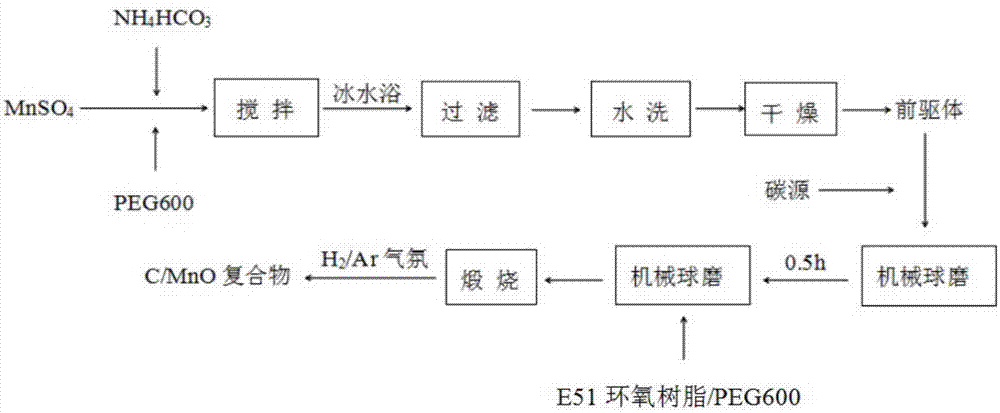

Preparation method of C/MnO composite electrode material

A composite electrode and mixed liquid technology, which is applied in the direction of hybrid capacitor electrodes, battery electrodes, circuits, etc., can solve the problems of unfavorable product industrialization, environmental pollution, and complicated process, and achieve the effect of improving the wrapping rate, improving the dispersion effect, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Prepare 1L of MnSO with a concentration of 0.25mol / L respectively 4 solution and 0.5L of NH with a concentration of 0.25mol / L 4 HCO 3 solution, mix the two solutions, and add 2.22g of PEG600 to the solution, with a mass fraction of 7% H 2 SO 4 Adjust the pH value of the solution to control the pH of the solution to 6.5.

[0025] Step 2: Put the mixed solution in an ice-water bath and stir for 2 hours at a speed of 180 r / min. After the reaction, filter the solution, rinse the precipitate with deionized water, and then dry it at 60° C. for 6 hours to obtain a precursor.

[0026] Step 3: Mix 100g of precursor with 4g of graphene, and then add it into a ball mill, the temperature of the ball mill is 45°C, the speed of the ball mill is 500r / min, and after 0.5h of ball milling, add a mixture containing 0.25g of E51 epoxy resin and 4.75g of PEG600 , continue ball milling for 1.5h, and take out the mixture after ball milling.

[0027] Step 4: Place the mixture in H...

Embodiment 2

[0029] Step 1: Prepare 1L of MnSO with a concentration of 0.25mol / L respectively 4 solution and 0.15L of NH with a concentration of 0.25mol / L 4 HCO 3 solution, the two solutions were mixed, and 1.89g of PEG600 was added to the solution, and the pH value of the solution was adjusted with a mass fraction of 10% HCl, and the pH of the solution was controlled to be 6.

[0030] Step 2: Stir the mixture in an ice-water bath at a speed of 200 r / min for 1.5 h. After the reaction, filter the solution, rinse the precipitate with deionized water, and dry at 40° C. for 7 h to obtain a precursor.

[0031] Step 3: Mix 100g of precursor with 2g of graphene, and then add it into the ball mill, the temperature of the ball mill is 30°C, the speed of the ball mill is 300r / min, after 0.5h of ball milling, add the mixture containing 0.125g of E51 epoxy resin and 6.125g of PEG600 , continue ball milling for 1 h, and take out the mixture after ball milling.

[0032] Step 4: Place the mixture in H...

Embodiment 3

[0034] Step 1: Prepare 1L of MnSO with a concentration of 0.25mol / L respectively 4 solution and 1 L of NH with a concentration of 0.25 mol / L 4 HCO 3 solution, mix the two solutions, and add 2 g of PEG600 to the solution, with a mass fraction of 7% H 2 SO 4 Adjust the pH value of the solution, and control the pH of the solution to be 7.

[0035] Step 2: Put the mixed solution in an ice-water bath and stir for 2 hours at a speed of 80 r / min. After the reaction, filter the solution, rinse the precipitate with deionized water, and then dry it at 60° C. for 3 hours to obtain a precursor.

[0036] Step 3: Take 100g of the precursor and mix it with 3g of graphite, and then add it into the ball mill, the temperature of the ball mill is 30°C, the speed of the ball mill is 400r / min, after 0.5h of ball milling, add the mixture containing 0.2g of E51 epoxy resin and 5.8g of PEG600, Continue ball milling for 2h, and take out the mixture after ball milling.

[0037] Step 4: Place the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com