separateOrganic compound preparationCarboxylic acid amides preparationHigh pressureReaction speed

The invention discloses a method for preparing amides by metallic sodium-catalyzed ester amination reaction: the reaction is carried out in an autoclave at 90-140°C with ester and liquid ammonia as raw materials and metallic sodium as a catalyst, ester:ammonia=1:1.2 The molar ratio of ~5.0, metal sodium is 4~10% of the molar weight of the ester; when the reaction pressure no longer drops, the reaction is stopped, the unreacted ammonia is recovered, and the obtained reaction product is post-processed to obtain the product. The method can efficiently prepare amides; and the raw materials are cheap, low in toxicity, high in reactivity, less in catalyst consumption, fast in reaction speed, high in reaction conversion rate, and easy to separate products.

Owner:ZHEJIANG UNIV

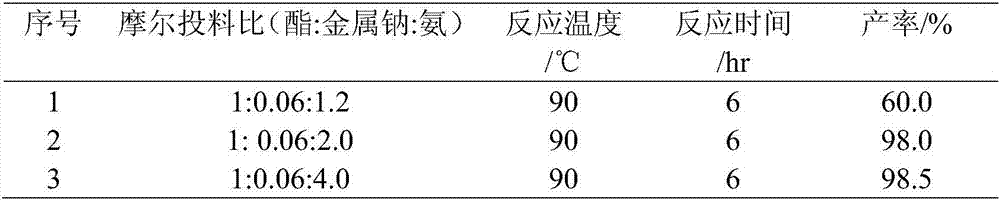

Preparation method of polyvinylidene fluoride resin for solar backboard film

The invention relates to a preparation method of polyvinylidene fluoride resin for a solar backboard film. According to the method, an initiator for polymerization is an organic lipoperoxide initiator being low in reaction activation energy, and an adjustor for polymerization is low molecular weight ester with high adjusting efficiency, wherein the concentration of the initiator is 10-30% and the concentration of the adjustor is 5-30%. The continuous feeding manner is adopted, the polymerization condition is mild, the temperature is 64.5-66.5 DEG C, the pressure of a kettle is 2.95-3.15MPa, the end group of a polymerization product is stable and the molecular weight of the polymerization product is controllable in size, and the distribution coefficient is narrow. The obtained polyvinylidene fluoride product cannot be yellowed, is free from big crystal points and can satisfy the demand on technical indexes of the solar backboard film.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

High-purity iron p-toluenesulfonate solution synthesis method

InactiveCN105017091AFerric hydroxide is activeHigh puritySulfonic acids salts preparationReaction intermediateImpurity ions

The present invention belongs to the technical field of electronic chemical production, and particularly relates to a high-purity iron p-toluenesulfonate solution synthesis method, which comprises: 1) preparing a ferric sulfate solution and a sodium hydroxide solution; 2) preparing ferric hydroxide floc; 3) preparing ferric hydroxide filter cake having sulfate ions achieving the standard; 4) preparing a p-toluenesulfonic acid solution having qualified sulfate ions; and 5) preparing the high-purity iron p-toluenesulfonate solution. According to the present invention, the prepared reaction intermediate ferric hydroxide has good activity and completely reacts with p-toluenesulfonic acid, the product has high purity, and the impurity ions are less.

Owner:武汉海斯普林科技发展有限公司

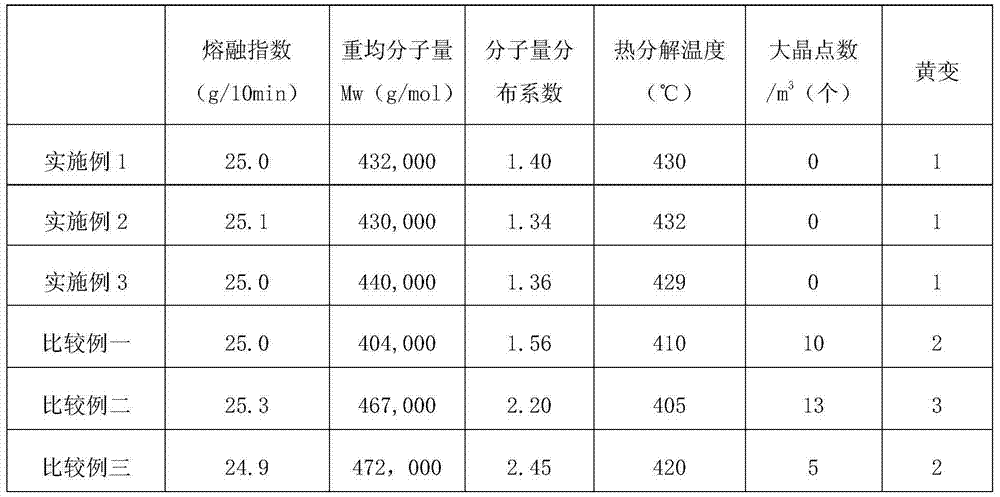

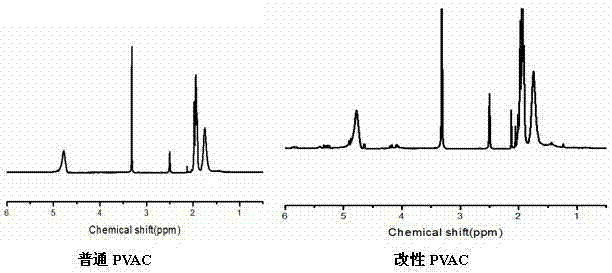

Modified polyvinyl alcohol and preparation method thereof

The invention relates to modified polyvinyl alcohol, which has the following structure formula defined in the specification, wherein x, y and z are integers, x is more than 1 and is less than or equal to 500, y is more than 1 and is less than or equal to 2000, z is more than 1 and is less than or equal to 200, y is more than x, y is more than z, R1 is an oxygen atom or -CO- or -(CH-OH)-, and R2 is alkyl, alkoxy or hydroxyl-terminated alkyl. According to the present invention, the monomer copolymerization consumption is less, the reaction rate is moderate, the conversion rate of the prepared vinyl acetate-branched vinyl copolymer is 40-80%, the alcoholysis degree of the alcoholysis product is 98-99.8 mol%, the crystallinity is less than 20%, the melting point is 160-195 DEG C, the viscosity is 3.0-25.0 mPa.S (20 DEG C, 4% aqueous solution), and the obtained product can be subjected to melting processing and has good processability.

Owner:SINOPEC SICHUAN VINYLON FACTORY +2

Preparation method of double functionality lithium system initiator

In the mixed solvent using non-polar solvent as main component the metal lithium and alpha-methylstyrene or isoprene are reacted to directly prepare bifunctionality anionic oligomer. Its mixed solvent uses arene or paraffine or their mixture as main component, contains ether or amine or both mixture, in which arene and paraffine content is 50-99.9% (valoume) and ether and amine content is 0.1-50%(valume), the conjugated arene and metal lithium are reacted for 1-6 hr. under the condition of -50- -50 deg.C to obtain reactino product, said product is filtered to obtain bifunctionality initiator.

