Welding method for impeller locking bolt and locking pin

A technology for locking bolts and welding methods, which is applied in welding equipment, arc welding equipment, and greenhouse gas reduction, and can solve the problems of reduced impact toughness of joints, physical and mechanical properties of welded joints, and uneven chemical composition and metallographic structure. , to prevent delayed cracks, improve microstructure and mechanical properties, and eliminate welding residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

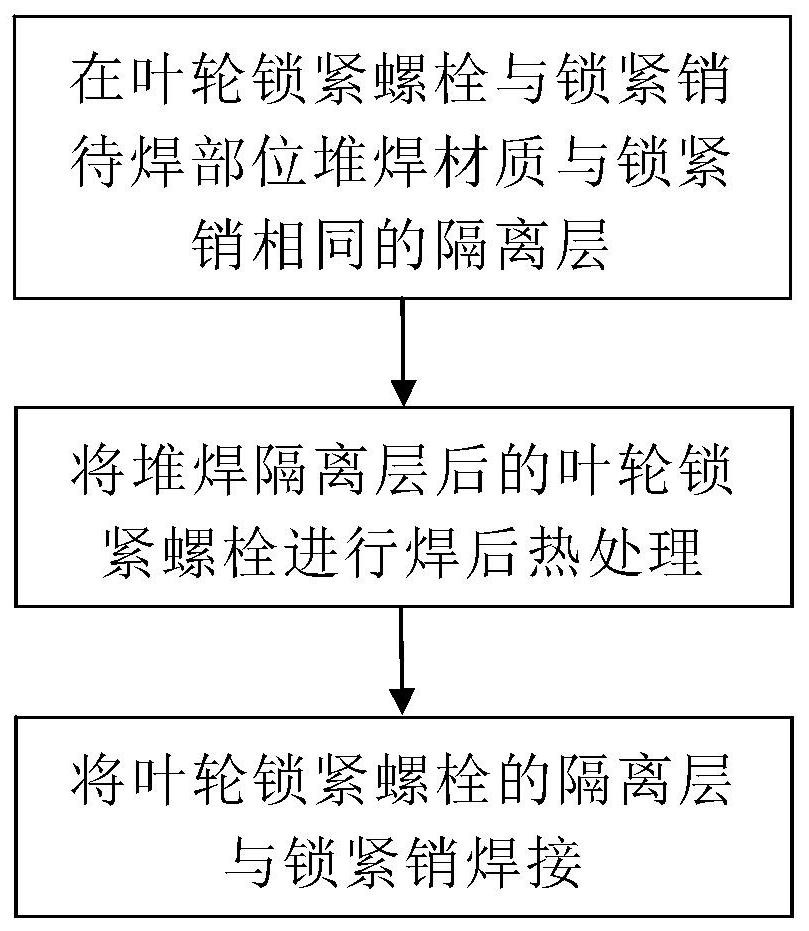

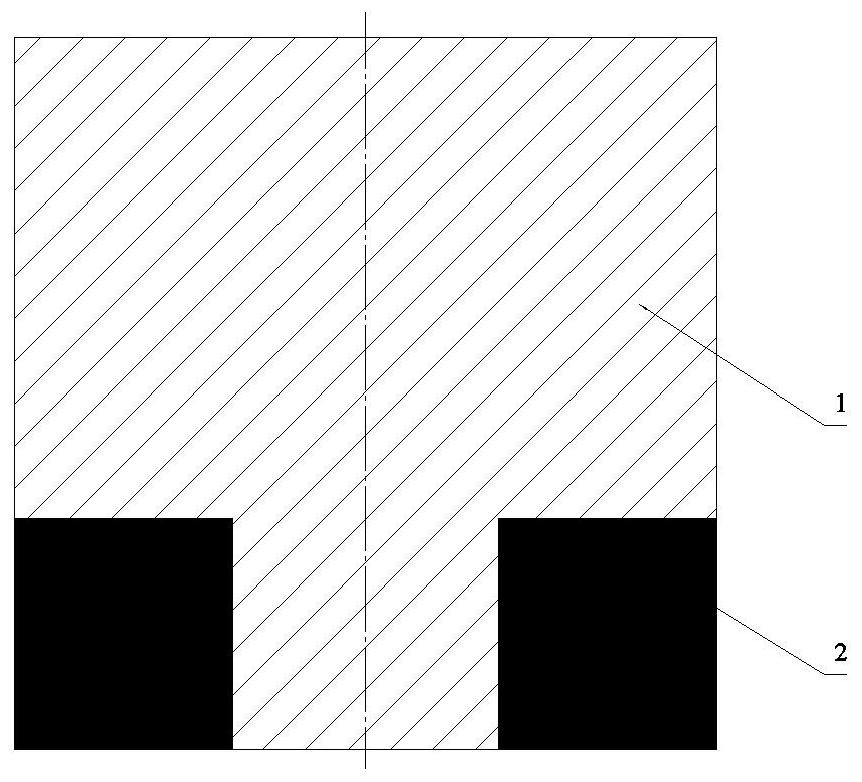

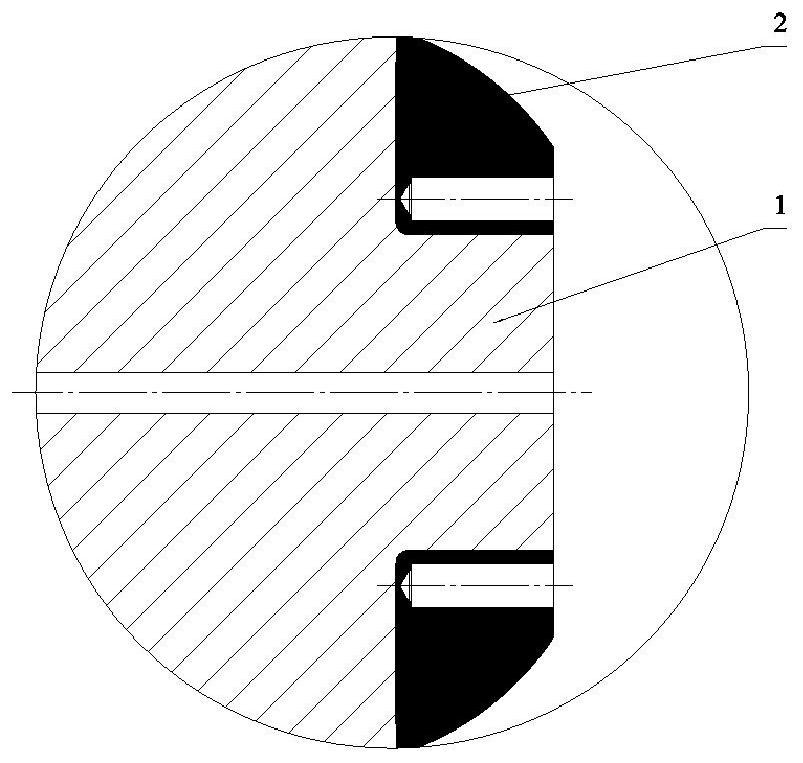

[0022] see figure 1 The embodiment of the present invention provides a welding method for impeller locking bolts and locking pins, which is suitable for welding martensitic stainless steel and nickel-based alloy dissimilar steel when post-weld heat treatment cannot be achieved in the final assembly stage of the pump. The material of the impeller locking bolt is martensitic stainless steel, and the material of the locking pin is nickel-based alloy. The welding method includes the following steps:

[0023] Overlay the isolation layer with the same material as the locking pin on the impeller locking bolt and locking pin to be welded;

[0024] Perform post-weld heat treatment on the impeller locking bolts after the surfacing welding isolation layer;

[0025] Weld the isolation layer of the impeller locking bolts to the locking pins.

[0026] As a specific embodiment of the present invention, the impeller locking bolts are preheated at a temperature higher than 150° C. before wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com