Patents

Literature

85results about How to "Eliminate welding residual stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for welding thick aluminum alloy plate

InactiveCN102363237AEliminate welding residual stressEliminate processing stressArc welding apparatusWelding/soldering/cutting articlesMachining processWeld strength

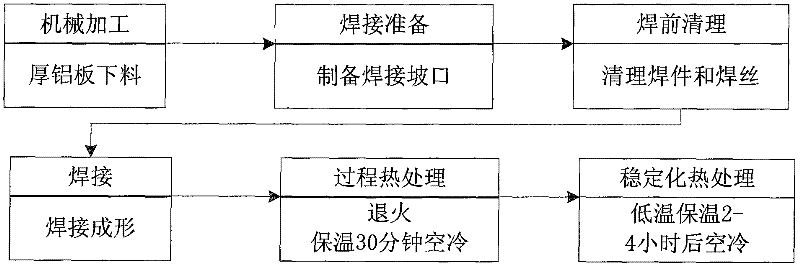

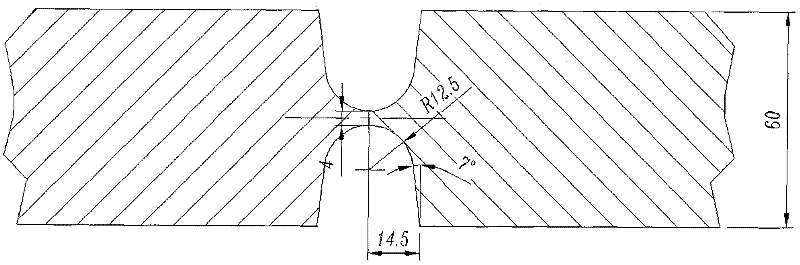

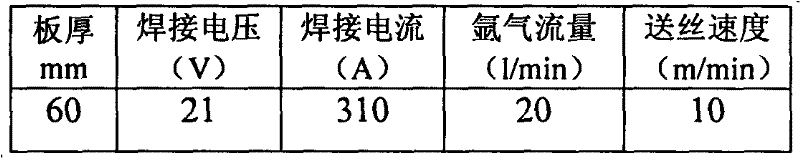

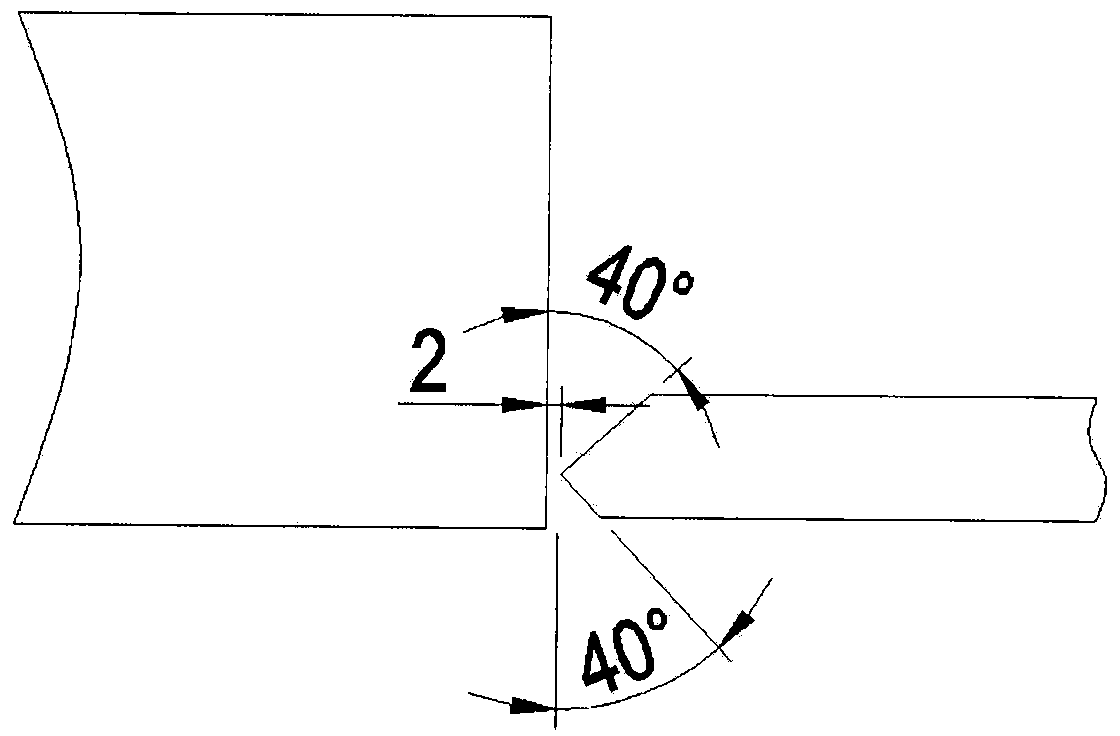

The invention discloses a method for welding a thick aluminum alloy plate. The method comprises the following steps of: blanking from a large aluminum plate according to a specified size: butting two opposite edges to be welded and forming two U-shaped welding grooves on the upper surface and the lower surface of the thick aluminum alloy plate; washing an aluminum alloy and a welding wire with acetone, removing oxidation films on the surfaces of the U-shaped welding grooves, and wiping; and welding the U-shaped welding grooves by using an inverted consumable electrode argon arc welding machine of which the maximum output current is 500 A, welding, annealing, and performing relief annealing in a subsequent further machining process. In the method, preheating is not required before welding, so that the labor intensity is effectively lowered, the mechanical property of a welding joint is improved, the internal quality of a weld seam of a thick aluminum plate is improved, and the welding strength is required to be over 90 percent of parent substrate strength.

Owner:中国航天科工集团第二研究院二一〇所

Welding process special for thick dissimilar material plate

ActiveCN104002023AImprove welding efficiencyGuaranteed StrengthArc welding apparatusEngineeringSpot welding

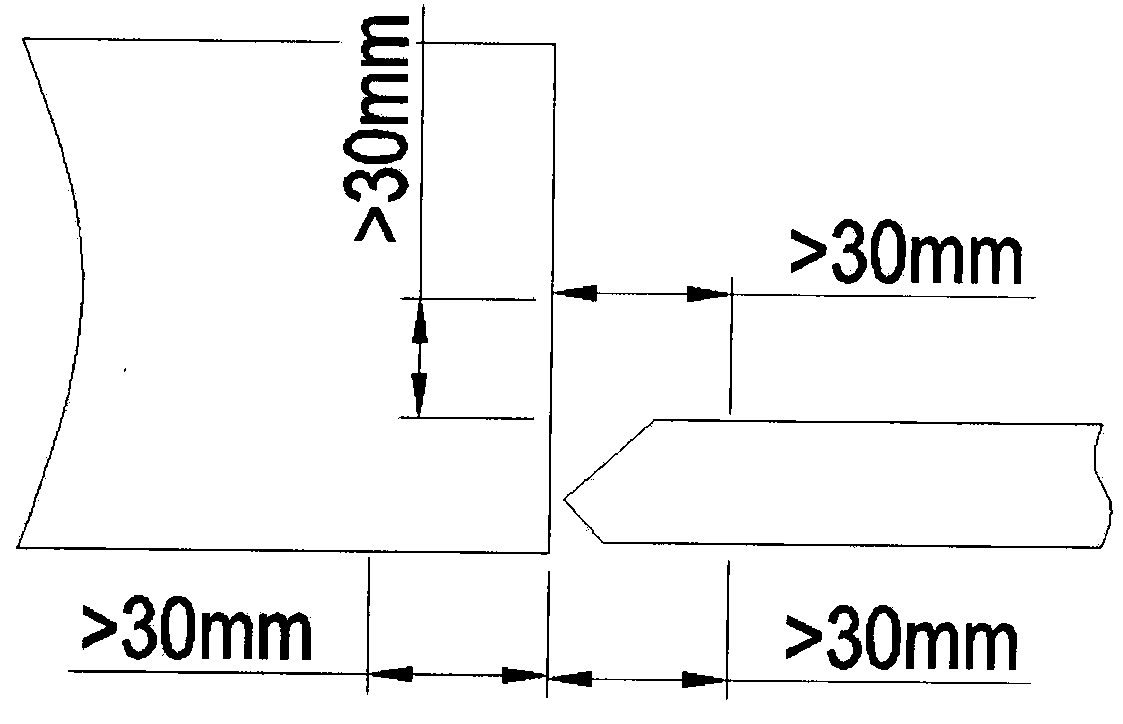

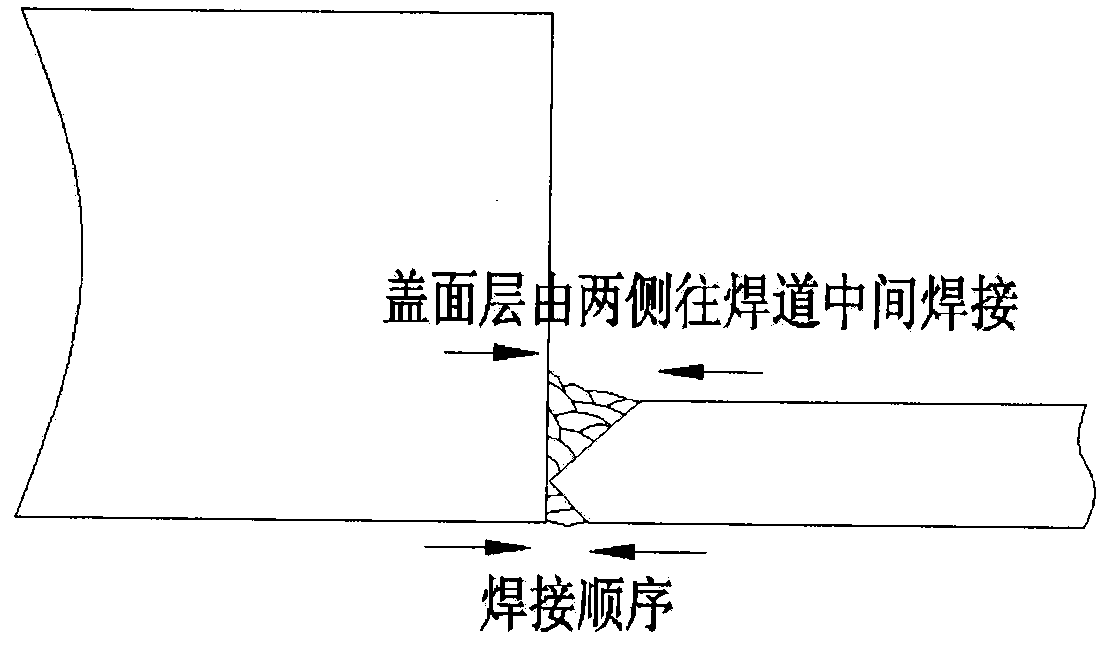

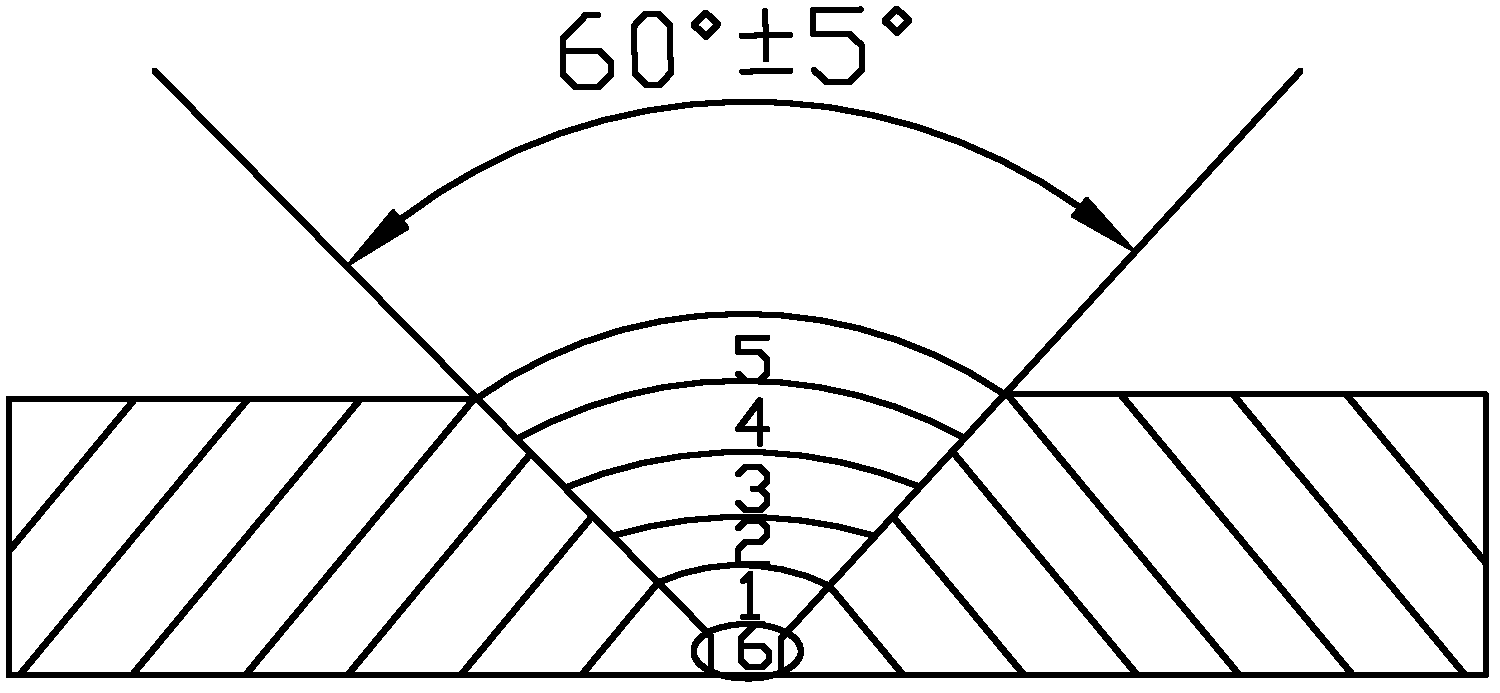

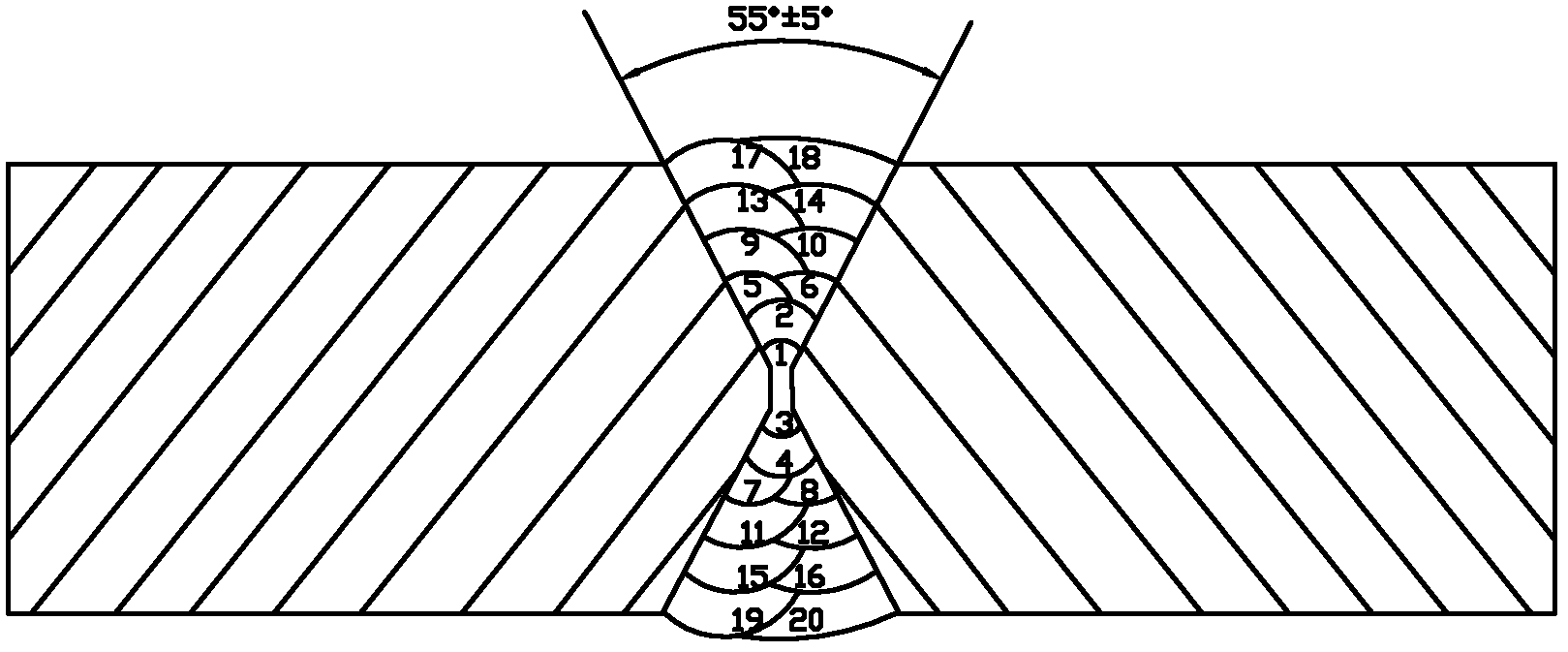

The invention discloses a welding process special for a thick dissimilar material plate. The welding process is characterized by comprising the following steps: a, cutting double-surface and one-side grooves in a welding material; b, grinding the cut grooves and parts within at least 30mm site around a welding area; c, performing spot welding at positions 30mm away from the top ends of two sides of a weld joint, and avoiding any defect in spot welding; d, preheating a base metal at a temperature of at least 150 DEG C; e, welding the weld joint at one side of a large groove, welding a surface covering layer by the method of welding from two sides to the middle, and then performing carbon gouging and back chipping for the other side; f, welding another weld joint at one side of a small groove by the same method as the large groove; g, thermally treating a welding part. The process is high in welding efficiency and small in welding-caused deformation; the weld joints have the characteristics of being high in strength, high in toughness, no defect, and no delayed crack.

Owner:NANTONG COSCO HEAVY IND

Domestic 08Ni3DR steel thin multi-pass welding process

ActiveCN102806405ARealize technological innovationAchieve upgradeArc welding apparatusFurnace typesCo2 absorptionDehydrogenation

The invention discloses a domestic 08Ni3DR steel thin multi-pass welding process, which is characterized by comprising the following steps of: machining a welding part into a single V-shaped or symmetrical double V-shaped groove, employing thin layer multi-pass welding, wherein on each layer, the weld pass thickness is less than 3mm, the diameter of a welding wire is 3.2mm, the welding current is 350 to 380A, the welding voltage is 34 to 38V and the welding speed is 36 to 45cm per minute, and controlling the interlayer and inter-pass temperature to be less than or equal to 150 DEG C; and performing dehydrogenation treatment and overall stress relief heat treatment after welding, and manufacturing a pressure container with the temperature level of 100 DEG C below zero such as main low temperature methanol wash equipment H2S and a CO2 absorption tower by employing the process, wherein the impact work kv2 of the welding joint of the equipment at the temperature of 101 DEG C below zero is more than or equal to 47J, and the mean value of the technical index and physical level is higher than American society of mechanical engineers (ASME) standard technical index.

Owner:WUHAN EAST PETROCHEM HEAVY EQUIP

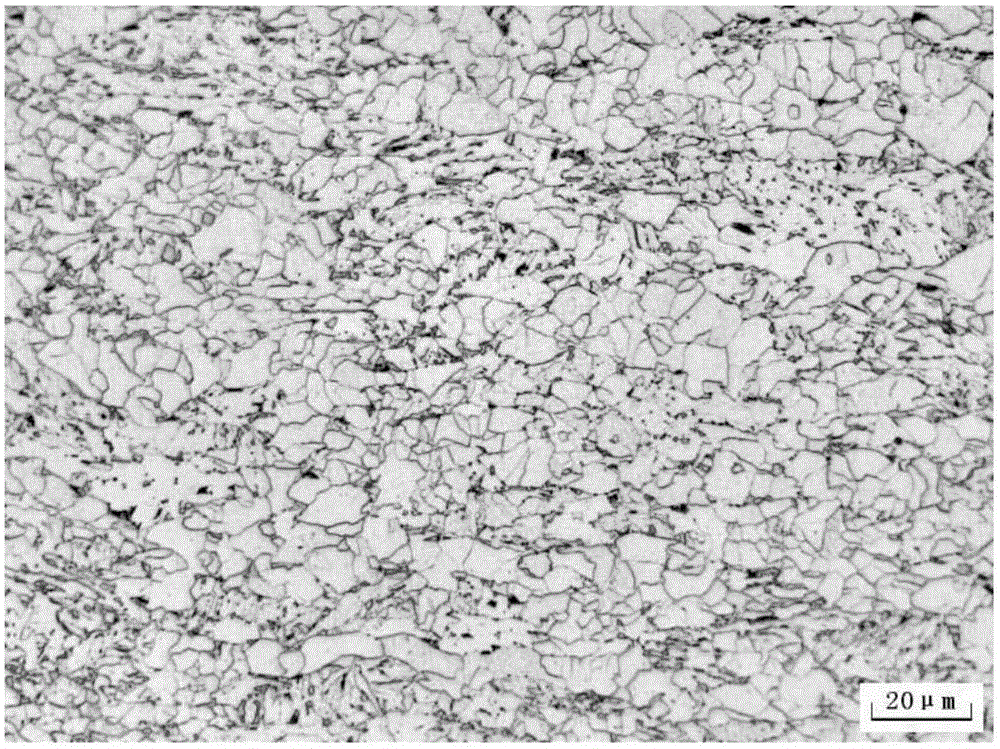

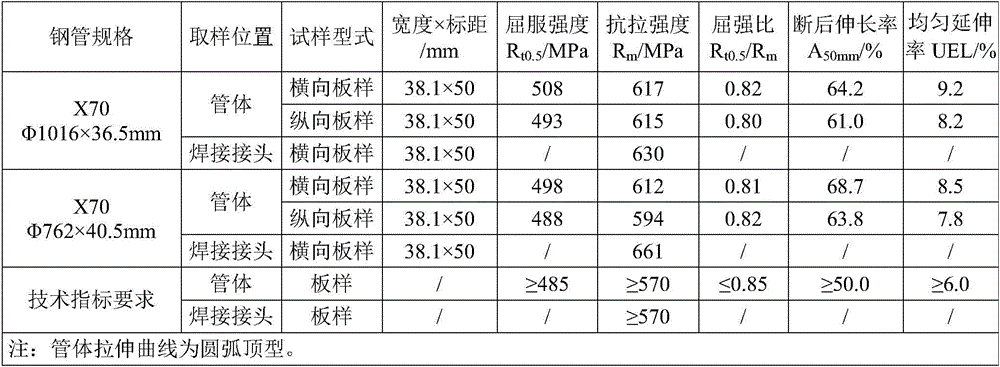

High-strength thick-wall welded steel pipe for deep sea pipeline and production method thereof

InactiveCN105734444AHigh strengthImprove toughnessArc welding apparatusMetal working apparatusHigh intensityThick wall

The invention discloses a high-strength thick-wall welded steel pipe for a deep sea pipeline and a production method thereof. The steel pipe plate contains the following components in percentage by mass: 0.03-0.07% of C, 0.10-0.40% of Si, 1.20-1.60% of Mn, less than or equal to 0.012% of P, less than or equal to 0.0015% of S, 0.10-0.35% of Ni, 0.10-0.35% of Cr, less than or equal to 0.35% of Cu, 0.10-0.35% of Mo, 0.01-0.06% of Nb, 0.01-0.06% of V, 0.005-0.025% of Ti, 0.01-0.06% of Al, 0.0020-0.0060% of N, 0.0005-0.0035% of Ca, 1.5-4.0% of Ti / N and the balance of Fe and inevitable impurities. The steel pipe disclosed by the invention has high plasticity and corrosion resistance and can be used for conveying the deep sea oil gas in a complicated working condition of deep sea service.

