Lightweight refractory for glass smelting kiln

A light-weight refractory material and glass melting furnace technology, applied in the field of refractory materials, can solve the problems of poor heat preservation performance and thermal shock resistance, high energy consumption of glass furnace, difficult temperature control, etc. Body weight, weight loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

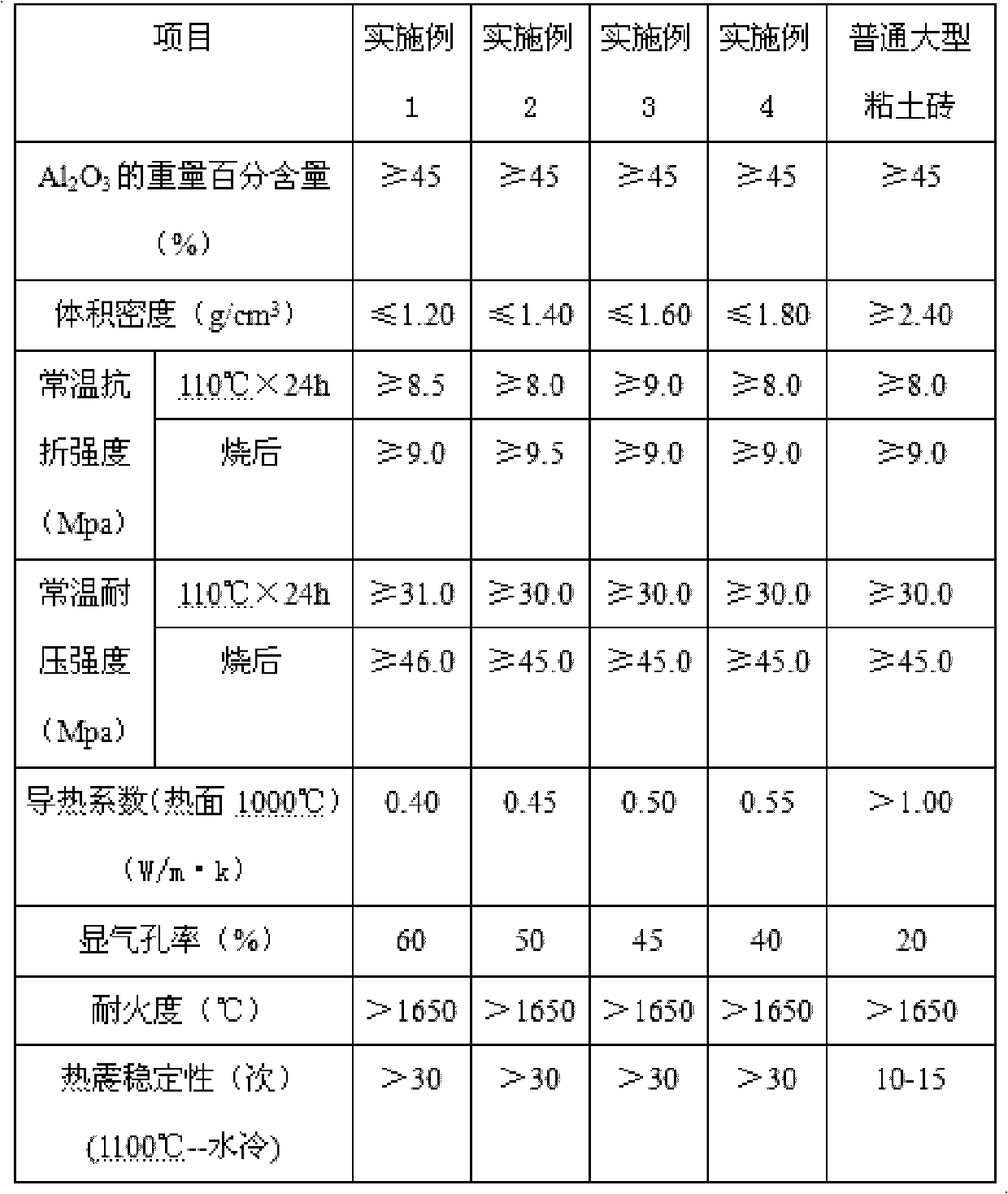

Examples

Embodiment 1

[0012] Lightweight refractory materials for glass melting furnaces, made of the following raw materials in weight percentage: bulk density 1.0g / cm 3 , 50% of microporous mullite lightweight aggregate with a particle size of 0.1-1mm, 15% of high-temperature cement, 8% of silicon micropowder, 10% of high alumina micropowder, 12% of clay powder, 4.7% of kyanite, tripolyphosphoric acid Sodium 0.3%.

Embodiment 2

[0014] Lightweight refractory materials for glass melting furnaces, made of the following raw materials in weight percentage: bulk density 1.25g / cm 3 , microporous mullite lightweight aggregate with a particle size of 1-3mm 40%, high temperature cement 11.7%, silicon micropowder 10%, high alumina micropowder 18%, clay powder 12%, andalusite 8%, sodium hexametaphosphate 0.3%.

Embodiment 3

[0016] Lightweight refractory materials for glass melting furnaces, made of the following raw materials in weight percentage: bulk density 1.45g / cm 3 60% of microporous mullite lightweight aggregate with a particle size of 3-5mm, 15% of high-temperature cement, 5% of silicon micropowder, 6% of high alumina micropowder, 11.9% of clay powder, 1% of andalusite, 1% of kyanite %, sodium hexametaphosphate 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com