Patents

Literature

139results about How to "Improve corrosion and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and preparation method thereof

ActiveCN105802460AHigh mechanical strengthAnti-corrosion and wear-resistantAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerEnd-group

The invention discloses a scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and a preparation method thereof. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is characterized by comprising an ingredient A and an ingredient B, wherein the ingredient A is prepolymers with NCO end groups obtained through the reaction between 30 to 40 mass percent of polyether polyol and 60 to 70 mass percent of polyisocyanates; the ingredient B is prepared from 30 to 40 mass percent polyaspartic acid ester, 60 to 70 mass percent of filling materials and a small number of auxiliary agents through high-speed dispersion grinding. In the use process, the prepared ingredient A and the prepared ingredient B are weighed according to the weight ratio of 1:4, and are then uniformly mixed; next, scraping coating construction is performed. The material has the characteristics of high mechanical intensity, corrosion resistance, wear resistance, good anti-seeping performance, aging resistance, proper reaction speed, no solvent, convenient construction and the like. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is particularly suitable for industrial and mining enterprise equipment and spare part anti-corrosion wear-resistant liners.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Nanocrystalline alloy coating and preparation thereof

The invention relates to a nano-crystalline alloy coating layer and a preparation method thereof. Particularly, the invention relates to a nano-crystalline alloy coating layer, the components of which, expressed by atomic ratio, satisfy the relational expression: (Fe1-aM1a)100-x-y-z-Alpha-Beta-GammaCuxSiyBzM2AlphaM3BetaXGamma, wherein, M1 is one or both of Co and Ni, M2 is at least one of Nb, W, Ta, Zr, Hf, Ti and Mo, M3 is at least one of V, Cr, Mn, Al, Sc, Y, Au, Zn, Sn and Re, X is at least one of C, Ge, P, Ga, Sb, In, Be and As, a is more than or equal to 0 and less than or equal to 0.5, x is more than or equal to 0.1 and less than or equal to 3, y is more than or equal to 0 and less than or equal to 30, z is more than or equal to 0 and less than or equal to 25, and furthermore, y plus z is more than or equal to 5 and less than or equal to 30, Alpha is more than or equal to 0.1 and less than or equal to 30, Beta is more than or equal to 0 and less than or equal to 10 and Gamma is more than or equal to 0 and less than or equal to 10, the volume percent of nano-crystals contained in the nano-crystalline alloy coating layer is above 50 percent and the crystal size of the nano-crystals is below 100nm. The invention also relates to the application and a preparation method of the nano-crystalline alloy coating layer.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