Owner:BAOJI PETROLEUM STEEL PIPE

Welding method for connecting ferrite stainless steel steel-strip with thickness of 3-6 mm

ActiveCN105479006AImprove the mechanical properties of jointsExcellent cupping performanceLaser beam welding apparatusWelding residual stressWeld seam

The invention belongs to the technical field of ferrite stainless steel steel-strip connecting, and particularly discloses a welding method for connecting ferrite stainless steel steel-strip with a thickness of 3-6 mm. The welding method comprises the following steps: shearing two steel strip heads to be welded, pressing a steel strip, and enabling the two steel strip heads to align to form a seam with a trapezoidal cross section; filling nickel-based welding material into the welding seam, and using a welding wire with the diameter of 1.2mm to weld along one end of the welding seam; and carrying out stress-relief annealing on the welding seam after the welding is completed. The welding method adopts a laser welding process to connect the ferrite stainless steel steel-strip, the welding seam is flat, free of the defects of welding pores, welding flash and the like, degree of welding seam heat effect on structure grain coarsening degree is controlled to be lower than level 2, annealing treatment is carried out on the welding seam, welding residual stress on the welding seam is eliminated, and joint mechanical properties of the welding seam is improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

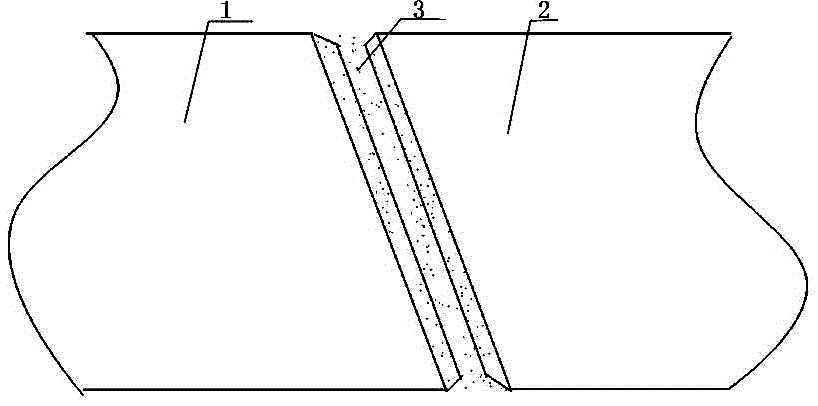

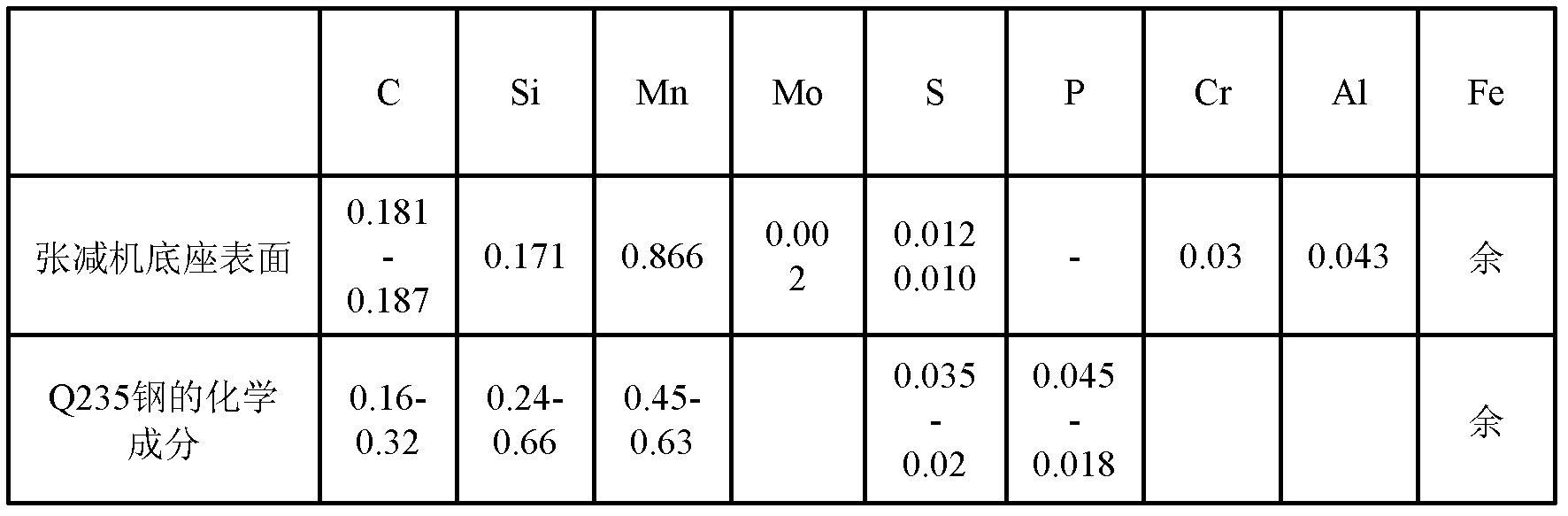

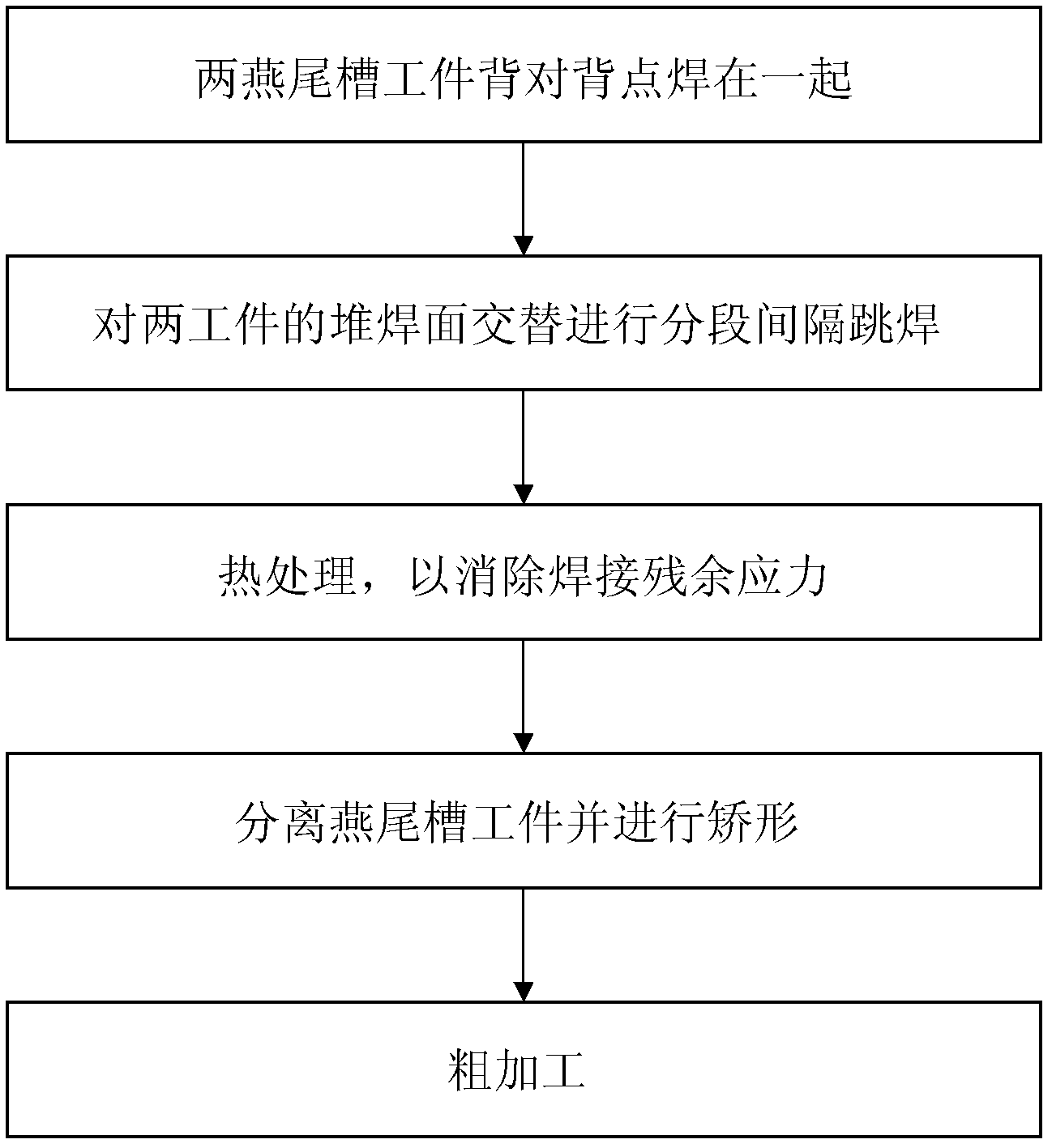

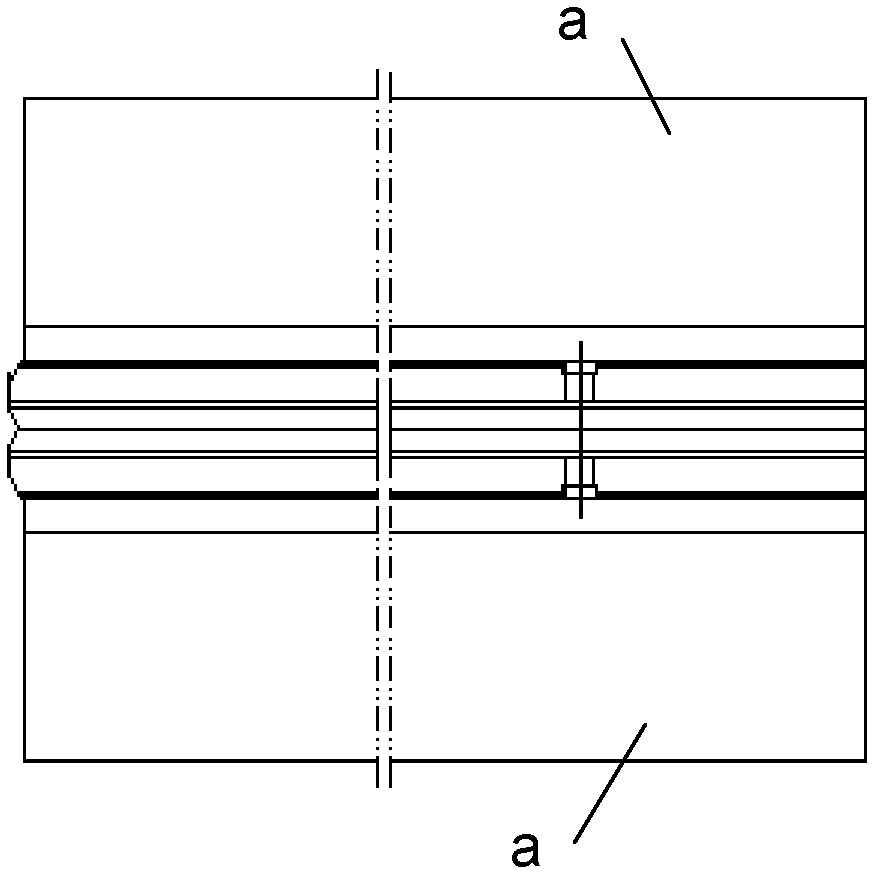

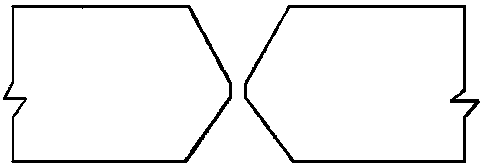

Surfacing method for antiseptic wear-resisting layer of dovetail groove

ActiveCN103008833AImprove corrosion and wear resistanceEliminate welding residual stressArc welding apparatusFurnace typesWelding residual stressEngineering

The invention discloses a surfacing method for an antiseptic wear-resisting layer of a dovetail groove. According to the method, two dovetail groove workpieces are spot-welded back to back, slant groove surfaces and horizontal groove surfaces of the upper dovetail groove workpiece and the lower dovetail groove workpiece are alternately skip-welded sectionally at intervals by ER410NiMoTi surfacing material, welding residual stress is eliminated through heat treatment, and finally the two dovetail groove workpieces are separated, corrected and roughly machined. According to the surfacing method disclosed by the invention, welding deformation can be effectively avoided, and the formed surfacing layer can improve the antiseptic wear-resisting performance of the dovetail groove.

Owner:BAOSHAN IRON & STEEL CO LTD

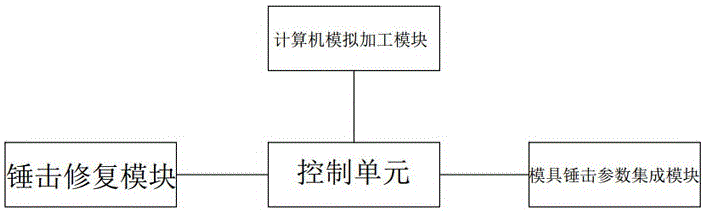

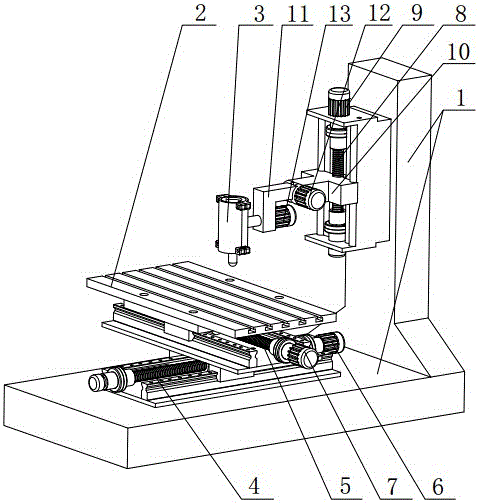

Mould repairing stress automatic eliminating system and method

ActiveCN106521138AEliminate welding residual stressReduce residual stressElectricityWelding residual stress

The invention belongs to the field of metal material processing, and especially relates to a mould repairing stress automatic eliminating system and a method. The mould repairing stress automatic eliminating system comprises a control unit, a mould hammering parameter integration module, a computer simulation processing module, and a hammering repairing module; and the mould hammering parameter integration module, the computer simulation processing module, and the hammering repairing module are all connected with the control unit via electric connection. The mould repairing stress automatic eliminating system is capable of realizing automatic hammering of moulds so as to reduce welding residual stress.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

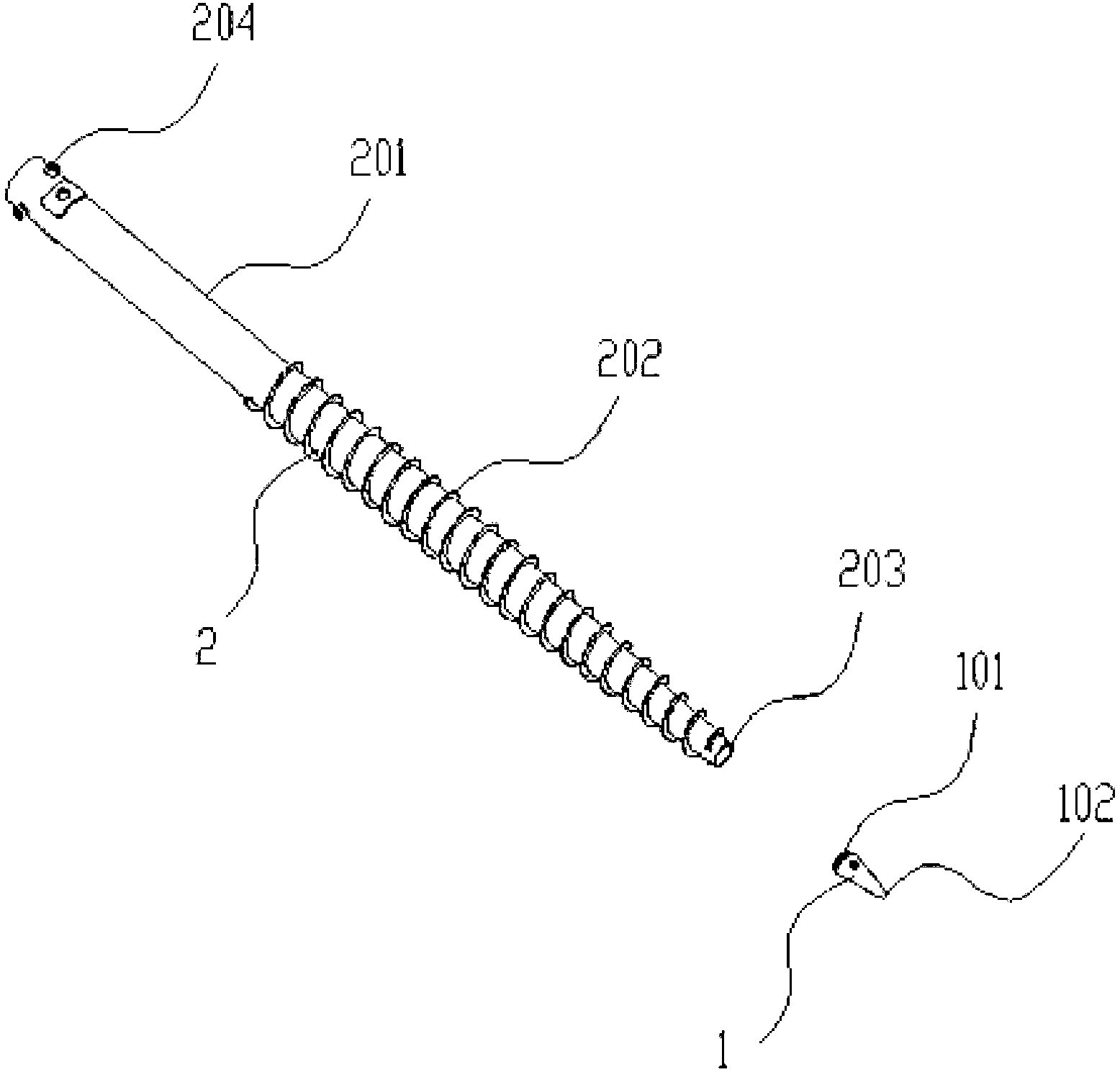

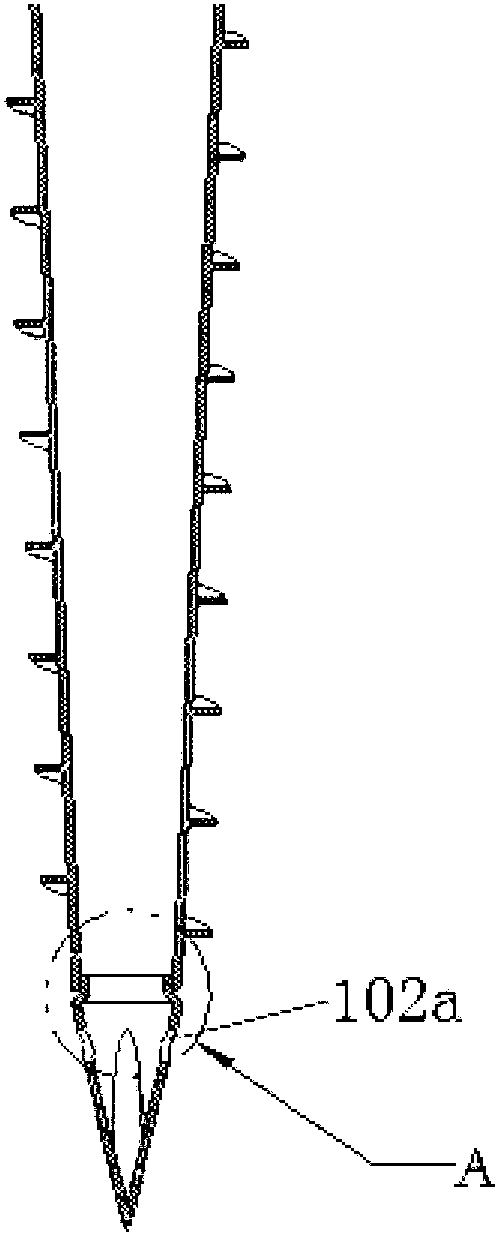

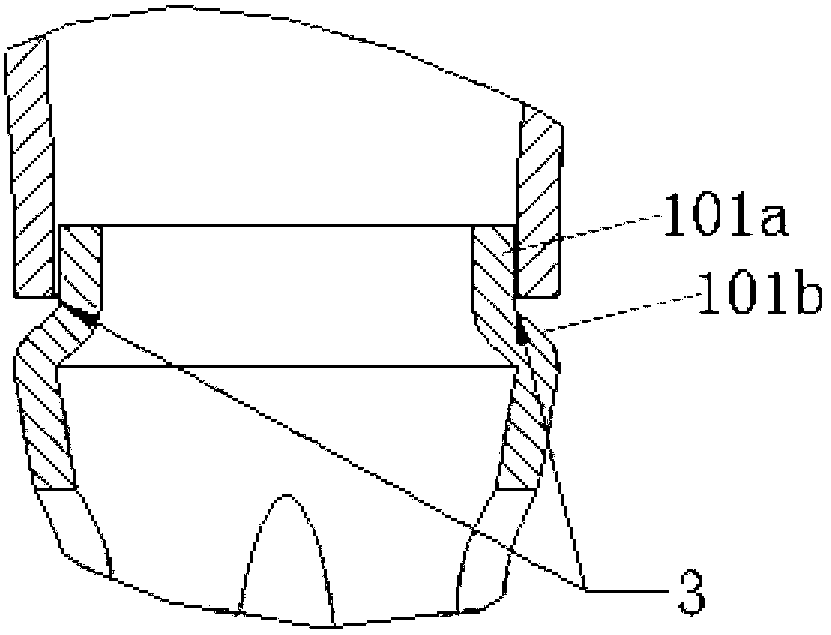

Split screw pile and welding method thereof

ActiveCN103061333ASimple structureSimple and reliable dockingWorkpiece edge portionsBulkheads/pilesShielded metal arc weldingButt welding

The invention discloses a split screw pile and a welding method thereof. The split screw pile comprises a pile body and a submerging tip, which are split. The submerging tip comprises a sharp end and a truncated-cone-shaped tail. An insert part of the submerging tip is inserted into a socket hole of the pile body so that a circular welding groove is formed between a slant part of the submerging tip and an open end of the pile body. The pile body is welded to the circular welding groove of the submerging tip to form an integrated structure. The welding method of the split screw pile includes the steps of firstly, performing connector butt welding; secondly, cleaning before welding; thirdly, preheating; fourthly, welding, namely performing manual gas tungsten arc welding to complete bottoming by nickel-base welding wires ERNiCrMo-3, and performing manual arc welding to complete filling and capping; and fifthly, thermally treating after welding. Therefore, the effective welding between the Q235B pile body and the 12Cr1MoV submerging tip is achieved, butt joint of connectors is simple and reliable, operating efficiency is improved, effective welding area is increased, weld strength is increased and processing and production costs are lowered.