Owner:BEIJING UNIV OF CHEM TECH

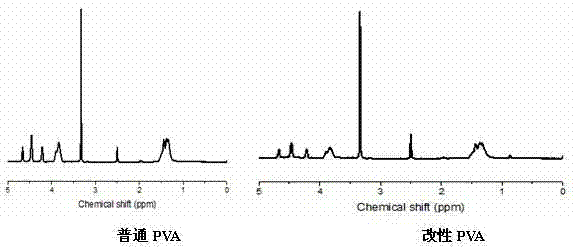

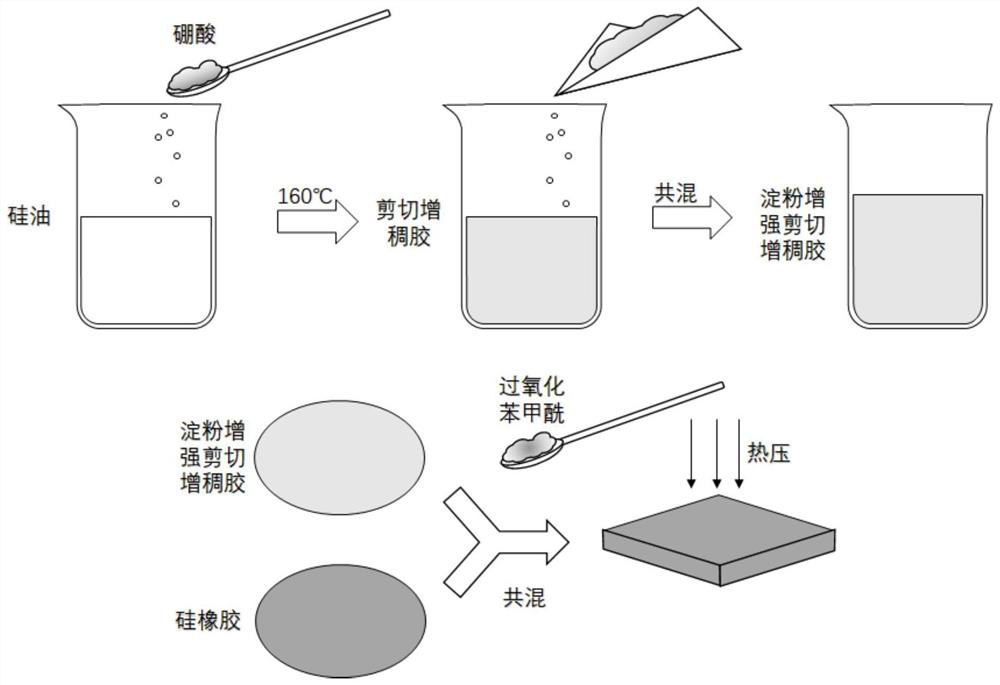

Crosslinked starch reinforced composite shear thickening elastomer

ActiveCN113072810ALow priceHigh yield stressProtective equipmentFibre treatmentElastomerPolymer science

The invention discloses a crosslinked starch reinforced composite shear thickening elastomer, and belongs to the technical field of composite material preparation. The crosslinked starch and the shear thickening glue are compounded to form a macromolecular network structure, so that the problem of cold flow property of the original shear thickening material is solved, meanwhile, the shear thickening material has better machinability, initial elastic modulus and elastic recovery capability; and the overall protection performance can be kept without attenuation in the long-time use process. The shear thickening elastomer prepared by the preparation method disclosed by the invention not only keeps good impact resistance, but also has excellent stability (namely no cold flow property). In the actual application process, the material serves as a core material and is easy to package, and when a plane material is damaged and loses sealing performance, the shear thickening elastomer does not leak like shear thickening glue.

