Pipeline sleeve joint welding process

A casing joint and welding process technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve problems such as incomplete cleaning of impurities, fast cooling speed, and excessive current, so as to prevent thermal cracks from occurring and slow down Effect of cooling rate and attenuation of residual tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

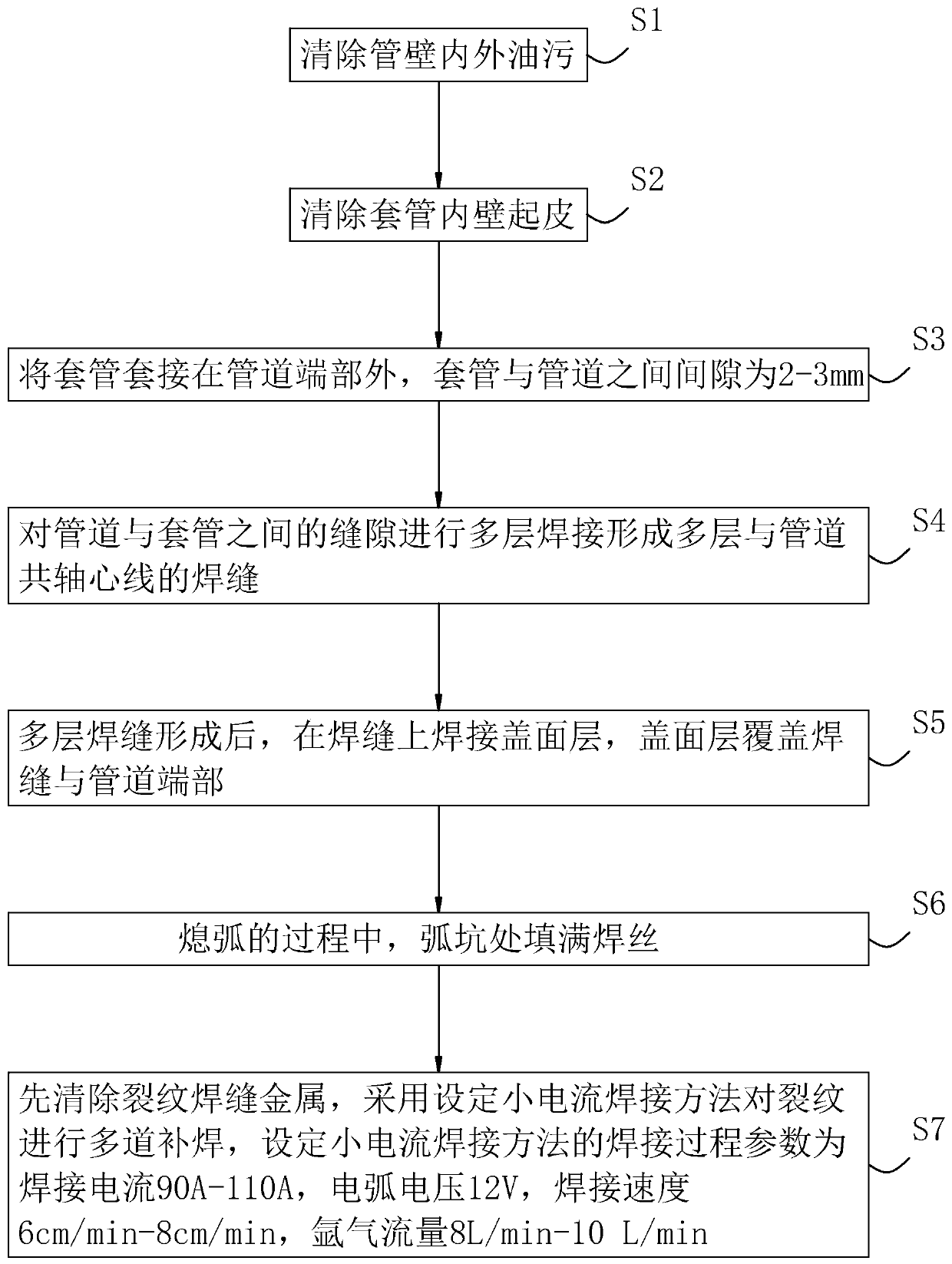

[0038] refer to figure 1 , is a casing joint welding process of a pipeline disclosed by the present invention, comprising the following steps:

[0039] S1: Remove oil stains inside and outside the pipe wall. Remove the oil, dust and other impurities inside and outside the pipe wall of the pipe 1, especially the oil left when the pipe is bent needs to be thoroughly cleaned, otherwise there will be bubbles, impurities, cracks in the weld, and the weld will not meet the standard.

