Acrylate processing aid as well as preparation method and application thereof

A technology of acrylates and processing aids, applied in the chemical industry, can solve the problems of low strength and high toughness, poor surface finish, poor dimensional stability, etc. , Good plasticizing effect and moderate reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

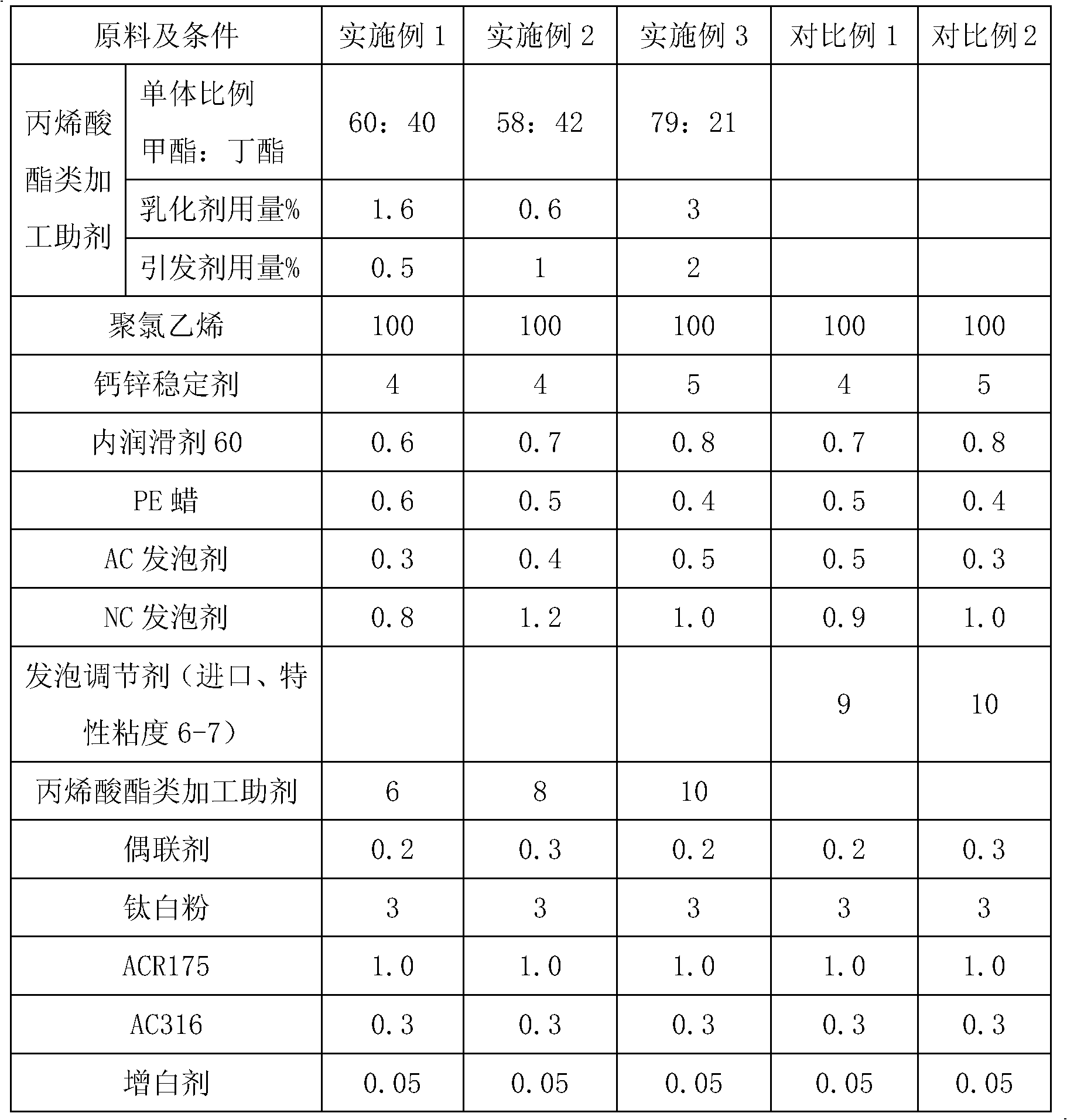

Embodiment 1

[0039] 1. Preparation of acrylate processing aids

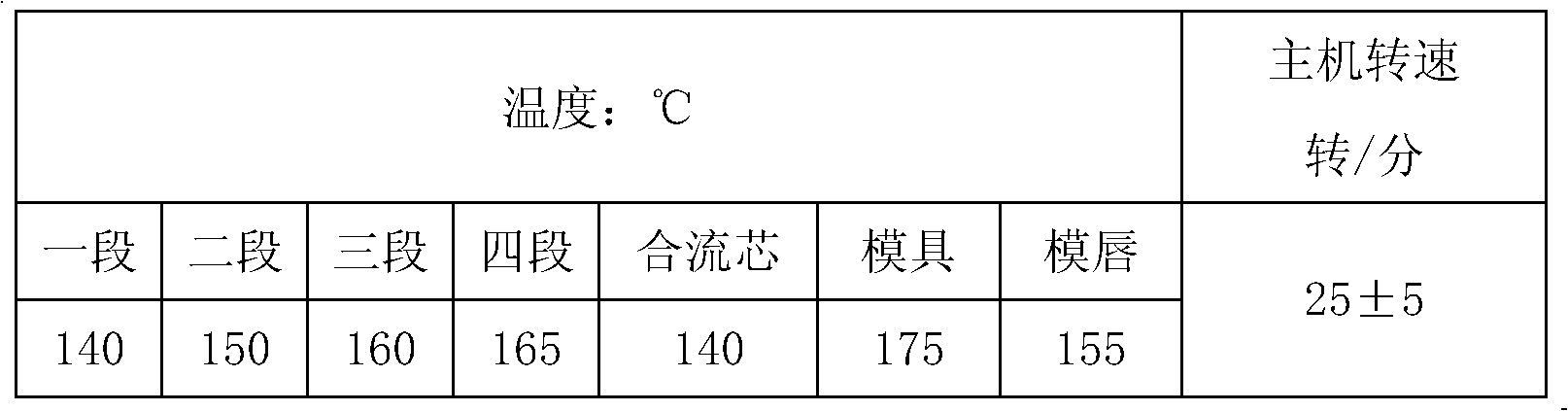

[0040] At room temperature, put the emulsifier aqueous solution containing 4g sodium lauryl sulfate and 0.8g co-emulsifier OP-10 into a three-necked flask equipped with a mechanical stirrer, and then mix the solution with 1.5g potassium persulfate The monomer (180g methyl methacrylate and 120g butyl acrylate) was added into the emulsifier aqueous solution through the addition funnel under stirring, and the phase separation did not occur by controlling the stirring speed and the dropping speed of the