Owner:广州无塑地球新材料科技有限公司

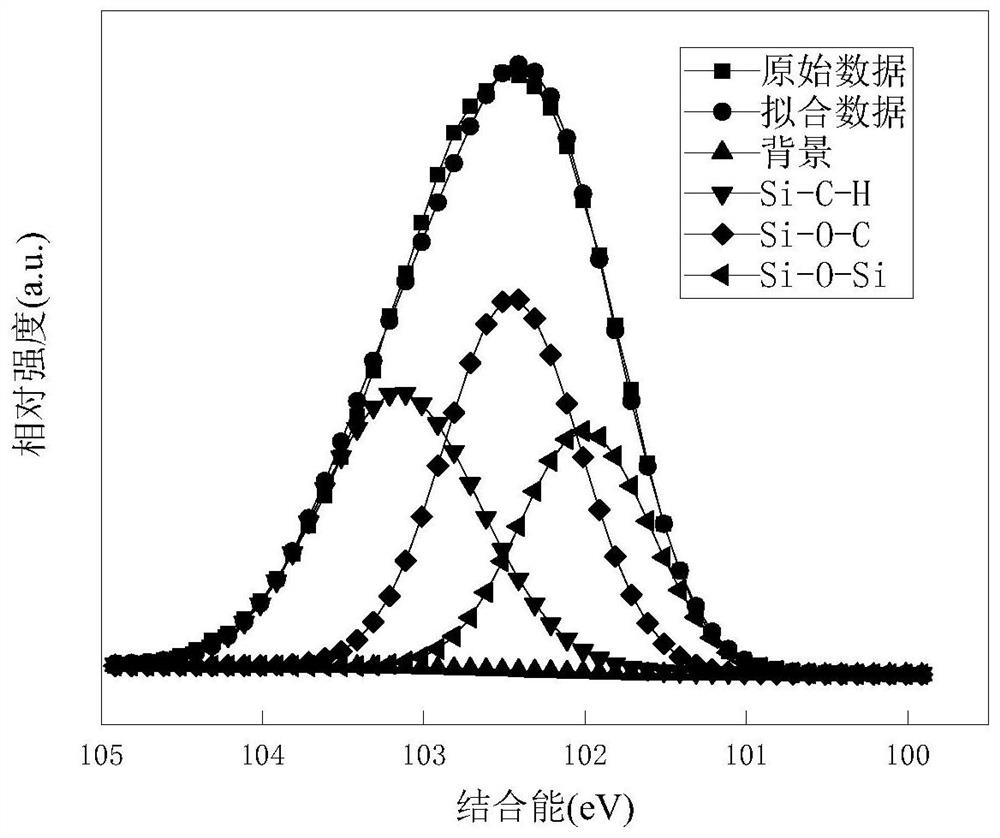

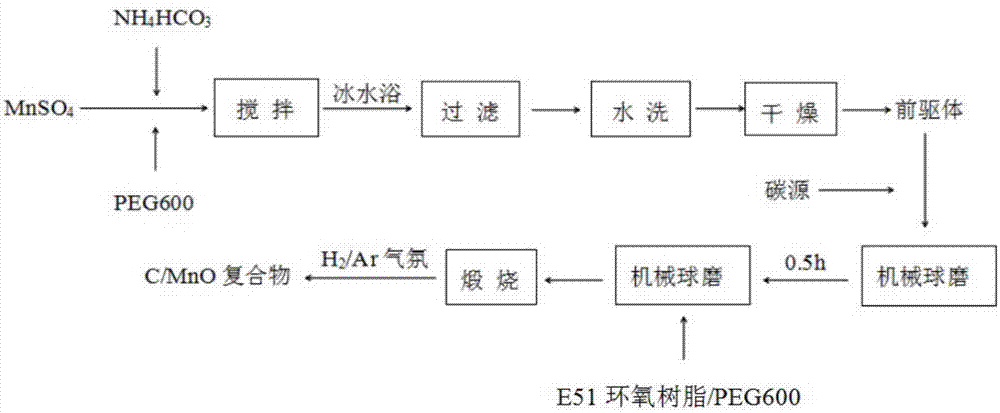

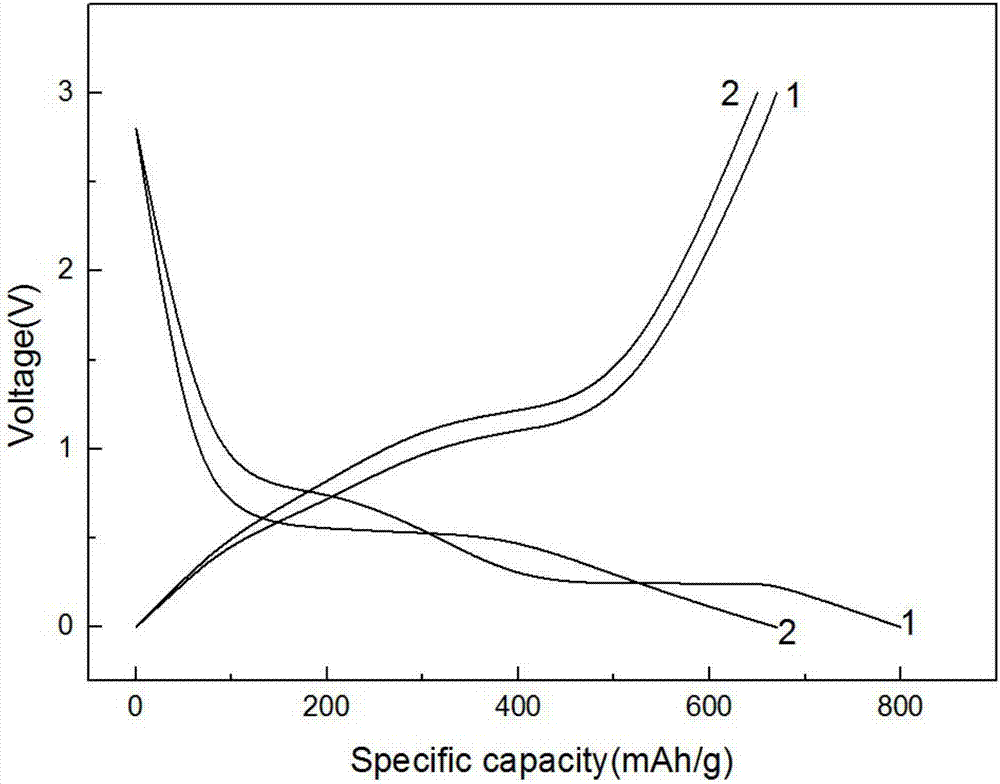

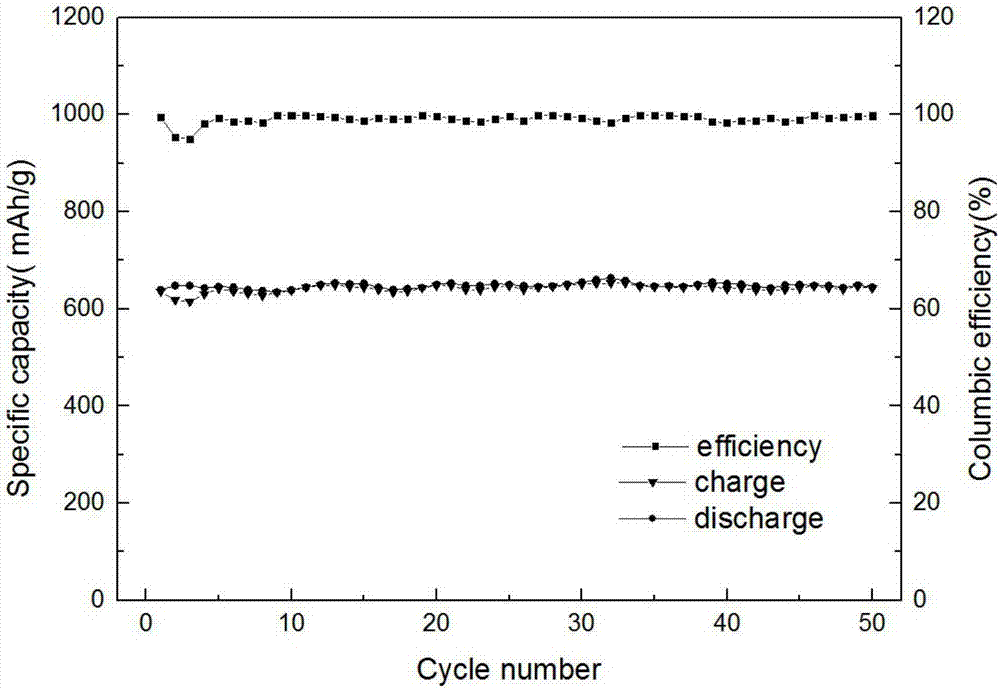

Preparation method of C/MnO composite electrode material

InactiveCN107546374AImprove uniformityGood dispersionHybrid capacitor electrodesCell electrodesEpoxyComposite electrode

The invention discloses a preparation method of a C / MnO composite electrode material, and belongs to the technical field of composite materials. The preparation method comprises the following steps: configuring an MnSO4 solution with the concentration of 0.25 mol / L and an NH4HCO3 solution with the concentration of 0.25 mol / L respectively, mixing the MnSO4 solution and the NH4HCO3 solution in the volume ratio of 1: (0.15 to 1), then adding PEG600 into the solution, and controlling the pH of the solution to be 6 to 7; putting the mixed liquor into an ice-water bath for stirring for 1.5 to 2 h, filtering the solution after the reaction is ended, washing the precipitate with deionized water, and then drying to obtain a precursor; mixing a carbon source and the precursor in a mass ratio of 1: (25 to 50), then carrying out mechanical ball-milling for 0.5 h, adding E51 epoxy resin / PEG 600, continuously carrying out ball-milling for 1 to 2 h, and then taking out a ball-milling product; puttingthe ball-milling product into H2 / Ar mixed gas for calcinations, carrying out natural furnace cooling after the reaction is ended, and finally obtaining the C / MnO composite material. The C / MnO composite material prepared in the invention is stable in performance and high in specific capacity; the method is simple in technology, mild in reaction conditions, low in cost and high in production efficiency, and is applicable for industrial production.

