Method for precisely manufacturing ultrathin-wall honeycomb ceramic carrier extrusion molding mold

A honeycomb ceramic carrier and extrusion molding technology, applied in the field of mechanical processing, can solve the problems of difficult extrusion, regular shape, easy corrosion, and scrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

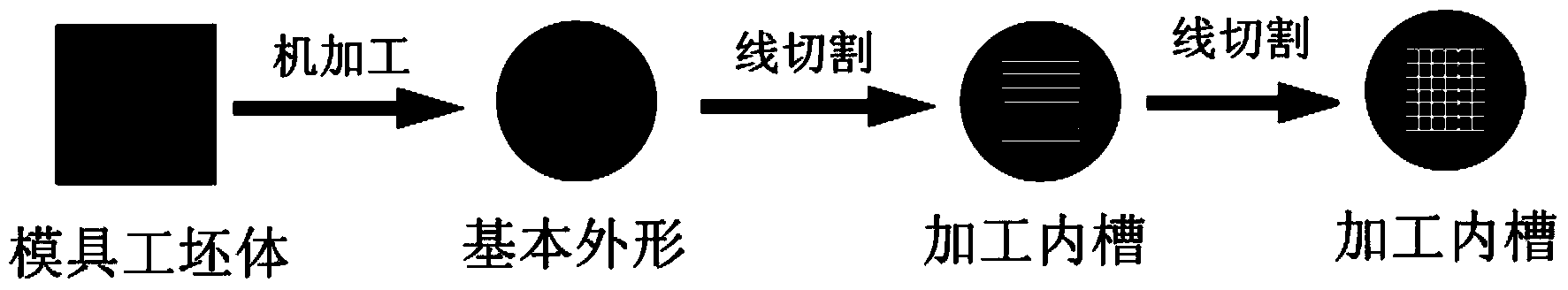

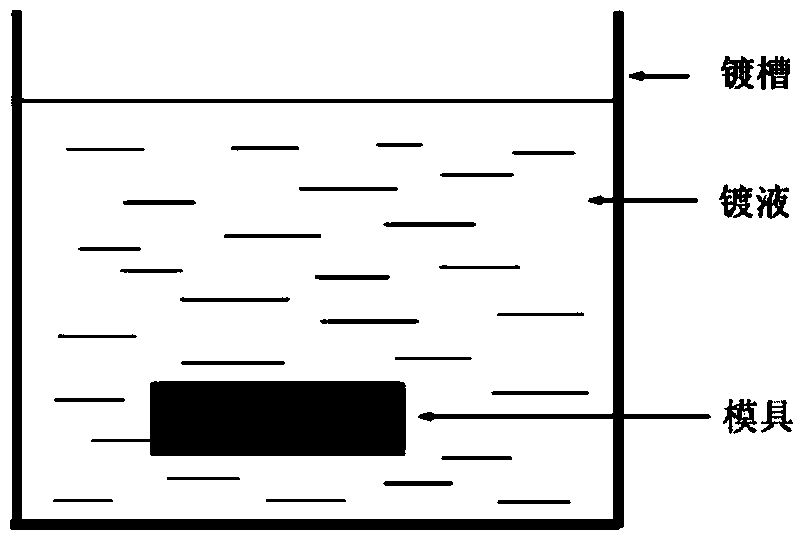

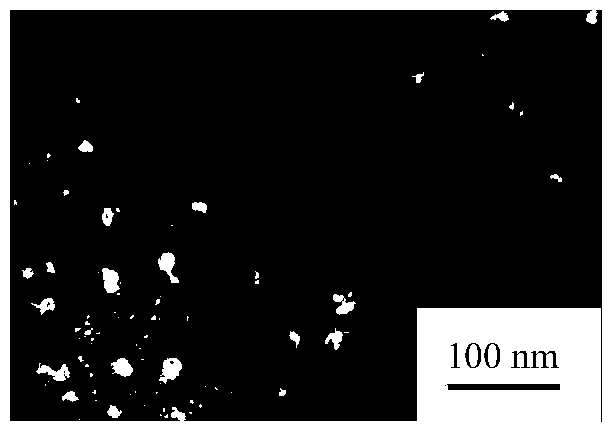

[0017] First, the machining technology is used to manufacture the mold steel body into the basic shape of the extrusion mold (such as figure 1 shown), and then use the wire cutting process to process the fine grooves inside the mold, and strictly control the width of the grooves. Afterwards, the preliminarily made mold is installed on the extrusion equipment, and 20kg of ceramic mud is extruded, and the surface of the inner tank is pre-ground, and then the mold is removed, and the mold is immersed in the plating solution tank (such as figure 2 shown), the main components of the plating solution are: nickel sulfate 18g / L, sodium hypophosphite 35g / L, copper sulfate 5g / L, cobalt sulfate 5g / L, sodium tungstate 2g / L, citric acid 0.3mol / L , sodium silicate 13g / L, acetic acid 2g / L. Control the pH of the plating solution to 2 and the temperature at 65°C, control the circulation of the plating solution in the solution tank through an external mechanical pump, and apply ultrasonic vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com