Low-temperature wet cured primer, anticorrosive composite structure and method for preparing and constructing low-temperature wet cured primer

A moisture-curing, low-temperature technology, applied in primers, anti-corrosion coatings, coatings, etc., can solve the problems of polyurea waterproof materials such as fast synthesis, weak compression resistance, and low film-forming strength, so that the synthesis process is easy to control, The effect of wide temperature application range and simple construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

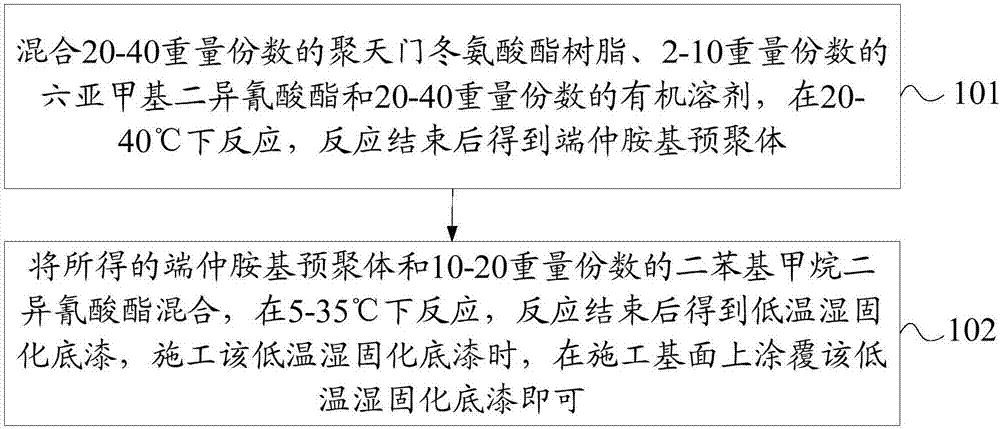

[0043] The embodiment of the present invention provides a method for preparing and applying a low-temperature moisture-curing primer. figure 1 It is a flowchart of a method for preparing and constructing a low-temperature moisture-curing primer provided by an embodiment of the present invention, figure 1 The preparation methods shown include:

[0044] Step 101, mixing 20-40 parts by weight of polyaspartic acid ester resin, 2-10 parts by weight of hexamethylene diisocyanate and 20-40 parts by weight of organic solvent, reacting at 20-40°C , After the reaction is finished, the terminal secondary amino group prepolymer is obtained.

[0045]Embodiments of the present invention first react polyaspartic acid ester resin with hexamethylene diisocyanate (HDI), specifically, the -NH- active group in polyaspartic acid ester resin and hexamethylene diisocyanate The isocyanate group -NCO in the reaction reacts to generate a secondary amino-terminated prepolymer with -NH-active groups in...

Embodiment 1

[0108] Mix 40 parts by weight of polyaspartic acid ester resin, 10 parts by weight of hexamethylene diisocyanate and 40 parts by weight of ethyl acetate, react at 30-40°C, and obtain terminal secondary amine after the reaction is completed base prepolymer;

[0109] Mix the obtained secondary amino-terminated prepolymer with 20 parts by weight of diphenylmethane diisocyanate, react at 25-35°C, and obtain a low-temperature moisture-curing primer after the reaction;

[0110] Spray the low-temperature moisture-curing primer on the construction base surface.

Embodiment 2

[0112] Mixing 20 parts by weight of polyaspartic acid ester resin, 2 parts by weight of hexamethylene diisocyanate, 10 parts by weight of ethyl acetate and 10 parts by weight of butyl acetate, at 20-30 ° C Reaction, after the end of the reaction, a terminal secondary amino group prepolymer is obtained;

[0113] Mix the obtained secondary amino-terminated prepolymer with 10 parts by weight of diphenylmethane diisocyanate, react at 5-20°C, and obtain a low-temperature moisture-curing primer after the reaction;

[0114] Spray the low-temperature moisture-curing primer on the construction base surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt spray resistance time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com