High-content fomesafen aqueous solution and preparation method thereof

A fomesafen, high-content technology, applied in the field of high-content fomesafen water agent and its preparation, can solve the problem of inability to configure high-content water agent, inability to configure high-content water agent, and increase consumer cost and other problems, to achieve the effect of excellent mutual solubility, simple equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

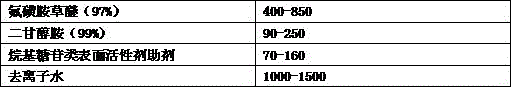

[0021] 400g / l fomesafen diglycolamine aqueous solution:

[0022]

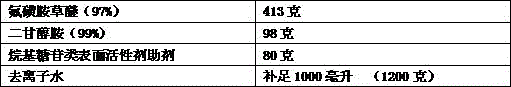

[0023] Add 609 grams of deionized water into a 2000ml round-bottomed flask, start stirring, add 413 grams of 97% content of fomesafen original drug, and then slowly drop in 98 grams of 99% diglycolamine solution, after the addition is complete Continue to stir for more than 10 minutes to fully react and neutralize the fomesafen technical substance and diglycolamine to form a transparent solution. Finally, add 80 grams of alkyl glycoside surfactant additives and stir evenly to obtain 1000 milliliters of 400 g / l fomesafen diglycolamine aqueous solution product.

example 2

[0025] 600g / l fomesafen diglycolamine aqueous solution

[0026]

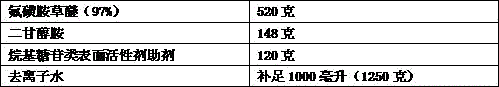

[0027] Add 462 grams of deionized water into a 2000ml round bottom flask, start stirring, add 520 grams of 97% content of fomesafen original drug, and then slowly drop in 148 grams of 99% diglycolamine solution, continue to Stir for more than 10 minutes to fully react and neutralize fomesafen technical substance and diglycolamine to form a transparent solution. Finally, add 120 grams of alkyl glycoside surfactant additives and stir evenly to obtain 1000 ml of 600 g / l Fomesafen diglycol ammonium aqueous solution product.

example 3

[0029] 800g / l fomesafen diglycolamine aqueous solution

[0030]

[0031]Add 125 grams of deionized water into a 2000ml round bottom flask, start stirring, first add 150 grams of 97% content of fomesafen original drug, and then slowly drop in about 40 grams of 99% diglycolamine solution, and the addition is complete After that, continue to stir for more than 10 minutes, so that the original drug of fomesafen and diglycolamine fully react and completely neutralize to form a transparent solution, and then continue to add 97% content of About 150 grams of fomesafen original drug, slowly drop about 40 grams of 99% diglycolamine solution to neutralize and form a transparent solution, so repeatedly add the original drug and dropwise addition of diglycolamine solution until finally Add all the fomesafen technical compound and diglycolamine solution, and finally add 150 grams of alkyl glycoside surfactant additives, slowly heat the temperature of the system to 60~70 degrees with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com