Owner:POWERWAY RENEWABLE ENERGY

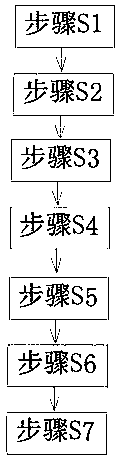

Welding method of super-thick steel casting

InactiveCN109108431AEliminate welding residual stressReduces the chance of weld cracksArc welding apparatusFurnace typesLayer removalWelding deformation

The invention discloses a welding method of a super-thick steel casting. Process steps include S1, preparing a joint: an asymmetric X-type groove is adopted; S2, preheating: the front side and the reverse side are uniformly heated, the preheating temperature is set within the range of 150-160 DEG C, and the heating rate does not exceed 100 DEG C / h; S3, back welding: gas shielded welding backingis carried out on flux-cored welding wires for three layers, and fire warming is carried out to remove stress after each weld seam is welded; S4, reverse side air gouging: air gouging back chipping and carburized layer removal are carried out; S5, reverse side back welding: back welding is carried out by three layers after the temperature of the steel casting reaches a preheating temperature according to the method described in the step 2, and fire warming is performed on each weld seam to remove stress; S6, filling and cover surface welding: the front side and the reverse side are welded respectively by one welder simultaneously and symmetrically, and hammering is carried out layer by layer after each layer of weld beads of each weld seam is welded; and S7, 550 DEG C *2h heat treatment after stress removal is carried out immediately after the completion of welding. By means of the method, welding stress and welding deformation can be significantly reduced, and the probability of generating steel casting welding cracks is greatly reduced.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU

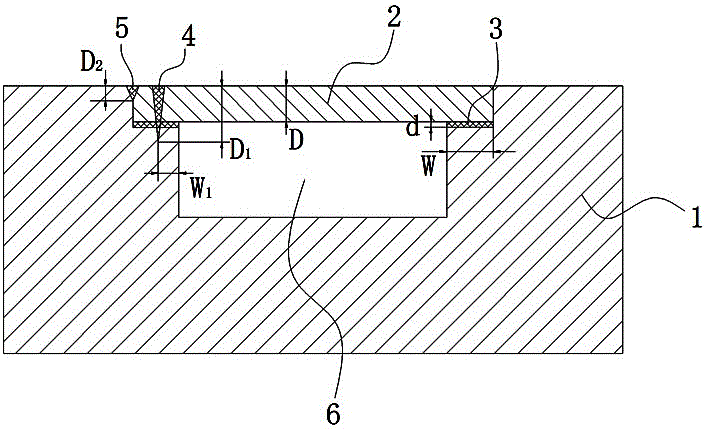

Moderate-strength aluminum liquid cooled shell welding method

The invention relates to a moderate-strength aluminum liquid cooled shell welding method. The method comprises the following steps: step S1, machining welding parts; step S2, pre-treating the parts; step S3, welding, wherein the distance from a seal weld to the inner wall of a liquid cooling flow channel is W1; the fusion depth D1 of the electron beam EB1 weld is equal to the summation of the thickness D of a cover plate, the thickness d of a solder material and (3-4)mm; a surface focus is adopted for welding; the scanning amplitude value of the electron beams is 0.2mm to 0.4mm; a finished weld adopts defocusing welding; the fusion depth D2 of the finished electron beam EB2 weld is 2mm to 4mm; the appearance condition of the electron beam weld is checked after welding; step S4, performing vacuum braze welding treatment; step S5, machining the shell after welding until a final product is obtained. The method disclosed by the invention has the advantages of realizing reliable welding of an embedded cover plate and a chamber body by adopting a reasonable joint design and electron beam welding and vacuum braze welding techniques, and greatly improve the maturity of a preparation technique of a liquid cooling project.

Owner:CHENGDU SIWI HIGH TECH IND GARDEN

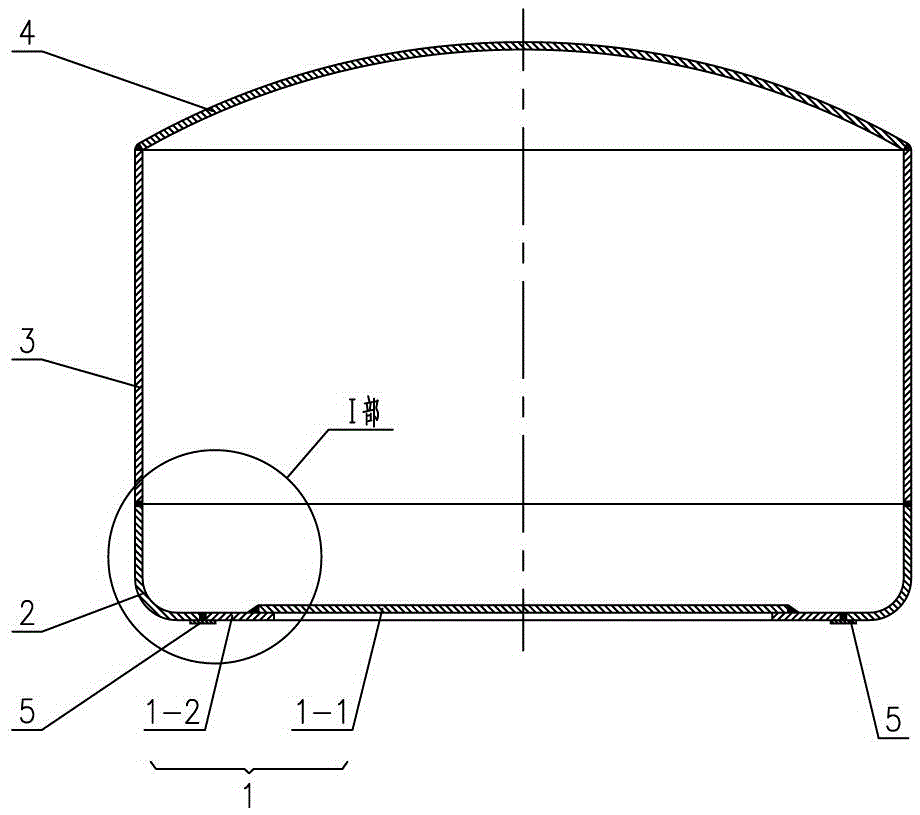

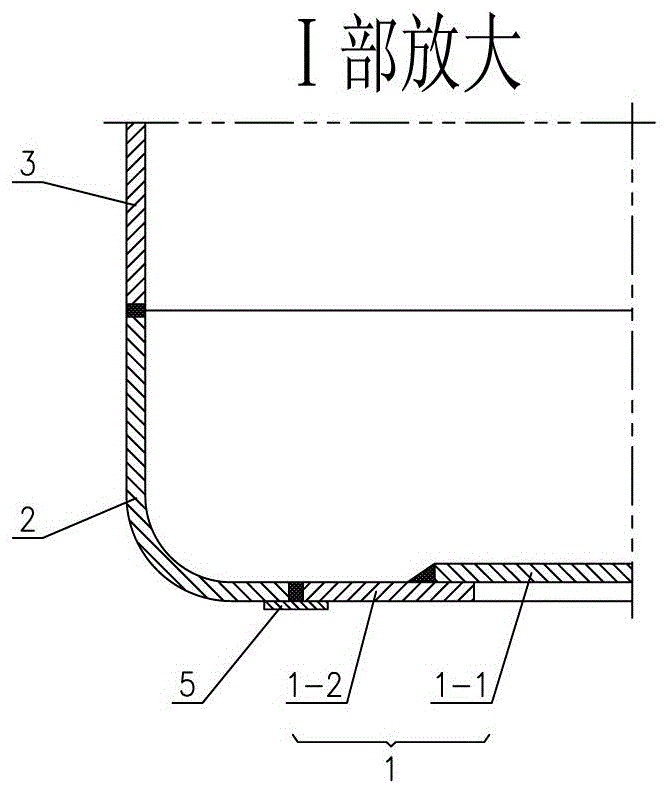

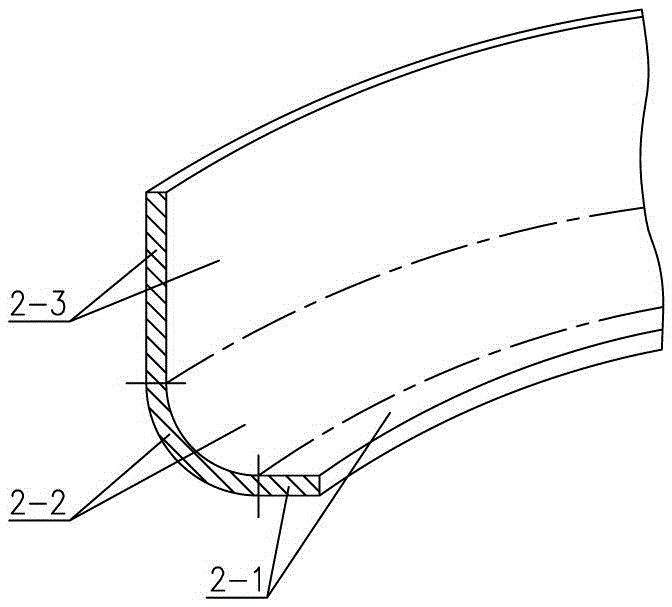

Large steel welded vertical oil tank

ActiveCN105600205AReduce edge stressEliminate welding residual stressLarge containersSafe operationWaste management

The invention provides a large steel welded vertical oil tank. The large steel welded vertical oil tank is provided with a tank bottom, a tank wall and a tank top. A transition connecting ring is arranged between the tank bottom and the tank wall and provided with an annular bottom section, an arc-shaped transition section and a vertical cylindrical section. The tank bottom is connected with the annular bottom section of the transition connecting ring in a welded mode. The tank wall is connected with the vertical cylindrical section of the transition connecting ring in a welded mode. The tank top can be a fixed top and can also be an outwards-floating top. The large steel welded vertical oil tank has the advantages that T-shaped joints of a tank wall and a tank bottom of an existing large oil tank and large fillet welds on the joints are omitted, main danger points of the whole oil tank are eliminated, and safe operation of the large oil tank is guaranteed, wherein the transition position between the tank wall and the tank bottom is not prone to low-cycle fatigue damage, an attachment weld of the transition portion between the tank wall and the tank bottom is not prone to tearing damage, the anti-seismic property of the large oil tank is greatly improved, and the anti-seismic property of the large oil tank is good.

Owner:JIANGSU CHEM EQUIP MFG & INSTALLATION CO LTD

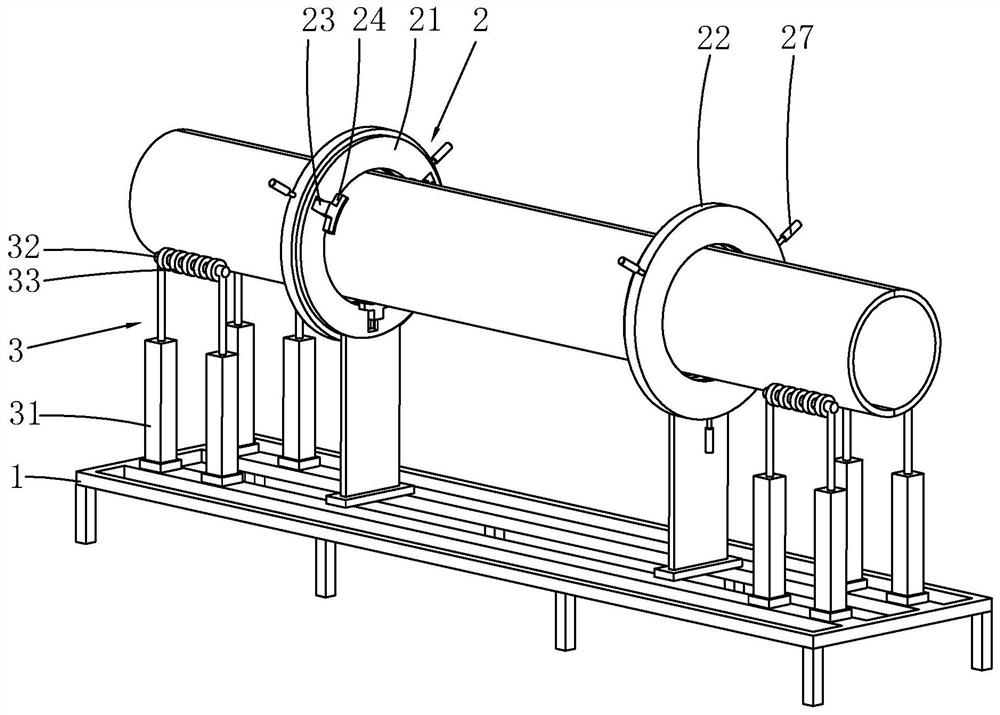

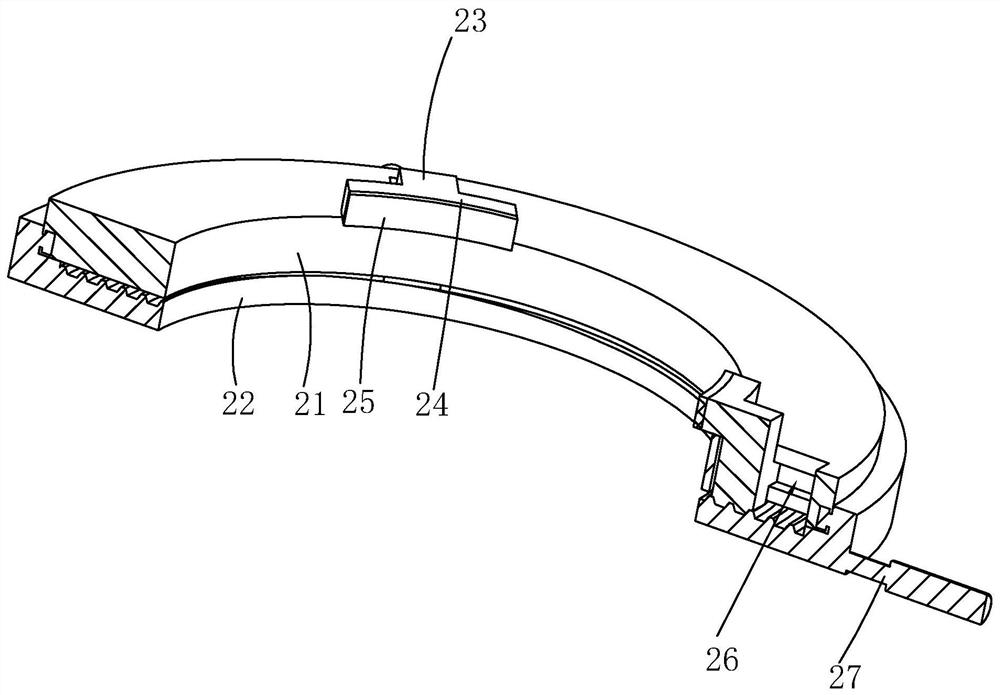

Method for guaranteeing uniformity of heat treatment of large-diameter thick-wall pipe weld

ActiveCN108866314AImprove performanceImprove the problem of poor heat treatmentFurnace typesHeat treatment process controlWelding residual stressTemperature difference

The invention relates to a method for guaranteeing the uniformity of heat treatment of a large-diameter thick-wall pipe weld. The method comprises the following steps: heating the pipe cavity of a pipe located at a weld position when heating the outer wall of the pipe located at the weld position, and then heating the inner wall of the pipe. Through the heat treatment process for simultaneously heating the inner wall and the outer wall, the temperature difference between the inner wall and the outer wall of the large-diameter thick-wall pipe weld can be reduced; the purpose of eliminating thewelding residual stress through heat treatment and improving the welding joint performance can be fulfilled; the problem about the poor heat treatment of the inner wall of the pipe can be solved; thepurpose of the uniform heat treatment of the weld can be integrally fulfilled; and especially, the heat treatment effect on a thick-wall pipe weld can be more obvious. The method is obvious, simple and economical; and furthermore, the method is strong in real-time performance and easy to operate on site.

Owner:SUZHOU NUCLEAR POWER RES INST +2

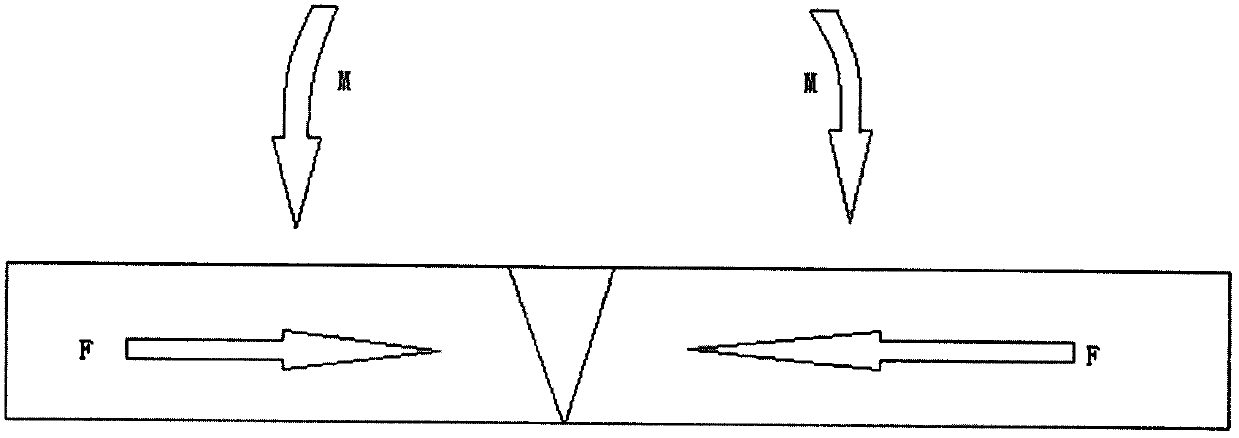

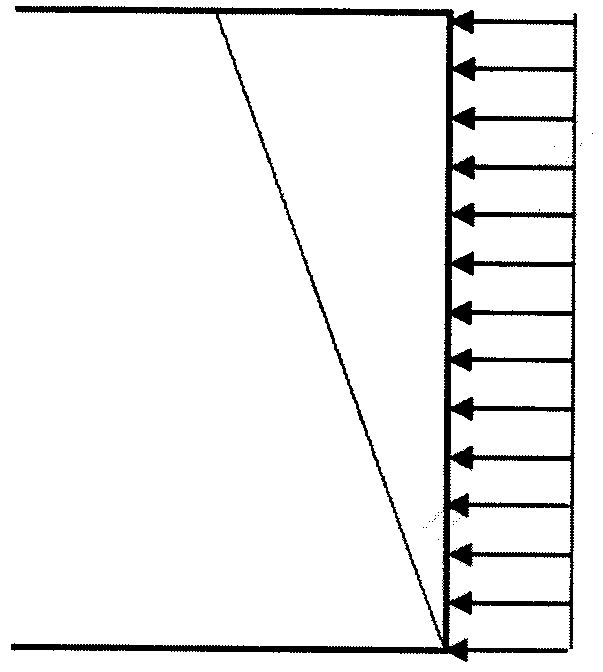

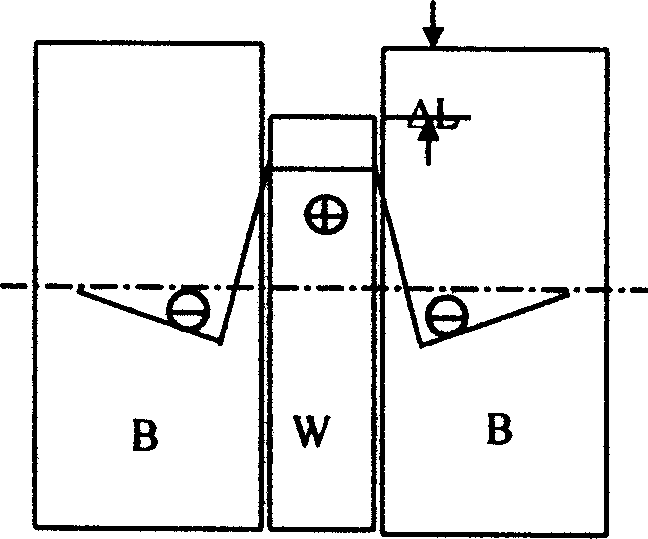

Method for removing welding residual stresses

InactiveCN107557549AEliminate thermal stressImprove securityFurnace typesHeat treatment process controlWelding residual stressEngineering

The invention discloses a method for removing welding residual stresses. The method includes the following steps that first, a temperature distribution field of welding parts is calculated at first, and the distribution and dimensions of the welding residual stresses around a welded joint are calculated according to the temperature distribution field; and second, the external force and moment of force are applied to the welding parts beside a welded splice, and plastic deformation of the welding parts is caused so that the welding residual stresses calculated in the first step can be removed.By adoption of the method, the residual stresses of the welding parts can be effectively removed, and the problems of stress corrosion cracking and high-temperature fatigue cracking of the welding parts are solved.

Owner:吴谦

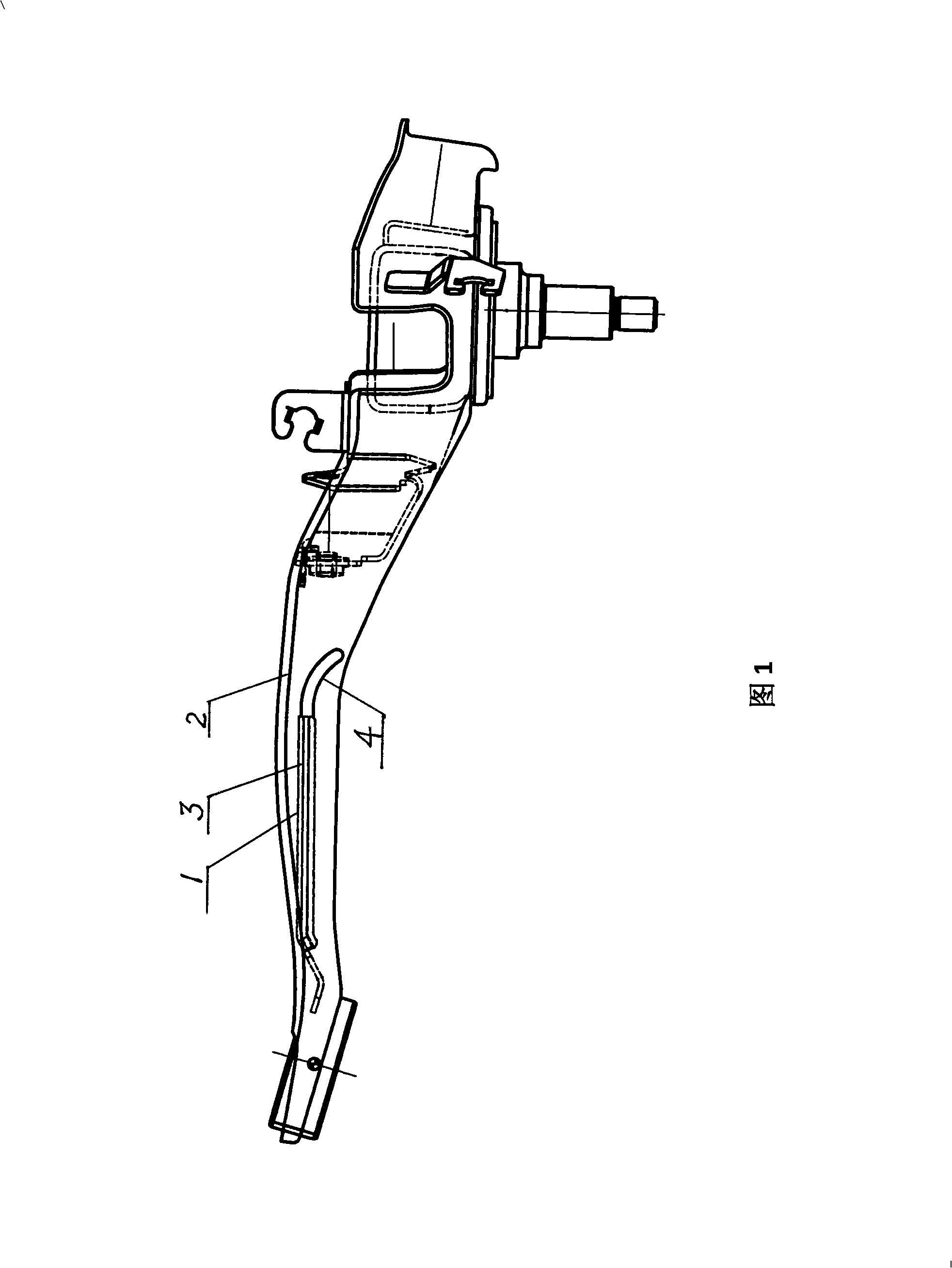

Welding process for rear overhang rack

InactiveCN101293468AEliminate welding residual stressReduce heat treatment processPivoted suspension armsWelding residual stressWeld line

The invention relates to a welding technique of a back suspension fork of an automobile; a reinforced plate is connected with a dragging arm; the invention is characterized in that the head part of a welding line is welded with a smooth arc and then is transited to the bottom side of the dragging arm; the welding technique of the invention has the advantages of removing the heat treatment after the welding and eliminating welding residual stress of the welding joint of the reinforced plate, thereby simplifying the technique during manufacture, being easy to control the quality, improving the fatigue strength of a product and reducing the manufacturing cost.

