Method for preparing nanosilicon dioxide modified styrene-butadiene latex

A technology of nano-silica and styrene-butadiene latex, which is applied in the field of preparation of nano-silica modified styrene-butadiene latex, can solve the problems of poor product stability and high viscosity, and achieves lower viscosity, lower viscosity and structural gel content. , the application effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

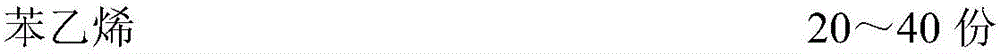

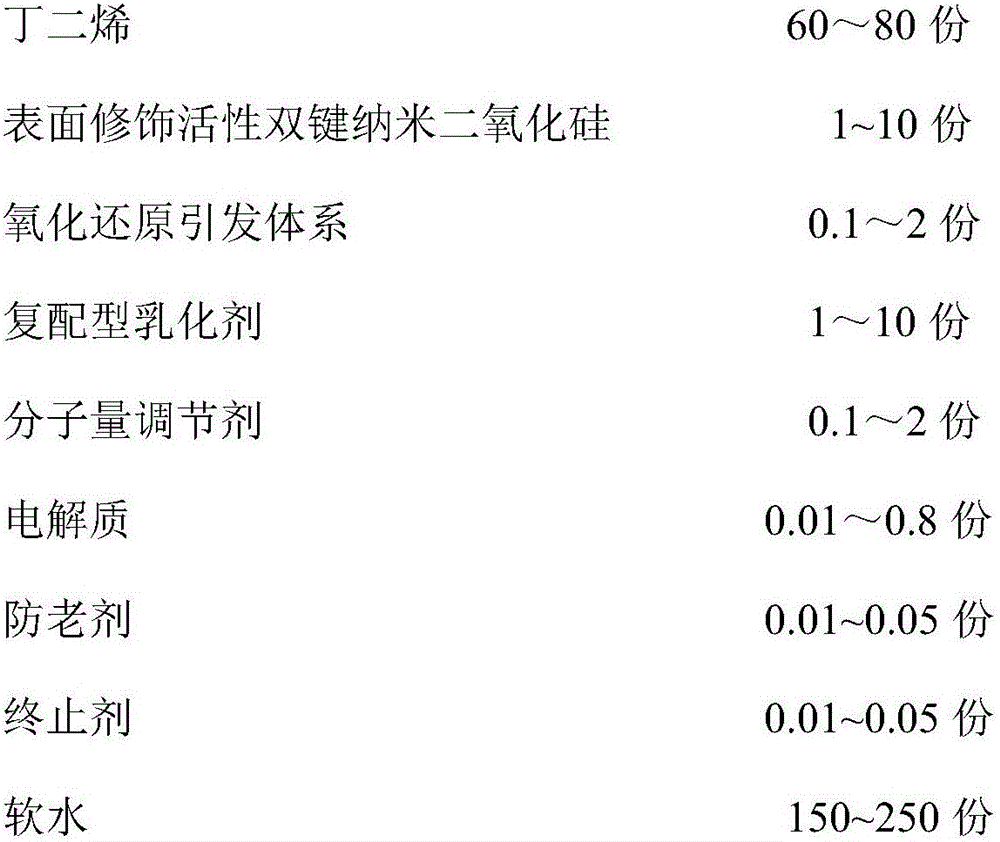

Method used

Image

Examples

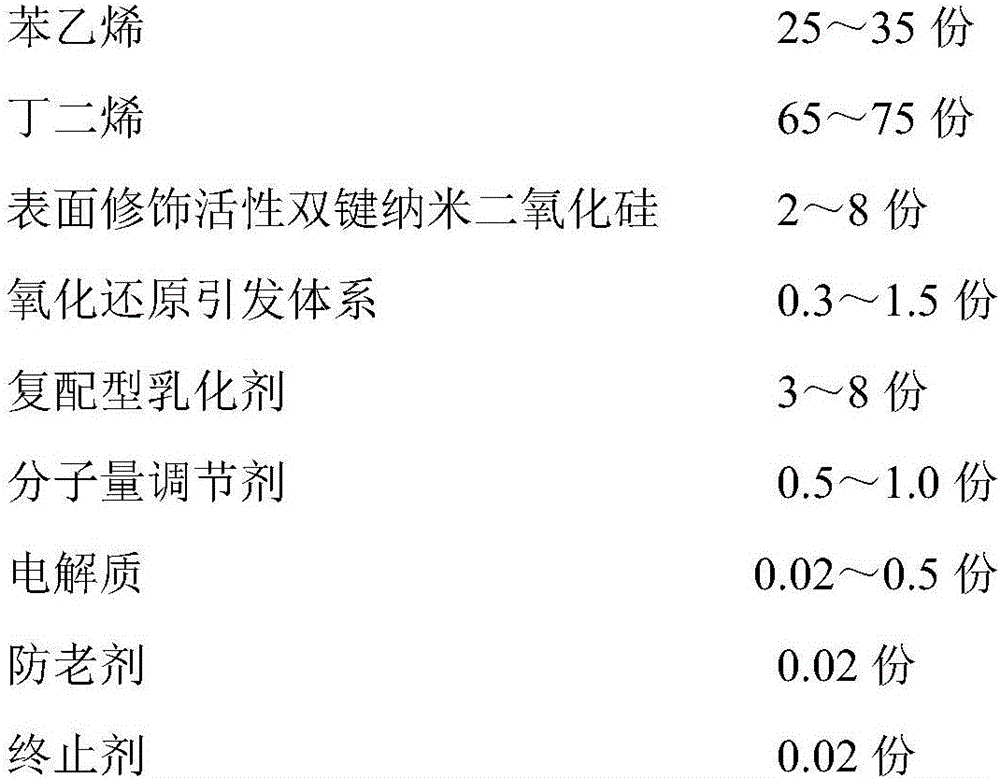

Embodiment 1

[0031] Add 10-20 parts of nano silicon dioxide into 300 parts of ethanol solution. After ultrasonic dispersion for 10-15 minutes, add 20-40 parts of silane coupling agent 3-(methacryloyloxy)propyltrimethoxysilane, and continue ultrasonic dispersion for about 1 hour. After suction filtration, washing and vacuum drying, the nano-silica with active double bonds for surface modification is obtained.

[0032] Fatty acid sodium (chemical formula is RCOONa (R=C 11~17 )) mixed with rosin soap at a mass ratio of 1:1 to 2 to obtain a complex emulsifier.

[0033] Provide a redox initiation system composed of oxidizing agent cumene hydroperoxide, tert-butyl hydroperoxide, reducing agent ferrous sulfate, EDTA iron sodium salt.

[0034] 200 parts of solvent soft water, 25 parts of styrene, 2 parts of nano-silica with active double bonds for surface modification, 0.5 parts of oxidizing agent, 0.8 part of reducing agent, 0.06 part of co-reductive agent carved white powder, 0.1 part of elect...

Embodiment 2