monomer, and the dropping time lasted about 10 to 15 minutes, pass N 2 , The three-necked flask was placed in a constant temperature water bath, and the reaction was carried out at 25°C. After reacting for 2 hours, raise the temperature to 45°C, fully react for 20 minutes, then pour the reaction product into a large beaker, add 15% magnesium sulfate solution for salting out, put it in an oven at 50°C and dry it to obtain a unifor...

Embodiment 2

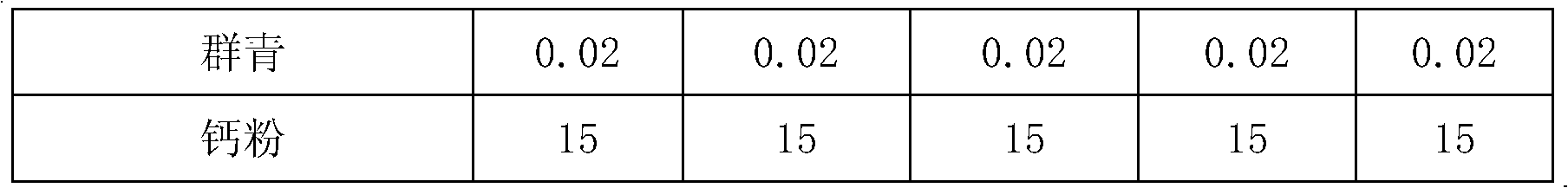

[0048] The conditions and proportions of synthetic acrylic processing aids were changed, as shown in Table 2; the formula for producing polyvinyl chloride foamed boards was changed, as shown in Table 2, and others were the same as in Example 1.

Embodiment 3

[0050] The conditions and proportions of synthetic acrylic processing aids were changed, as shown in Table 2; the formula for producing polyvinyl chloride foamed boards was changed, as shown in Table 2, and others were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com