Owner:SHANGHAI ZHONGLI AUTO PARTS

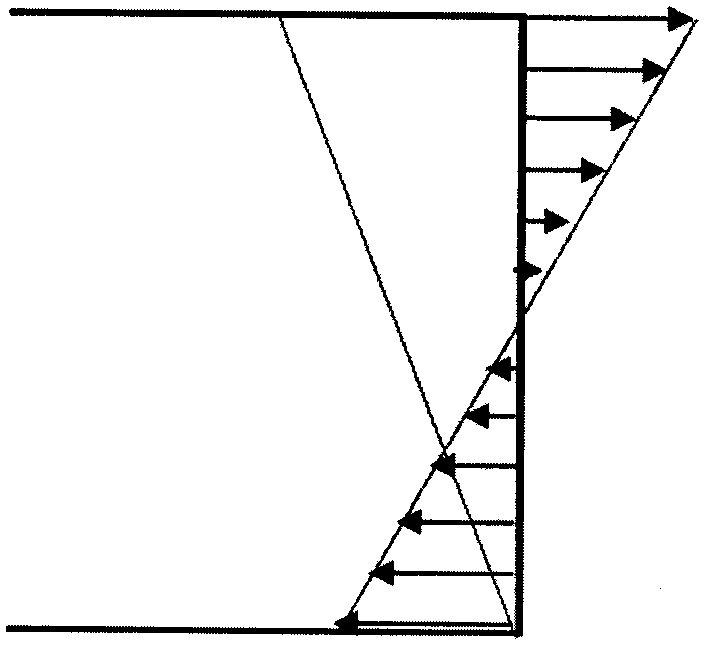

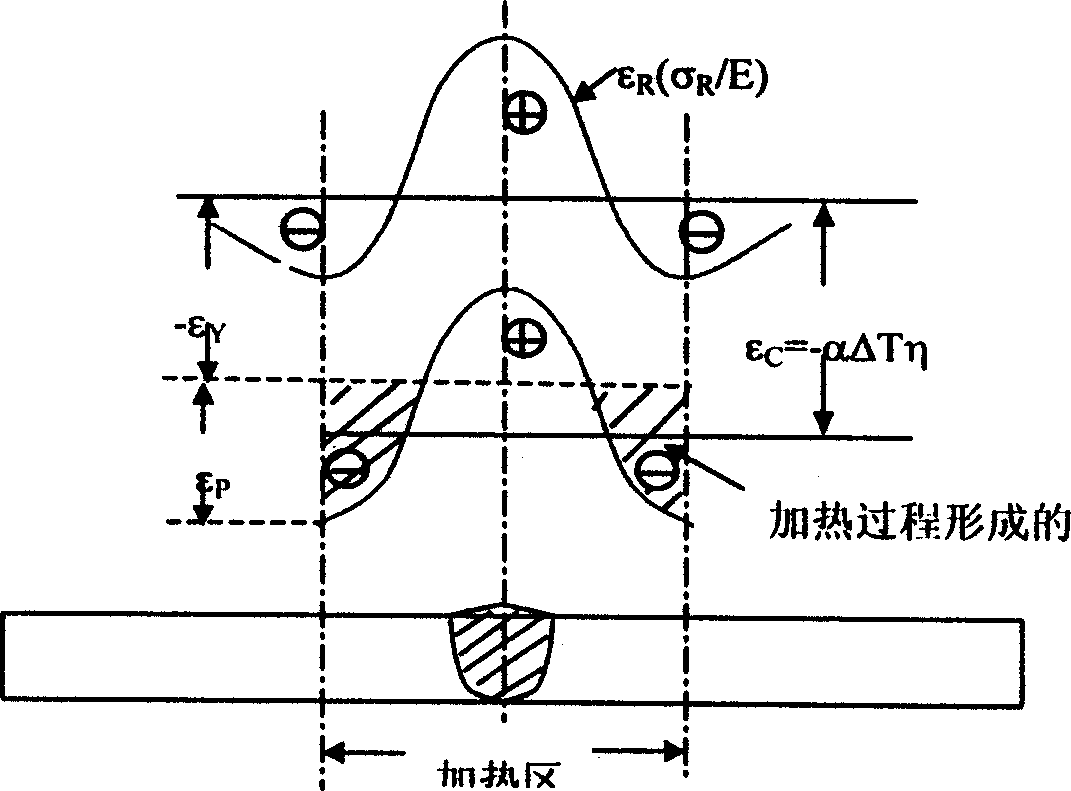

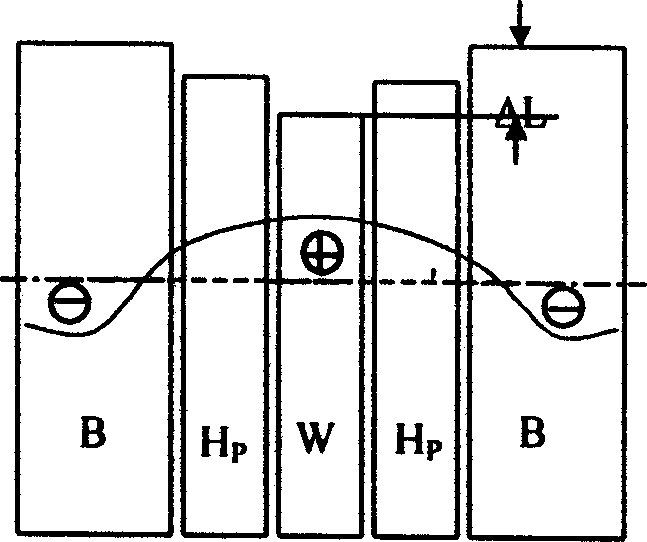

Method of eliminating welding residual stress by low temperature compression deformation treatment

InactiveCN1459354AReduce welding tensile stressEliminate welding residual stressMetal working apparatusWelding residual stressPlastic property

A method for eliminating the residual welding stress in the low-temp. compressive strain includes such steps as quickly heating the welded position within a limited region (width of 50-200 mm) to 200-400 deg.C for generating compressive plastic strain under the action of cold neighbouring region, resulting in the original compressive stress in the heated region also to produce the plastic compressive strain and after cooling, the residual stress in the welded joint produces radistribution. Its advantages are high effect and easy operation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