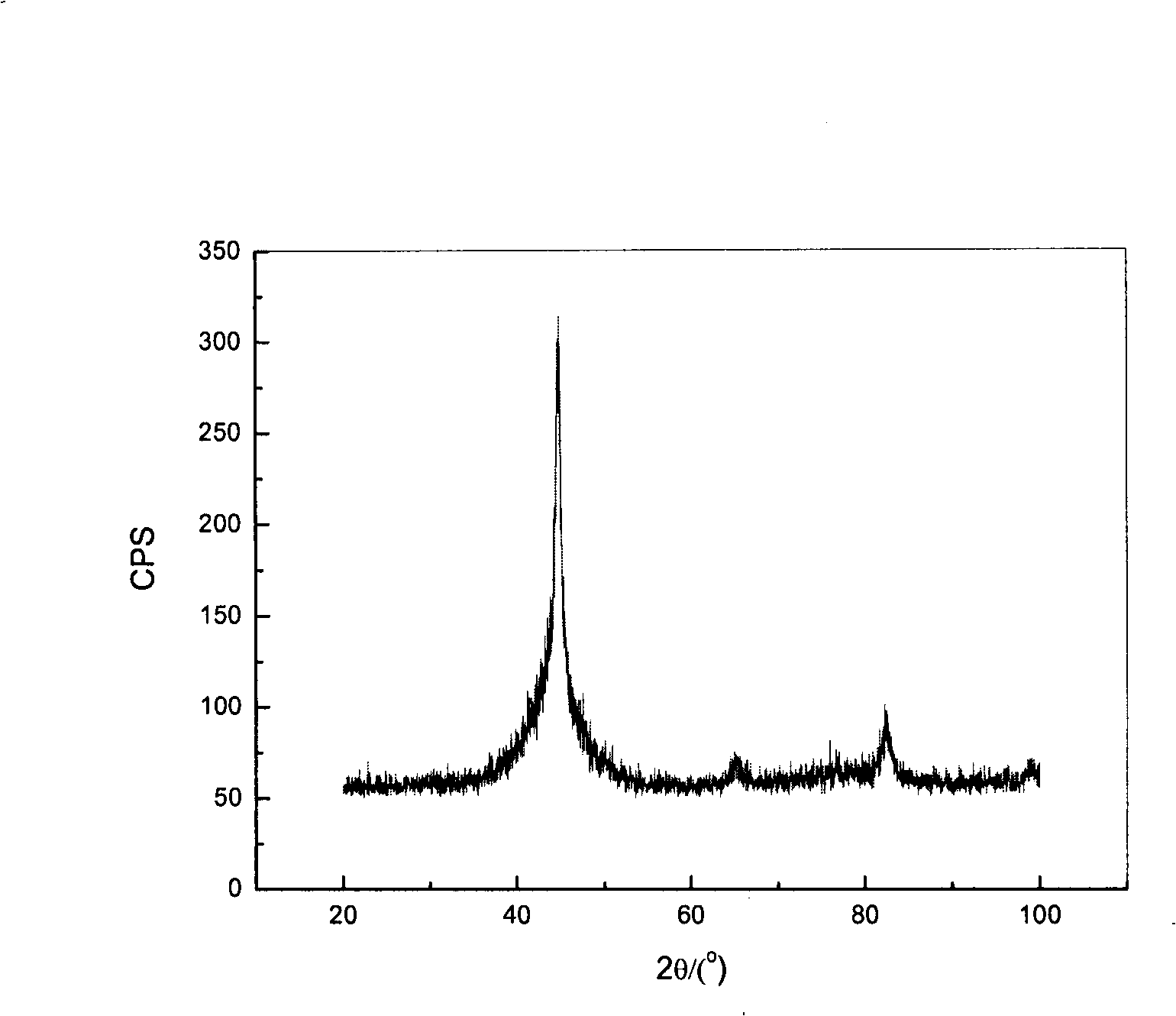

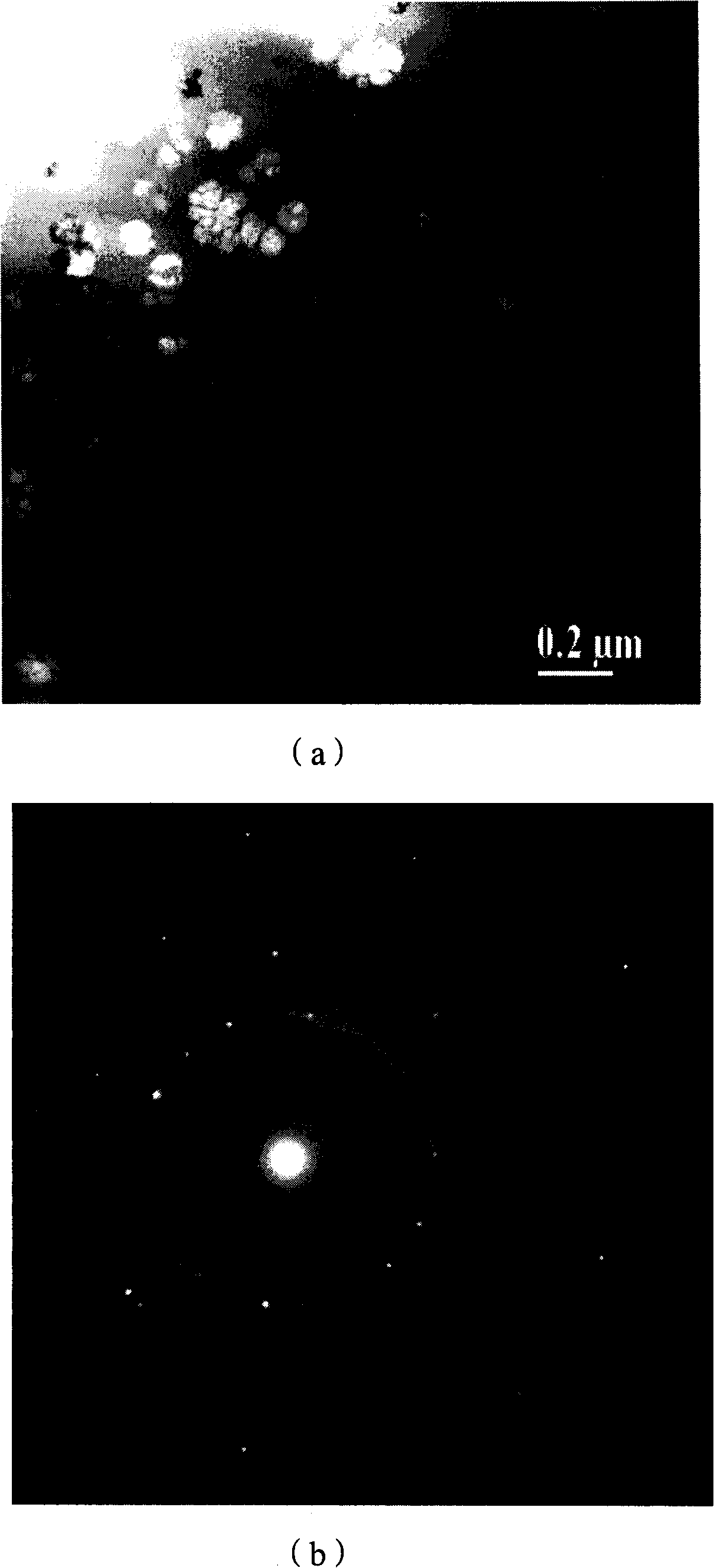

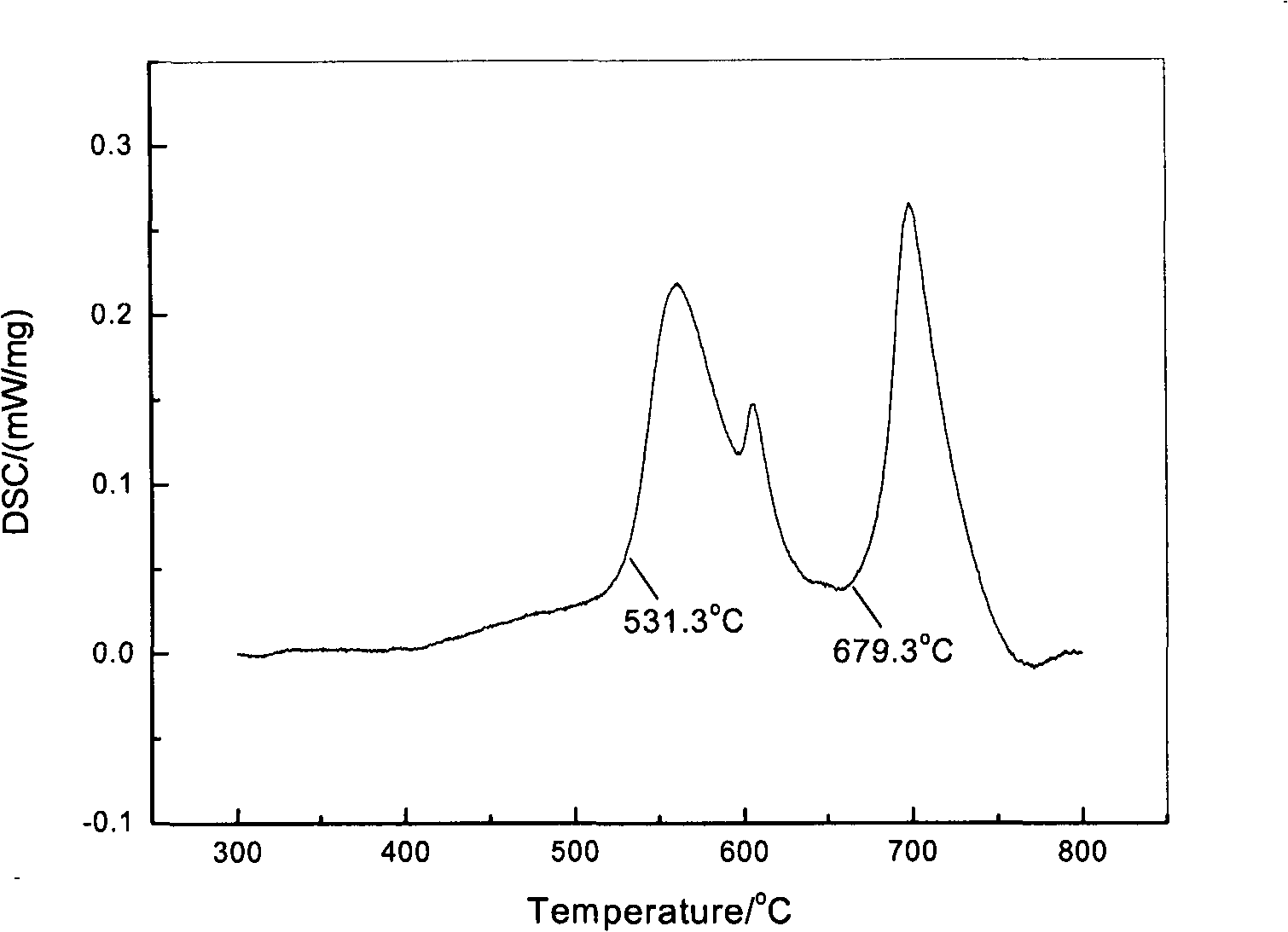

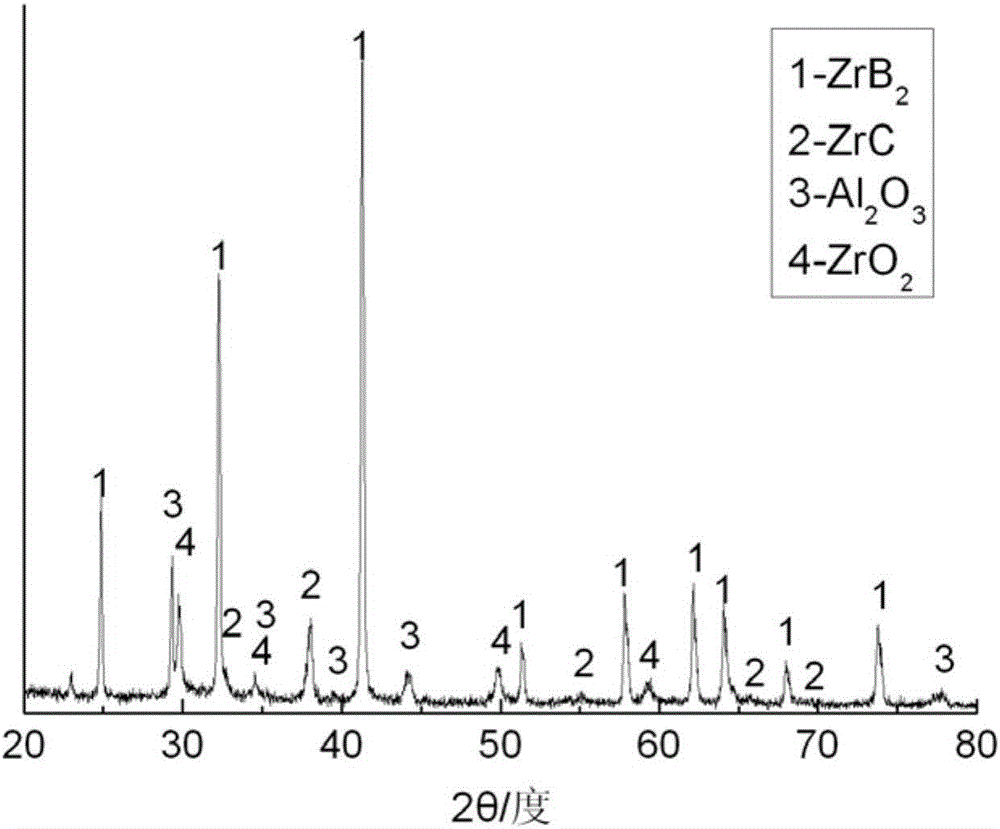

Preparation method for zirconium boride-based coating

The invention relates to a preparation method for a zirconium boride-based coating and relates to plating of a material by a boride. The method of in-situ synthesizing the zirconium boride-based coating comprises the steps of: preparing zirconium oxide / boron carbide / aluminum compound powder for thermal spraying; pre-treating a base material; and spraying the prepared zirconium oxide / boron carbide / aluminum compound powder for thermal spraying to the surface of the pre-treated base material by adopting a thermal spraying method so as to form the zirconium boride-based coating. The method provided by the invention overcomes the defects that in the prior art, the prepared zirconium boride-based coating is high in porosity, poor in uniformity, rough in tissue, low in toughness, small in thickness, poor in bonding force with a matrix, easy to crack and poor in thermal shock resistance; and the defects in the prior art that the preparation process is complicated, the process cost is high, the depositing efficiency is low, the cost of raw materials is high, the energy consumption is great, the efficiency is low, and the preparation method is not suitable for being applied to industrial production on a large scale.

Owner:HEBEI UNIV OF TECH

Anticorrosive and antiwear cast cobalt-base alloy

The present invention relates to Co-base alloy, especially, an anticorrosive and antiwear cast Co-base alloy. The alloy consists of C 1.0-2.5 wt%, Cr 20-35 wt%, W 5-20 wt%, Mo 1-6 wt%, Nb 1-8 wt%, Cu0.5-2.0 wt%, Si 0.5-3.0 wt%, Ni 2-15 wt% and Co 35-65 wt%. It has excellent anticorrosive performance and average hardness of about 48 HRC, and may be used in making cutter of water flow type chemical fiber cutting machine. Substituting partial Co with Ni can reduce the cost of the alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

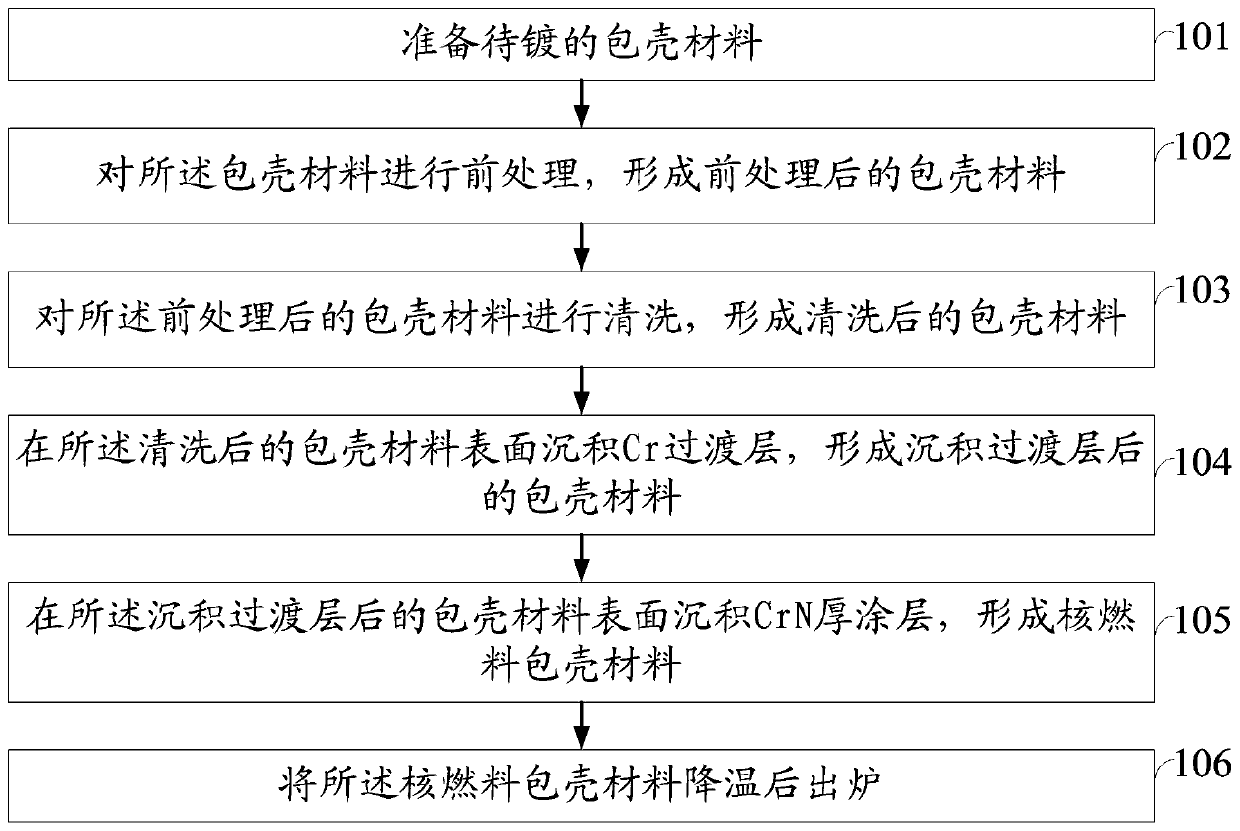

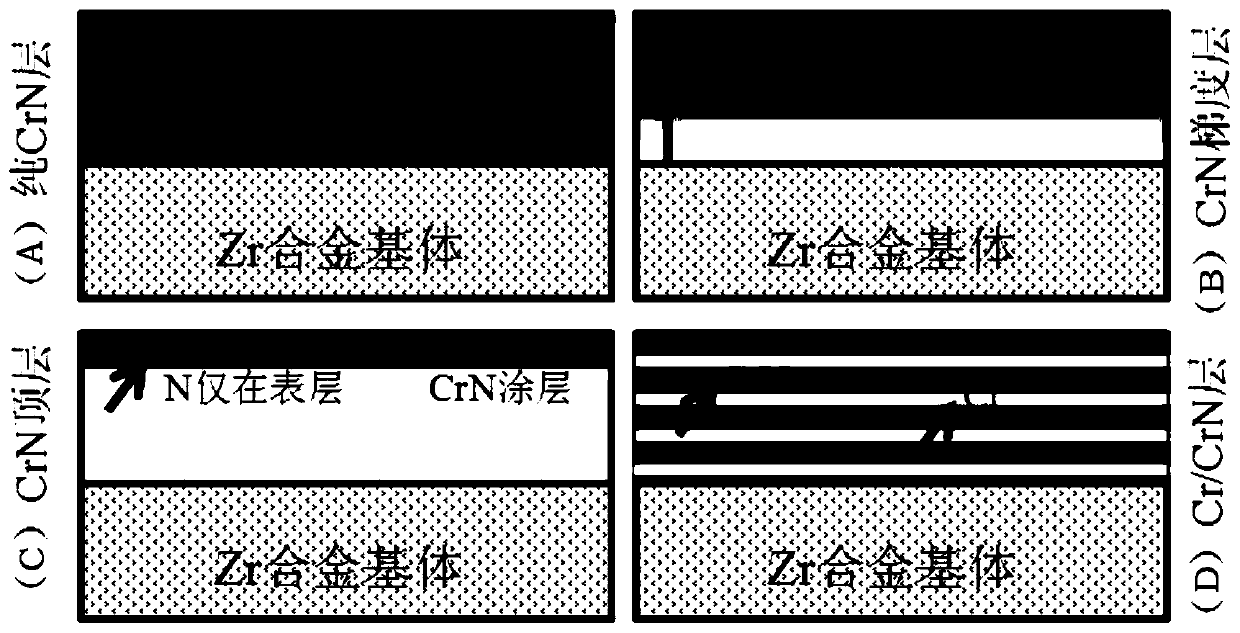

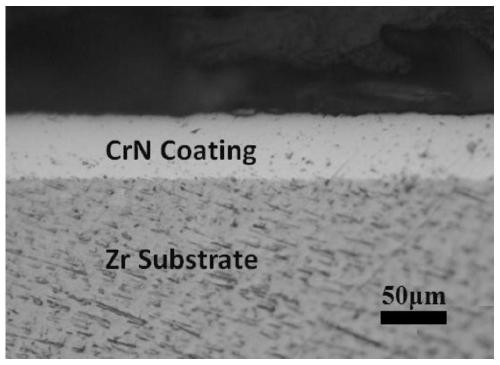

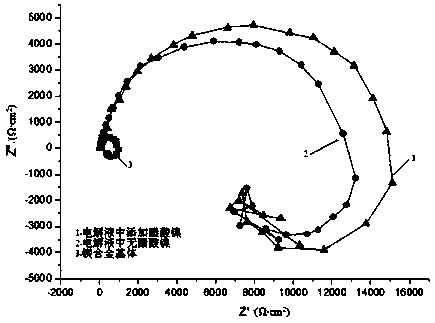

Preparation method of thick CrN coating on surface of cladding material

InactiveCN109972098AImprove accident toleranceImprove mechanical propertiesOptical rangefindersNuclear energy generationZirconium alloyBinding force

The invention discloses a preparation method of a thick CrN coating on the surface of a cladding material. A multi-arc ion plating technology is adopted, the zirconium alloy cladding material serves as a matrix, a high-purity Cr target serves as a cathode arc source, high-purity nitrogen serves as reactive gas, by adjusting the technological conditions such as the bias, the temperature, the arc current and the deposition time, a deposition process of depositing a single CrN layer, a CrN gradient layer, a Cr and CrN layer or a Cr / CrN circulating layer is selected, the unsaturated thick CrN<x> uniform coating with excellent binding force is obtained in a short time, the mechanical properties such as high-temperature oxidation resistance, abrasion resistance and corrosion resistance of the coating can be significantly improved under the situation of not affecting the properties of the matrix, thus protection is provided for the cladding material to resist the harsher working environment when a nuclear accident occurs suddenly, the response time is provided for workers to repair a system in a reactor in time, and the accident fault-tolerant capability of the cladding material made of azirconium alloy is greatly improved.