Owner:GUANGXI NORMAL UNIV OF SCI & TECH

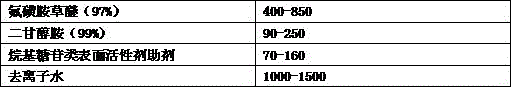

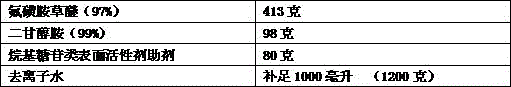

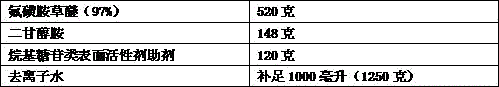

High-content fomesafen aqueous solution and preparation method thereof

InactiveCN106386794AEasy to useMild in natureBiocideDead animal preservationGlycosideAqueous solution

The invention relates to a high-content fomesafen aqueous solution and a preparation method thereof. The preparation method comprises the following steps: adding deionized water into a container, stirring, adding a 97% fomesafen raw medicine, slowly dropping a 99% 2-(2-aminoethoxy) ethanol solution, after dropping is completed, continuously stirring for more than 10 minutes to sufficiently react and neutralize the fomesafen raw medicine with 2-(2-aminoethoxy) ethanol so as to form a transparent solution, finally adding an alkyl glycoside surfactant aid, and uniformly stirring to obtain a fomesafen aqueous solution product.

Owner:江苏长青生物科技有限公司

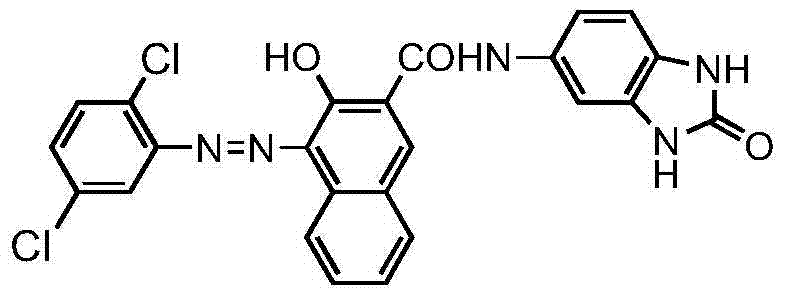

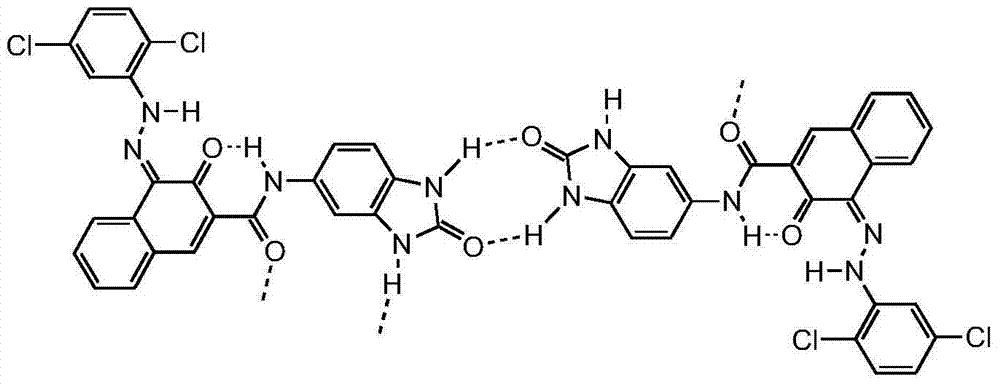

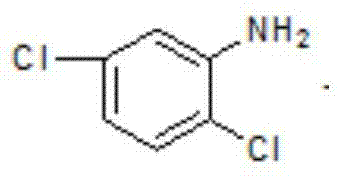

Preparation method of C.I. pigment brown 25

InactiveCN104497619AGuaranteed uniformityImproves color and tinting strengthMonoazo dyesBenzimidazoleAcid water

The invention discloses a preparation method of C.I. pigment brown 25. The preparation method comprises the following steps: (1) preparing a diazo salt liquid of 2,5-dichloroaniline; (2) dissolving 5-(2'-hydroxy-3'-naphthalene-carbamoyl)-2-benzimidazolone in an alkaline water liquid, and adding an acid water liquid to acidify, so as to prepare a suspended coupling liquid; (3) adding the diazo salt liquid into the coupling liquid to carry out a coupling reaction, controlling the pH value of the reacted mixed liquid at 5.5-6.5 by virtue of an alkaline additive in a coupling process, and processing after the coupling so as to obtain a rough pigment; and (4) carrying out pigmentation on the rough pigment to obtain the finished C.I. pigment brown 25. According to the preparation method, coupled components are separated out in a particle manner in an acidification process and are coupled with added diazo components, so that the uniformity of the coupling reaction is guaranteed, and the obtained C.I. pigment brown 25 has the beneficial effects that the particle sizes are uniform, particles are floppy, the dispersibility is excellent, the color is bright, and the coloring strength is high.

Owner:SHANGYU SHUNLIAN CHEM

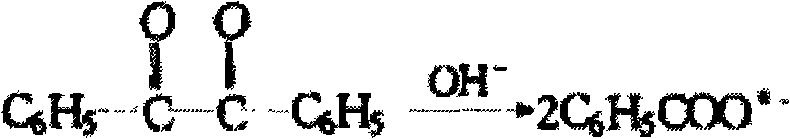

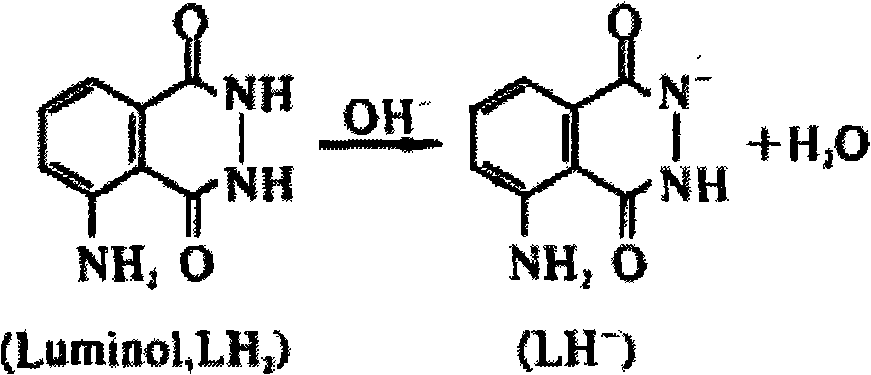

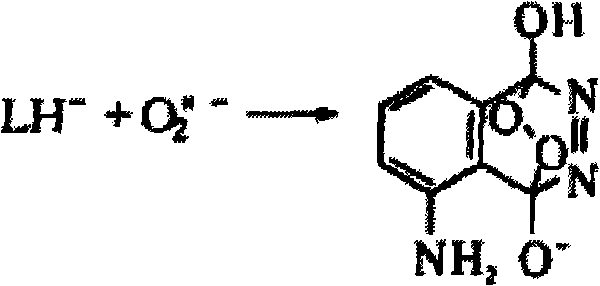

Chemiluminescence system for determining benzoyl peroxide and method

InactiveCN101339136AImprove stabilityHigh sensitivityChemiluminescene/bioluminescencePreparing sample for investigationLuminous intensityBenzoyl peroxide

The invention relates to a chemiluminescent system and a method which uses the system to determine benzoyl peroxide in flour. The chemiluminescent system is a mixed reaction system of A solution and B solution; the A solution is a luminescent reagent which contains Luminol of 6.0*10<-5> to 2.5*10<3>mol / L, CO3<2-> of 0.20 to 1.00mol / L and OH<-> of 0.08 to 0.20mol / L; the B solution is detected solution which contains Co<2+> of 1.0*10<-8> to 1.0*10<-6>. The method mainly comprises the following steps: mixing A and B with a volume ratio of from 0.8 to 1.2 to 1 in the detection container of a chemiluminescent instrument, and detecting and reading the luminous intensity of the chemiluminescent reaction. The chemiluminescent system has the advantages of high stability, high sensitivity, moderate reaction velocity, anti-interference performance, and excellent selectivity of the detected matter. The method of operation is simple, time-saving and efficient.

