Miniature magnetic-driven pump

A micro-pump and magnetic energy technology, applied in the direction of pumps, pumps, machines/engines with flexible working elements, etc., can solve the problems such as the inability of micro-pumps to be applied, human body danger, etc., to achieve high safety and reliability, high safety, Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

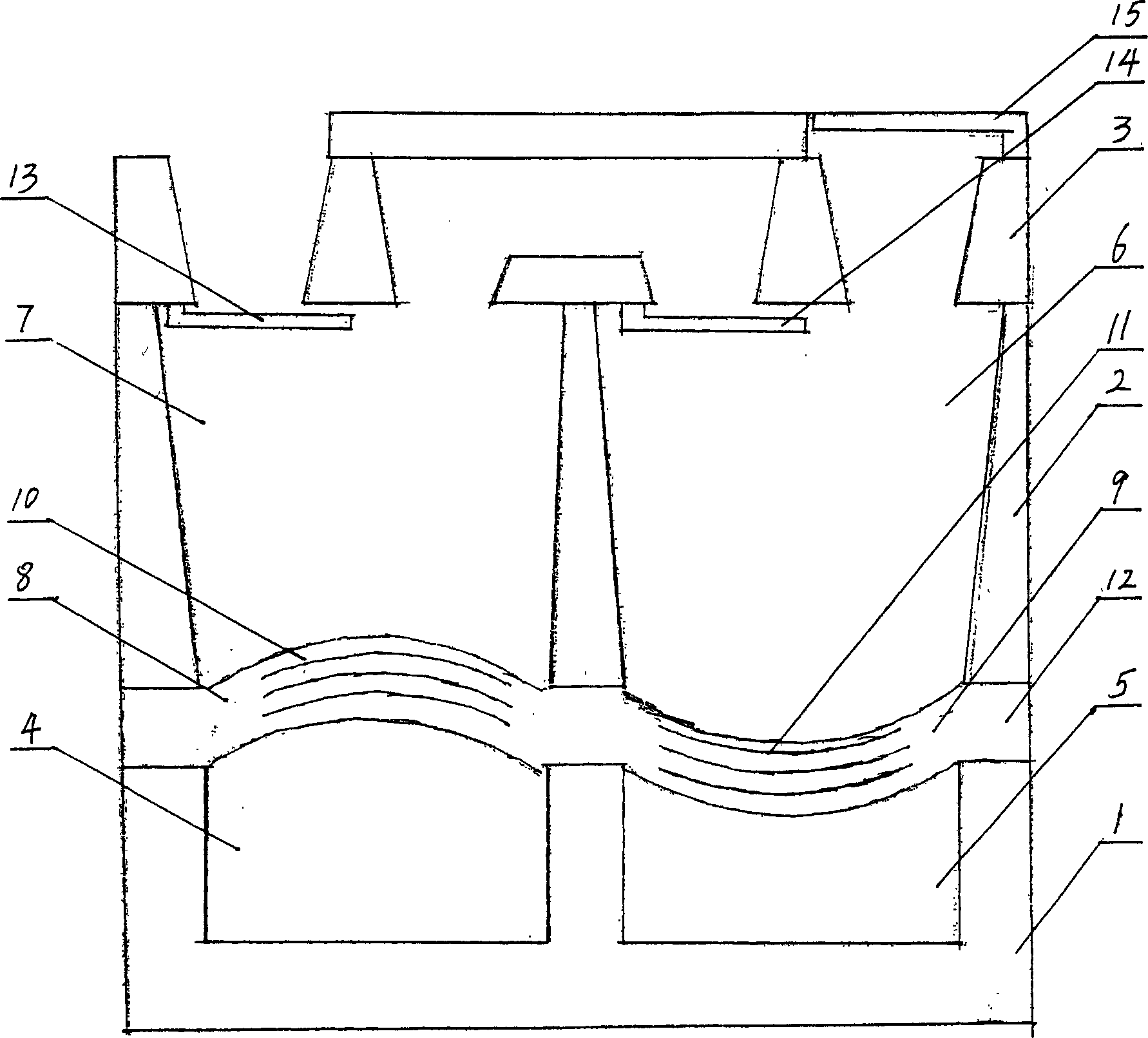

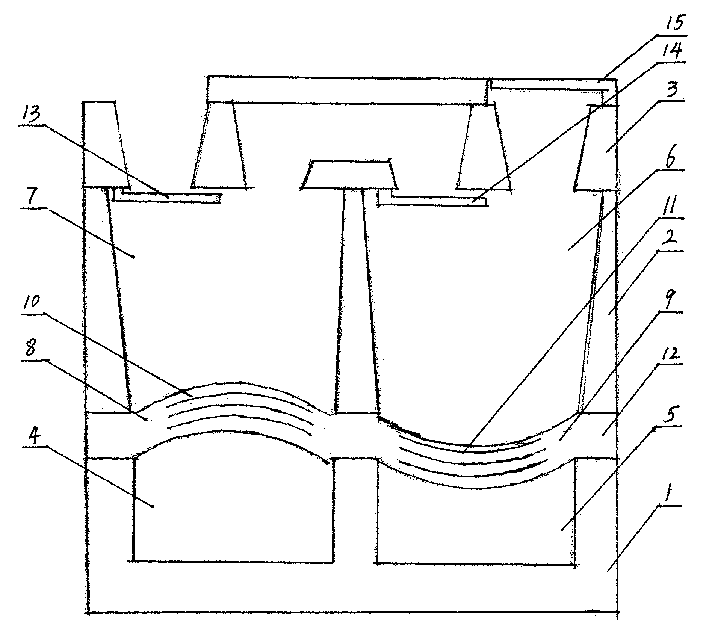

[0018] Below in conjunction with embodiment the present invention is further described.

[0019] Examples of the present invention are figure 1 As shown, the overall dimensions are 6×6×6 mm. The surface structures of the base plate (1), the middle plate (2), and the top plate (3) are etched by processes such as bulk machining, surface machining, and LIGA of micromechanical surface machining. The metal copper sheet cantilever beam valve plate (13), (14), (15) is obtained by first depositing a metal copper film with a thickness of 0.1 to 100 microns on the photoresist sacrificial layer of the top plate (3), and then dissolving the sacrificial layer. of. The total thickness of the support film (12) is 10-500 microns, and the radius is 1000-4000 microns.

[0020] The micropump is divided into three layers as a whole: the upper layer is the outlet check valve (15) and the inlet check valve (13); the middle layer is the two main pump chambers (6), (7) and free surfaces (8), (9): ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com