Owner:DALIAN UNIV OF TECH +1

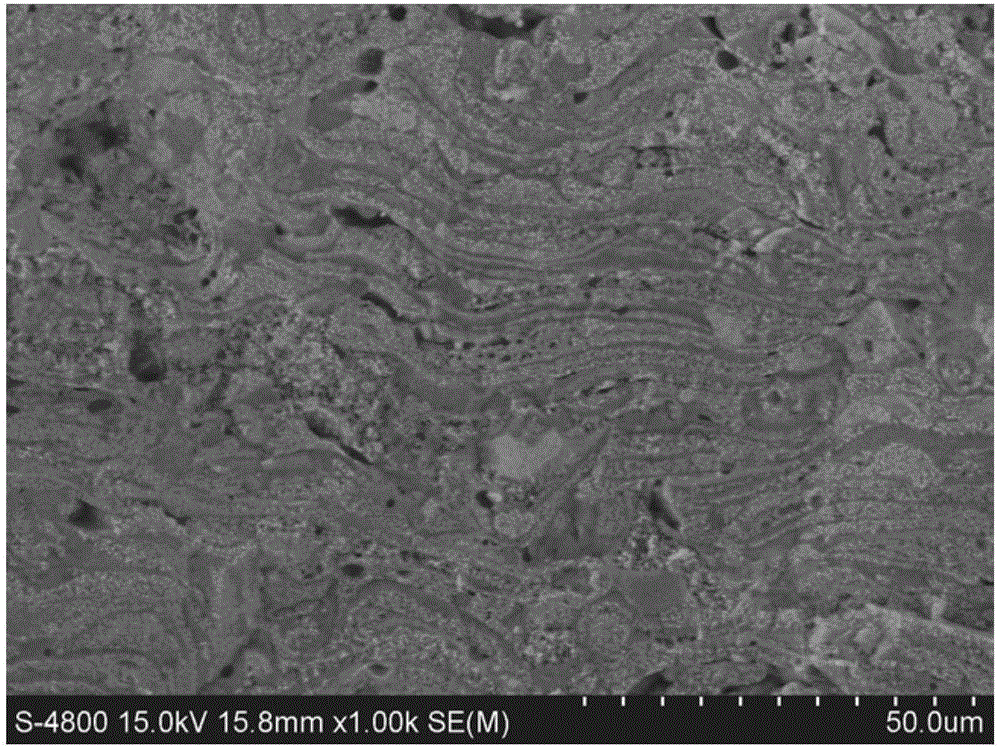

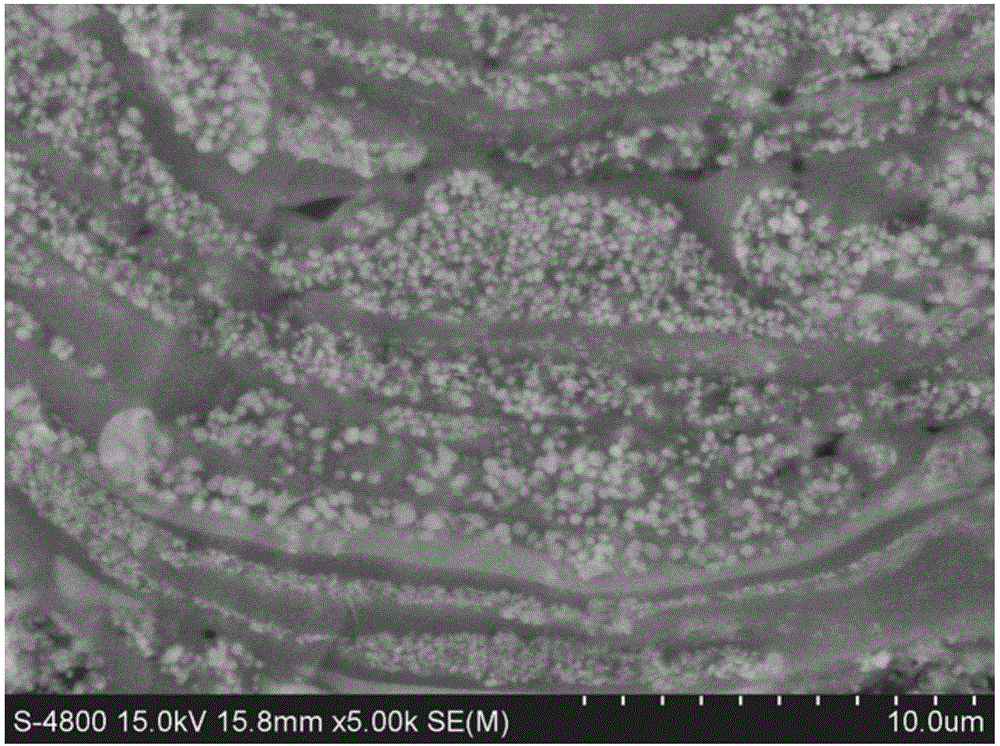

Method of adopting environment-friendly nickel-containing electrolyte to prepare microarc oxidation film layer on surface of magnesium alloy

ActiveCN103726093AReduce hole sizeImprove corrosion and wear resistanceAnodisationPlasma electrolytic oxidationNickel salt

The invention discloses a method of adopting an environment-friendly nickel-containing electrolyte to prepare a microarc oxidation film layer on surface of a magnesium alloy, and belongs to the technical field of metal finishing. The method comprises the following steps: taking the magnesium alloy as an anode, and a phosphorus and fluorine-free nickel salt-containing aqueous solution electrolyte; performing microarc oxidation processing under the process conditions so as to generate a ceramic microarc oxidation film layer on the surface of the magnesium alloy material; performing routine plugging processing on the ceramic microarc oxidation film layer so as to form a high erosion-resistant and wear-resistant microarc oxidation film layer on the surface of the magnesium alloy, wherein the aqueous solution electrolyte comprises the following components: 0.5-1.5 g / L nickelous acetate or nickel sulfate, 15-30 g / L sodium silicate, 20-40 g / L sodium borate, 10-30 g / L sodium hydroxide or potassium hydroxide, 10-20 mL / L triethavolamine, and 5-10 mL / L ethylene diamine. The electrolyte contains the nickel salt, but not the phosphorus and fluorine, and is environment-friendly. The microarc oxidation film layer on the surface of the magnesium alloy is a nickeliferous ceramic film with relatively small film hole size, and has relatively high wear resistance, corrosion resistance and binding force, and therefore is wide in application.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Preparation method of high-boron and wear-resistant alloy

ActiveCN104195362AHigh hardnessGood resistance to zinc liquid corrosion and wearMetallic material coating processesIron powderWear resistant

The invention discloses a preparation method of a high-boron and wear-resistant alloy, belonging to the technical field of molten zinc corrosion wear materials. The preparation method comprises the steps of uniformly mixing 45-50% of boron and iron powder, 14-16% of chromium iron powder, 3-5% of molybdenum iron powder, 4-4.6% of pure nickel powder, 1.5-2.5% of WC powder and 25-30% of pure iron powder which are within the particle size range of 140-200 meshes; and carrying out laser cladding on a stainless steel base material by using a fiber laser and a synchronous powder feeding method to obtain a high-boron and wear-resistant alloy laser cladding layer, the surface of which has no cracks, inclusions and air holes and is smooth.

Owner:BEIJING UNIV OF TECH

Alloy powder for circulating fluidized bed boiler water wall tube laser cladded coating

InactiveCN102021558AHigh hardnessHigh strengthMetallic material coating processesLaser processingFluidized bed

The invention discloses alloy powder for a circulating fluidized bed boiler water wall tube laser cladded coating. The powder comprises the following components in percentage by mass: 1.0 to 1.6 percent of C, 28 to 34 percent of Cr, 2 to 5 percent of Ni, 3 to 8 percent of W, 0.2 to 0.5 percent of Mn, 1.0 to 1.4 percent of Si, 0.02 to 0.06 percent of B, 0.05 to 0.10 percent of Zr, 0.02 to 0.06 percent of Ce and the balance of Co. The powder is cladded on the surface of the water wall tube by laser to form the cobalt-base alloy coating with relatively high hardness, oxidation resistance, corrosion resistance, erosion wear resistance and excellent cladding performance. Therefore, the technical problem on corrosion resistance and wear resistance of a circulating fluidized bed boiler water wall tube is solved.

Owner:上海大陆天瑞激光表面工程有限公司

Film system structure of moderate and high temperature solar energy selective absorption coating and production method thereof

ActiveCN103234294AHigh bonding strengthNo cracking and falling offSolar heat devicesVacuum evaporation coatingTitanium nitrideDiffusion barrier

The invention discloses a production method of a film system structure of a moderate and high temperature solar energy selective absorption coating. The film system structure is characterized in that an ion etching layer, an aluminum infrared reflection film layer, a titanium nitride thermal diffusion barrier film layer, a titanium oxynitride absorbing film layer with high metal content, a titanium oxynitride absorbing film layer with low metal content, a silicon nitride antireflection film layer and a silicon dioxide antireflection film layer are sequentially arranged on one surface of a substrate. The production method of the film system structure is characterized in that firstly the surface of the metal copper substrate is etched, and then the aluminum infrared reflection film layer, the titanium nitride thermal diffusion barrier film layer, the titanium oxynitride absorbing film layer with high metal content, the titanium oxynitride absorbing film layer with low metal content, the silicon nitride antireflection film layer and the silicon dioxide antireflection film layer are sequentially plated. The production method has the advantages of being simple, easy to control, good in product quality, suitable for industrial mass production and the like.

Owner:JIANGSU DOCTORXIA SOLAR ENERGY

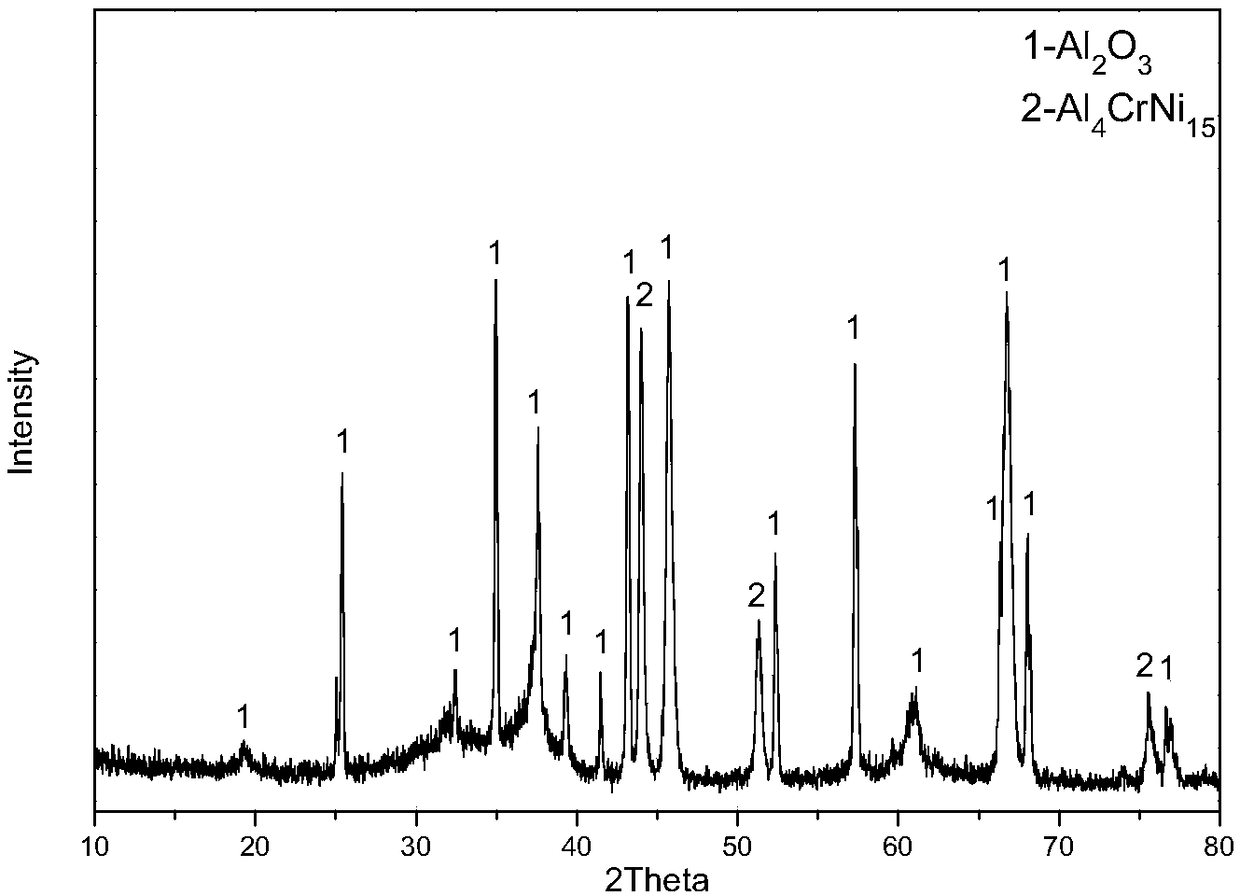

Preparation method of NiCr/Al2O3 composite coating

The invention discloses a preparation method of a NiCr / Al2O3 composite coating. The preparation method comprises the steps of firstly, mechanically mixing Ni-Cr alloy powder with Al2O3 powder, and conducting ultrasonic oscillation, so that NiCr / Al2O3 composite powder is obtained; and then, conducting plasma spraying, so that the NiCr / Al2O3 composite coating with the NiCr content ranging from 10% to 30% is synthesized. By means of the preparation method, bonding strength of an Al2O3 coating is improved, and the defect that corrosion resistance of an aluminum oxide coating is lost in a strong acid environment is overcome.