Owner:ZHENGZHOU XIANJIE TECH

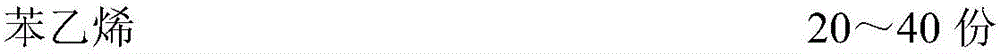

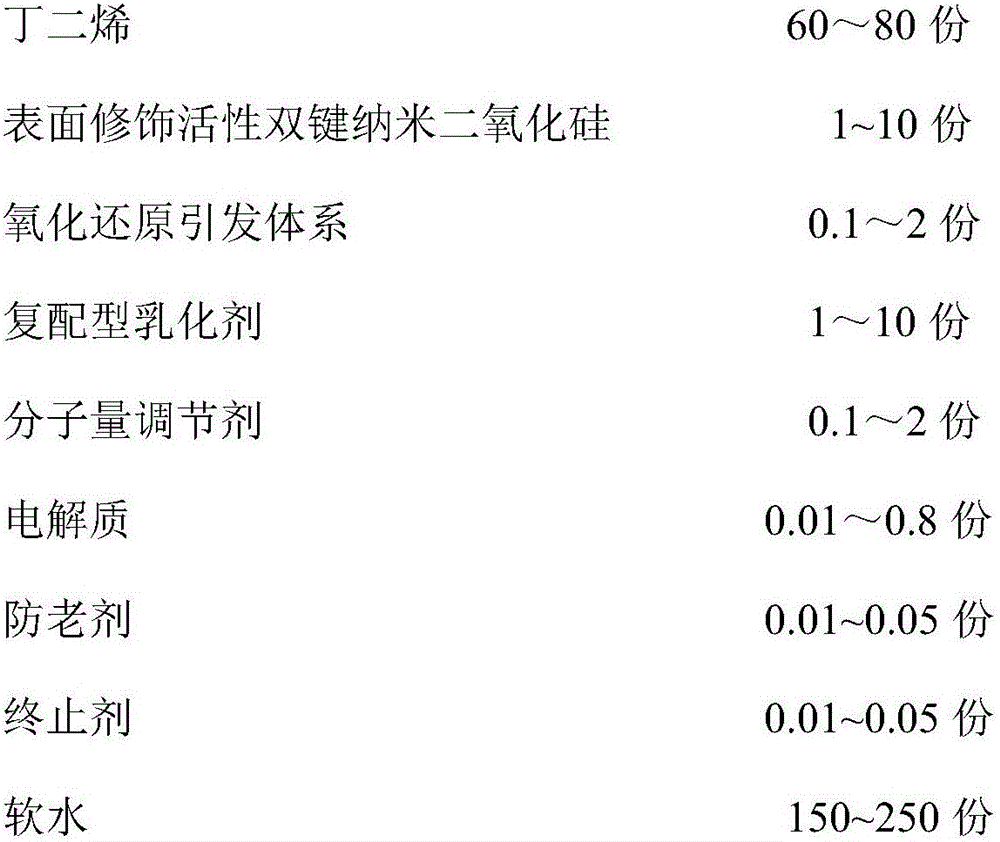

Method for preparing nanosilicon dioxide modified styrene-butadiene latex

The invention discloses a method for preparing nanosilicon dioxide modified styrene-butadiene latex. An emulsion polymerization mode of stepwise heating is adopted, styrene and butadiene monomers are added into a polyreactor at a time, meanwhile, nanosilicon dioxide with the surface modified with activated double bonds is added to serve as functional filler, a molecular weight modifier, an emulgator and an oxidizing agent are added in batches, and finally the styrene-butadiene latex with good mechanical stability, bonding strength and the like is obtained. The styrene-butadiene latex is good in heat resistance and wear resistance, and is mainly applied to road asphalt modification.

Owner:XIAMEN UNIV

Method for synthesizing diamide podand extraction agent

ActiveCN102993042BEasy to purifyMild reaction conditionsOrganic compound preparationCarboxylic acid amides preparationLiquid wasteFuel reprocessing

