Method of eliminating welding residual stress by low temperature compression deformation treatment

A technology of residual stress and compression deformation, applied in the direction of metal processing, etc., can solve the problems such as difficult to guarantee the effect of stress relief, long construction period, multi-energy, etc., and achieve the effect of eliminating welding residual stress, low cost, and small energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

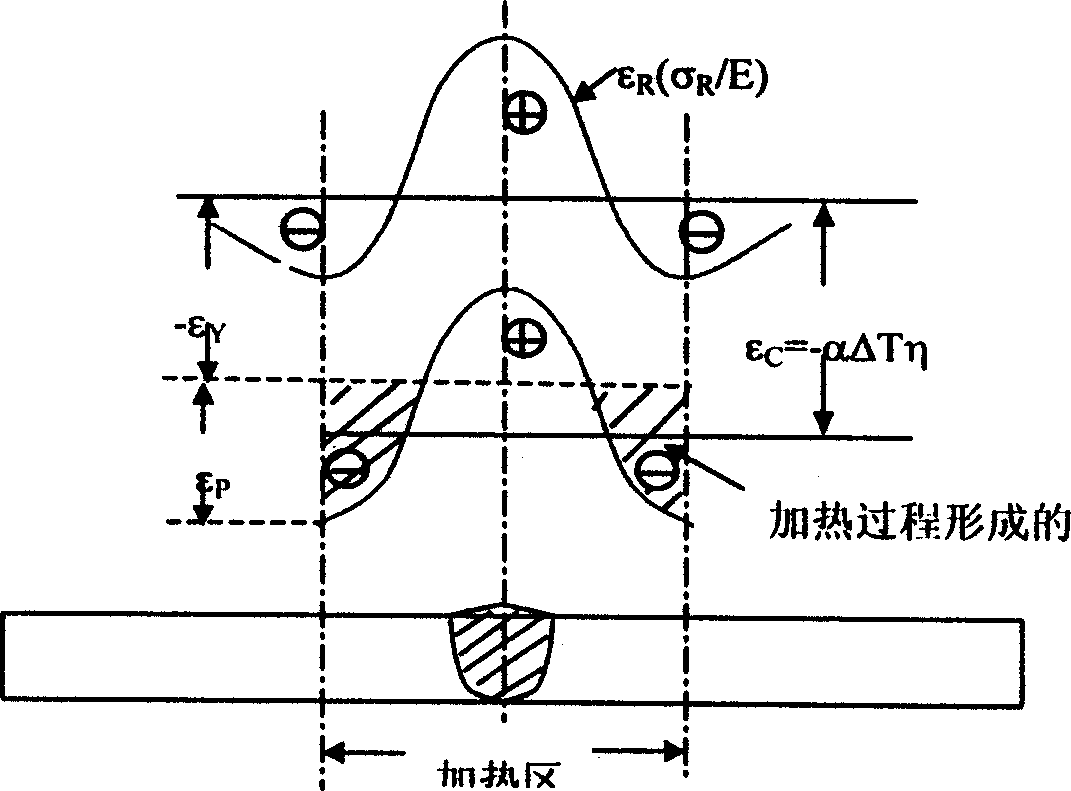

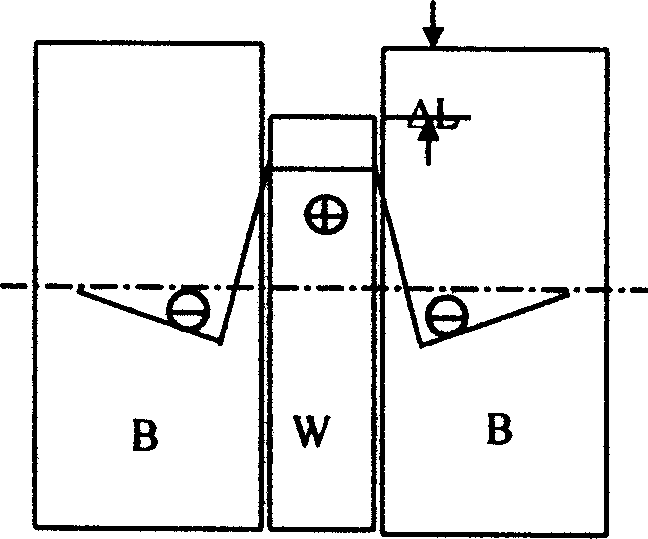

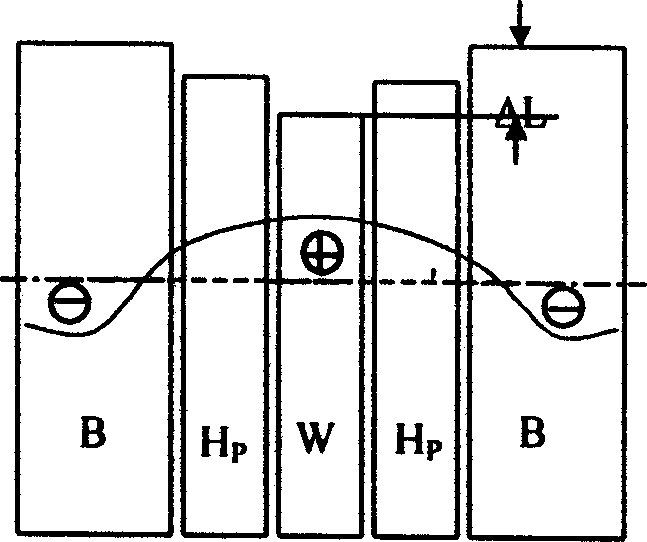

[0016] The present invention aims at welded structural parts made of various thicknesses and made of various materials, and adopts general heating technology to create a certain temperature difference in the limited width area (50-200mm) of the welded joint, so that the residual compressive stress area of the welded joint Produce compressive plastic deformation, so as to achieve the purpose of reducing welding residual stress. Specifically, the welding zone is rapidly heated to a certain temperature (200-400°C, depending on the yield strength of the material) to cause it to expand, and the thermal expansion in the heating zone of the welded joint is constrained by the metal in the adjacent cooler area, resulting in Compressive plastic deformation ε C (See figure 1 ), this deformation is superimposed with the original welding residual stress (given by residual strain εR in the figure), and as a result, the original compressive stress in the heating zone produces plastic comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com