Hastelloy alloy composite material welding and heat treatment process method in modular production

A technology of Hastelloy and composite materials, which is applied in the field of welding and heat treatment in the welding of Hastelloy composite materials in modular production, and can solve the problems of difficult welding technology, long working cycle, and large amount of weld deposit metal filling and other problems to achieve the effect of avoiding cracking and unqualified defects, eliminating welding residual stress, and restoring plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] The present invention will be described in further detail below through specific examples.

[0107]The large diameter and large wall thickness of the present invention generally refer to materials with an outer diameter greater than 508mm and a wall thickness of 15-52mm.

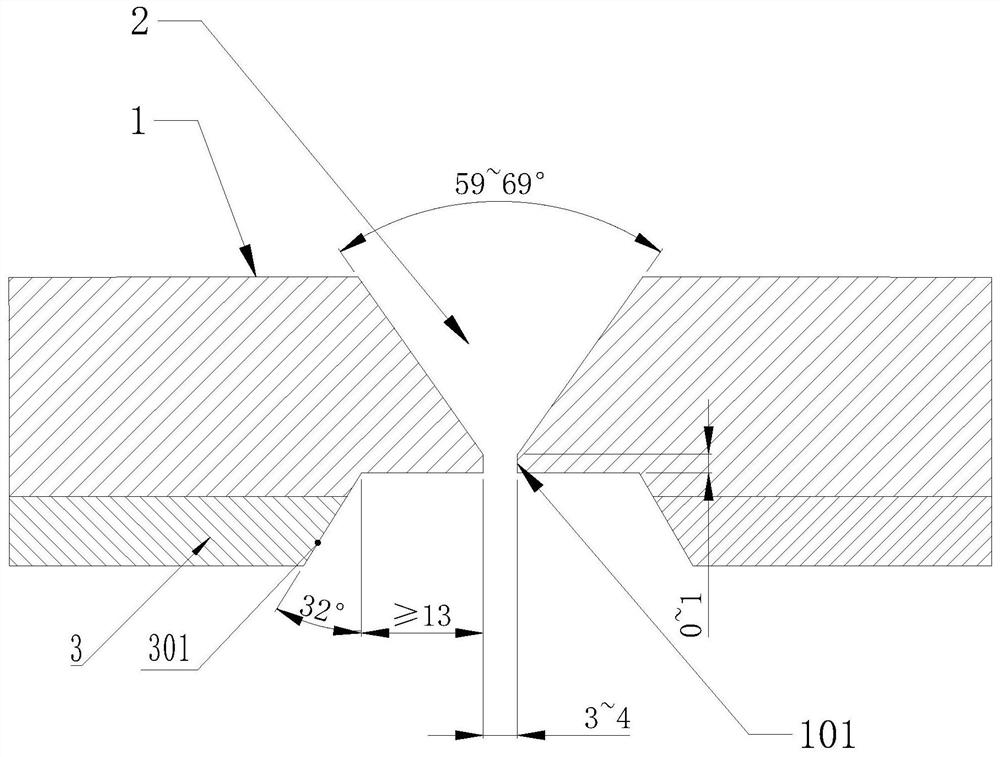

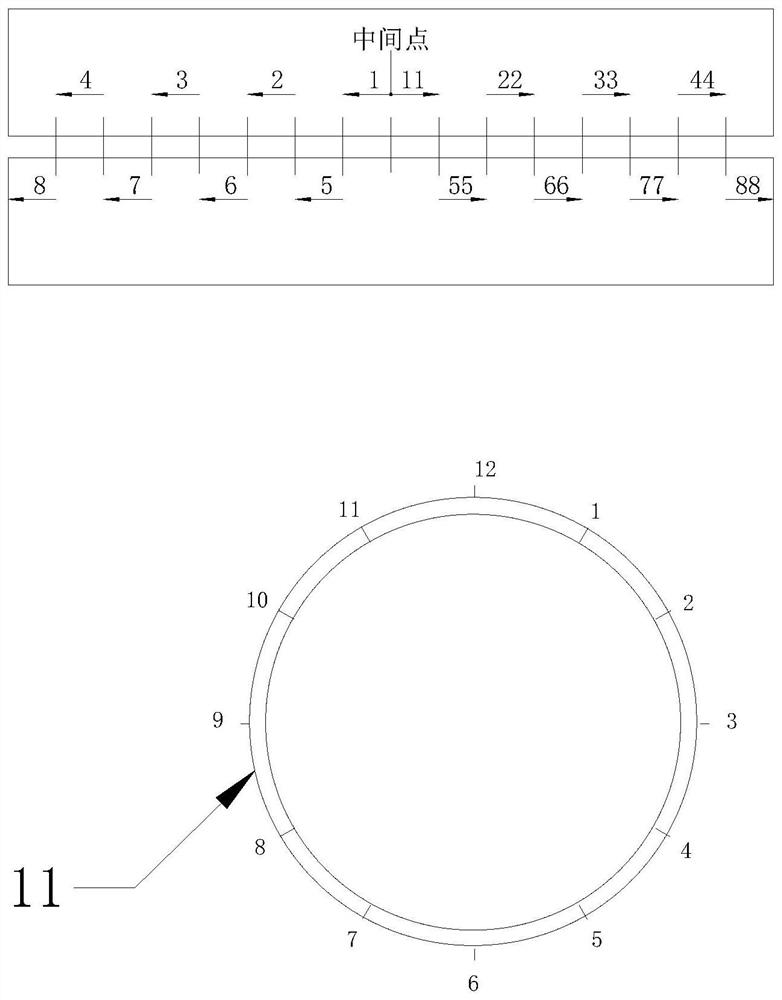

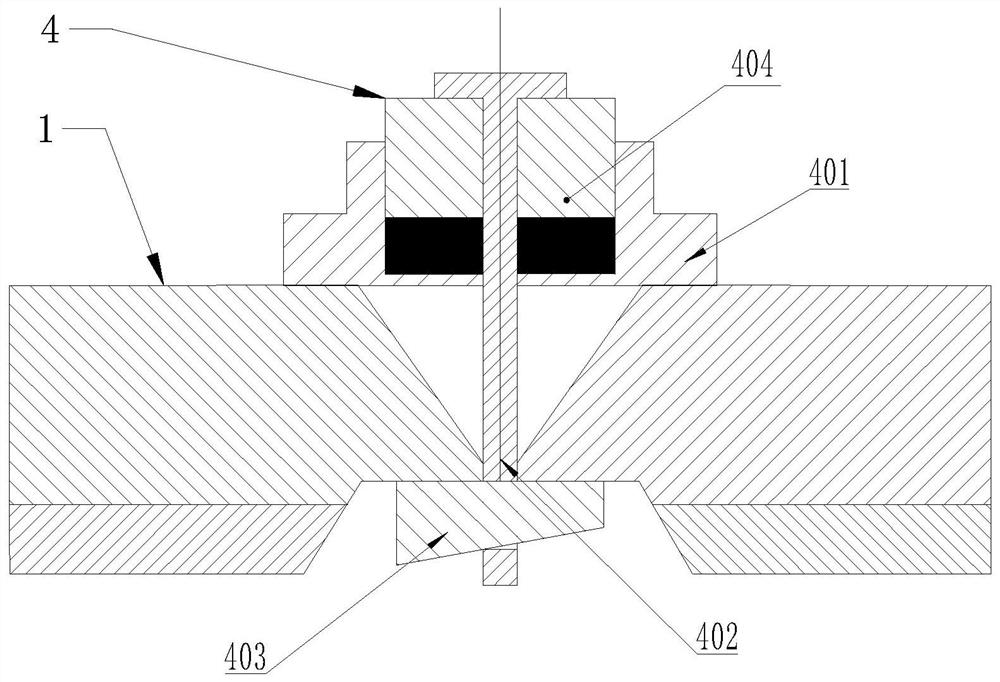

[0108] The welding of the Hastelloy composite material in the present invention is suitable for butt welding of annular workpieces such as pipe containers, and is also suitable for butt welding of plate-mounted workpieces.

[0109] Such as Figure 1 to Figure 9 As shown, a Hastelloy composite material welding and heat treatment process method in modular production includes the following steps:

[0110] A. Preparation before welding, including the following sub-steps:

[0111] a1) Determine the execution standards of welding and heat treatment;

[0112] The execution standard in this embodiment is:

[0113] ASME Ⅸ-2017 "Welding and Brazing Procedures, Welders, Brazers, Welding and Brazing Operators...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com