Owner:HEBEI UNIV OF TECH

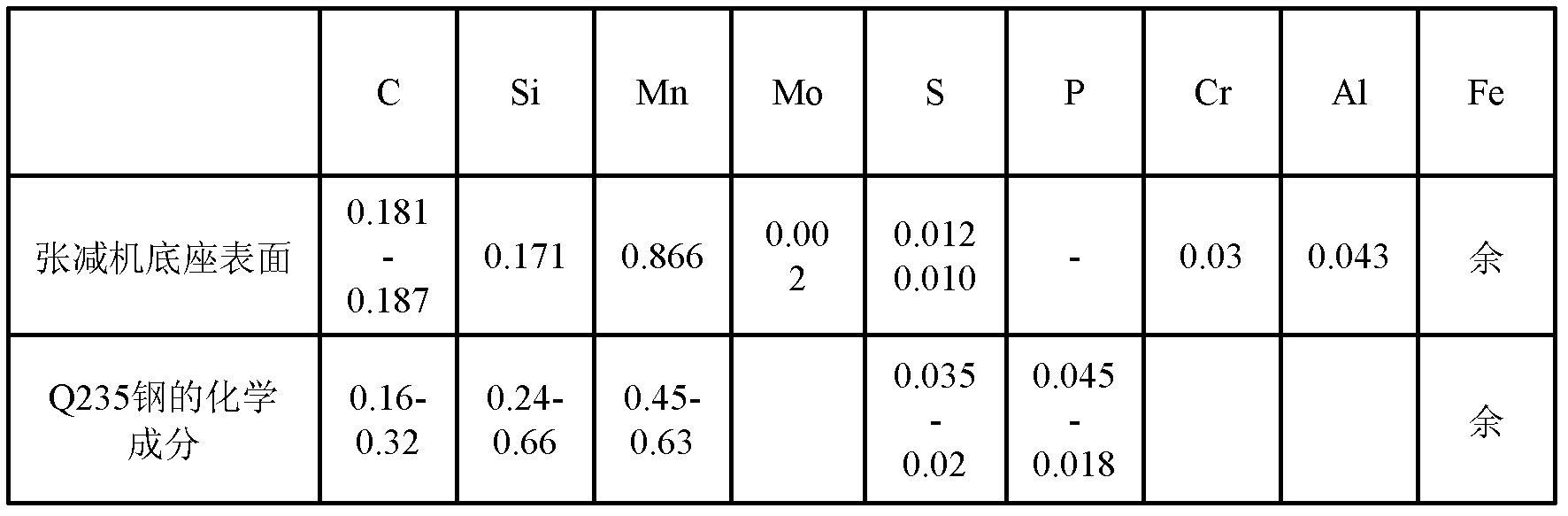

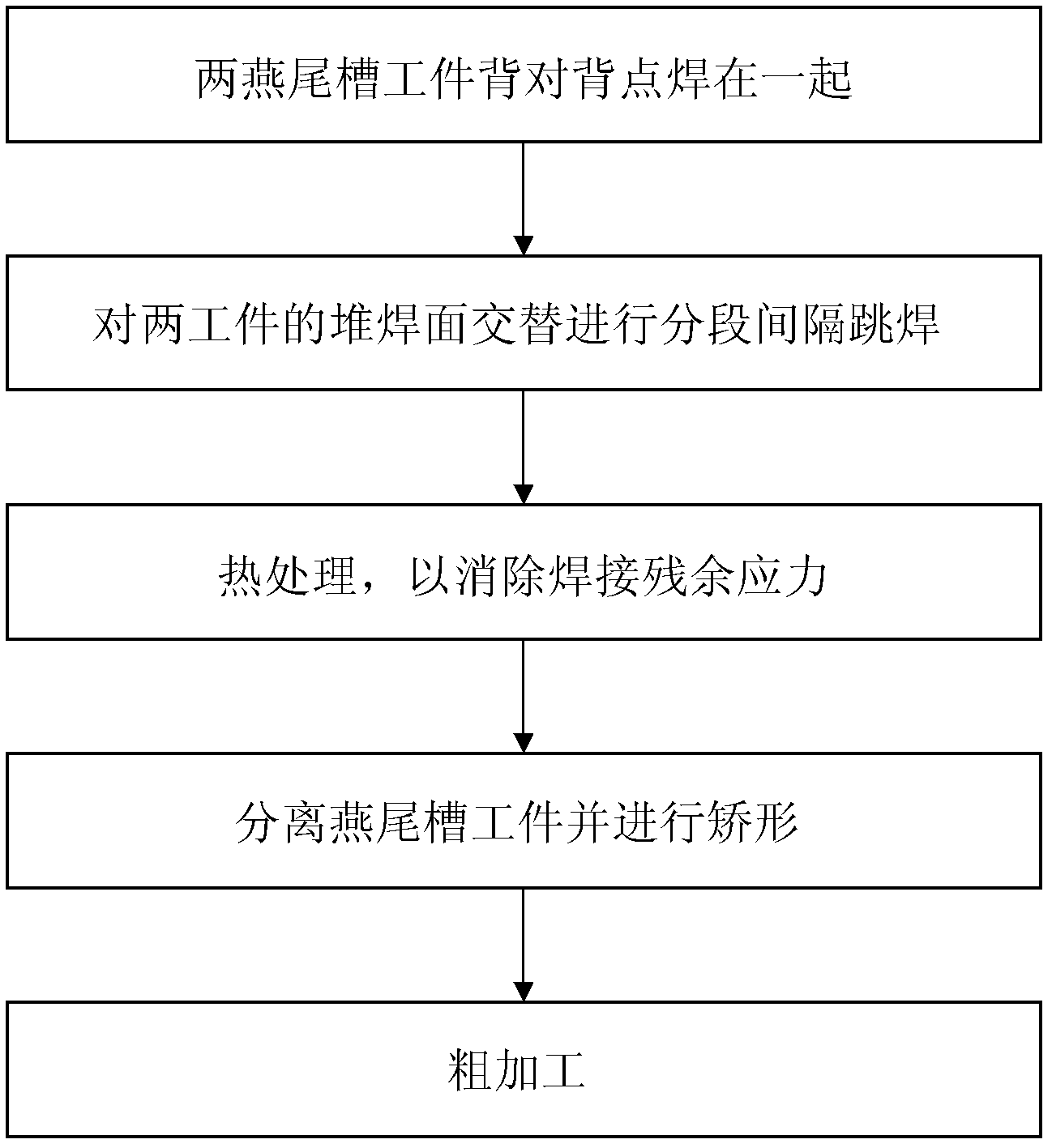

Surfacing method for antiseptic wear-resisting layer of dovetail groove

ActiveCN103008833AImprove corrosion and wear resistanceEliminate welding residual stressArc welding apparatusFurnace typesWelding residual stressEngineering

The invention discloses a surfacing method for an antiseptic wear-resisting layer of a dovetail groove. According to the method, two dovetail groove workpieces are spot-welded back to back, slant groove surfaces and horizontal groove surfaces of the upper dovetail groove workpiece and the lower dovetail groove workpiece are alternately skip-welded sectionally at intervals by ER410NiMoTi surfacing material, welding residual stress is eliminated through heat treatment, and finally the two dovetail groove workpieces are separated, corrected and roughly machined. According to the surfacing method disclosed by the invention, welding deformation can be effectively avoided, and the formed surfacing layer can improve the antiseptic wear-resisting performance of the dovetail groove.