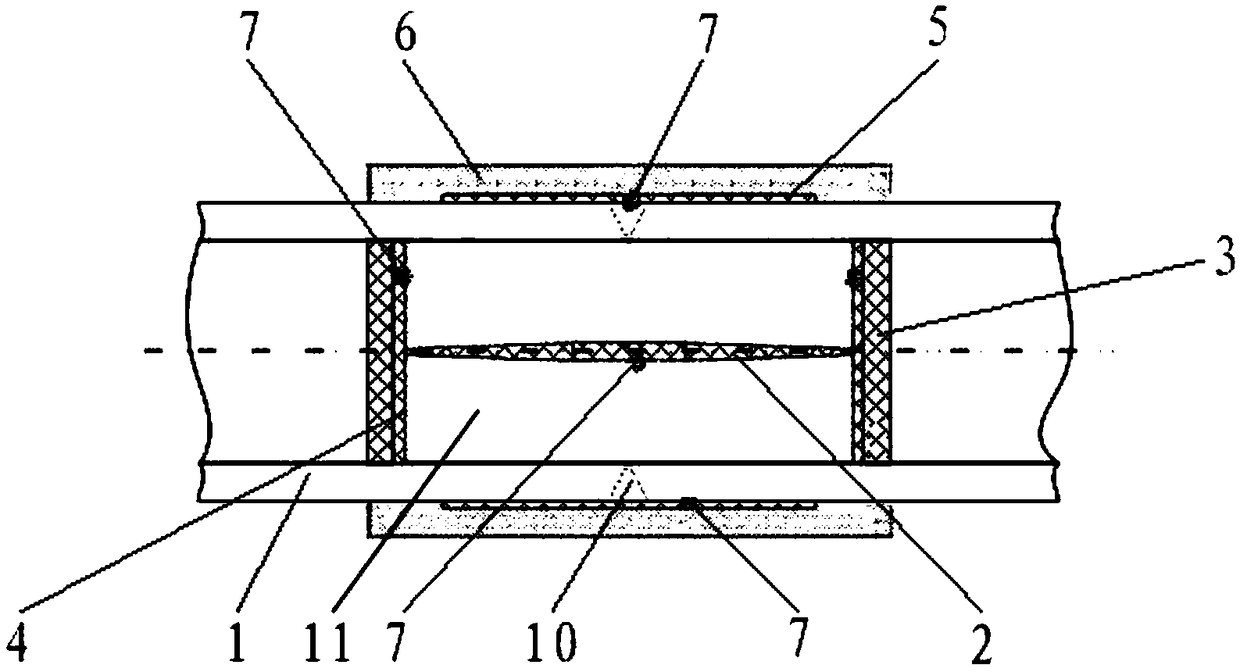

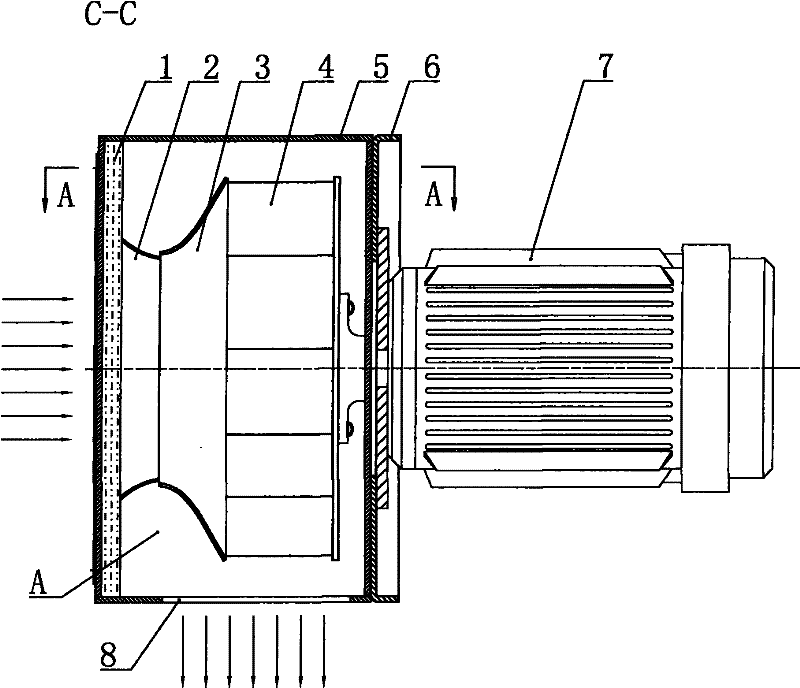

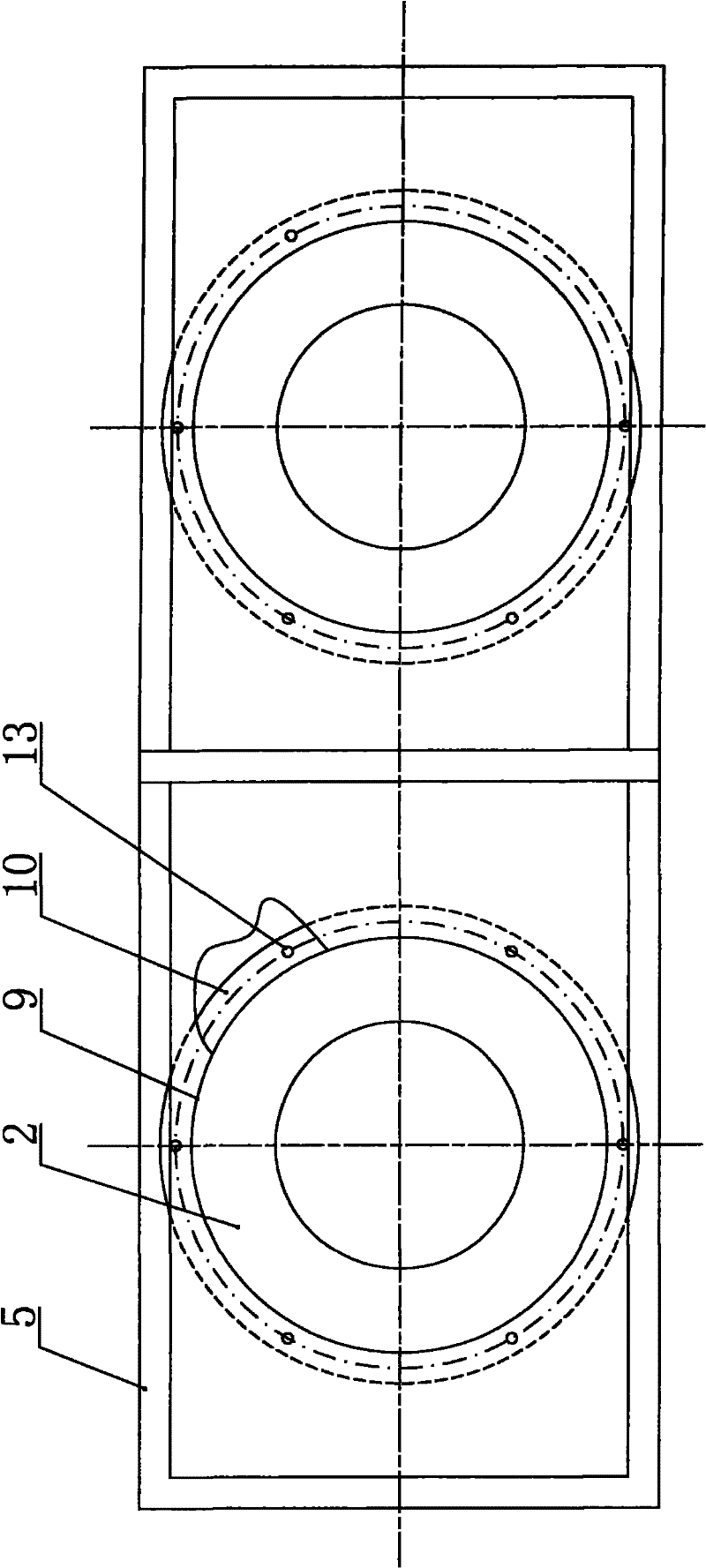

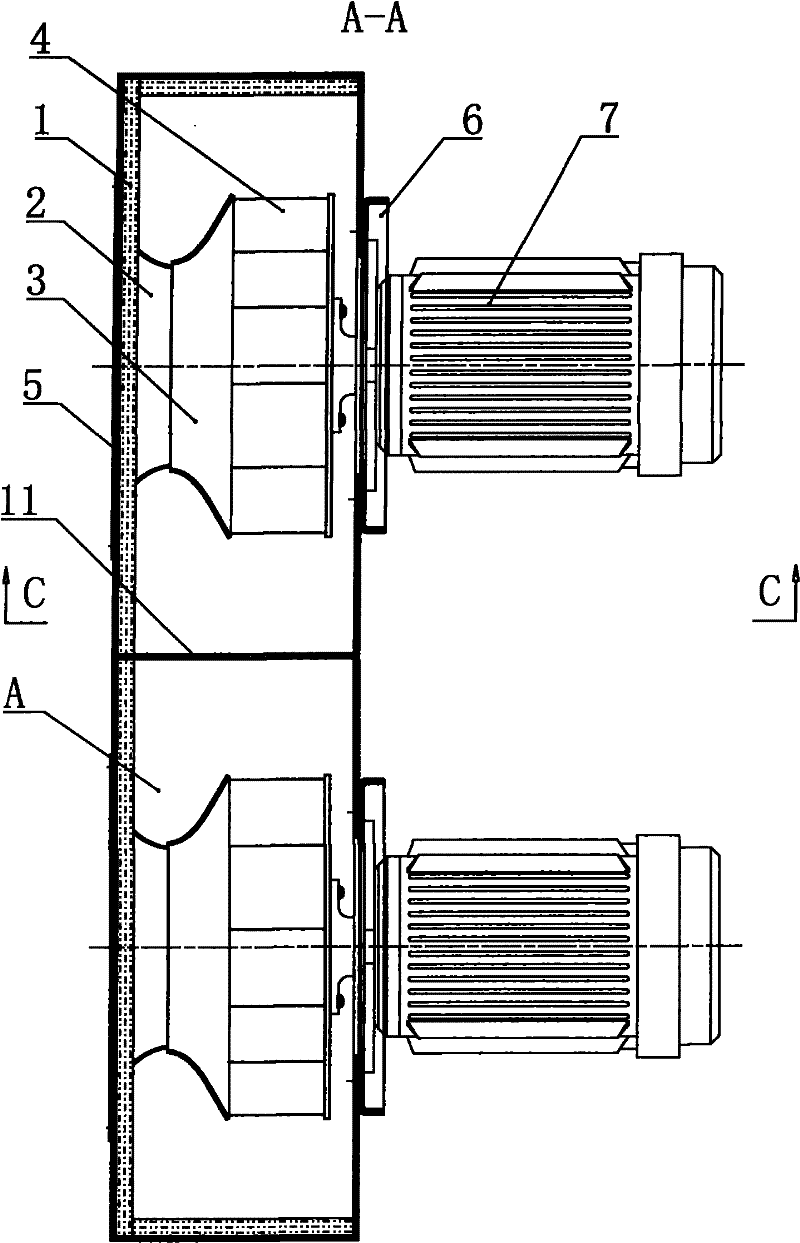

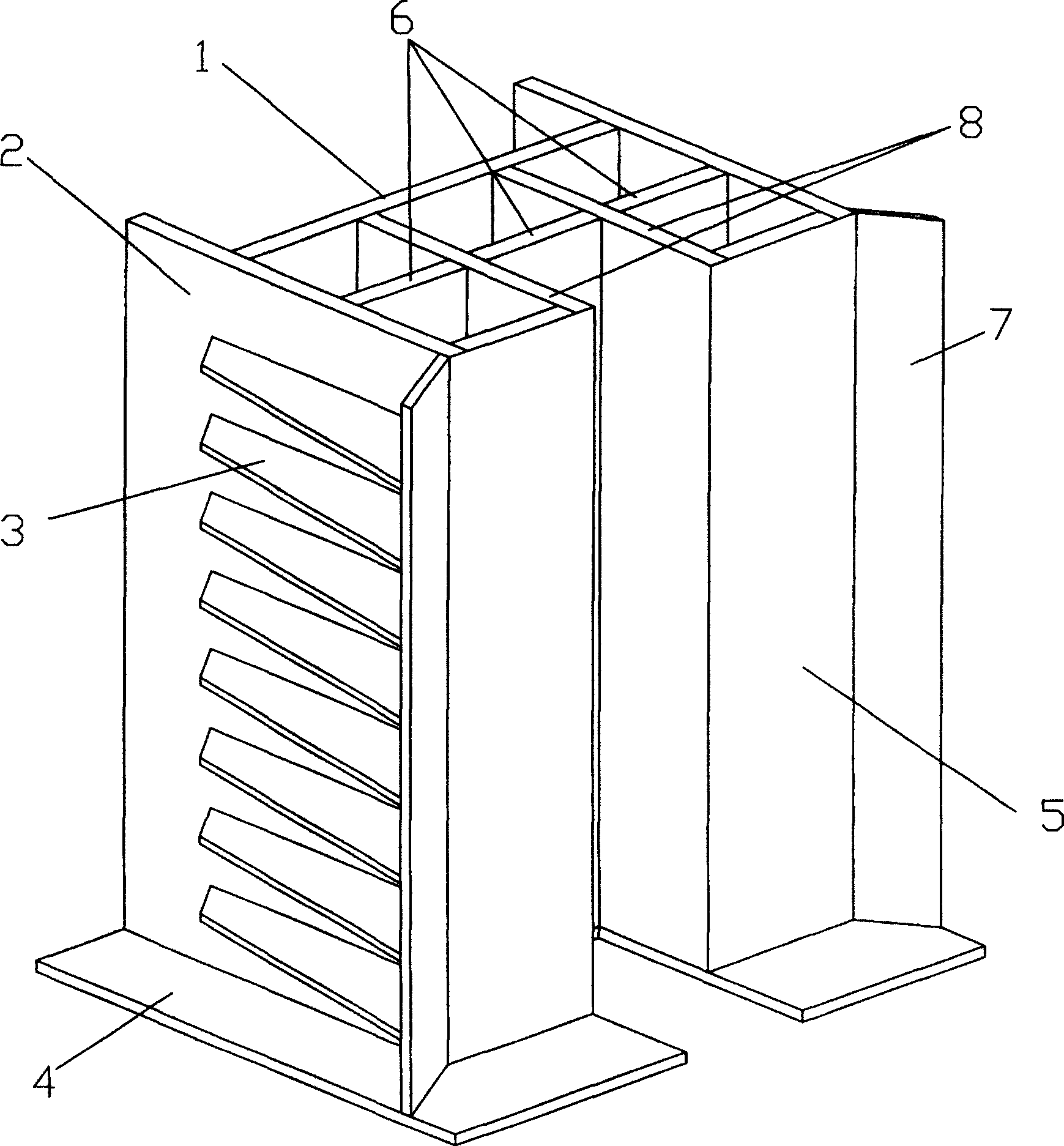

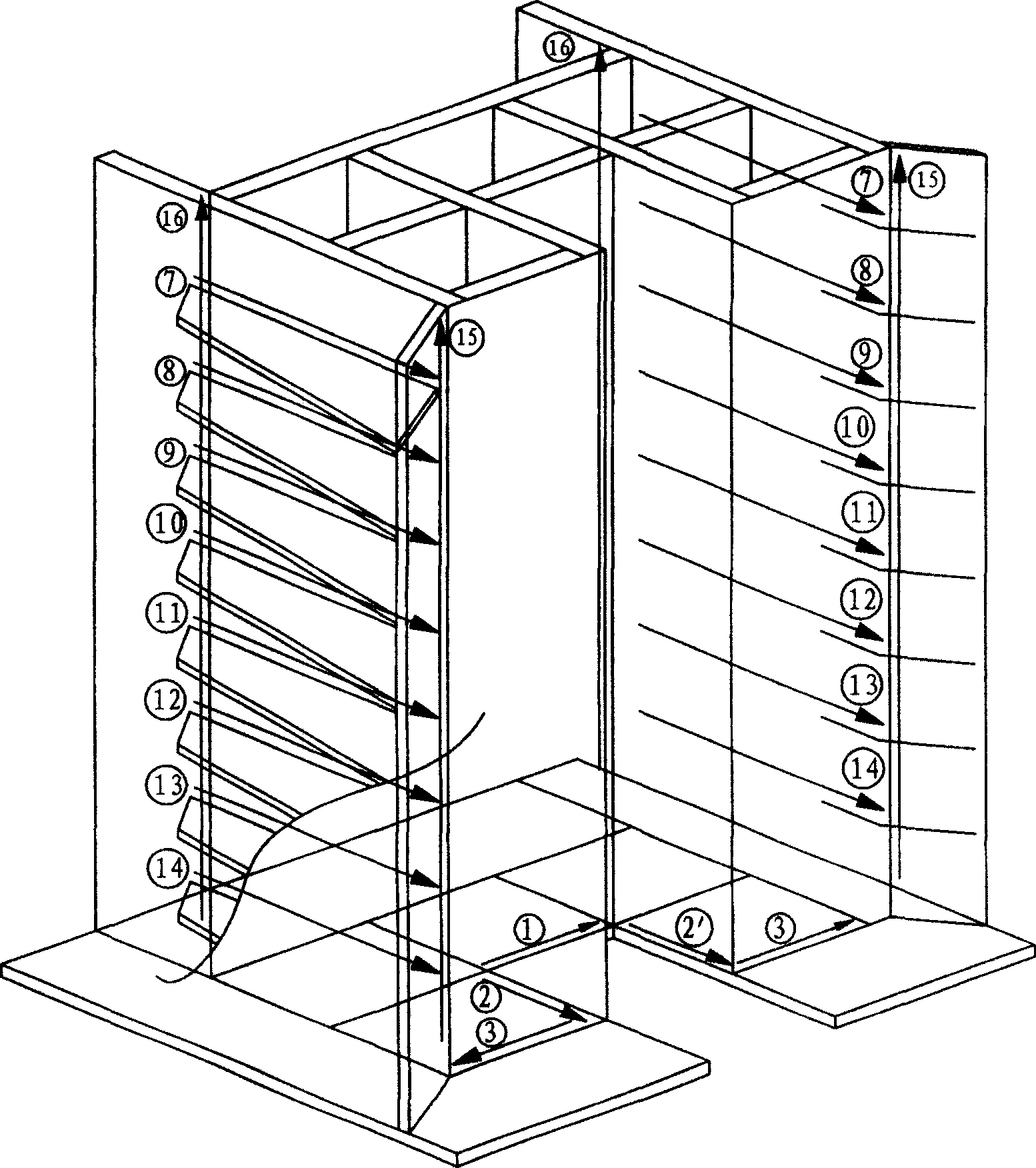

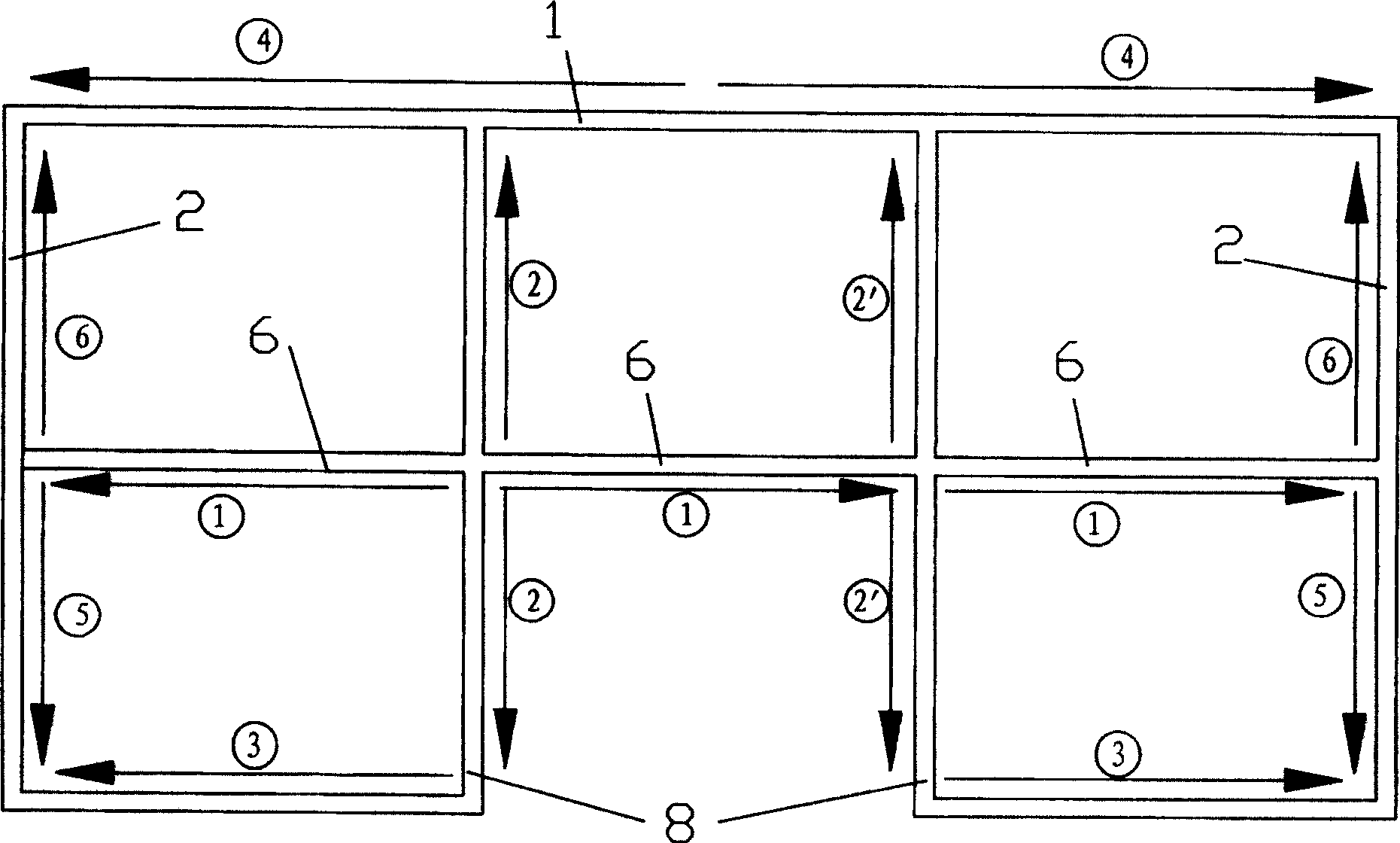

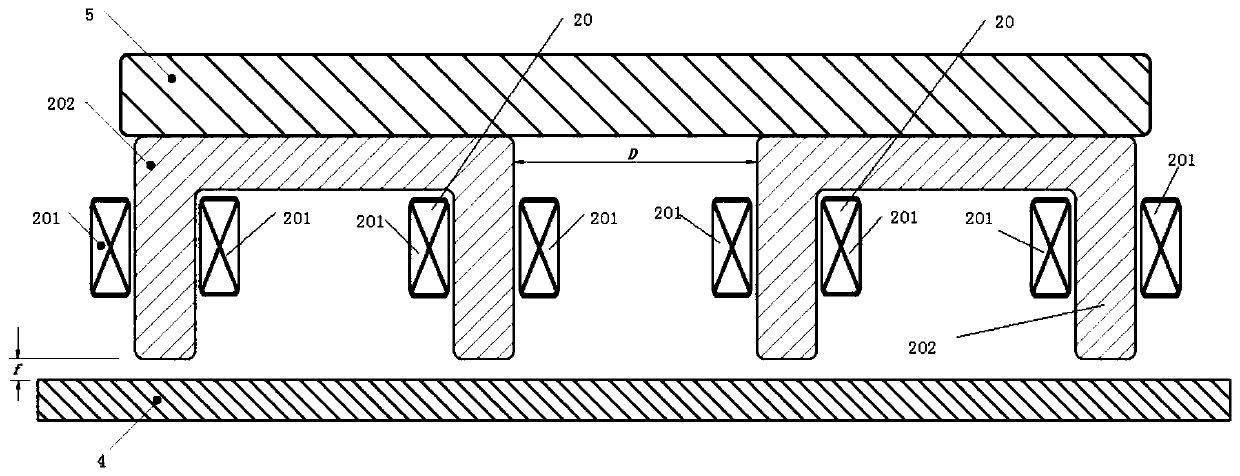

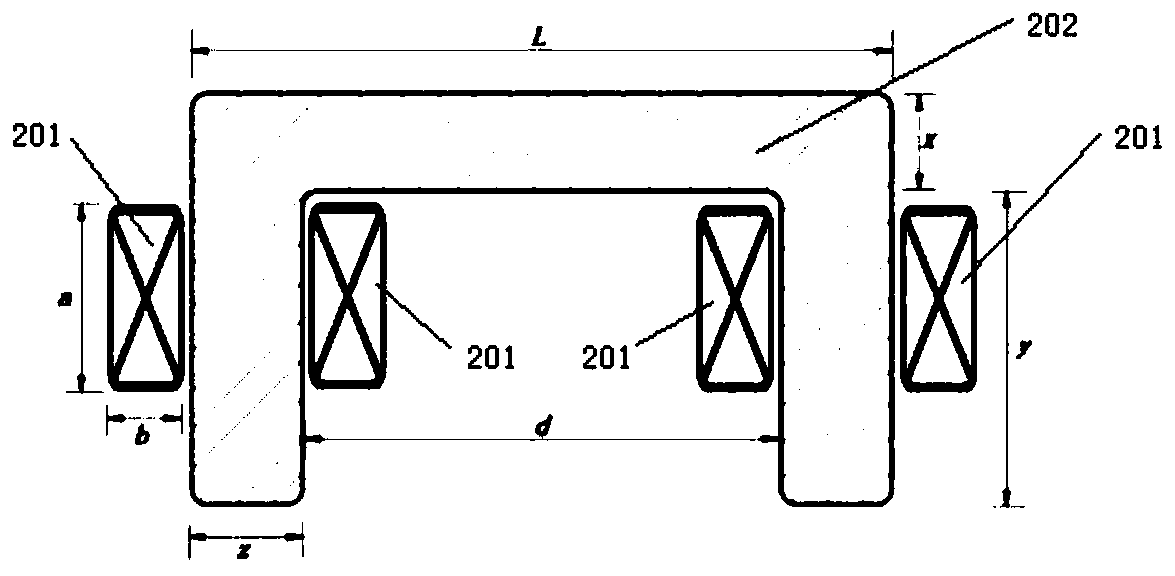

Cooling fan for traction converter of high-speed electric locomotive

InactiveCN102536857AGuaranteed cooling effectControl power consumptionPump componentsPump installationsImpellerElectric power

The invention relates to a cooling fan for a traction converter of a high-speed electric locomotive. The cooling fan comprises a rectangular box body (5), wherein a clapboard (11) is arranged at the middle of the box body (5) to divide the box body (5) into two independent cavities, a motor (7) is installed at rear side of each cavity, and an air inlet (9) and an air outlet (8) are respectively arranged at the front side and the lower side of each cavity. The cooling fan is characterized in that the rear side of each cavity is connected with the front end of the motor (7), an impeller (4) is arranged in each cavity and is coaxially installed on the output shaft of the motor (7), and two impellers (4) rotate counterclockwise during working so as not to mutually intervene. The cooling fan provided by the invention is mainly used for cooling the traction converters of motor trains with speed per hour of more than 380 km / h, and can satisfy the requirements of resisting low-temperature impact and high-speed vibration.

Owner:洛阳北玻三元流风机技术有限公司 +1

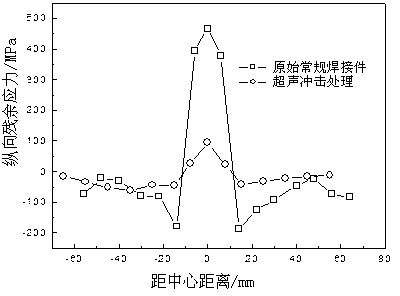

Method for controlling heat crack and residual stress of Fe-based fusion-repair layer via ultrasonic impact

InactiveCN103343205ASmall amount of plastic deformationFine grain sizeProcess efficiency improvementWorking lifeWear resistance

The invention discloses a method for controlling the heat crack and residual stress of a Fe-based fusion-repair layer via an ultrasonic impact, which belongs to the field of process technology. The method comprises the following steps of: step 1, controlling installation for an ultrasonic impact gun for heat crack; step 2, controlling installation for an ultrasonic impact gun for residual stress; and step 3, performing impact treatment on the Fe-based self-fluxing alloy powder fusion-repair layer having a thickness of 0.5-3 mm during a welding process. The method disclosed by the invention has the following advantages that (1) the heat crack tendency of the Fe-based self-fluxing alloy powder fusion-repair layer caused by the difference of material parameters with matrix metal can be suppressed; (2) the surface residual tensile stress of the fusion-repair layer can be reduced, and the working life of a workpiece can be prolonged simultaneously; and (3) the crystalline grain diameter of the fusion-repair layer can be reduced, and the ductility and toughness of the fusion-repair layer can be improved based on improvement for the wear resistance of the fusion-repair layer.

Owner:LIAONING TECHNICAL UNIVERSITY +1

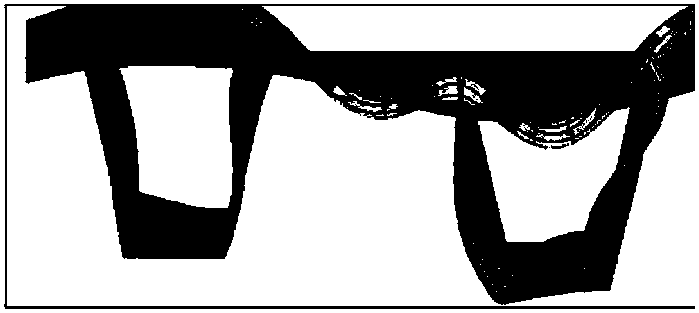

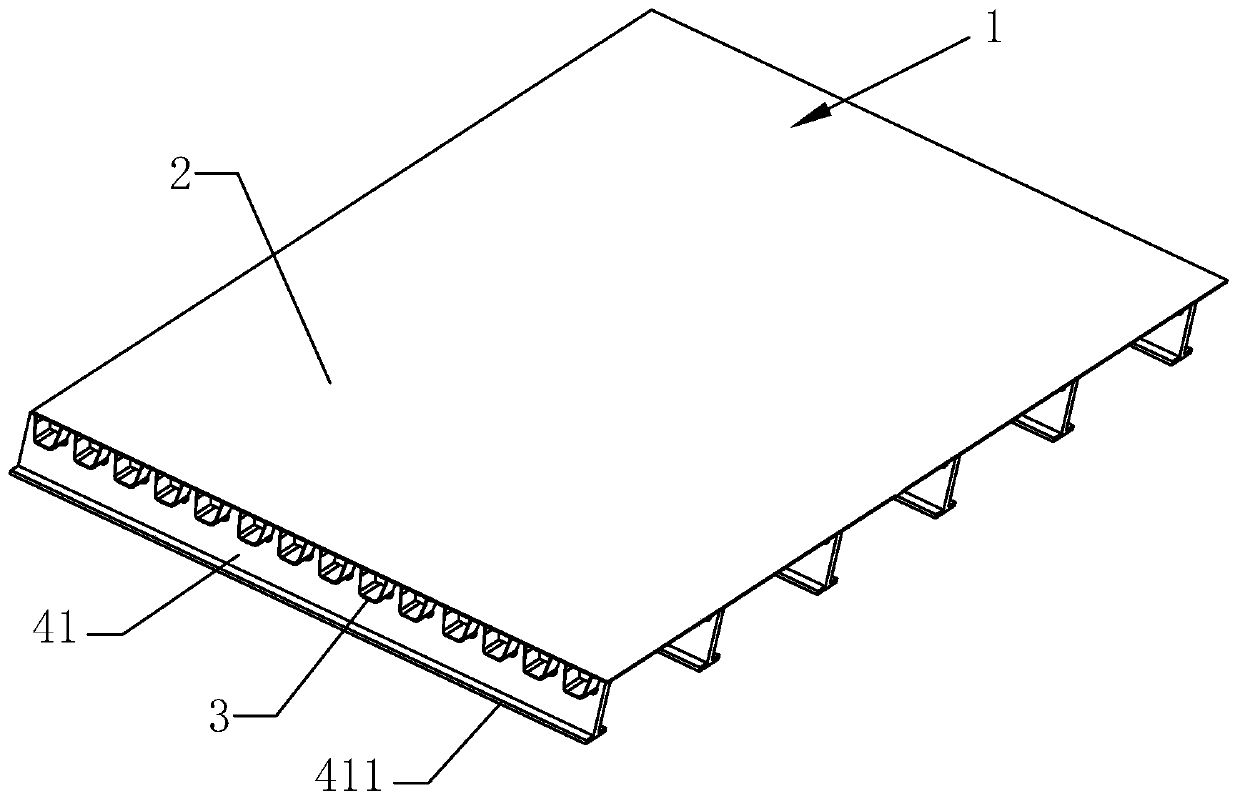

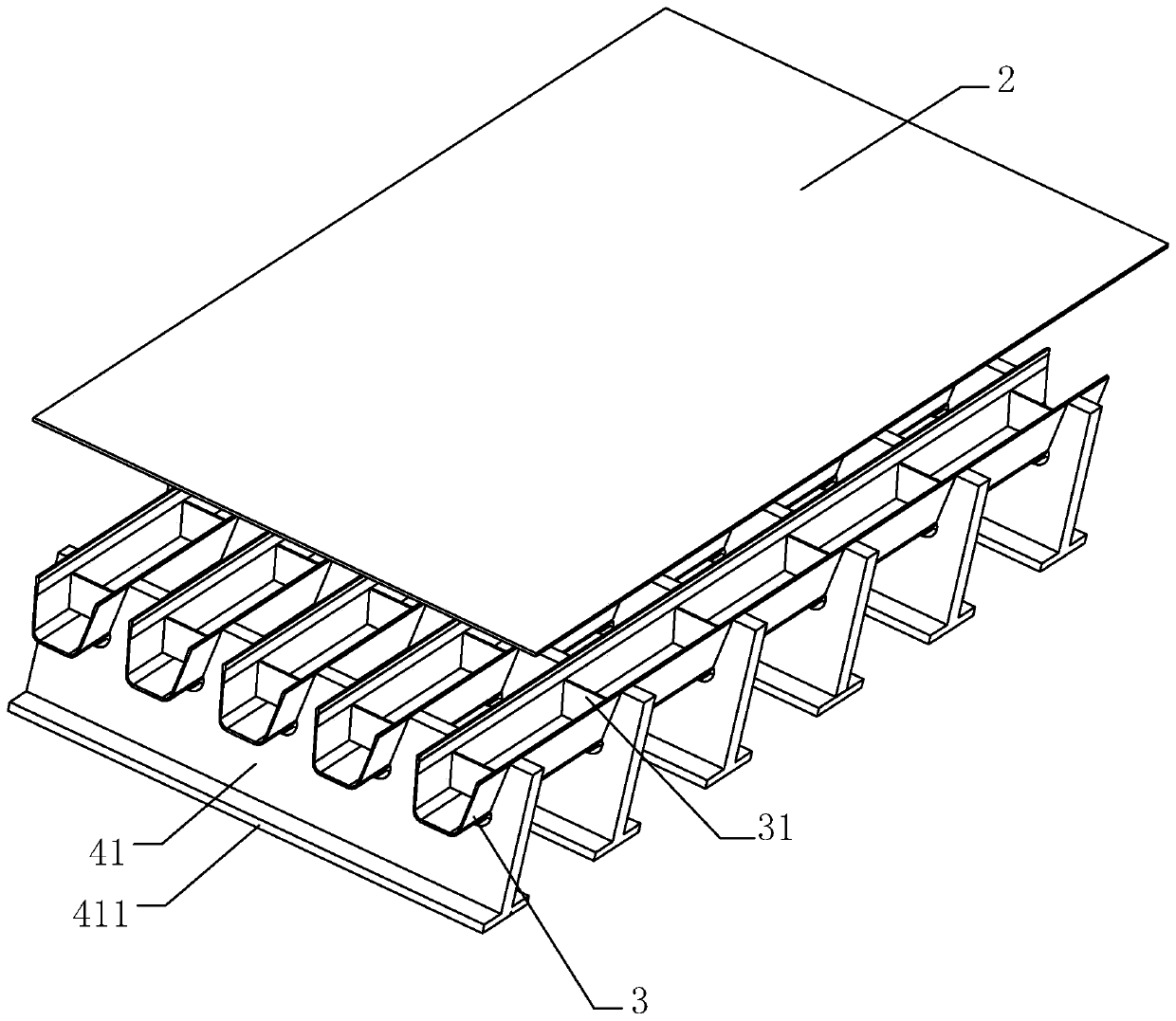

Anti-fatigue orthotropic plate structure and producing process

ActiveCN111545940AReduce the difficulty of productionImprove performanceFurnace typesWelding apparatusWelding residual stressBridge deck

The invention discloses an anti-fatigue orthotropic plate structure and a manufacturing process. Design and manufacturing processes of a traditional orthotropic plate are changed and optimized. The process comprises the following steps that 1, a transverse partition plate with a certain height is welded when a panel and a longitudinal stiffening rib are welded to form an orthotropic plate, and overall rigidity of the plate is improved; 2, the longitudinal stiffening rib adopts a variable cross-section structure with a thickened end portion to increase welding strength with a bridge deck slab;3, a rib inner transverse partition plate is additionally arranged in the position, corresponding to the transverse partition plate, of the longitudinal stiffening rib, so that anti-torsion performance of the longitudinal stiffening rib is increased, and welding seam cracking of arc-shaped notches of the longitudinal stiffening rib and the transverse partition plate is eliminated; and 4, a weldedplate structure is subjected to integral annealing heat treatment, and welding residual stress generated by a large quantity of welding among the steel panel, the longitudinal stiffening rib and the transverse partition plate (beam) are eliminated. By means of comprehensive measures above, overall anti-fatigue performance of the orthotropic plate structure is greatly improved, the century difficulty of orthotropic welding seam fatigue cracking is solved, and service lives of the steel panel and a bridge are prolonged.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