Owner:SICHUAN UNIV

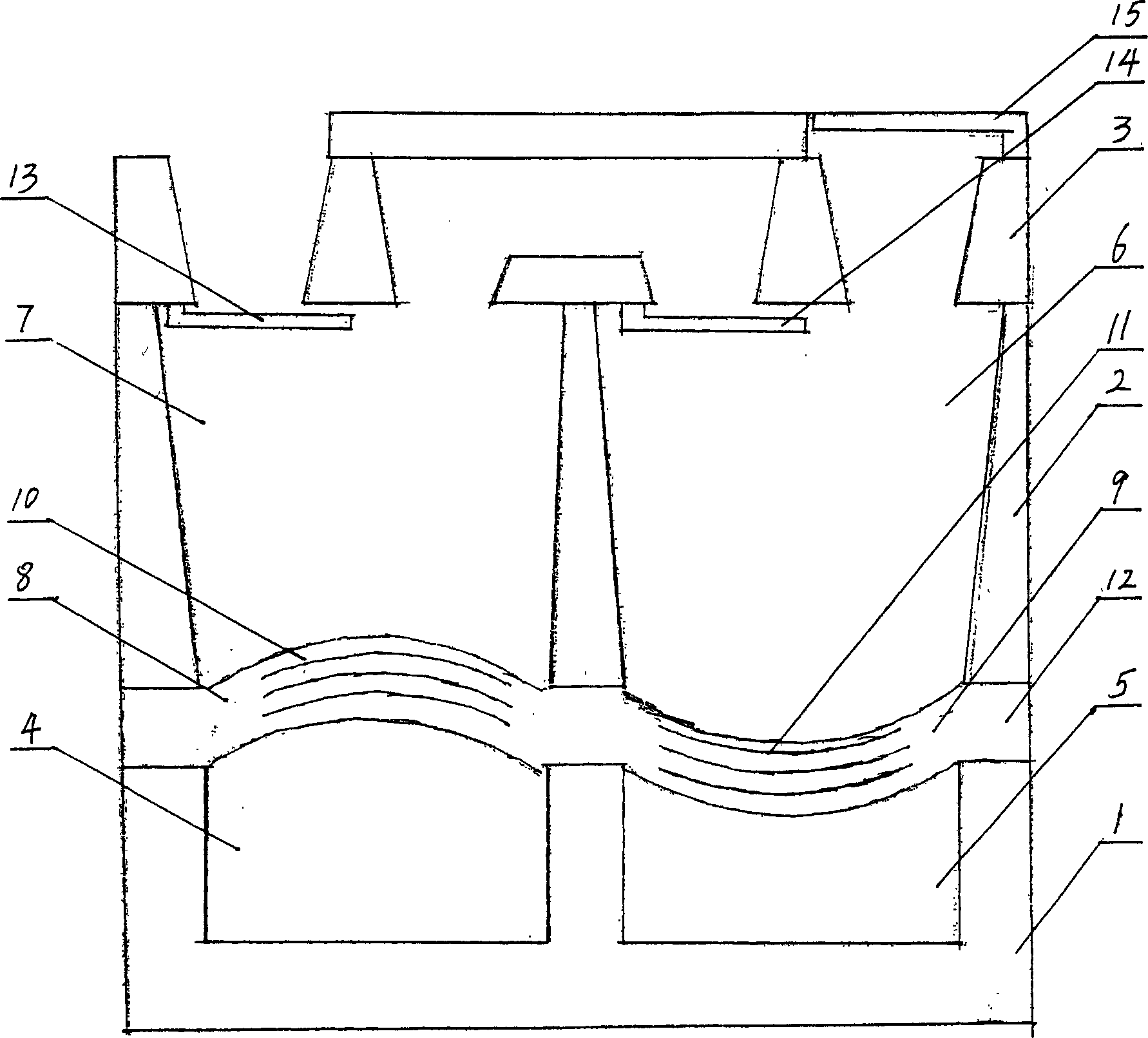

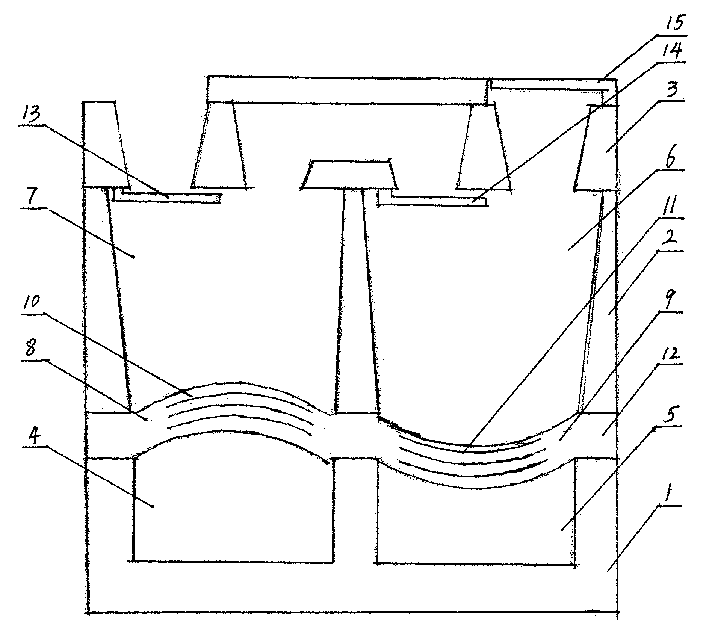

Miniature magnetic-driven pump

InactiveCN1423052AHigh trafficImprove performanceFlexible member pumpsPositive-displacement liquid enginesPower flowEngineering

The invention is a kind of minim pump droved by magnetism energy, it comprises a base board, a head board and a middle board which is in the middle of the other two boards, so forms four pump cavities, it has entrance and exit; it includes two free surface which are formed in the middle board; the head board has hole connected to outside; there are magnetism energy driving device in the two free surfaces to drive them, the magnetic field formed by fixed current interacts with outer magnetic field, it make the free surface change to make the volume of cavity change periodically.

Owner:CHONGQING UNIV

Scratch-coated polyurea elastomer corrosion-resistant and wear-resistant material and preparation method thereof

ActiveCN105802460BIncrease crosslink densityHigh tensile strengthAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerWear resistant

The invention discloses a scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and a preparation method thereof. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is characterized by comprising an ingredient A and an ingredient B, wherein the ingredient A is prepolymers with NCO end groups obtained through the reaction between 30 to 40 mass percent of polyether polyol and 60 to 70 mass percent of polyisocyanates; the ingredient B is prepared from 30 to 40 mass percent polyaspartic acid ester, 60 to 70 mass percent of filling materials and a small number of auxiliary agents through high-speed dispersion grinding. In the use process, the prepared ingredient A and the prepared ingredient B are weighed according to the weight ratio of 1:4, and are then uniformly mixed; next, scraping coating construction is performed. The material has the characteristics of high mechanical intensity, corrosion resistance, wear resistance, good anti-seeping performance, aging resistance, proper reaction speed, no solvent, convenient construction and the like. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is particularly suitable for industrial and mining enterprise equipment and spare part anti-corrosion wear-resistant liners.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