Owner:BAOSHAN IRON & STEEL CO LTD

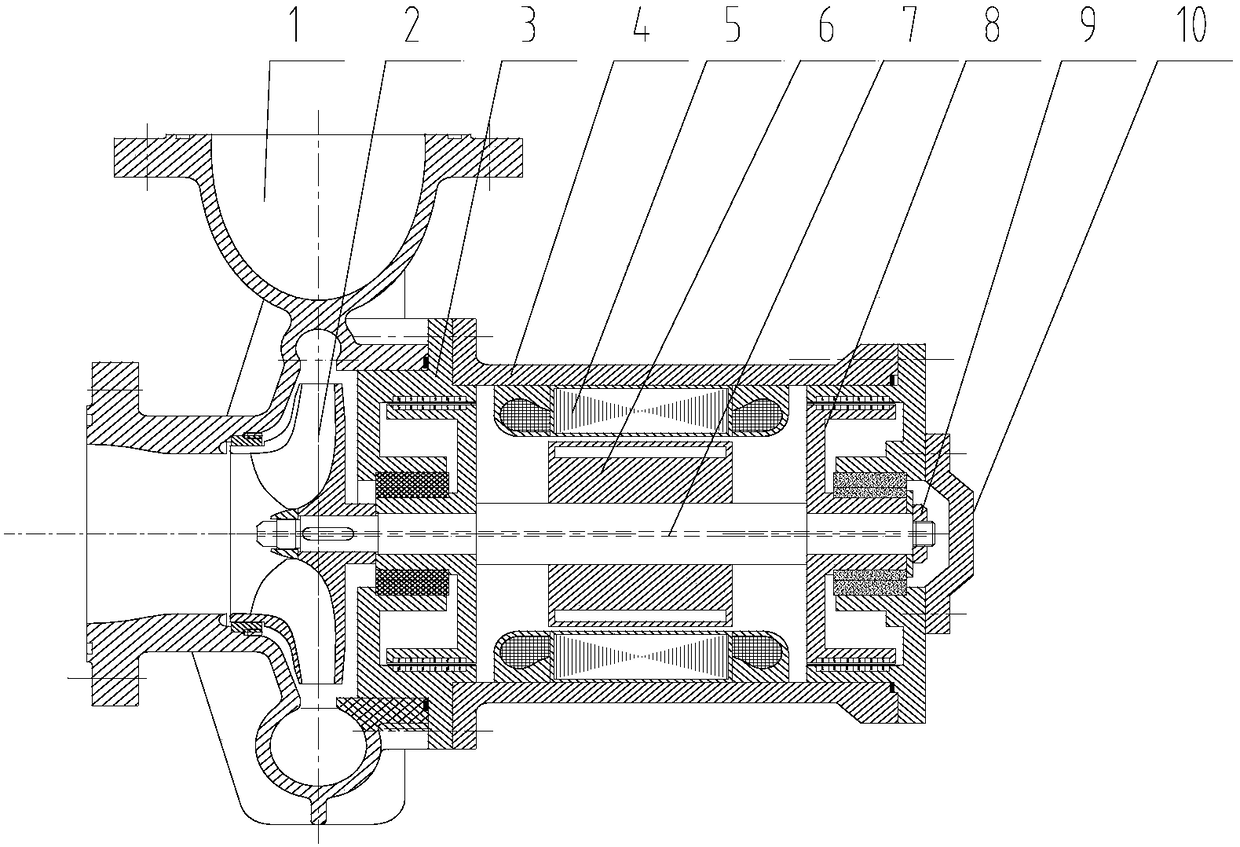

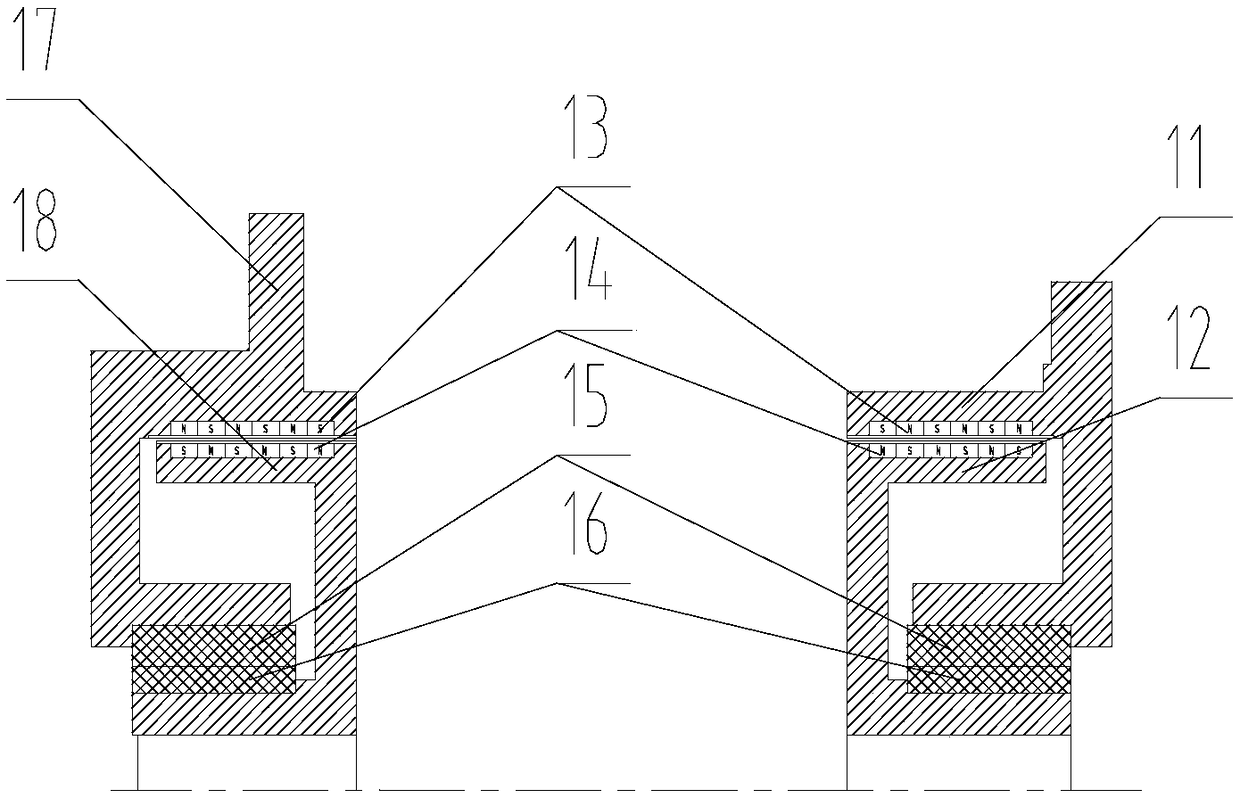

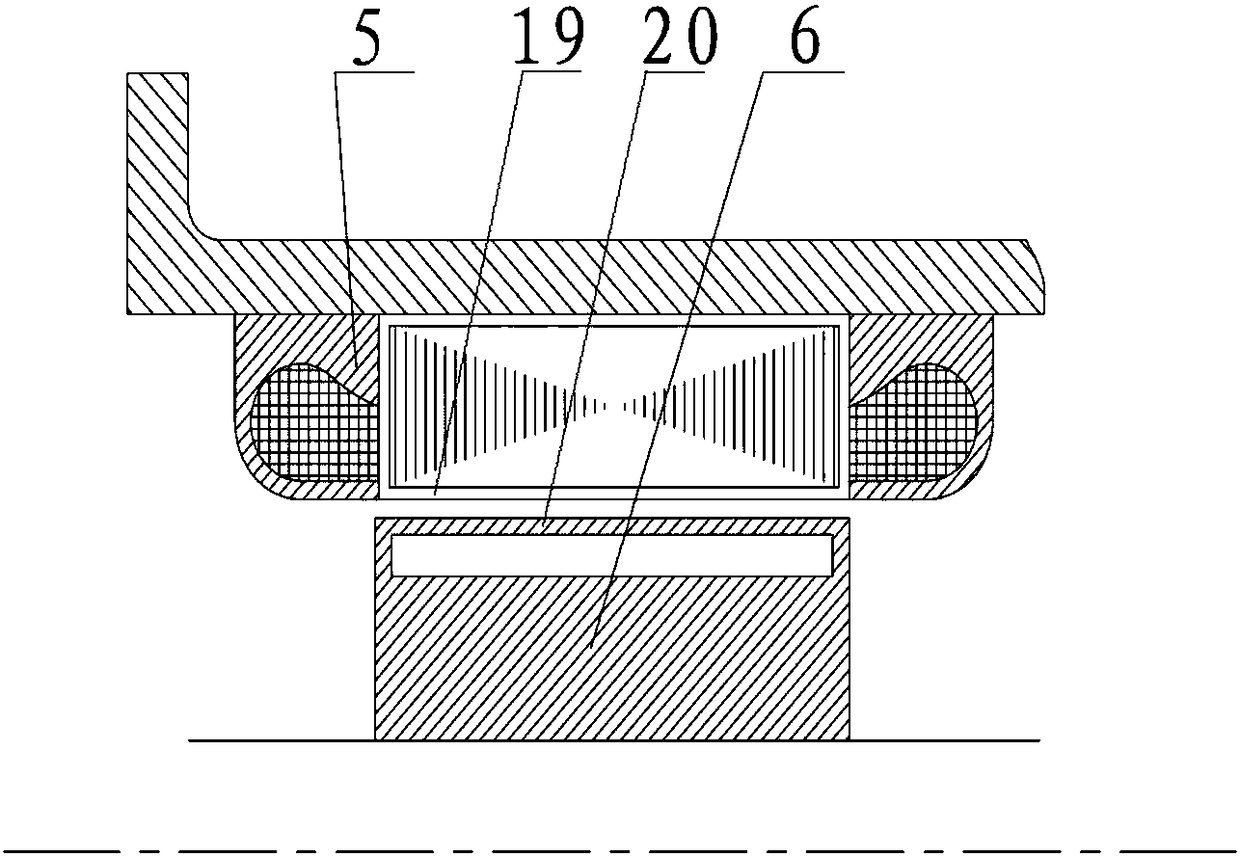

Integrated axial-suspension permanent-magnet synchronous shielding pump

PendingCN108518347ACompact structureImprove reliabilityPump componentsPump installationsPermanent magnet rotorImpeller

The invention discloses an integrated axial-suspension permanent-magnet synchronous shielding pump. The integrated axial-suspension permanent-magnet synchronous shielding pump comprises a pump body and a permanent-magnet shielding motor, wherein the permanent-magnet shielding motor is equipped with a winding stator, a pump shaft and a permanent-magnet rotor fixedly arranged on the pump shaft; thehead part of the pump shaft is connected with an impeller in the pump body; the pump shaft is supported by an axial-suspension bearing device on the end part of the permanent-magnet shielding motor; the axial-suspension bearing device comprises a bearing base and a shaft sleeve base; the bearing base is fixed with the permanent-magnet shielding motor, and comprises a static magnetic ring and a bearing; the shaft sleeve base is fixed with the pump shaft, and comprises a movable magnetic ring and a shaft sleeve which is positioned between the pump shaft and the bearing; each of the static magnetic ring and the movable magnetic ring is formed by axially combining a plurality of ring-shaped magnetic rings, wherein polarity of magnetic poles of the inner ring of the static magnetic ring and theouter ring of the movable magnetic ring alternatively changes axially; and polarity of the magnetic poles opposite to the inner ring of the static magnetic ring and the outer ring of the movable magnetic ring is reverse. The integrated axial-suspension permanent-magnet synchronous shielding pump can be utilized to reduce eddy-current loss of a permanent magnet motor, improves efficiency, and utilizes magnetic force of the permanent magnet to completely balance axial force.

Owner:杭州大路实业有限公司

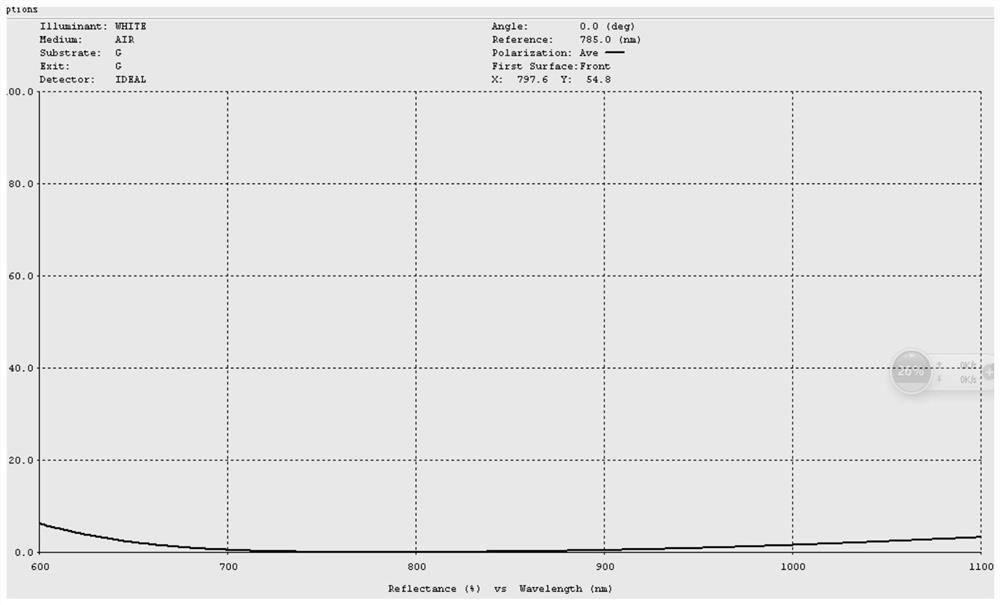

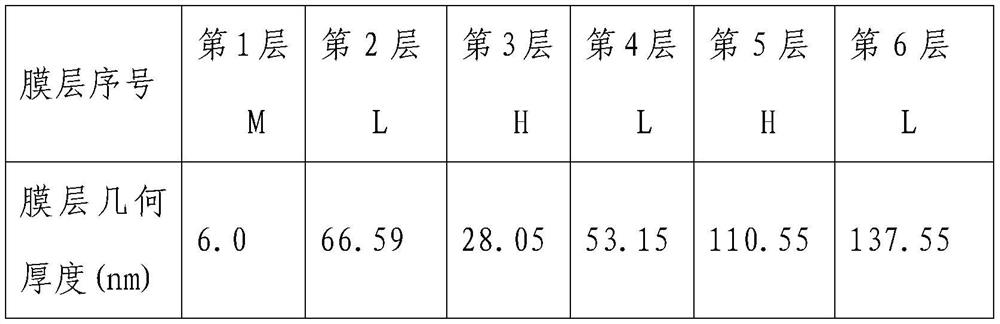

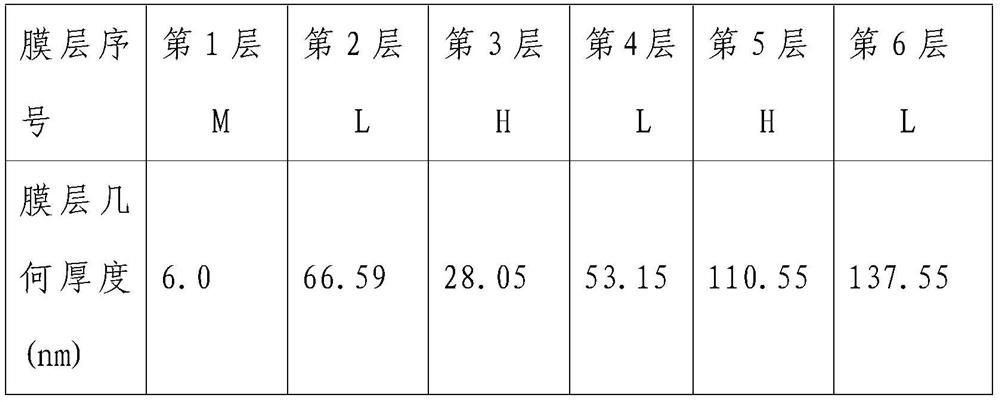

High-damage-threshold laser film process technical method

InactiveCN111679347AExcellent resistance to laser damageImprove permeabilityVacuum evaporation coatingSputtering coatingRefractive indexOptical thin film

The invention relates to a high-damage-threshold laser film technological method, and belongs to the field of optical film plating. The invention aims to overcome the defect that the laser damage resistance threshold of a laser film plated in visible light and near-infrared bands by a conventional laser film plating technology is relatively low. Quartz or K9 is used as a coating substrate, sapphire is used as a substrate film material M, HfO2 is used as a high-refractive-index film material H, SiO2 is used as a low-refractive-index film material L, and TFC is used for giving geometric thicknesses and film system sequence calculation results of all layers of film systems; ultrasonic cleaning and heating baking are carried out on the coating substrate; in an optical film layer bonding bottoming process and a stress matching process, three film materials are sequentially put into an electronic gun evaporation source crucible boat, and then a coating process is completed according to the geometric thickness of each layer of film system and the sequence of the film systems; and the coating substrate is bombarded by using an ion source before coating and in the coating process. The filmlayer is hard, firm, excellent in laser damage resistance and good in permeability, and can be used for a long time in a severe field environment.

Owner:SOUTH WEST INST OF TECHN PHYSICS +1

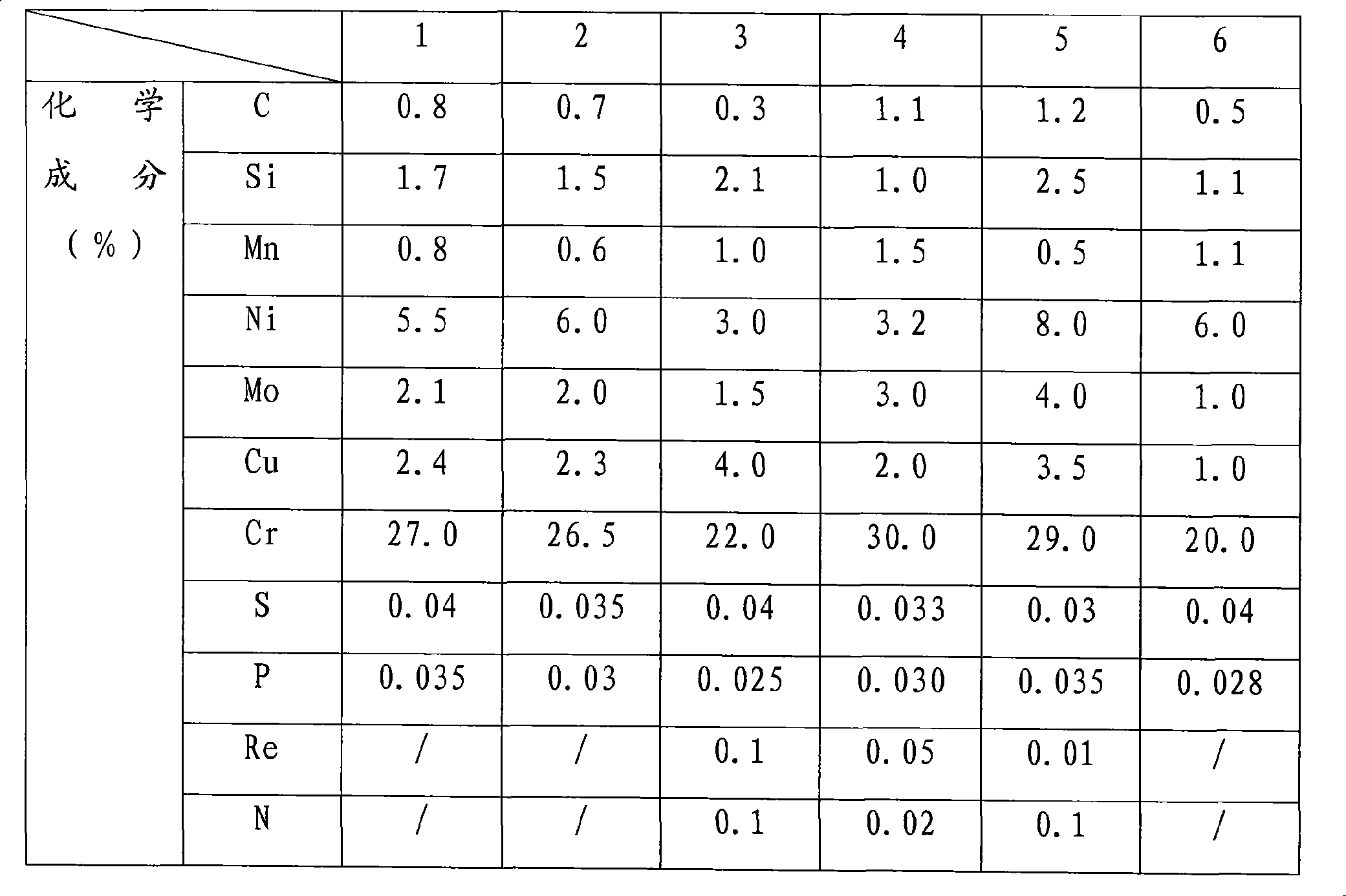

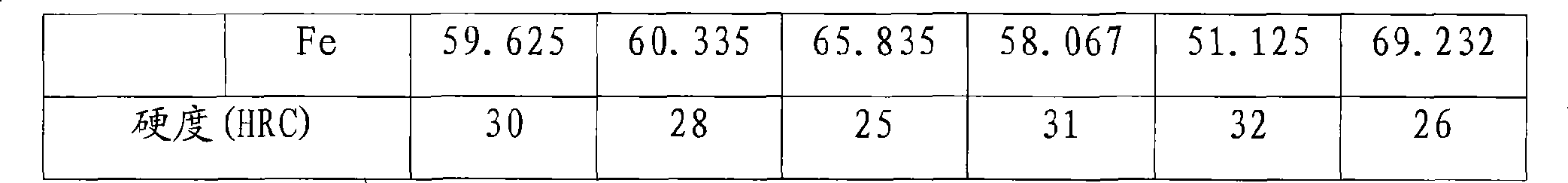

Novel corrosion resistant antiwear metallic material

The invention discloses a novel corrosion-resistant anti-wear metallic material which has the components with the weight percentage of 0.3-1.2% of C, 20-30% of Cr, 1-2.5% of Si, 0.5-1.5% of Mn, 3-8% of Ni, 1-4% of Mo, 1-4% of Cu, less than or equal to 0.035% of P, less than or equal to 0.04% of S, and the rest of Fe. As the novel corrosion-resistant anti-wear metallic material properly increases the carbon content and is added with the right amount of alloying elements, so that material structure contains a certain amount of alloy carbide, and the anti-wear performance of the material is greatly improved. Although the static corrosion-resistant performance is slightly reduced, the comprehensive corrosion-resistant anti-wear performance is greatly improved. In addition, the novel corrosion-resistant anti-wear metallic material can be smelted in an intermediate frequency furnace and needs no concentrated feeding stuff. The production cost is reduced more than CD4M-Cu material.