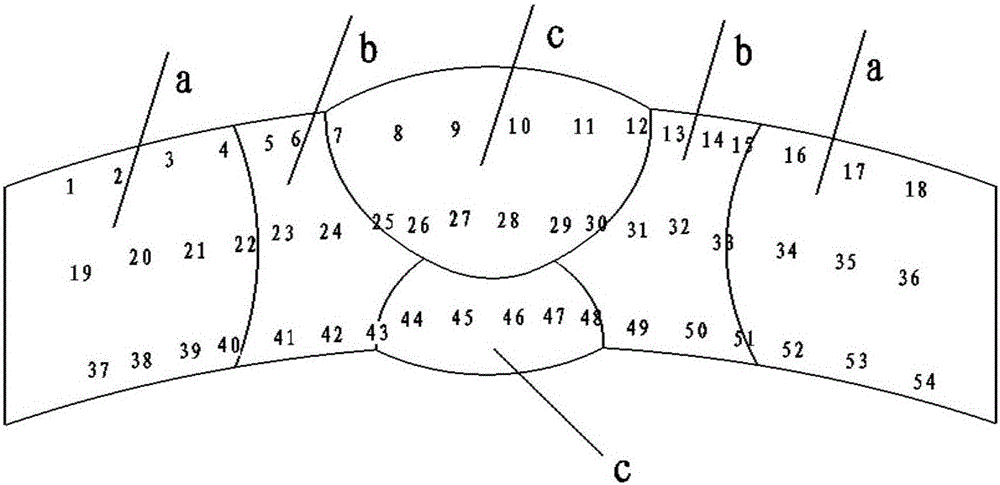

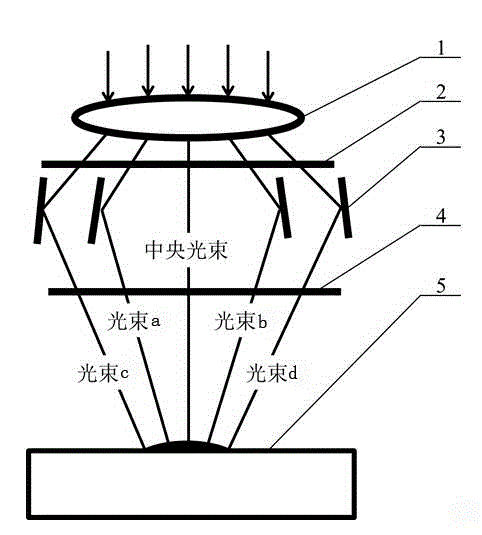

Laser-pulsed magnetism-based welded-pipe welding residual stress relieving method

ActiveCN104131154ARelief of residual stressEliminate welding residual stressProcess efficiency improvementPulsed magnetParticle physics

The invention provides a laser-pulsed magnetism-based welded-pipe welding residual stress relieving method. The laser-pulsed magnetism-based welded-pipe welding residual stress relieving method comprises laser splitting treatment and pulsed magnetism treatment and concretely comprises the following steps of 1, laser treatment: by a spectroscope, carrying out splitting on an original laser beam emitted by a laser, treating the laser beams by a first grating to obtain a central beam, a beam a, b and a beam c, d, and controlling spot sizes and positions of the three beams by a reflector and a second grating, and 2, pulsed magnetism treatment: carrying out pulsed discharging by different types of magnetizers of a pulsed discharging device to obtain a strong pulsed magnet field, and carrying out pulsed magnetism treatment on a welded-pipe welding line by outputting pulsed magnetism having pulsed magnetism treatment parameters by a magnetic read to carry out scanning treatment on the welding line. The method provided by the invention utilizes combination of laser treatment and pulsed magnetism treatment. The laser treatment aims at thermal stress and the pulsed magnetism treatment aims at structural stress and thus surface treatment can be realized by the laser treatment and the inner treatment can be realized by the pulsed magnetism treatment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

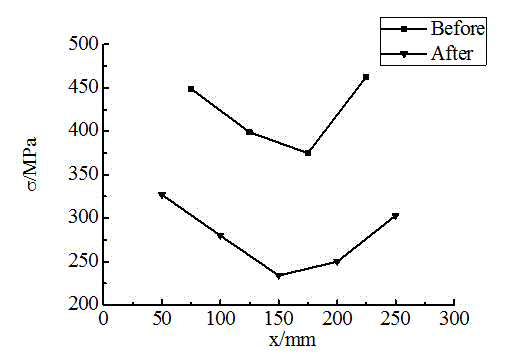

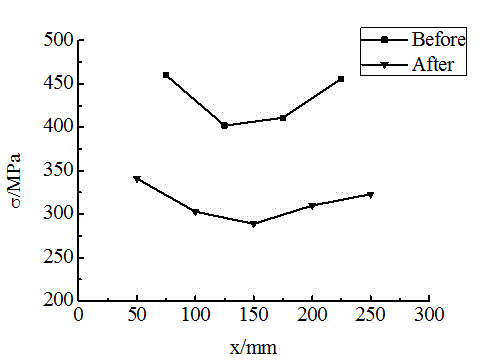

Correcting process for post welding distortion of friction stir welding

InactiveCN110014221AReduce warping angle deformationEliminate welding residual stressNon-electric welding apparatusDistortionWeld seam

The invention belongs to the technical field of aluminum alloy welding and relates to a correcting process for the post welding distortion of friction stir welding. For a raised surface of a weld seamof an aluminum alloy profile to be welded, a stir-welding head without a stirring pin is used to perform "similar friction stir welding" on the weld seam; according to the raising degree of a bulge near each weld bead, the parameters, a revolution speed at 700-1,200 r / min and a feed speed at 1,300-1,800 mm / min, are adopted for re-stirring on the weld bead, so as to apply the effects of force andheat onto the product evenly; according to the distortion formed in the previous friction stir welding, a "reverse distortion" is applied in the same way to achieve a correcting effect, so as to allowthe amount of the distortion formed in the friction stir welding to be less than 3 mm and reduce the angular warping distortion of the weld seam; and the welded profile meets the requirement of product weld seam flatness.

Owner:辽宁忠旺铝合金精深加工有限公司

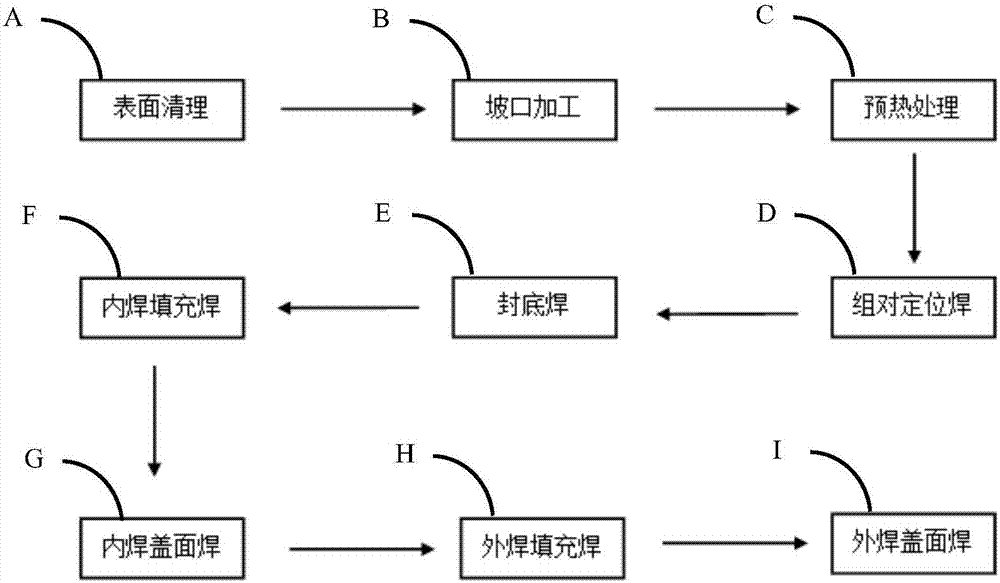

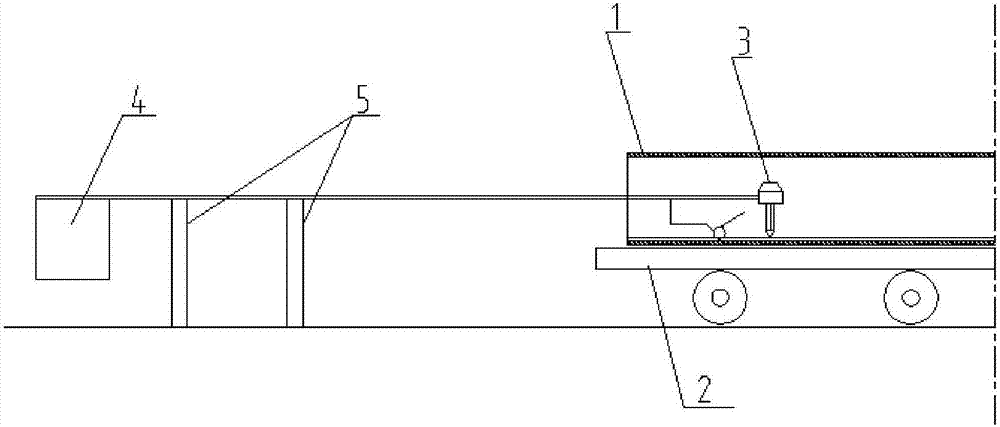

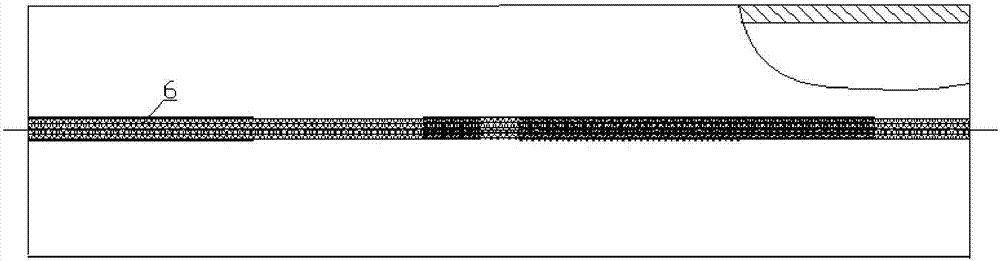

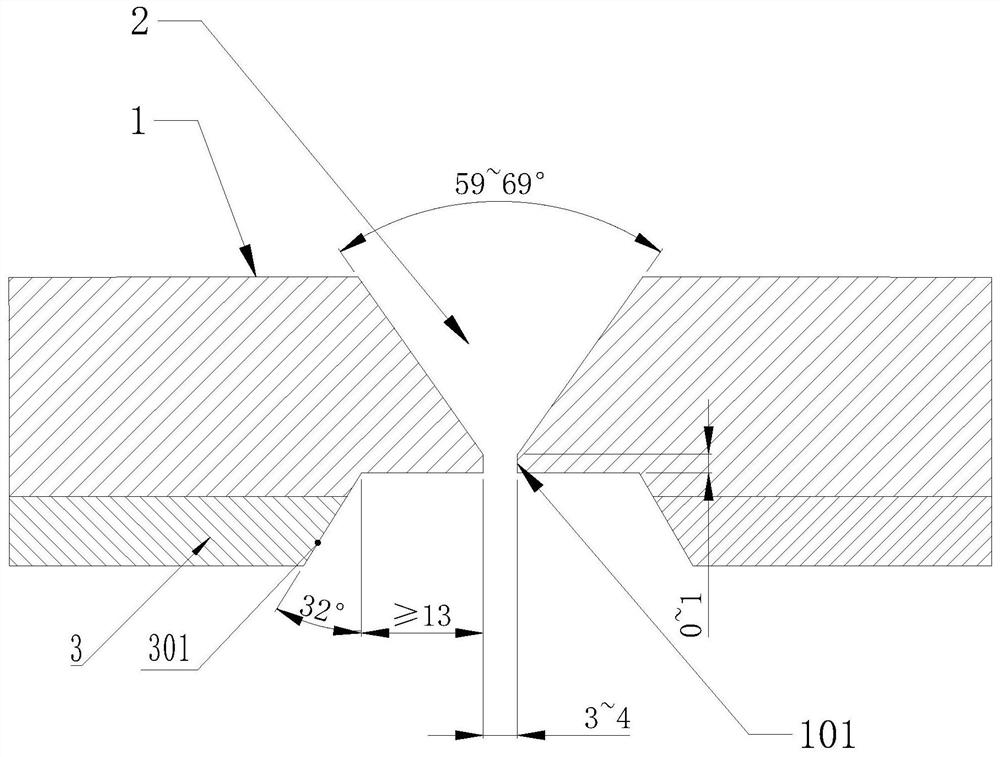

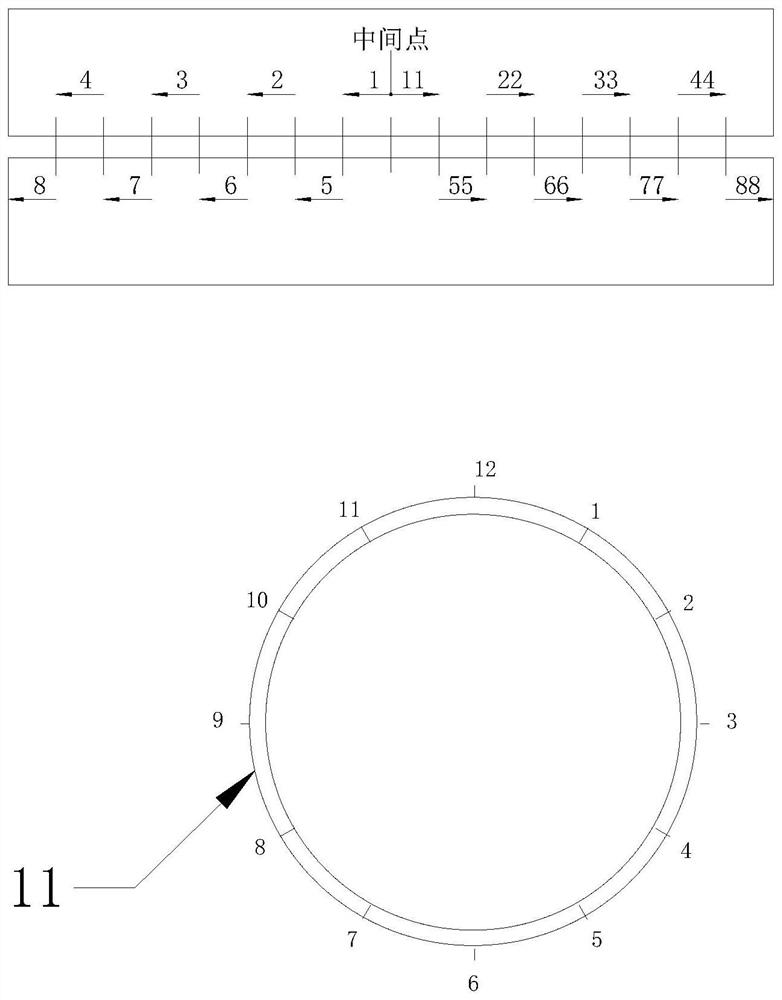

Welding process for straight seam welded pipe

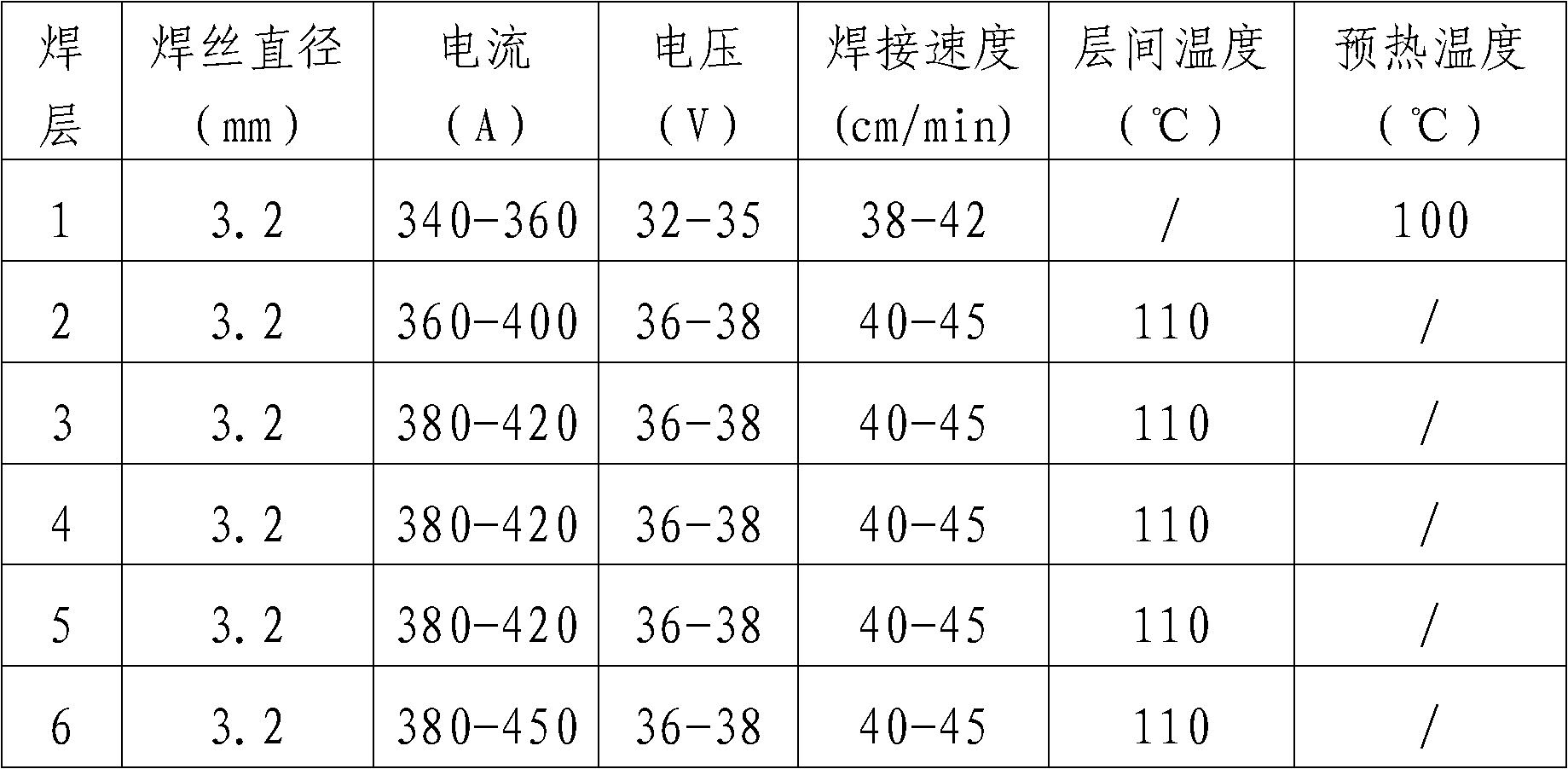

ActiveCN107538142APrevent splashBeautiful weld shapeArc welding apparatusTubular articlesSeam weldingMaterials science

The invention provides a welding process for a straight seam welded pipe, and relates to the technical field of pipeline welding. The straight seam welded pipe with five welding layers is made by welding a steel plate in a winded mode, and the welding process comprises the following steps that edge preparation is conducted on a steel plate to obtain a curled steel plate; group alignment positionedwelding is conducted on the curled steel plate and a base body of the straight seam welded pipe is formed; and the straight seam welded pipe with the five welding layers can be obtained by sequentially conducting back run welding, inner welding filling welding, inner welding cosmetic welding, outer welding filling welding and outer welding cosmetic welding on the base body of the straight seam welding pipe.

Owner:JIANGSU TONGYU STEEL PIPE GRP

Hastelloy alloy composite material welding and heat treatment process method in modular production

ActiveCN114247965AGuarantee welding qualityUniform thicknessWelding accessoriesStress relievingAlloy composite

The invention discloses a Hastelloy alloy composite material welding and heat treatment process method in modular production, which is used for welding Hastelloy alloy composite materials in modular production, and can be suitable for welding annular welding seams and longitudinal welding seams. The method comprises the following steps: firstly, welding a groove of a base layer base metal to form a base layer welding seam, then, back chipping and polishing, then, carrying out back cover welding, welding two transition layers, and carrying out stress relief heat treatment, so that the welding stress during welding of a hastelloy covering layer base metal can be reduced, and finally, welding a groove of the covering layer base metal to form a covering layer welding seam. According to the welding and heat treatment process, the strength and toughness of the base layer material are met, the strong internal stress generated by hastelloy deposited metal of the coating base material on the base layer base material, especially the bonding surface base material, is eliminated, and the product welding seam quality is stable and reliable.