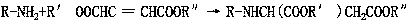

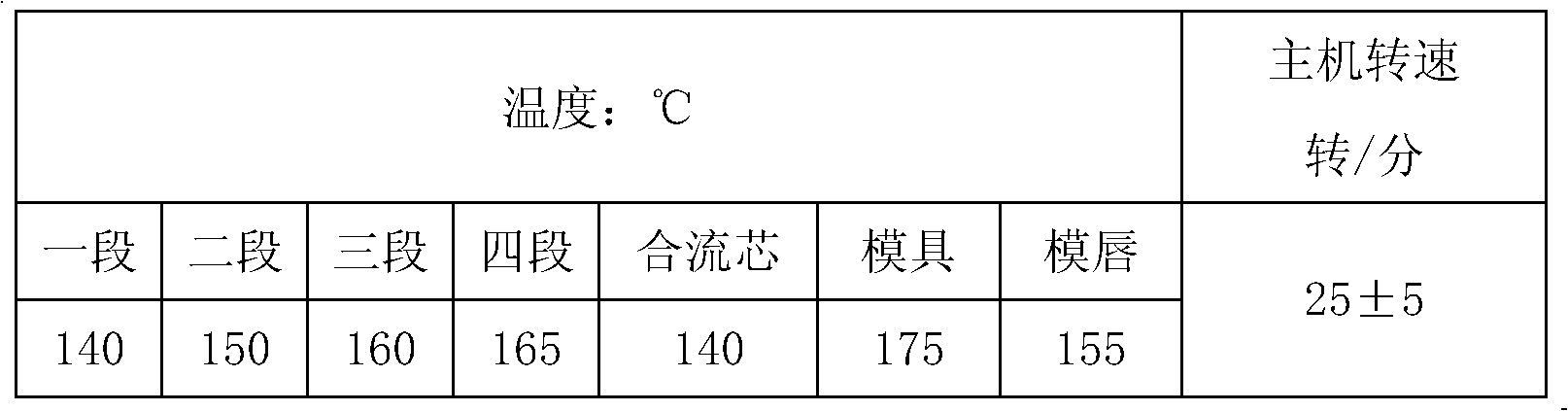

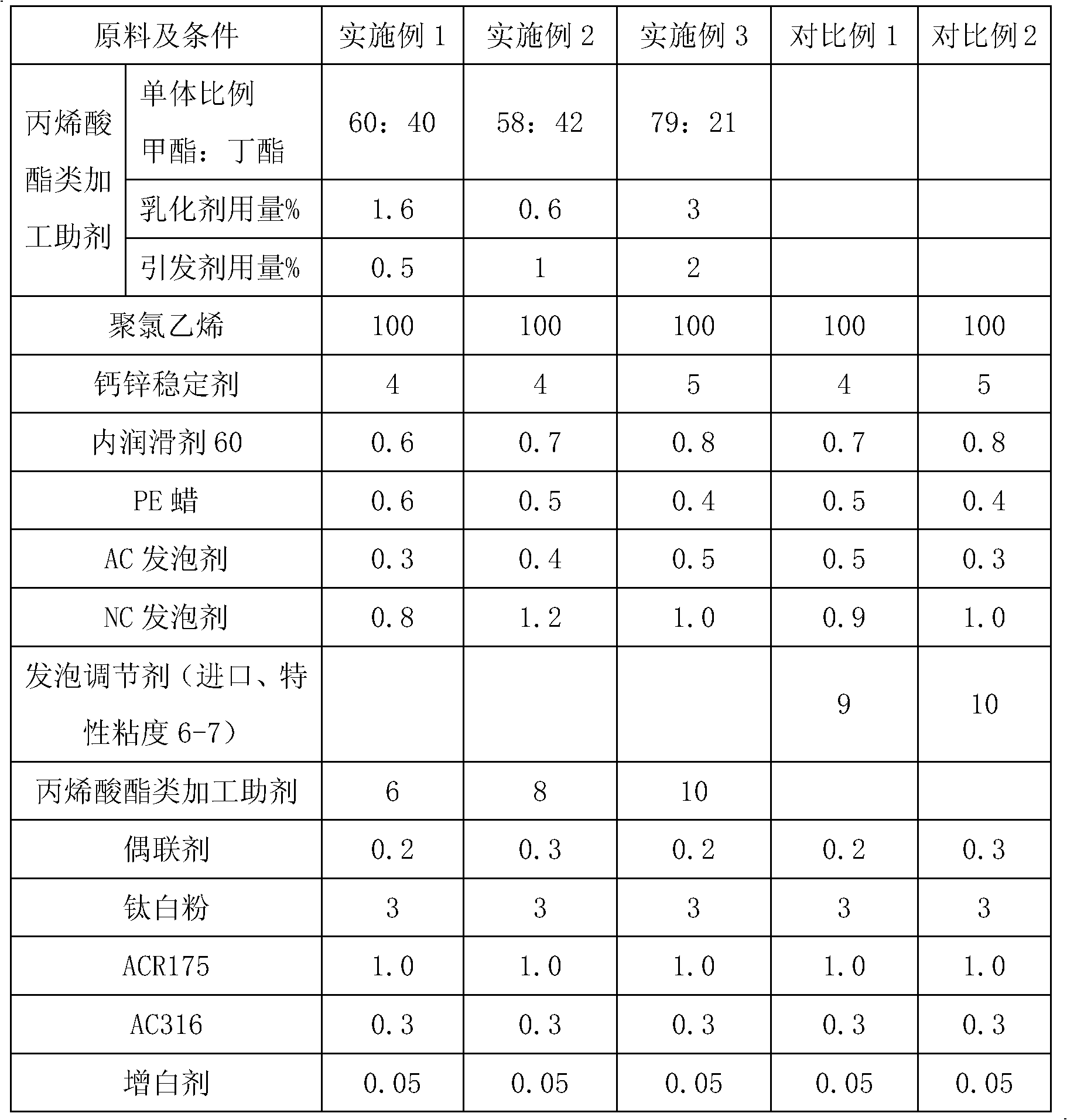

Acrylate processing aid as well as preparation method and application thereof

The invention belongs to the field of chemical engineering and particularly relates to an acrylate processing aid as well as a preparation method and an application thereof in production of polyvinyl chloride foam boards. Calculated by taking the total weight of polymerization monomers as 100%, the acrylate processing aid is formed by polymerization reaction of 58-79% of methyl methacrylate and 39-18% of butyl acrylate via emulsion; a surfactant adopts a mixture of sodium dodecyl sulfate and OP-10 at the weight ratio of 5:1, the using quantity of the surfactant accounts for 0.5%-3% of the total weight, an initiator adopts potassium persulfate, and the using quality of the initiator is 0.3-2% of the total weight of the processing aid. When the acrylate processing aid disclosed by the invention is used as a foam regulator for polyvinyl chloride, the viscosity can be up to 12-13; and an acrylate polymer is good in powder fluidity and can be used for preparing polyvinyl chloride foam board products with uniform foam holes.

Owner:SHANDONG RUIFENG CHEM

Aqueous transfer membrane demolding agent as well as preparation method and application thereof

ActiveCN110527348AExtended service lifeFast and efficient strippingChemical paints/ink removersSolventSURFACTANT BLEND

The invention relates to an aqueous transfer membrane demolding agent as well as a preparation method and application thereof. The aqueous transfer membrane demolding agent consists of the following components in parts by mass: 10-25% of an inorganic strong base, 10-20% of an organic weak base, 8-20% of a main solvent, 5-20% of a cosolvent, 2-5% of a surfactant, 1-15% of a chelating agent and thebalance of water. The aqueous transfer membrane demolding agent provided by the invention has the properties of rapidness and high efficiency, can be repeatedly used for a long time, has no influenceupon a substrate surface, particularly the precision of a sapphire cover plate, and has good application prospects in the precise processing industry.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

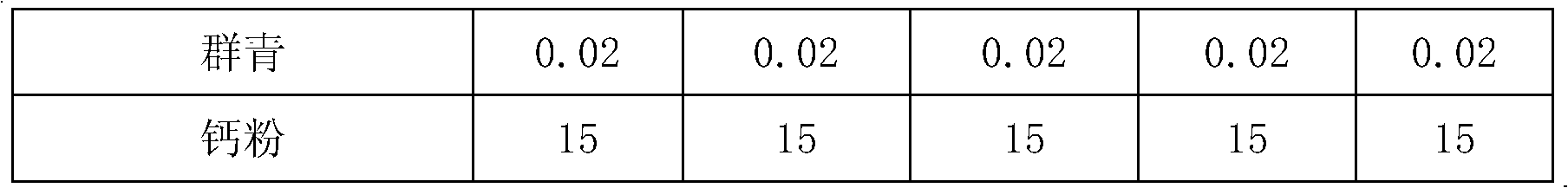

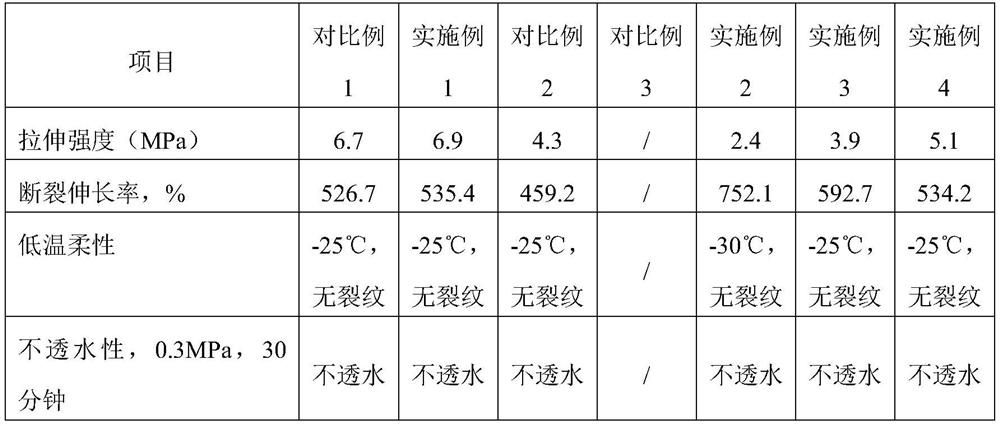

Single-component waterborne polyurethane waterproof coating and preparation method thereof