Owner:SHIJIAZHUANG IND PUMP FACTORY CO LTD

Nickel base alloy powder for manufacturing anticorrosive coating of boiler tube

ActiveCN102021567AImprove performanceHigh hardnessMetallic material coating processesCrack resistanceTemperature resistance

The invention relates to nickel base alloy powder for manufacturing an anticorrosive coating of a boiler tube, which comprises 40 to 45 percent of Cr, 4 to 8 percent of Ti, 0.1 to 0.3 percent of Si, 0.1 to 0.3 percent of Nb, 0.1 to 0.3 percent of Y, 0.1 to 0.3 percent of Hf, 0.1 to 0.3 percent of B and the balance of Ni. The nickel base alloy powder has the excellent comprehensive properties by selecting strengthening elements of an alloy matrix and strengthening elements of a grain boundary of grain refinement and selecting the percentage content of each element preferably, so that the alloy has a higher melting point and higher wear-resisting and corrosion-resisting properties besides moderate rigidity and strength. Therefore, the crack resistance, moldability, process stability and component uniformity of the alloy powder in laser cladding coatings are improved fundamentally, and the requirements of the boiler tube on comprehensive properties of temperature resistance, corrosion resistance, wearing resistance, high strength and the like of the cladding coatings are met.

Owner:四川大成涡轮设备再制造技术有限公司

Surface anticorrosion wear-resistant composite coating for cylinder sleeve of automobile engine applying bio-oil

ActiveCN104313554AReduce concentrationRealize the effect of degreasing and derustingLiquid/solution decomposition chemical coatingChemical platingWear resistant

A surface anticorrosion wear-resistant composite coating for a cylinder sleeve of an automobile engine applying bio-oil is disclosed. The coating comprises a Ni-Cu-Ce-La-P-Graphene composite material, and can be prepared by adopting a gradient chemical plating coating process. The coating is characterized in that: Ni, Cu, Ce, La and P in a special ratio, and Graphene are simultaneously deposited on the surface of the cylinder sleeve, and the composite coating with good anticorrosion and wear-resistant functions is prepared. The coating is advantageous in that: the binding force of the coating and a substrate is strong, compactness of the coating is high, the coating has excellent anticorrosion and wear-resistant effects especially for the bio-oil, a preparing method of the coating is simple, convenient, and prone to industrial production, and the coating can be widely used in the fields of metal material protection, mechanical surface treatment, energy-saving and environmental friendly automobiles, and the like.

Owner:黄山市开发投资集团有限公司

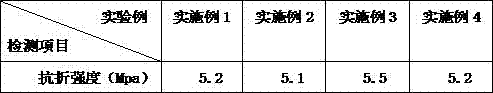

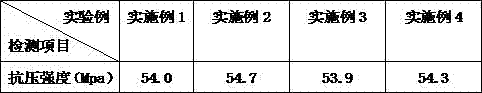

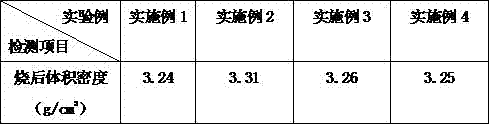

High-aluminum high-strength refractory castable material

The invention relates to a high-aluminum high-strength refractory castable material which is prepared from the following components in parts by weight: 40-60 parts of bauxite, 5-10 parts of special kaolin, 2-8 parts of dolomite, 5-10 parts of zircon, 1-15 parts of silicon carbide, 5-10 parts of binder, 2-5 parts of coagulating powder, 1-2 parts of emery powder, 10-15 parts of aluminum oxide micro powder and 1-5 parts of water. Bauxite, special kaolin, dolomite, zircon and silicon carbide are mixed to prepare particles and fine powder, wherein the particles and fine powder comprise 40-60 parts by weight of particles and 60-40 parts by weight of fine powder; the particle size range of the particles is 3.0-1mm and the grain size of the fine powder is 0.9-0.1mm.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Anti-corrosion durable flange plate

InactiveCN102996932AImprove corrosion and wear resistanceEasy to useFlanged jointsCorrosion preventionEngineeringWear resistance

The invention discloses an anti-corrosion durable flange plate which comprises a flange body (3), an adapter hole (6), bolt holes (2) and a protecting layer (1), wherein the adapter hole (6) is formed in the center of the flange body (3); a plurality of bolt holes (2) are distributed in the flange body (3) and at the periphery of the adapter hole (6); and the protecting layer (1) is adhered to the outer surface of the flange body (3). The protecting layer is added to the outer surface of the flange body, so that the corrosion resistance and the wear resistance of the flange plate are effectively improved, the flange plate can be better used in a severe environment, and the service life of the flange plate is prolonged.

Owner:XUZHOU ZHIDIAN ELECTROMECHANICAL EQUIP

High-temperature refractory material for kiln lining and preparation method of high-temperature refractory material

The invention discloses a high-temperature refractory material for a kiln lining. The high-temperature refractory material comprises the following raw materials in parts by weight: 20-40 parts of a high alumina material, 12-25 parts of special grade kaolin, 5-12 parts of an adhesive, 2-8 parts of an admixture, 10-15 parts of corundum fine powder, 8-15 parts of zircon sand, 5-15 parts of zirconium dioxide and 5-15 parts of chromium dioxide, wherein the high alumina material refers to special grade or first-grade bauxite and comprises coarse aggregate, fine aggregate and superfine powder. The invention further provides a method for preparing the high-temperature refractory material. The high-temperature refractory material prepared according to the raw material ratio and the preparation method provided by the invention is applied to the kiln lining. According to experimental detection, the high-temperature refractory material has excellent stability at a high temperature, the refractoriness reaches 1700 DEG C or higher even reaches 2000 DEG C, and the conventional market requirements are completely met.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

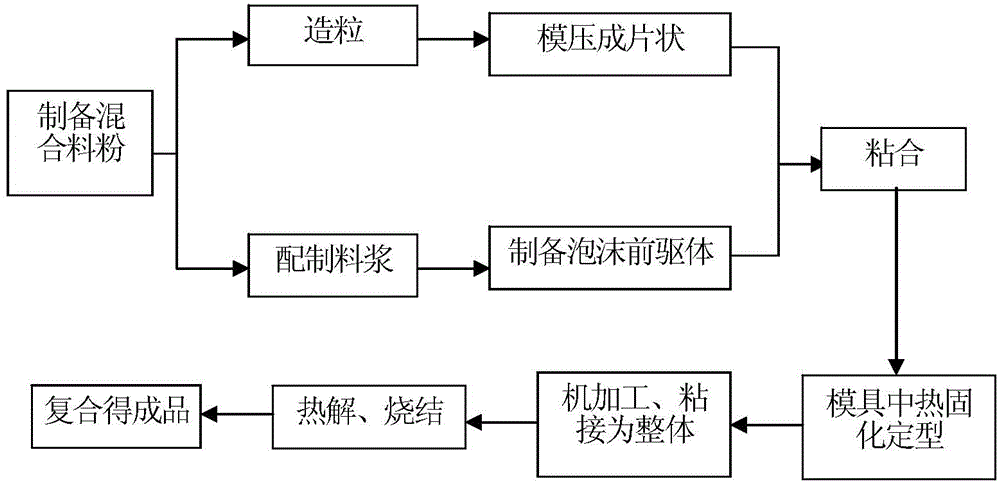

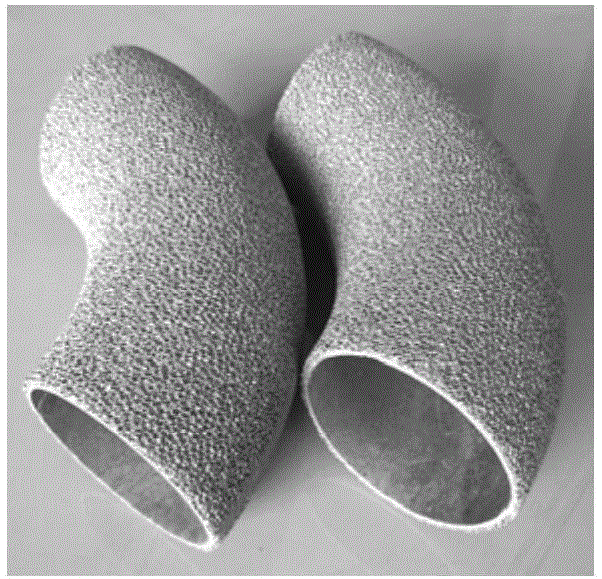

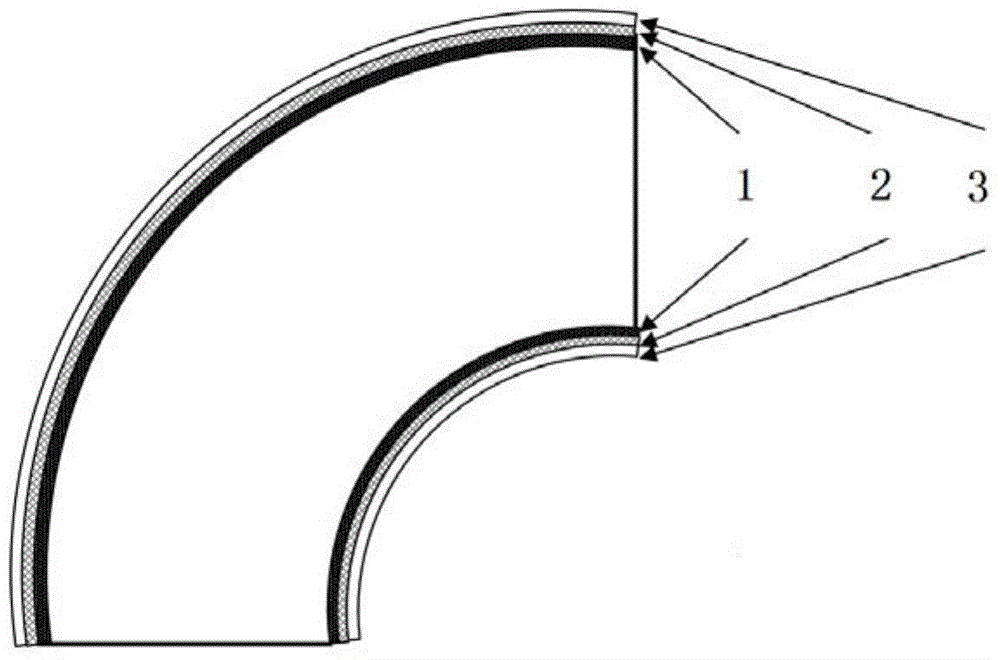

Abrasion-resistant and anticorrosion pipe or pipe fitting with double ceramic lining layers and preparation method of abrasion-resistant and anticorrosion pipe or pipe fitting

ActiveCN106321991AImprove wear resistanceImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationParticulatesSurface layer

The invention relates to metal pipe or pipe fitting surface abrasion-resistant and anticorrosion protection technologies, in particular to an abrasion-resistant and anticorrosion pipe or pipe fitting with double ceramic lining layers and a preparation method of the abrasion-resistant and anticorrosion pipe or pipe fitting. The pipe or pipe fitting is composed of an abrasion-resistant and anticorrosion lining layer and a metal layer from inside to outside. The abrasion-resistant and anticorrosion lining layer is composed of a surface layer and a composite layer. The surface layer is a compact ceramic layer. The composite layer is a foamed ceramic layer. The composite layer is directly grown on the back face of the compact ceramic layer. The preparation process comprises the following steps of preparation of mixed powder, prilling and slurry preparing, sheet forming through mold pressing and preparation of a foam precursor, bonding, thermosetting forming in a mold, machining and bonding forming, pyrolyzing and sintering, and finished product obtaining through compositing. According to the ceramic lining layer abrasion-resistant and anticorrosion pipe or pipe fitting prepared through the method, the abrasion-resistant service life can be 5-10 times that of rubber lining abrasion-resistant layers, the pipe or pipe fitting has good tolerability to acid and alkali corrosion and high-temperature impact, and the replacement cycle of pipe or pipe fitting equipment can be effectively prolonged, so that the operating cost of enterprises is reduced, and emission of particulate pollutants is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

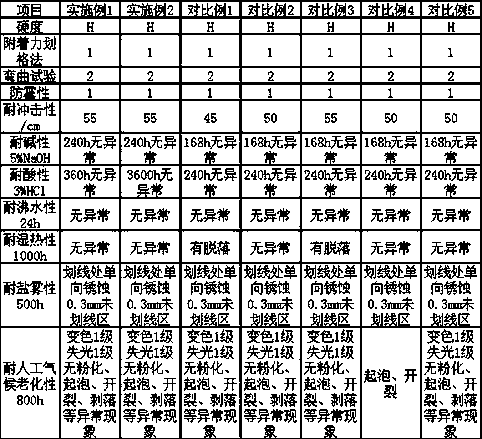

Preparation method of wear-resistant, heat-insulation and corrosion-resistant powder coating

InactiveCN110760234AMeet the needs of efficient operationReduce harmFireproof paintsCarboxyl rubber coatingsNitrile rubberFirming agent

The invention discloses a preparation method of a wear-resistant, heat-insulation and corrosion-resistant powder coating. The powder coating is prepared from the following raw materials: benzoxazine resin, epoxy resin, chlorinated polyether, carboxylated-terminated acrylonitrile-polybutadiene rubber, a curing agent, barite powder and wollastonite powder. The wear-resistant, heat-insulation and corrosion-resistant powder coating can be prepared by processes such as melting, mixing and extruding, cooling for tabletting, crushing and sieving and has excellent wear and corrosion resistance and heat insulation properties, the surface of a processed coating meets the national and industrial standards on the aspects such as adhesive force, flexibility, impact strength, smoothness, hardness and chemical resistance, and the wear-resistant, heat-insulation and corrosion-resistant powder coating is low in curing temperature, convenient to use and capable of reducing the cost.

