Chemiluminescence system for determining benzoyl peroxide and method

A technology of benzoyl peroxide and chemiluminescence, which is applied in chemiluminescence/bioluminescence, analysis through chemical reaction of materials, preparation of test samples, etc., can solve the problem of poor selectivity, cumbersome operation and equipment Expensive and other issues, to achieve the effect of moderate reaction speed, good selectivity, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

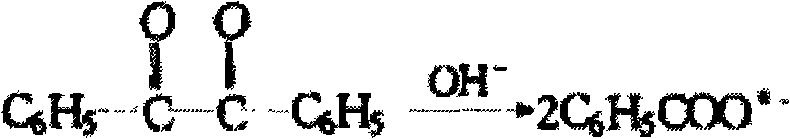

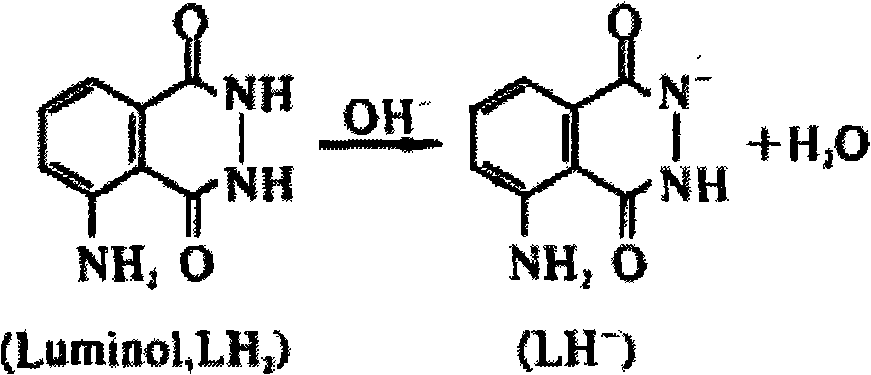

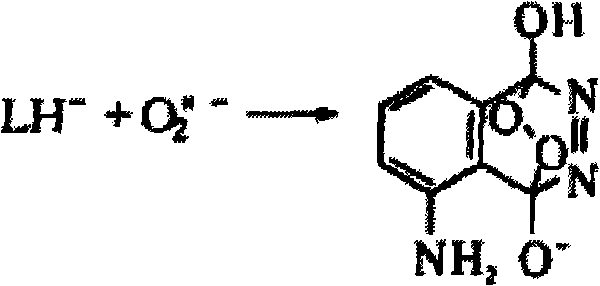

Method used

Image

Examples

Embodiment 1

[0043] Example 1 A chemiluminescence system for measuring benzoyl peroxide is a reaction system in which two solutions of A and B are mixed at a volume ratio of 1:1 to present a chemiluminescence reaction system, and solution A contains 2.5×10 -4 mol / L Luminol, 0.60mol / L CO 3 2- , 0.14mol / L OH - The luminescence reagent, solution B contains 1.5×10 -6 mol / L Co 2+ of the liquid to be tested.

[0044] Utilize above-mentioned chemiluminescence system to measure the concrete steps of benzoyl peroxide in flour as follows:

[0045] (1) Preparation of luminescent reagent ①Weigh 0.2215g of Luminol stock solution, add 0.2g of potassium hydroxide, and 250mL of water. -3 mol / L Luminol stock solution; ② Luminol working solution Take a certain volume of the above-mentioned Luminol stock solution, dissolve it in a certain amount of potassium hydroxide and potassium bicarbonate, dilute with water to make the solution Luminol concentration 1 / 10 of the stock solution concentration, and mak...

Embodiment 2

[0052] Example 2 A chemiluminescence system for measuring benzoyl peroxide is a reaction system in which two solutions of A and B are mixed at a volume ratio of 1:1 to present a chemiluminescence reaction system, and solution A contains 5.0×10 -4 mol / L Luminol, 0.596mol / L CO 3 2- , 0.134mol / L OH - The luminescence reagent, solution B contains 7.7×10 -7 mol / L Co 2+ of the liquid to be tested.

[0053] Utilize above-mentioned chemiluminescence system to measure the concrete steps of benzoyl peroxide in flour as follows:

[0054] (1) Preparation of luminescent reagent ①Weigh 0.4429g of Luminol stock solution, add 0.2g of sodium hydroxide, and 200mL of water. -3 mol / L Luminol stock solution; ② Luminol working solution Pipette 50.0mL of the above stock solution into a 500mL volumetric flask, add 200mL of water, add 14.3g of sodium hydroxide, 25.00g of sodium bicarbonate, and dilute to volume with water after complete dissolution, which is 2.5 ×10 -4 mol / L Luminol working sol...

Embodiment 3

[0061] Example 3 A chemiluminescence system for measuring benzoyl peroxide is a reaction system in which two solutions of A and B are mixed at a volume ratio of 0.8:1 to present a chemiluminescence reaction system, and solution A contains 1.5×10 -3 mol / L Luminol, 0.30mol / L CO 3 2- , 0.18mol / L OH - The luminescent reagent, solution B contains 8.0×10 -7 mol / L Co 2+ of the liquid to be tested.

[0062] The reagent preparation method and specific determination steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com