High-temperature refractory material for kiln lining and preparation method of high-temperature refractory material

A refractory material and high temperature technology, applied in the field of high temperature refractory materials, can solve the problems of damage and unusability of refractory castables, and achieve the effects of low production cost, stable volume and protection of the furnace body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

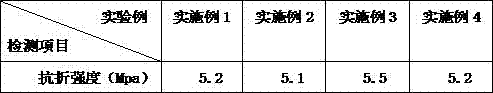

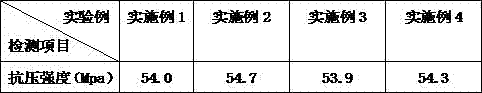

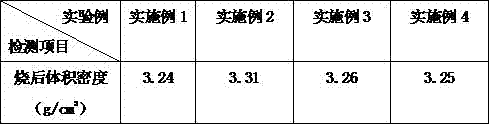

Examples

Embodiment 1

[0025] This embodiment provides a high-temperature refractory material for the inner wall of a kiln, including the following raw materials in parts by weight: 20 parts of high-alumina materials, 12 parts of super-grade kaolin, 5 parts of binder, yellow dextrin and sodium carboxymethyl cellulose CMC and 2 parts of polyphosphate mixture, 10 parts of corundum fine powder, 8 parts of zircon sand, 5 parts of zirconium dioxide, and 5 parts of chromium dioxide. The binder is a mixture of powdered water glass and powdered phenolic resin, wherein the powdered water glass accounts for 40% of the total weight of the binder, and the powdered phenolic resin accounts for 60% of the total weight of the binder.

[0026] The high-alumina material mentioned above is special-grade or first-grade bauxite, including coarse and fine aggregates, fine powder and ultra-fine powder, of which coarse aggregate accounts for 5%, medium aggregate accounts for 20%, and fine aggregate accounts for 25%. , fine...

Embodiment 2

[0036] This embodiment provides a high-temperature refractory material for the inner wall of a kiln, including the following raw materials in parts by weight: 20-40 parts of high-alumina material, 25 parts of super-grade kaolin, 12 parts of binder, sodium carboxymethylcellulose CMC and polyphosphoric acid 8 parts of salt and lignosulfonate mixture, 15 parts of corundum fine powder, 15 parts of zircon sand, 15 parts of zirconium dioxide, and 15 parts of chromium dioxide. The binder is a mixture of powdered water glass and powdered phenolic resin, wherein the powdered water glass accounts for 85% of the total weight of the binder, and the powdered phenolic resin accounts for 15% of the total weight of the binder.

[0037] The high-alumina material mentioned above is special-grade or first-grade bauxite, including coarse and fine aggregates, fine powder and ultra-fine powder, of which coarse aggregate accounts for 10%, medium aggregate accounts for 20%, and fine aggregate accounts...

Embodiment 3

[0047] This embodiment provides a high-temperature refractory material for the inner wall of a kiln, including the following raw materials in parts by weight: 30 parts of high-alumina materials, 20 parts of super-grade kaolin, 8 parts of binder, polyphosphate and lignosulfonate, and polycarbonate 5 parts of ester PC mixture, 13 parts of corundum fine powder, 10 parts of zircon sand, 10 parts of zirconium dioxide, and 10 parts of chromium dioxide. The binder is a mixture of powdered water glass and powdered phenolic resin, wherein the powdered water glass accounts for 70% of the total weight of the binder, and the powdered phenolic resin accounts for 30% of the total weight of the binder.

[0048] The high-alumina material mentioned above is super-grade or first-grade bauxite, including coarse and fine aggregates, fine powder and ultrafine powder, of which coarse aggregate accounts for 8%, medium aggregate accounts for 12%, and fine aggregate accounts for 30%. , fine powder acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com