Owner:孙振龙

High-alumina high-temperature refractory castable for power station boiler

ActiveCN103539468AImprove corrosion and wear resistanceExtended service lifePower stationArray data structure

The invention discloses a high-alumina high-temperature refractory castable for a power station boiler, which is prepared from the following components in parts by weight: 60-80 parts of high-alumina aggregate, 5-12 parts of special-grade kaolin, 5-12 parts of binder, 2-8 parts of silicon micro-powder, 2-10 parts of alumina micro-powder and 1-5 parts of water, wherein in the 60-80 parts of high-aluminum aggregate, coarse aggregate accounts for 30-40%, medium aggregate accounts for 35-45%, and fine aggregate accounts for 20-30%; the binder is prepared from the following components in parts by weight: 20-40 parts of magnesium silicate and 80-60 parts of phosphate. The high-alumina high-temperature refractory castable disclosed by the invention has the beneficial effects that the boiler box temperature can be increased by 60-250 DEG C, the thermal efficiency can be improved to 8%, and the service life of the boiler body is prolonged.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Preparation method of tantalum boride composite coating

InactiveCN107287547AHighlight substantive featuresHigh densityMolten spray coatingThermal sprayingBoron carbide

The invention discloses a preparation method of a tantalum boride composite coating, and relates to coating of boride to metal materials. The tantalum boride composite coating is obtained through the thermal spraying in-situ reaction in a synthesis manner. The preparation method comprises the steps of preparing tantalum oxide / boron carbide / aluminum composite powder for thermal spraying, carrying out pretreatment on the surface of a matrix material needing the coating and preparing the tantalum boride composite coating. According to the preparation method, the defects that a tantalum boride composite coating prepared in the prior art is complex in preparation process, high in cost, large in pollution, low in deposition efficiency, small in coating thickness, small in coating density, poor in uniformity, low in toughness, poor in coating and matrix binding force, prone to cracking and not suitable for being applied to large-scale industrial production are overcome.

Owner:HEBEI UNIV OF TECH

Resin button formula and production technology thereof

InactiveCN107325508ASimple preparation processHigh strengthClothes buttonsChemistryGlass microsphere

The invention discloses a resin button formula and a production technology thereof. A resin button is prepared from, by weight, 30-50 parts of unsaturated polyester resin, 10-20 parts of calcium propionate, 5-10 parts of chitosan, 2-8 parts of glass fiber, 2-10 parts of microcrystalline wax, 2-8 parts of hollow glass microspheres, 1-5 parts of a curing agent, 1-6 parts of cobalt naphtenate, 5-10 parts of color paste, 1-8 parts of pearl powder and 2-10 parts of a thixotropic agent. Accordingly, the preparation technology is simple, the prepared resin button is high in strength, good in toughness and not likely to break, and meanwhile the resin button has the anti-corrosion and wear-resistant functions.

Owner:温州舒尔达工贸有限公司

Surface treatment method for automobile chassis parts

ActiveCN107419212AHigh bonding strengthImprove corrosion and wear resistanceMolten spray coatingSand blastingSpray coating

The invention discloses a surface treatment method for automobile chassis parts. The surface treatment method comprises the steps of (1) workpiece cleaning; (2) sand blasting; and (3) spraying treatment. The surface treatment method is reasonably optimized and improved, enhances the bonding strength of a spraying coating and a workpiece surface, and meanwhile reduces the stress produced during processing. The workpiece surface after final treatment has enhanced wear resistance and corrosion resistance, high fatigue strength and good integrated use quality.

Owner:阜南县申通机械制造有限公司

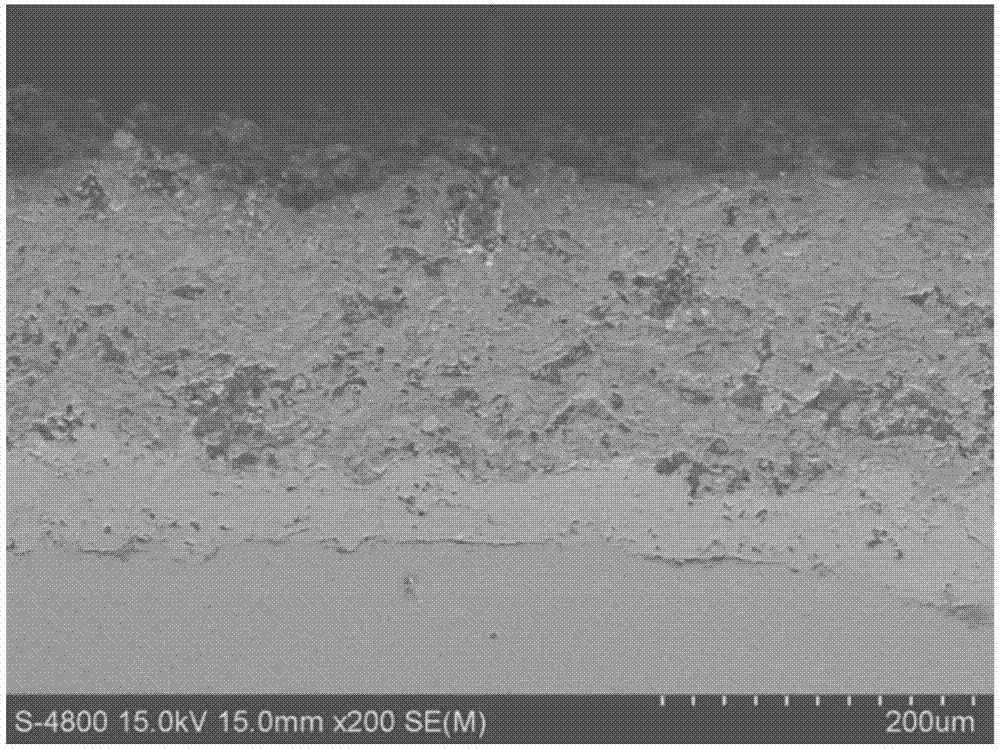

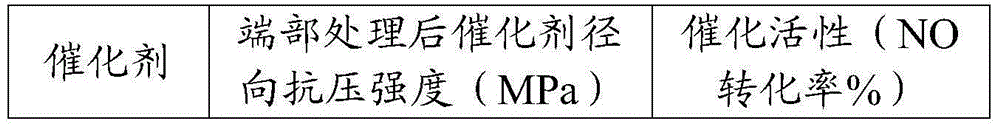

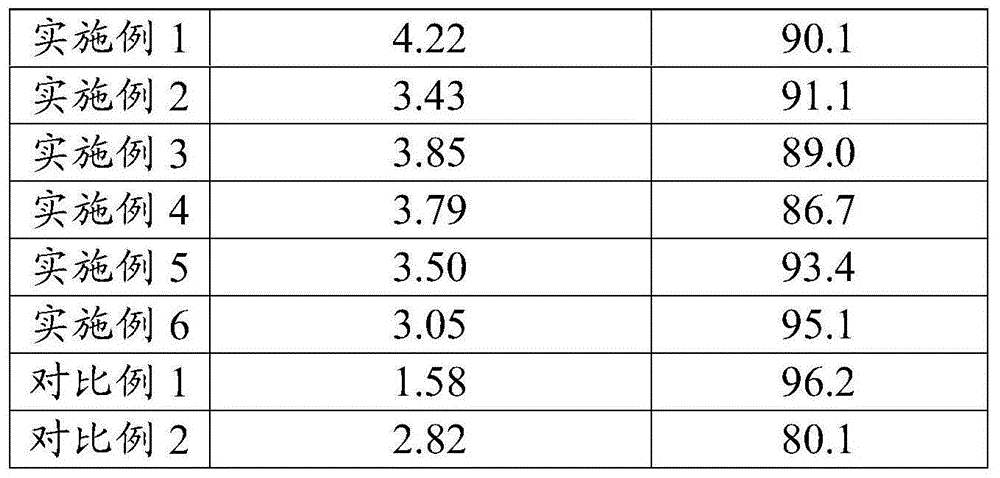

Denitration catalyst terminal hardening liquid as well as preparation method and application thereof

ActiveCN105057005AHigh hardnessEasy to operateCatalyst protectionCatalyst activation/preparationAluminium hydroxideFlue gas

The invention belongs to the technical field of catalysts and particularly relates to denitration catalyst terminal hardening liquid as well as a preparation method and application thereof. The denitration catalyst terminal hardening liquid is applied to a coal-fired boiler flue gas denitration catalyst. The hardening liquid comprises the following raw materials in parts by weight: 5-25 parts of aluminum hydroxide, 30-60 parts of phosphoric acid, 30-60 parts of de-ionized water, 1-10 parts of metal oxide powder and 0.1-1 part of a suspension dispersant. With the adoption of the denitration catalyst terminal hardening liquid, the radial compressive strength of a catalyst terminal part can be improved by 150% or more; and meanwhile, more than or equal to 90% of catalytic activity is kept.

Owner:HAO HUA CHENGDU TECH

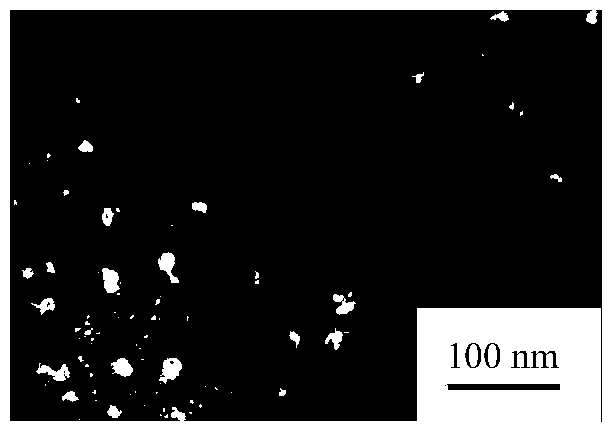

Ultrasonic-assisted nano cerium oxide doped Ni-W-TiN composite coating and preparation method thereof

InactiveCN111334827AReduce contentIncrease component contentElectrolytic coatingsElectrolytic agentNanoparti cles

The invention relates to a preparation method of an ultrasonic-assisted nano cerium oxide doped Ni-W-TiN composite coating. According to the preparation method, the concentration of nickel ions in a plating solution is reduced, the concentration of W ions is increased, the content of a complexing agent is reduced, and the content of W components in the coating is increased; through an ultrasonic-assisted method, the concentration of TiN nano particles is reduced, an SDS auxiliary agent is used, agglomeration is reduced, and the distribution uniformity of the particles in the coating is improved; the corrosion resistance of the Ni-W-TiN coating is improved through doping of nano rare earth oxide CeO2; and meanwhile, the plating solution ratio and the process parameters are optimized. The preparation process comprises the following steps of 1, preparation of an electrolyte; 2, pretreatment of a base material; and 3, electro-deposition. According to the ultrasonic-assisted nano cerium oxide doped Ni-W-TiN composite coating, the agglomeration problem of the nano particles is effectively solved, the dispersion uniformity of the nano particles is improved, and the CeO2 and the TiN are coordinated to improve the protection performance of a Ni-W alloy. The coating has better wear resistance and corrosion resistance, the comprehensive performance is obviously improved, and the coating can better adapt to a severe corrosion environment.

Owner:HOHAI UNIV

Iron-based self-fluxing alloy amorphous coating method adopting supersonic arc spraying

InactiveCN108330425AReduce manufacturing costImprove wear resistance and corrosion resistanceMolten spray coatingRevolutions per minuteCorrosion

The invention relates to an iron-based self-fluxing alloy amorphous coating method adopting supersonic arc spraying. According to the method, an iron-based self-fluxing alloy is prepared into sprayingpowder, the spraying powder is sprayed to the surface of a cold roll workpiece by the adoption of the supersonic arc spraying mode, and the iron-based self-fluxing alloy comprises, by mass percentage, 5-11% of Cr, 3.0-5.0% of B, 2.0-5.5% of Si, 2-5% of C, 1-3% of W, 0.3-1% of Mo, 0.1-1% of Nb, 0.1-3% of Y, 1-5% of NaBH4 and K2WO4 and NaF, 0.5-2% of nano-silica, 1-6% of nano-titania and the balance Fe. The powder is mixed by a fluidized bed for 120 minutes and then mixed with large and small balls at a rotation speed of 200-260 revolutions per minute. A coating is completely amorphous, the coating is compact, the bonding strength with a substrate is high, the hardness is high, the corrosion resistance is high, the thermal stability of the coating is good, and the coating has excellent comprehensive properties of wear resistance and corrosion resistance.