[0036] Please refer to Example 1 for the preparation methods of nano-silica with active double bonds on the surface, complex emulsifier and redox initiation system. 200 parts of soft water as a solvent, 35 parts of styrene, 4 parts of nano-silica with active double bonds for surface modification, 0.2 parts of oxidizing agent, 0.3 part of reducing agent, 0.08 part of co-reducing agent carved white powder, 0.1 part of electrolyte potassium phosphate and molecular weight regulator Add 0.1 parts of carbon tetrachloride and 2 parts of compound emulsifier into the polymerization reaction kettle, after vacuuming to -0.05MPa, feed 65 parts of butadiene, and react according to the three-stage heating method, the initial temperature is 20°C After 5 minutes, the temperature was raised to 28° C. and kept for 10 hours, and then after 5 minutes, the temperature was raised to 38° C. and kept warm. When the conversion rate of the monomer was measured to reach 50%, 0.9 parts of molecular weight...

Embodiment 3

[0038] Please refer to Example 1 for the preparation methods of nano-silica with active double bonds on the surface, complex emulsifier and redox initiation system. 200 parts of soft water as a solvent, 25 parts of styrene, 4 parts of nano-silica with active double bonds for surface modification, 0.3 parts of oxidizing agent, 0.8 part of reducing agent, 0.06 part of co-reducing agent carved white powder, 0.3 part of electrolyte potassium phosphate and molecular weight regulator Add 0.2 parts of dodecyl mercaptan and 2 parts of compound emulsifier into the polymerization reactor. After vacuuming to -0.05MPa, 75 parts of butadiene are introduced, and the reaction is carried out in a three-stage heating method. The initial temperature is 20°C, heat up to 28°C for 5 minutes and keep it warm for 10 hours, and then raise the temperature to 38°C for 5 minutes and keep it warm. When the measured monomer conversion rate reaches 50%, add 1.8 parts of molecular weight regulator dodecyl me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com