Method for mounting bottom plates and cylinder of steel lining of nuclear power plant

An installation method and steel lining technology, applied in covering/lining, arc welding equipment, construction, etc., can solve the problems of large amount of steel lining installation welding, affecting weld sealing, wave deformation, etc., to shorten the installation and construction period, High welding efficiency and reduced construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described below with reference to the drawings.

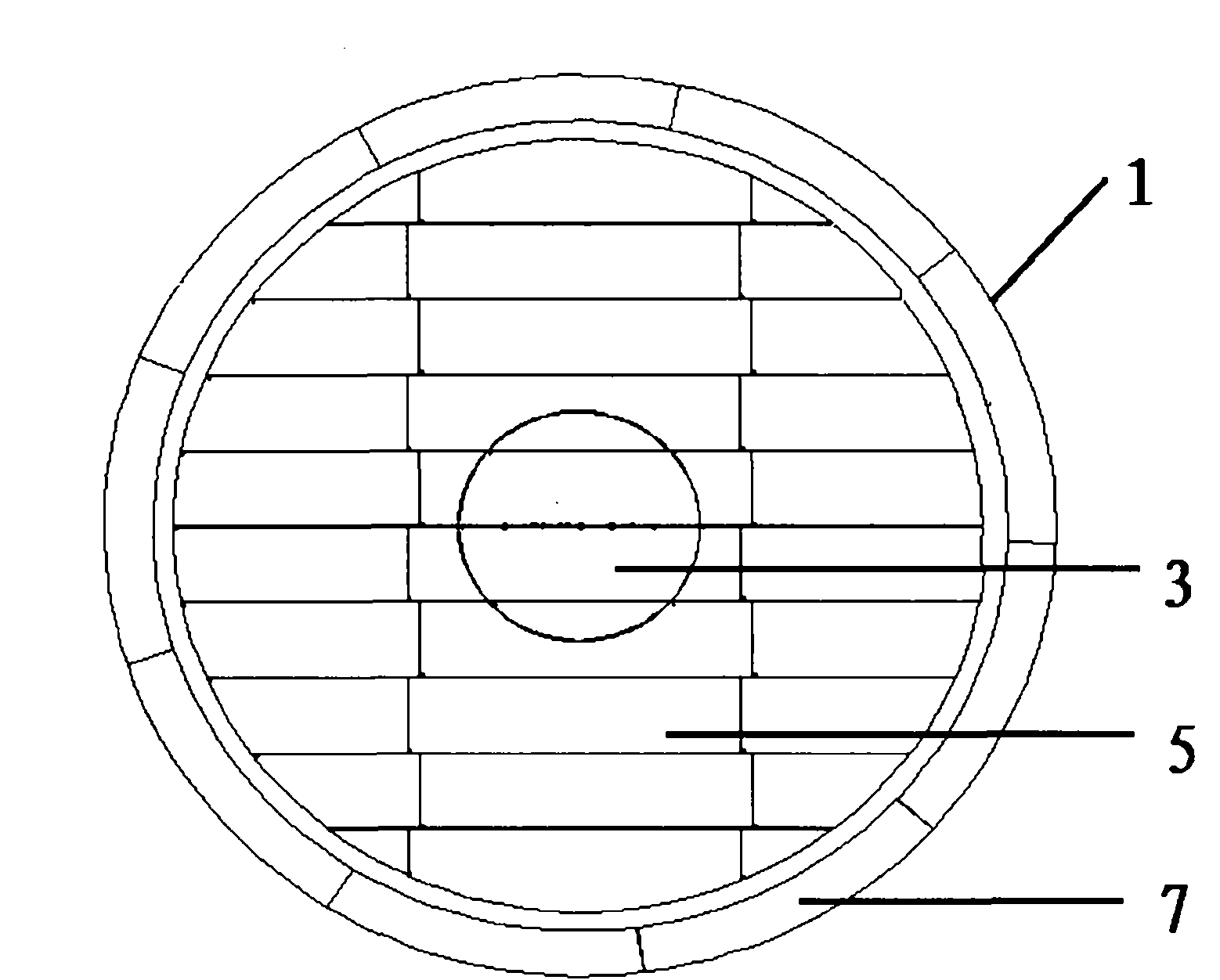

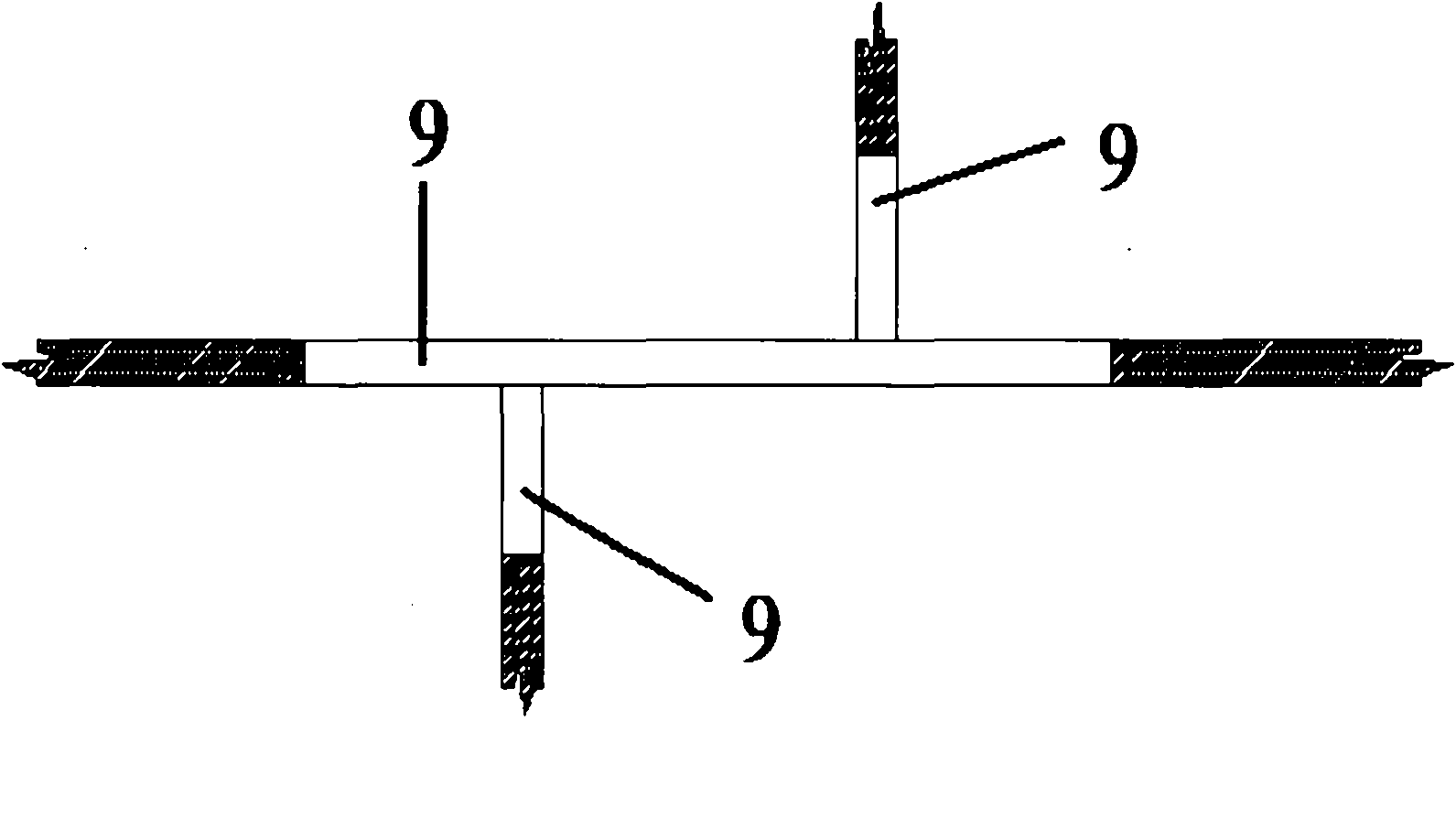

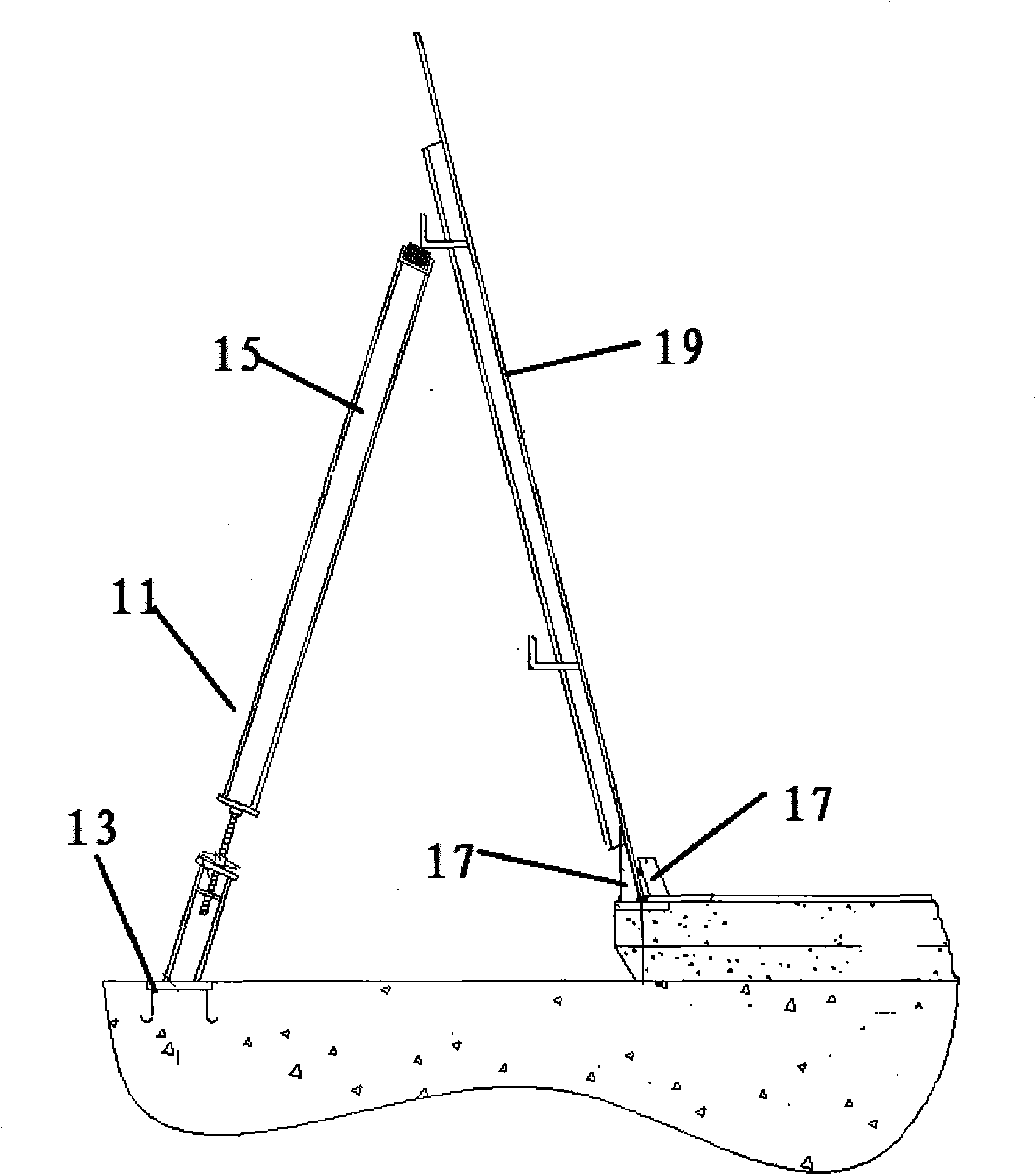

[0034] The steel lining of the nuclear power plant in this embodiment includes a bottom plate 1 and a cylinder, which is subdivided into two parts: a truncated cone 19 and a cylinder wall 21 . Among them, the radius of the steel-lined bottom plate 1 is 17290mm; the radius of the lower mouth of the truncated cone 19 is 17299mm, and the radius of the upper mouth is 18500mm; 11 equally divided prefabricated panels are assembled and welded, and the 6th to 12th floors are assembled and welded by 9 prefabricated panels equally divided along the perimeter, and the height of each layer is 3777.5mm. The steel material of the steel lining is steel plate P265GH for pressure vessels, and the thickness of the steel plate is δ=6mm.

[0035] The steel lining installation process of the present embodiment is as follows:

[0036] Construction preparation → floor support system insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com