Owner:戴亚洲

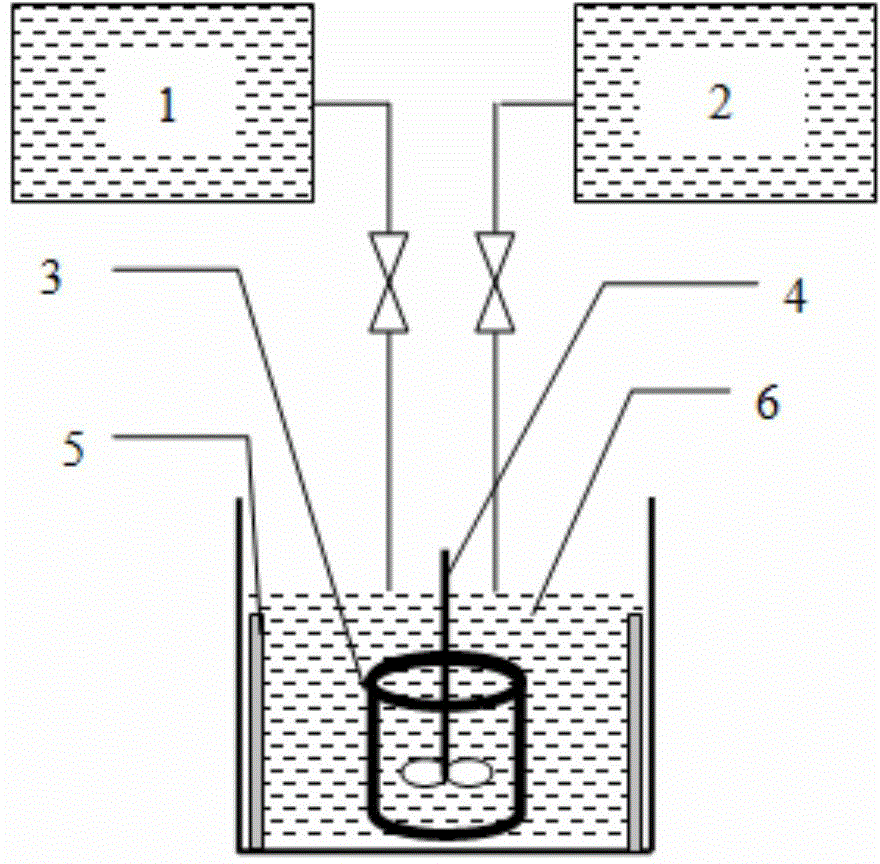

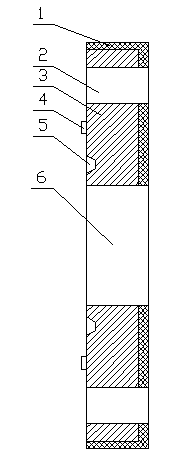

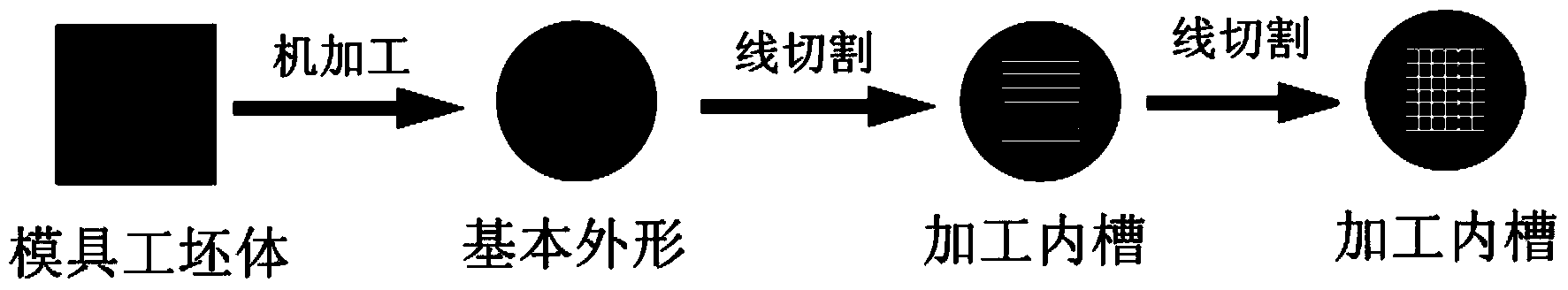

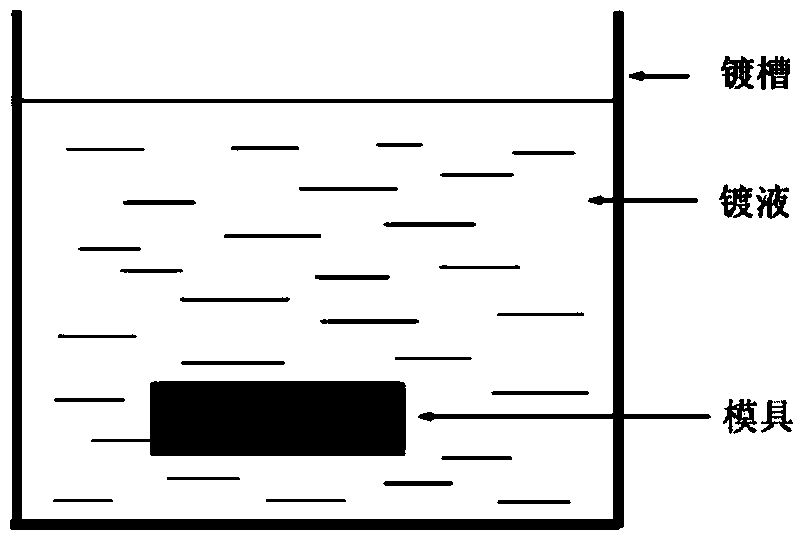

Method for precisely manufacturing ultrathin-wall honeycomb ceramic carrier extrusion molding mold

InactiveCN103707396AHigh hardnessQuality improvementCeramic extrusion diesLiquid/solution decomposition chemical coatingHardnessMachining

The invention belongs to the field of machining, and particularly relates to a method for precisely manufacturing an ultrathin-wall honeycomb ceramic carrier extrusion molding mold. The method comprises the following steps that firstly, the machining technology is used for manufacturing and machining a mold billet body to form the basis appearance of the extrusion molding mold, then the linear cutting technology is used for machining internal thin grooves of the mold, and the surfaces of the internal thin grooves are pre-ground by extruding pug out; the mold is immersed into a plating solution groove, the inner surface of the mold is plated with a protective coating, and the thickness of the coating is precisely controlled according to deposition time; finally, the mold is subjected to heat treatment under the protection of argon to form a nanocrystalline-noncrystalline composite microscopic structure; the extrusion molding mold which is high in size precision and hardness, abrasion resistant and corrosion resistant and has the self-lubricating property is obtained.

Owner:UNIV OF SCI & TECH BEIJING

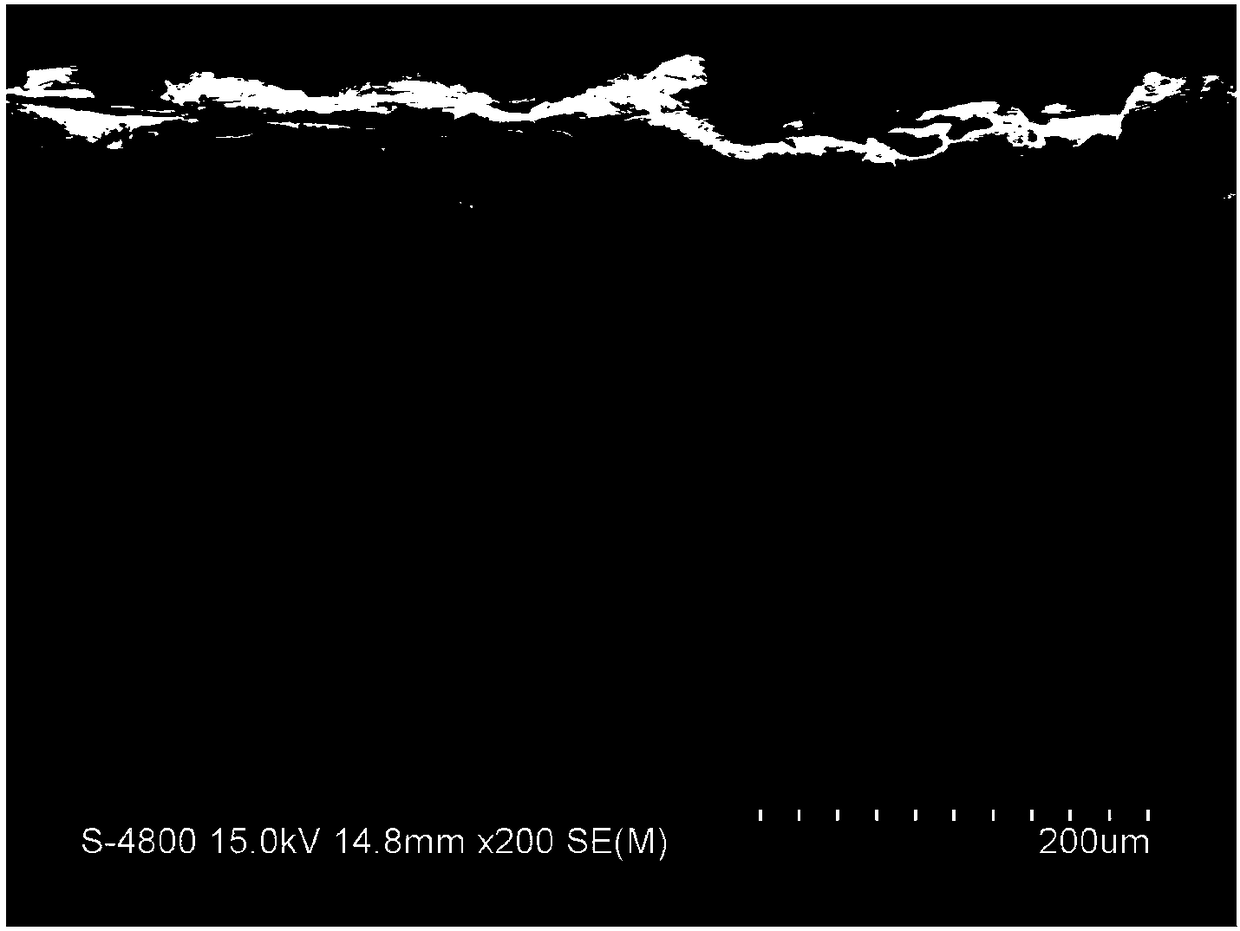

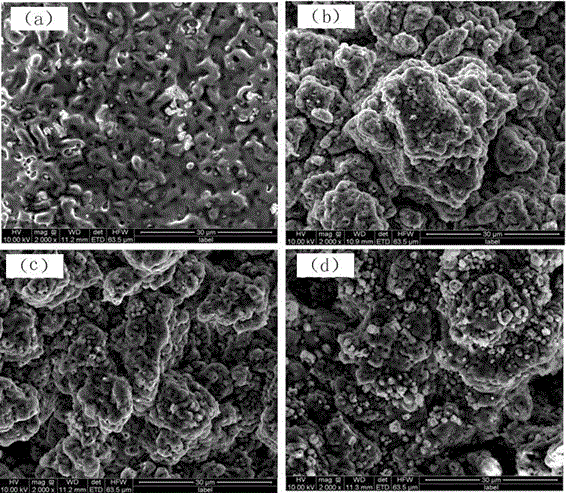

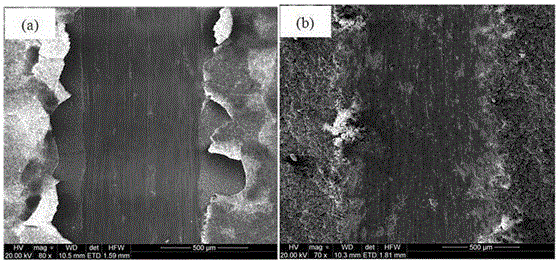

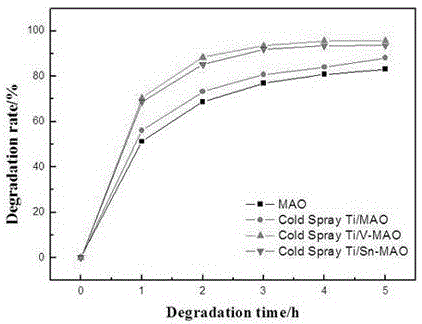

Preparing method for composite coating integrating photocatalysis and protection performance of magnesium alloy surface

InactiveCN106637183AGood binding force to membrane baseLarge specific surface areaSurface reaction electrolytic coatingSuperimposed coating processMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a composite coating integrating photocatalysis and wear resistance of a magnesium alloy surface. The composite coating is composed of a cold spraying Ti coating located on the surface of a magnesium alloy matrix and a titanium oxide layer located on the surface of the Ti coating and prepared through micro-arc oxidation. The cold spraying technology is adopted in the Ti coating so that the Ti coating with the rough surface characteristic is formed on the surface of the magnesium alloy matrix, wherein the thickness of the Ti coating ranges from 100 microns to 300 microns. Micro-arc oxidation is used for preparing the titanium oxide layer with vanadium and tin or without doping of other metal elements, and the titanium oxide layer having photocatalytic activity is obtained through regulation on the electrolyte composition and technological parameters, wherein the thickness of the titanium oxide layer ranges from 6 microns to 20 microns. Compared with an existing magnesium alloy micro-arc oxide layer and a titanium surface micro-arc oxide layer, the composite coating is a film layer having more excellent corrosion-resisting and wear-resisting performance and photocatalytic performance, beneficial modification on the surface of the magnesium alloy matrix can be achieved, application of magnesium alloys in the photocatalytic field is promoted, and the technology can be popularized to modification of surfaces of aluminum alloys.

Owner:XIAN TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com