Owner:江苏利柏特股份有限公司

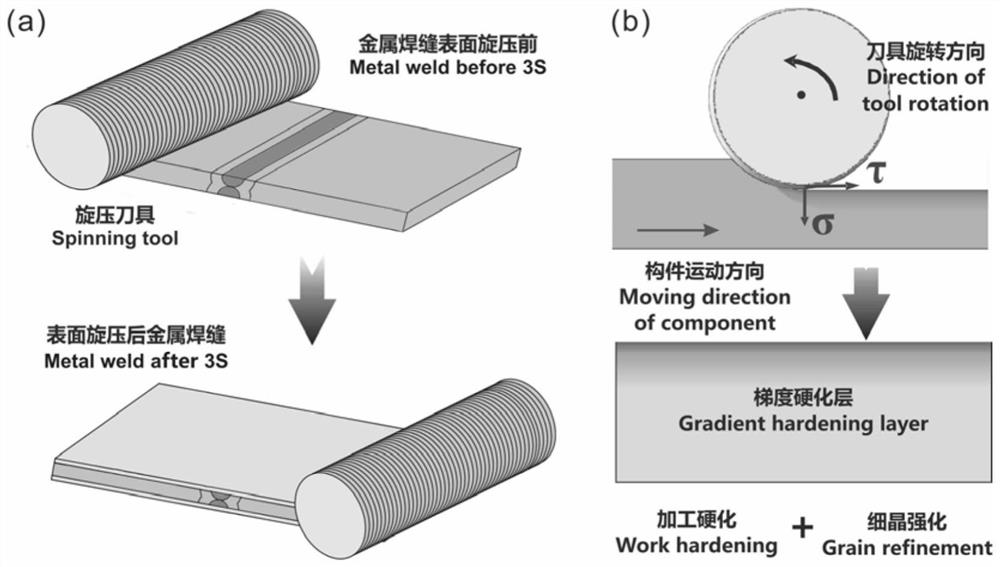

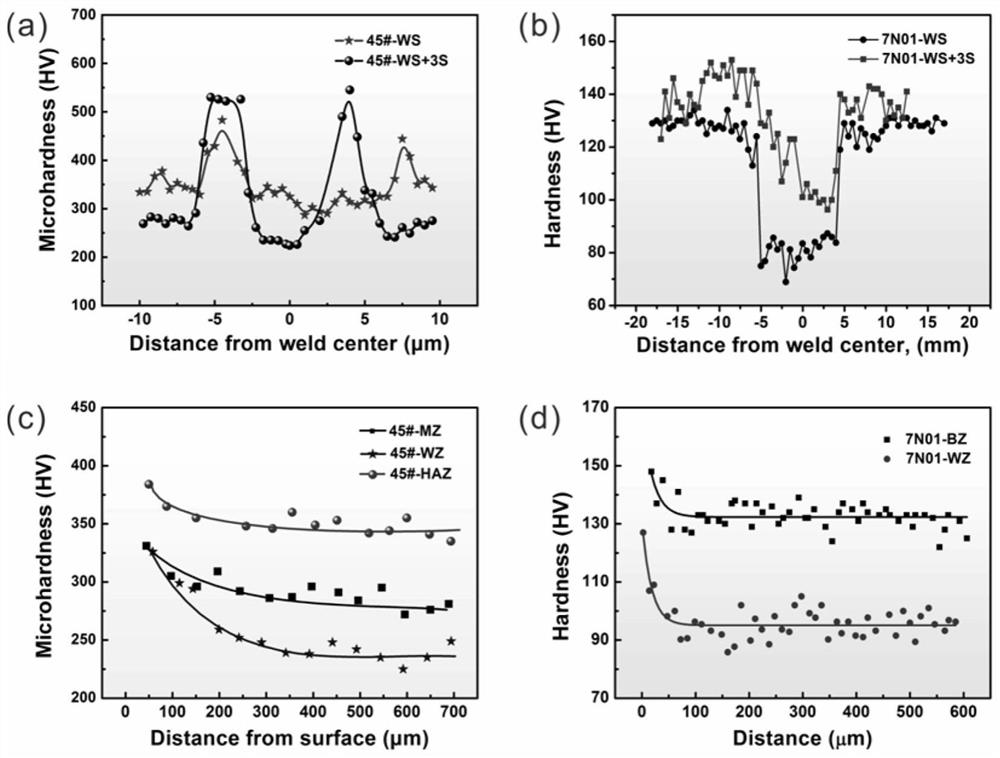

Welded joint fatigue life prolonging method

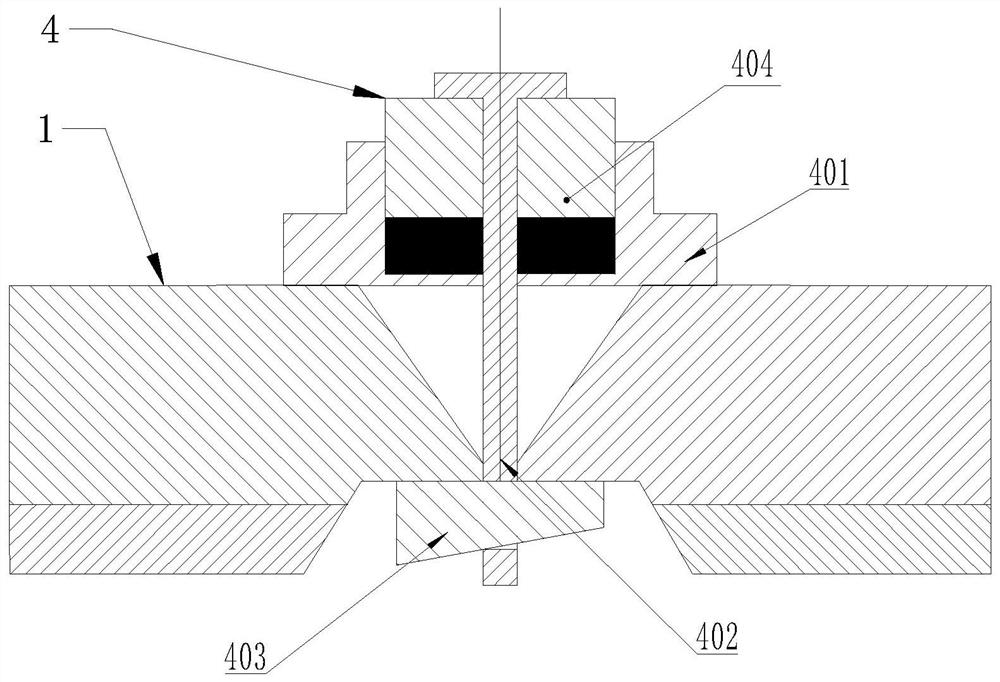

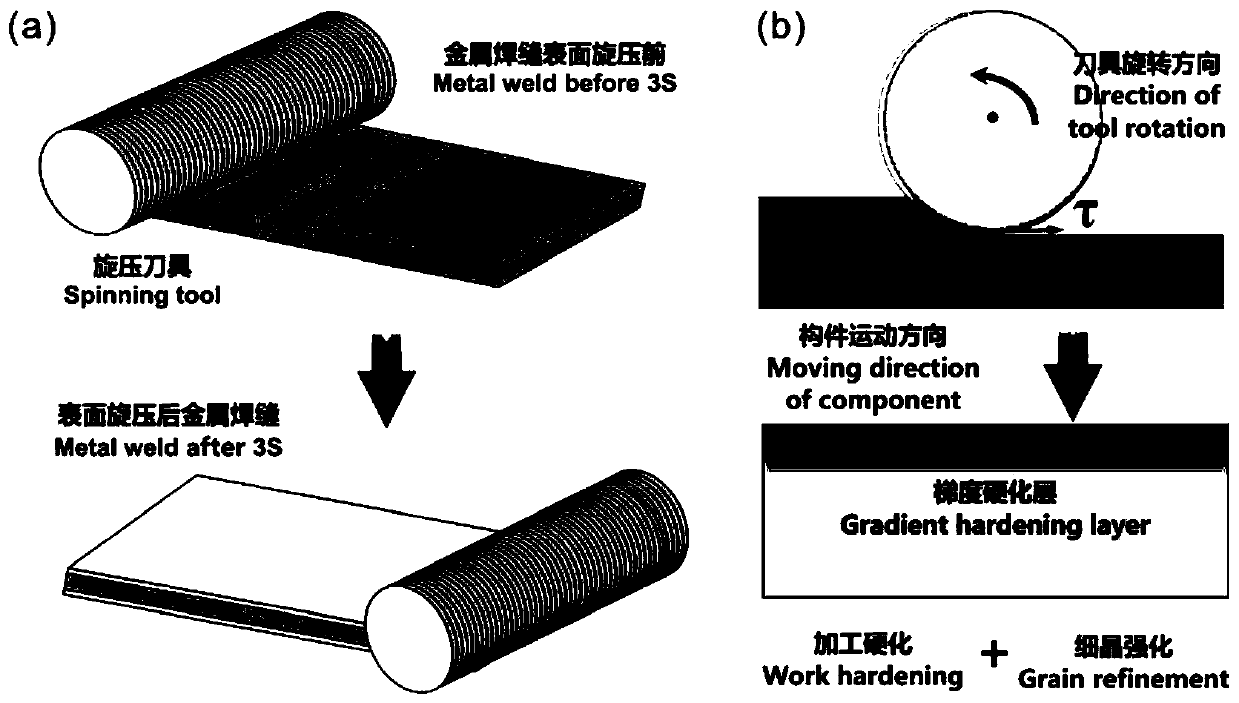

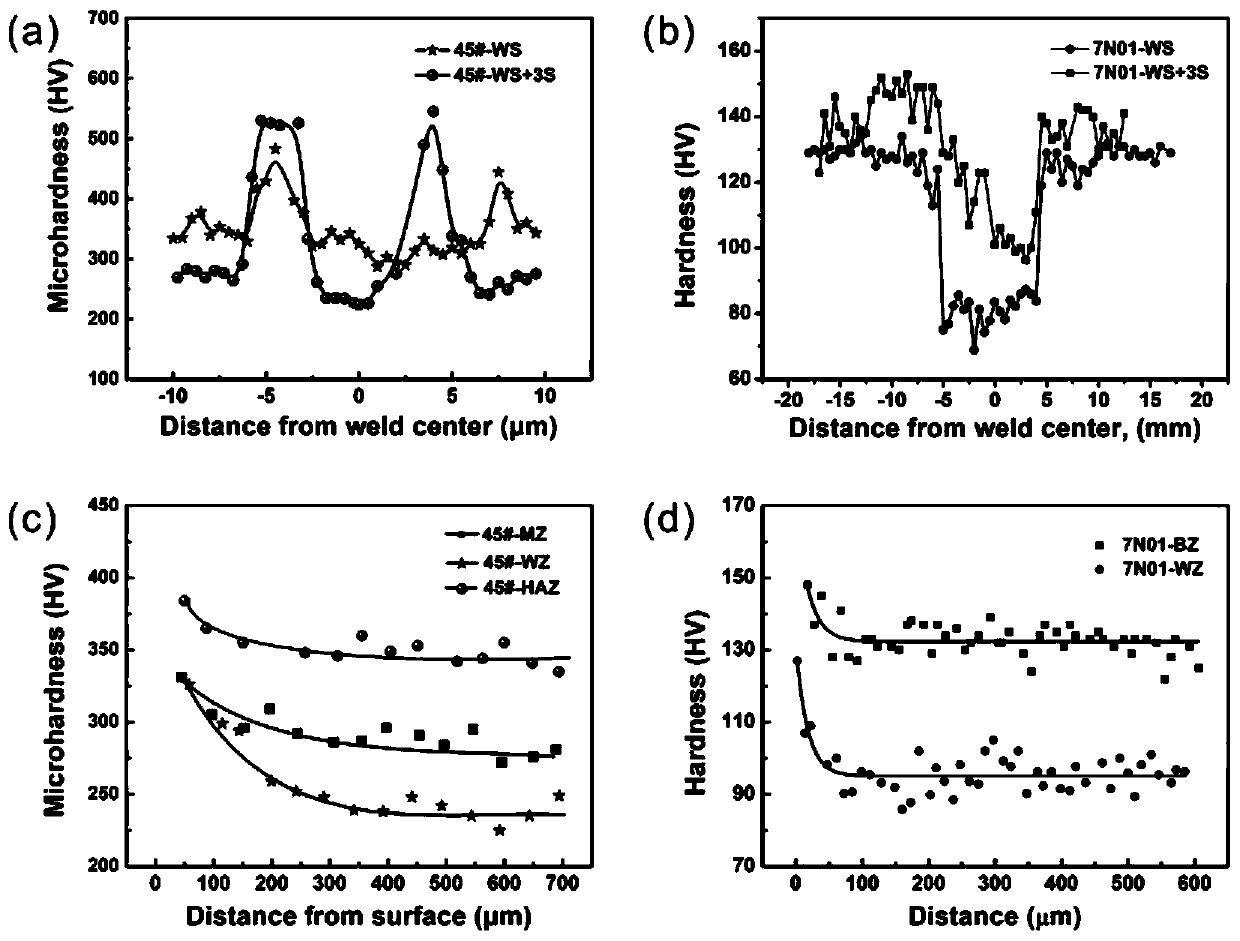

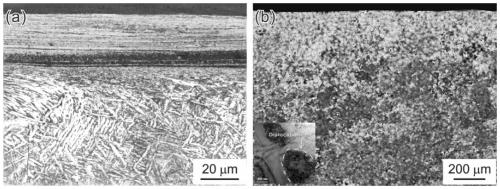

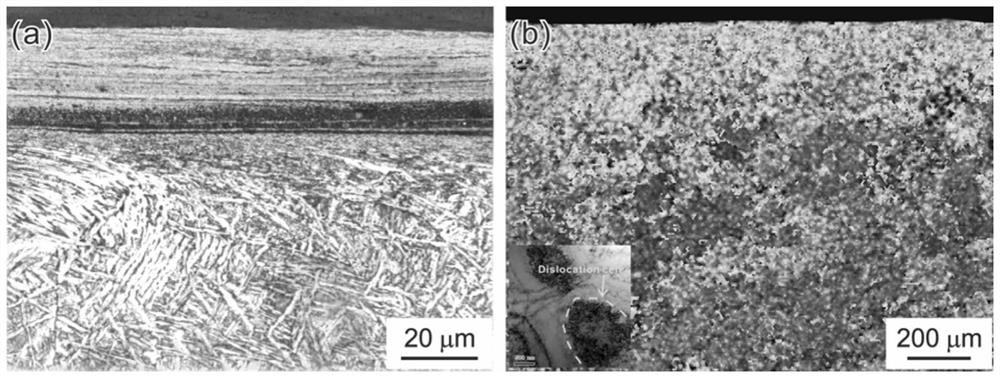

ActiveCN111069703AAchieving grain refinementAchieve refinementMachined surfaceStructural engineering

The invention discloses a welded joint fatigue life prolonging method and belongs to the technical field of surface strengthening processing for improving the fatigue property of a metal welding seam.According to the welded joint fatigue life prolonging method, the surface spinning strengthening technology is adopted to carry out surface strengthening processing on a welded joint so as to obtaina metal surface layer microstructure with hardness gradient, so that surface strengthening and hardening of the metal welded joint are realized; and in addition, the processing surface is smooth, so that the surface stress concentration level and the postwelding residual stress level of a welded component are lowered. When the metal welded component takes service under the action of cyclic load, afatigue crack can be restrained from generating on the surface of the welded joint after spinning processing to improve the fatigue property of the metal welded joint.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Welding technology method of lifting device box in self-lifting type drilling platform

ActiveCN100493804CReduce cooling rateFulfil requirementsArc welding apparatusFloating buildingsEngineeringMechanical property

The invention discloses a technique method of welding the body of an elevating gear in a self-elevating drilling platform. The maximum thickness of a steel plate is 76mm and the yield stress of the steel plate is 460 MPa. The gas of CO2 is adopted for protecting arc welding. Temperature is preheated to 110 DEG C before welding. Interlayer-temperature is 10 to 230 DEG C. The procedures of the welding comprises: a board, a backboard and a clapboard are welded to be integrated as a whole, and then the unit of three boards are welded on a bottom board; the close boards of both sides are welded on the bottom board. A bracing board is welded on the close board; a wing plate is welded on the close board; gaps among the wing plate, the bracing board and the bottom board are welded; and an attachment weld between the backboard and the close board is welded. The invention is able to improve the efficiency of welding processing, reduce the input of welding heat and decrease the cooling velocity of a junction, thereby solving the problem of a welding crack. The principle of even-number builder, symmetrical construction and dispersion and section construction adopted and vibration timing technique used for removing residue stress, the problems of welding cracks, welding joint mechanical property requirements and welding deformation control can be effectively solved.

Owner:DALIAN SHIPBUILDING IND

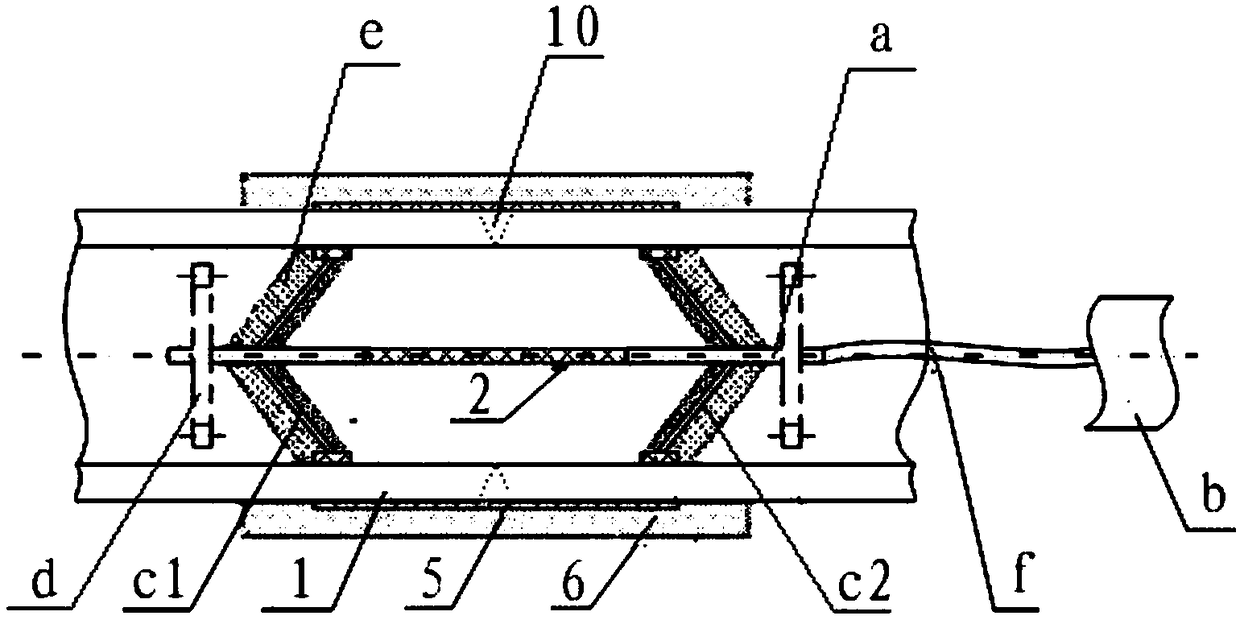

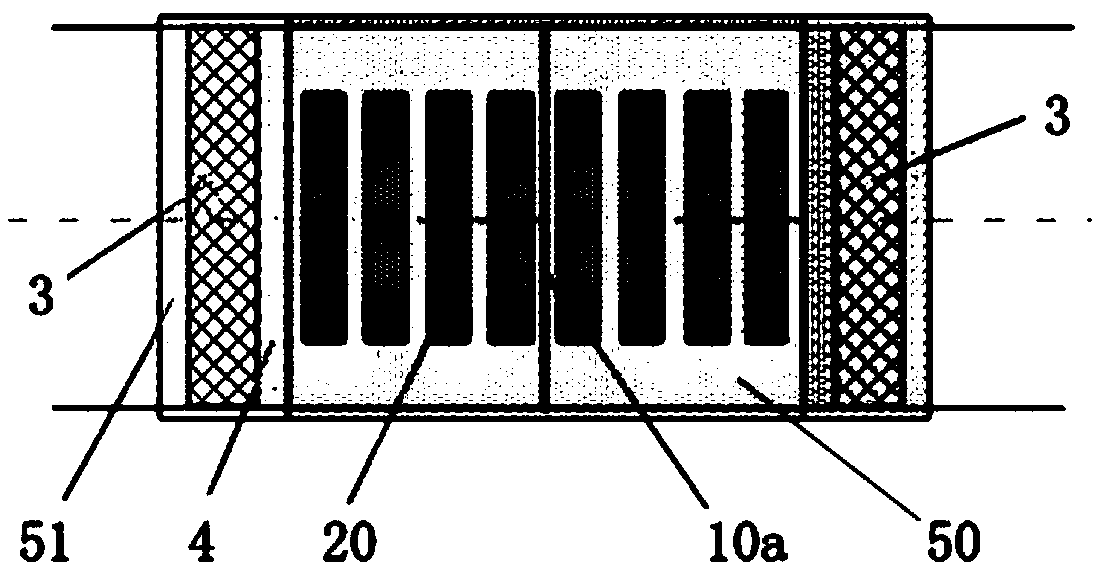

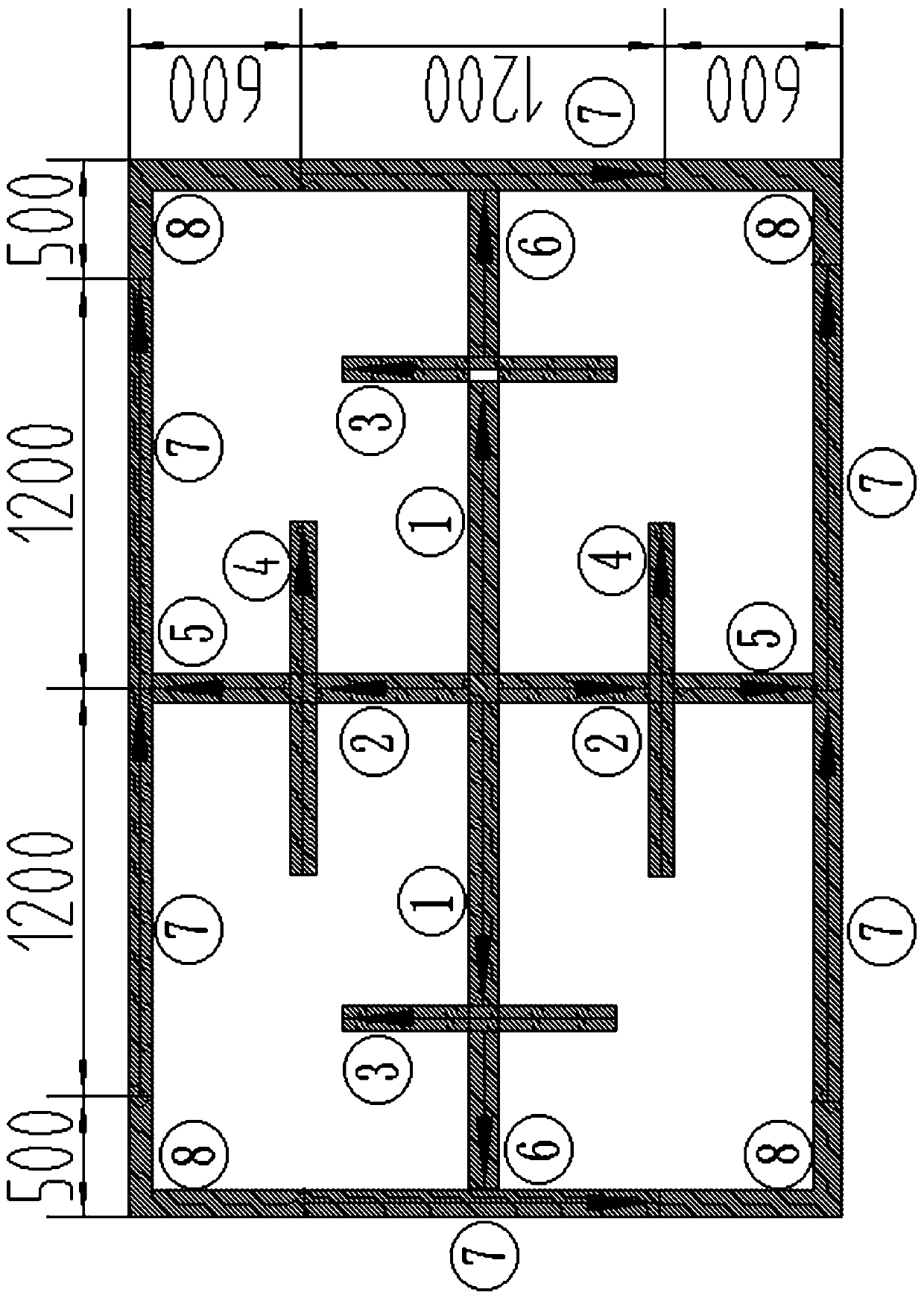

Device for eliminating welding residual stress based on electromagnetic energy

PendingCN110512053AImprove performanceEliminate welding residual stressFurnace typesProcess efficiency improvementElectromagnetic generatorWelding residual stress

The invention discloses a device for eliminating welding residual stress based on electromagnetic energy. The device includes a power supply system, an electromagnetism generator system and a coolingsystem, wherein the electromagnetism generator system includes a plurality of electromagnetic generators, and each electromagnetic generator includes a coil and a U-shaped iron core; the U-shaped ironcore is wound with the coil, and all the cores are connected with the power supply system; the cooling system is used for cooling the electromagnetism generator system; the electromagnetism generatorsystem is positioned right above a welding plate to be treated; and the treatment time for eliminating the welding residual stress is defined according to the length of the welding plate to be treated and amount of the U-shaped iron cores. According to the invention, energy for eliminating the welding residual stress is provided, joint microstructures cannot be affected, and corresponding performance of the joint is improved; stress relief is carried out instantly along with welding equipment, and can be carried out after welding is completed, so that high adaptation is realized.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +2

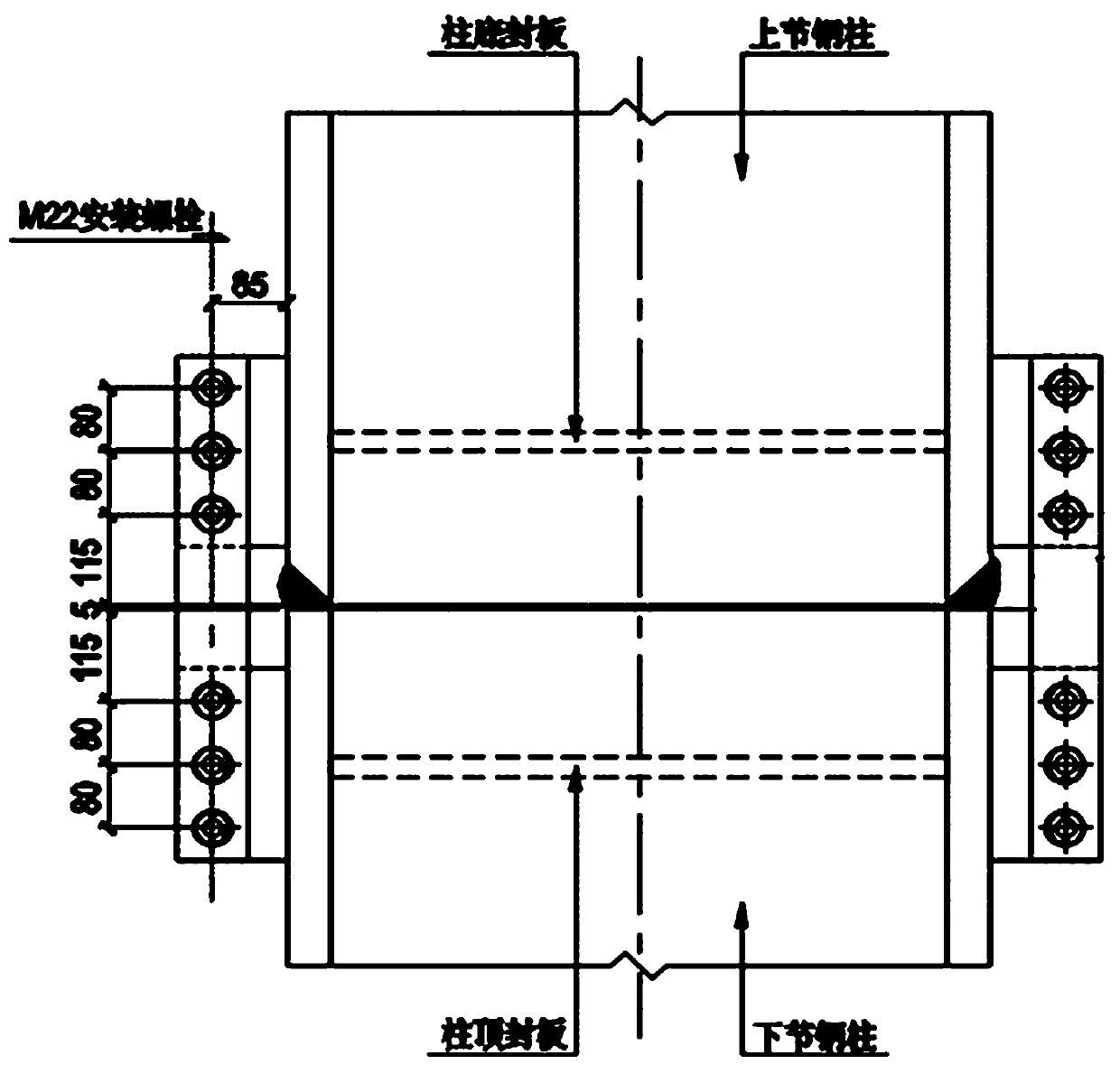

Welding process method suitable for large-section medium-thickness plate box column

PendingCN111168271APrevent defects such as cracksImprove welding qualityWelding/cutting media/materialsSoldering mediaWelding residual stressInternal stress

The invention discloses a welding process method suitable for a large-section medium-thickness plate box column. The same large-section medium-thickness plate box column is subjected to segment-by-segment welding by work shifts, a construction segment is reasonably divided, assembly construction is organized, before the whole-section welding line is closed, inner stress generated by welding is gradually released, in combination with after-welding heat treatment measures, welding residual stress is greatly reduced, the welding process method can effectively release welding stress at proper time, defects of cracks and the like generated by welding can be prevented, the welding quality is improved, the one-time yield of welding quality can be improved, the construction period is shortened, and cost is control is benefited.