ActiveCN114181605AImprove mechanical propertiesStrong hydrophobic functionPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a single-component waterborne polyurethane waterproof coating and a preparation method thereof. The coating is prepared from the following raw materials: polyether glycol, polyether triol, polytetrahydrofuran ether glycol, fluorine-containing hydroxyl-terminated polysiloxane, diisocyanate, aromatic diamine containing a polytetrahydrofuran ether chain segment, a water-based chain extender, a neutralizer, a solvent, a catalyst, deionized water, a water-based dispersant, a powder filler, water-based color paste, a thickener, an anticorrosive bactericide and a defoaming agent. And an antifreezing agent. The prepared single-component waterborne polyurethane waterproof coating has excellent comprehensive performance, the film-forming tensile strength ranges from 2.4 MPa to 6.9 MPa, the elongation at break ranges from 534.2% to 752.1%, and the water resistance can meet the requirements of solvent type polyurethane waterproof coatings.

Owner:YUZHONGQING WATERPROOF MATERIALS CO LTD

Prepn. method of double-functionality lithium system initiator

The present invention proposes a preparation method of a bifunctional lithium-based initiator, in which metal lithium reacts with α-methylstyrene or isoprene in a mixed solvent mainly composed of non-polar solvents to directly prepare a difunctional anion Polymer. The mixed solvent is mainly aromatic hydrocarbons or alkanes, or a mixture of the two, containing ethers or amines, or a mixture of the two, wherein the content of aromatic hydrocarbons and alkanes is 50-99.9% (volume), and the content of ethers and amines is 0.1-50%. (volume), conjugated olefin and metal lithium are reacted at a temperature of -50 to 50° C. for 1 to 6 hours, and the reactant is filtered to obtain a bifunctional initiator. The initiator prepared by this method does not contain fused-ring aromatic hydrocarbons, and the content of polar substances in the initiator system can be adjusted in a wide range. It can be used for the synthesis of polydiene series rubbers with low side group content, and has good stability and moderate reaction speed. specialty.

Owner:BEIJING UNIV OF CHEM TECH

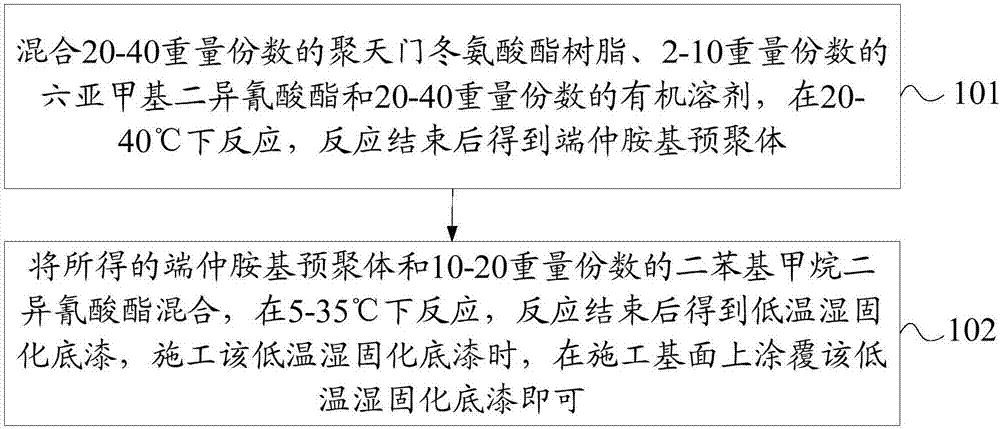

Low-temperature wet cured primer, anticorrosive composite structure and method for preparing and constructing low-temperature wet cured primer

ActiveCN107502167AModerate response speedLow temperature curableAnti-corrosive paintsPolyurea/polyurethane coatingsAdhesion forceOrganic solvent

The invention provides a low-temperature wet cured primer, an anticorrosive composite structure and a method for preparing and constructing the low-temperature wet cured primer. The method comprises the following steps: mixing 20-40 parts by weight of polyaspartic ester resin, 2-10 parts by weight of hexamethylene diisocyanate and 20-40 parts by weight of an organic solvent; reacting at 20-40 DEG C to obtain a secondary amino-terminated prepolymer at the end of the reaction; mixing the obtained secondary amino-terminated prepolymer with 10-20 parts by weight of diphenylmethane diisocyanate; reacting at 5-35 DEG C to obtain the low-temperature wet cured primer at the end of the reaction; coating the low-temperature wet cured primer on a construction base surface; and when the construction base surface is a wet base surface, reacting the low-temperature wet cured primer with moisture on the wet construction base surface to generate an adhesive substance beneficial for adhering the low-temperature wet cured primer to the wet base surface. The low-temperature wet cured primer provided by embodiments of the invention has excellent properties of easily controlled preparation process, strong adhesion force, low-temperature curability and the like.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

Moisture-permeable waterproof film used for fabric and fabrication process thereof

ActiveCN102555380BSolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilitySynthetic resin layered productsLaminationSlurryMoisture

The invention discloses a moisture-permeable waterproof film used for a fabric and a fabrication process thereof. According to the invention, a primary coating comprises polyurethane resin, butanone, toluene, water, hexane diisocyanate and N-methylethanolamine, and a first and second surface coatings comprise polyurethane resin, butanone, toluene, water and N-methylethanolamine. The fabrication process comprises the following steps: mixing hexane diisocyanate with main resin; mixing water with butanone to form a solvent which is put into a main resin mixed solution in at least six steps; filtering the mixed solution with a nylon net so as to obtain a filtered main resin mixed solution and carrying out deaeration treatment so as to form a primary coating slurry; preparing a surface coating slurry with the viscosity of a conjugate solution being 3500 to 6000 mpas; coating the primary coating slurry on the surface of release paper to form the primary coating, with coated weight being 4 to 6 g / m<2>; coating the surface coating slurry on the surface of the primary coat to form the surface coatings; and drying the release paper with the surface coatings and peeling the surface coatings off the release paper. According to the invention, the disadvantages that existing hydrophilic moisture permeable processing coating fabrics have nonuniform micropores and easily swell when contacting with water are overcome, and therefore, moisture permeable performance of a fabric itself is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com