Owner:郑州宝冶钢结构有限公司 +1

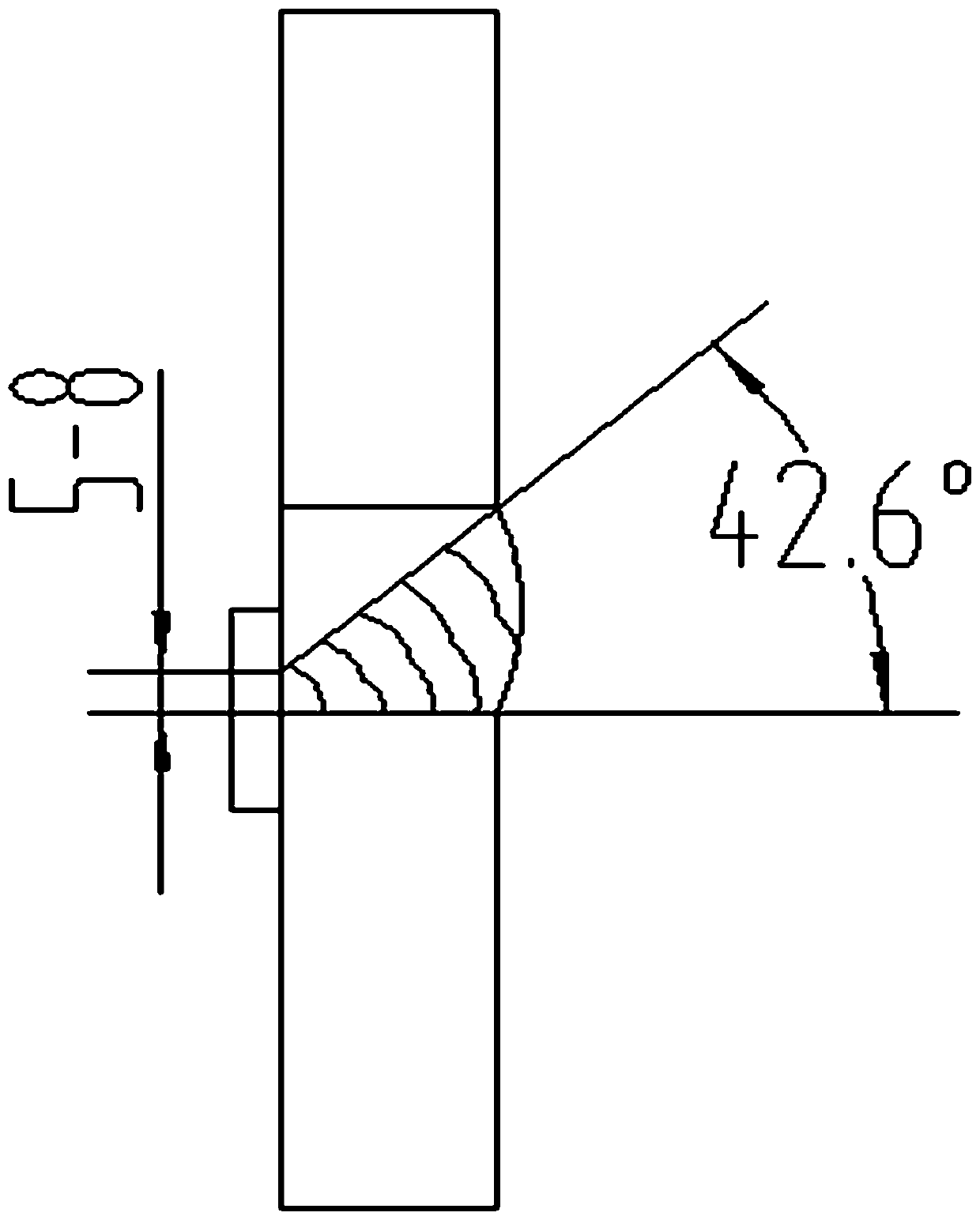

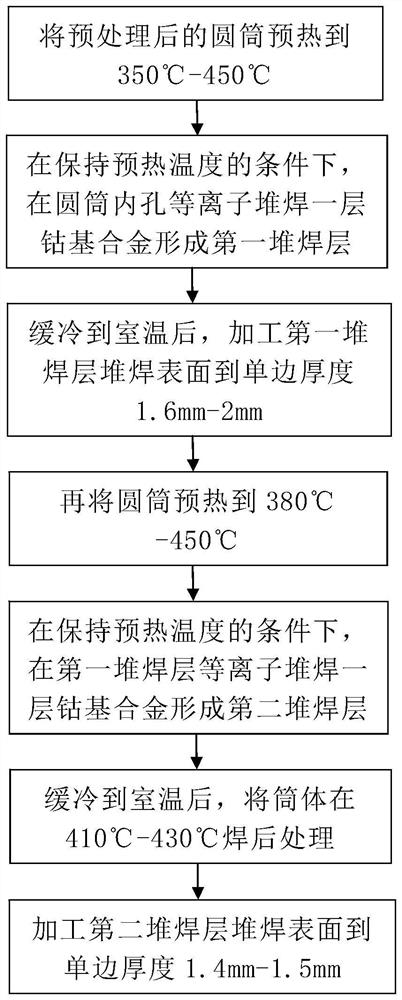

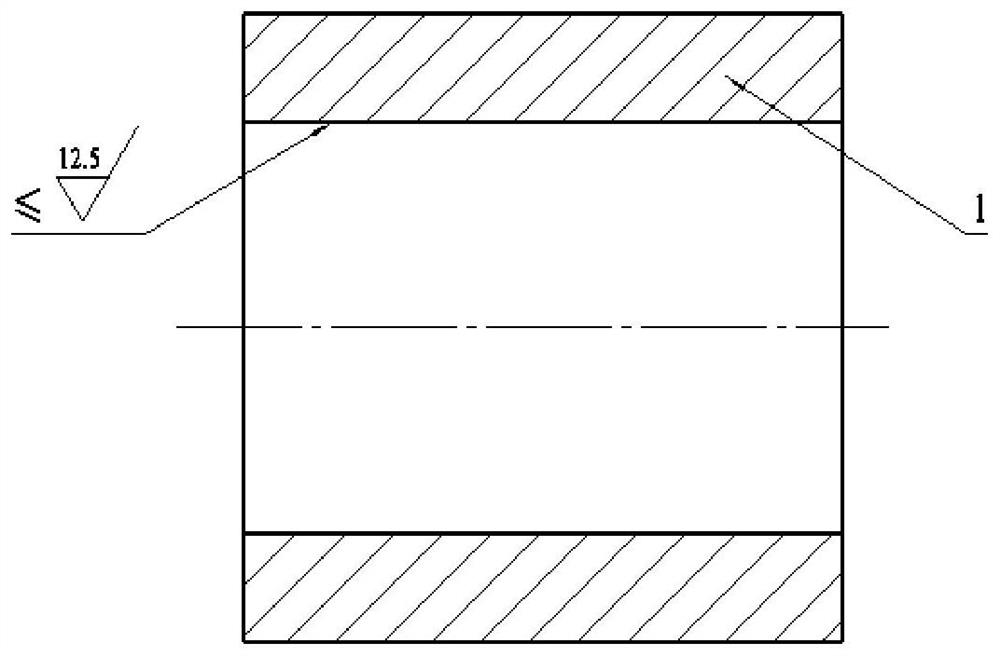

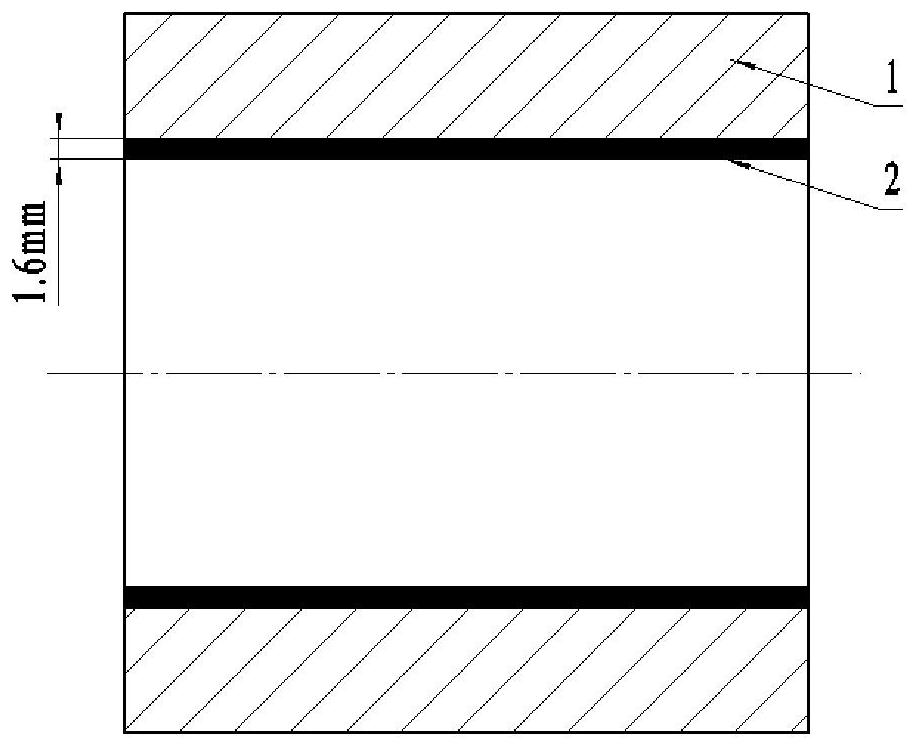

Method for plasma surfacing of cobalt-based alloy in inner hole of cylinder

PendingCN114160941ALow dilution rateHigh strengthPlasma welding apparatusWelding/soldering/cutting articlesSlow coolingAustenite

The invention provides a method for plasma surfacing of cobalt-based alloy in an inner hole of a cylinder. The method comprises the following steps that the pretreated cylinder is preheated to 350-450 DEG C; under the condition that the preheating temperature is kept, a layer of cobalt-based alloy is subjected to plasma surfacing on the inner hole of the cylinder to form a first surfacing layer; after slow cooling to the room temperature, the surfacing surface of the first surfacing layer is machined till the unilateral thickness is 1.6 mm-2mm; then the cylinder is preheated to 380 DEG C to 450 DEG C; under the condition that the preheating temperature is kept, a layer of cobalt-based alloy is subjected to plasma surfacing on the first surfacing layer to form a second surfacing layer; after the barrel is slowly cooled to the room temperature, the barrel is subjected to postweld treatment at the temperature of 410-430 DEG C; and the surfacing surface of the second surfacing layer is machined till the single-side thickness is 1.4 mm-1. 5 mm. According to the method for plasma surfacing of the cobalt-based alloy on the inner hole of the cylinder, the problem that cracks are prone to being generated in the surfacing process of the cobalt-based alloy on the inner hole of the cylinder made of austenite stainless steel can be solved.

Owner:SHENYANG BLOWER WORKS GRP NUCLEAR PUMP

Fan welding process

ActiveCN112620995AEliminate welding residual stressImprove connection performanceWelding/cutting auxillary devicesAuxillary welding devicesPhysicsEnvironmental geology

The invention relates to the technical field of fan production, in particular to a fan welding process. The fan welding process comprises the following process steps of S1, butt welding of a machine shell; S2, oil pipe welding, specifically, S21, rough machining; S22, segmented welding; S3, weld inspection; S4, kerosene penetration test; S5, heat treatment, wherein a jacking oil pipe, an oil return pipe and a threading pipe are made of 304 stainless steel, a fan casing is made of Q345C, heat treatment is conducted on the fan casing, the jacking oil pipe, the oil return pipe and the threading pipe according to the heat treatment requirements of the 304 stainless steel and the Q345C, the fan casing, the jacking oil pipe, the oil return pipe and the threading pipe are heated to 400-500 DEG C, and heat preservation time is 24 hours; S6, hydraulic pressure test; and S7, paint spraying. By means of the compiled fan welding process, the welding residual stress of the weld position of the fan casing and the weld position of the oil pipe can be eliminated, the connecting performance of the fan casing and the oil pipe is improved, then the overall performance of the fan casing is enhanced, and the service life of the fan casing is prolonged.

Owner:陕西广大重型机械有限公司

A method for prolonging fatigue life of welded joints

The invention discloses a method for prolonging fatigue life of welded joints, and belongs to the technical field of surface strengthening processing for improving the fatigue performance of metal welds. This method adopts surface spinning strengthening technology to carry out surface strengthening processing on welded joints to obtain metal surface structure with hardness gradient, realize surface strengthening and hardening of metal welded joints, and process smooth surface at the same time, which reduces the level of stress concentration and stress concentration on the surface of welded components. Post-weld residual stress levels. When metal welded components serve under cyclic loads, the initiation of fatigue cracks from the surface of welded joints can be inhibited after spinning, thereby improving the fatigue performance of metal welded joints.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

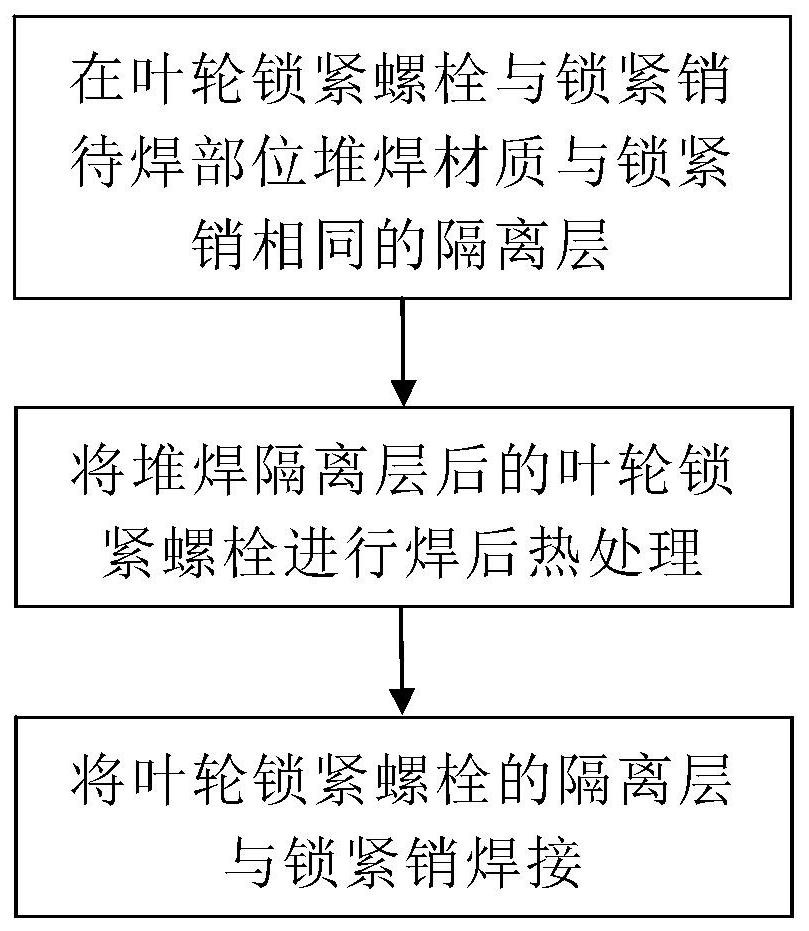

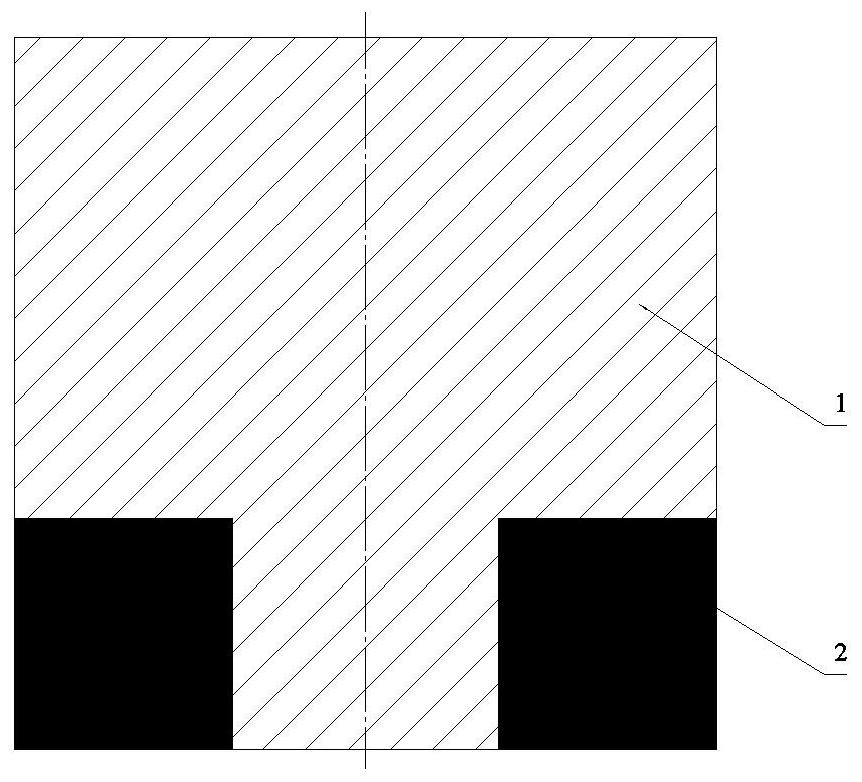

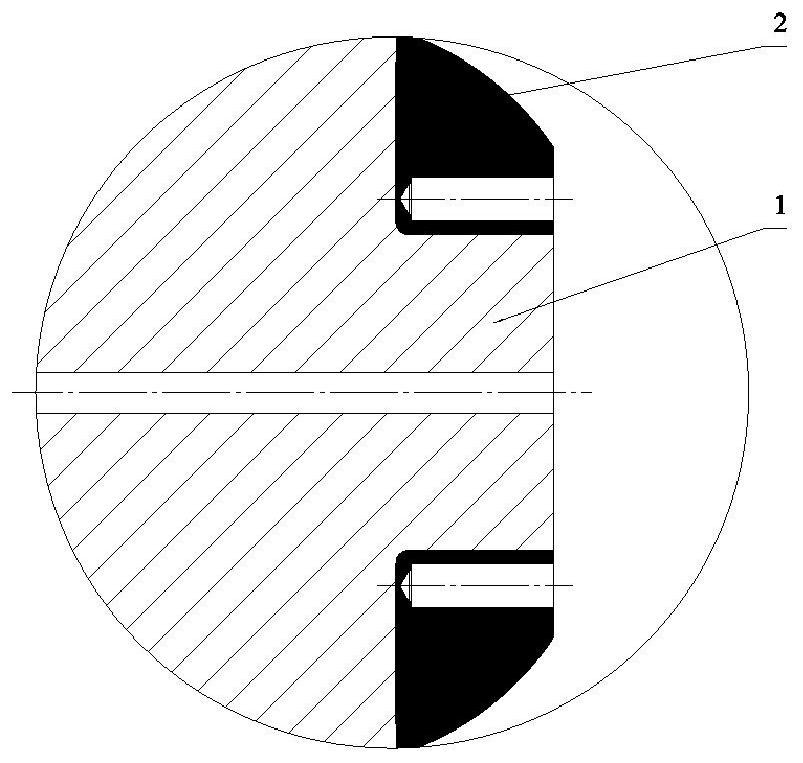

Welding method for impeller locking bolt and locking pin

ActiveCN112453642ASolve the problem that post-weld heat treatment cannot be realizedReduce hardnessNuclear energy generationArc welding apparatusImpellerMartensitic stainless steel

The invention provides a welding method for an impeller locking bolt and a locking pin. The welding method comprises the following steps that an isolation layer with the same material as the locking pin is overlaid on the to-be-welded portion of the impeller locking bolt and the locking pin; postweld heat treatment is carried out on the impeller locking bolt after overlaying of the isolation layer; and the isolation layer of the impeller locking bolt is welded to the locking pin. The welding method for the impeller locking bolt and the locking pin can solve the problem that when the impeller locking bolt made of martensitic stainless steel and the locking pin made of nickel-based alloy are welded, chemical components and metallographic structures of a welded joint are uneven due to the fact that the physical performance and the mechanical performance of parent metal of the impeller locking bolt and the locking pin are greatly different, and therefore, the impact toughness of the jointis reduced.

Owner:SHENYANG BLOWER WORKS GRP NUCLEAR PUMP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com