[0040] S2: Remove the peeling on the inner wall of casing 2. Use an angle grinding wheel to remove the peeling phenomenon on the inner wall of the casing 2. If the peeling part cannot be completely removed, replace the casing 2 to prevent the generation of low melting point eutectics.

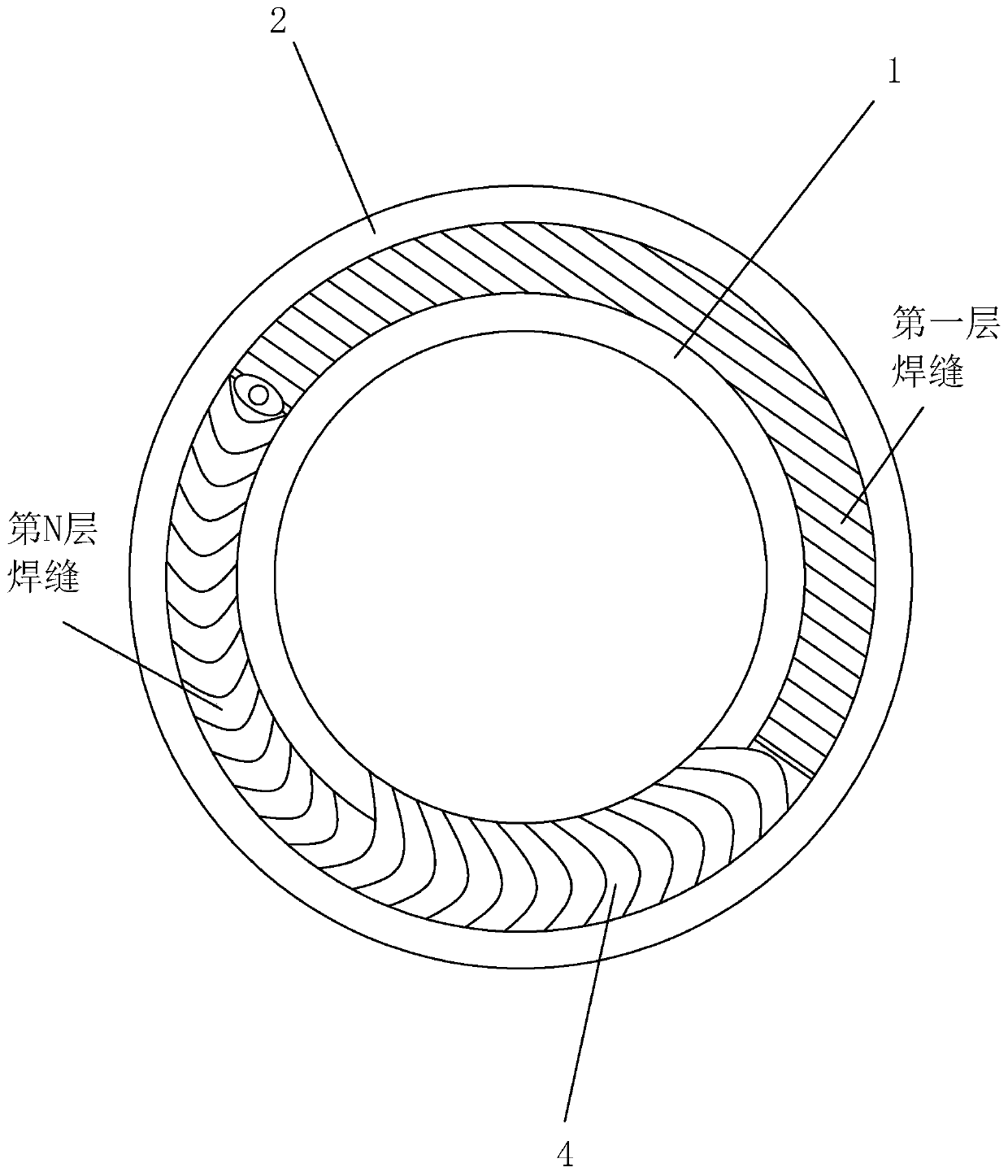

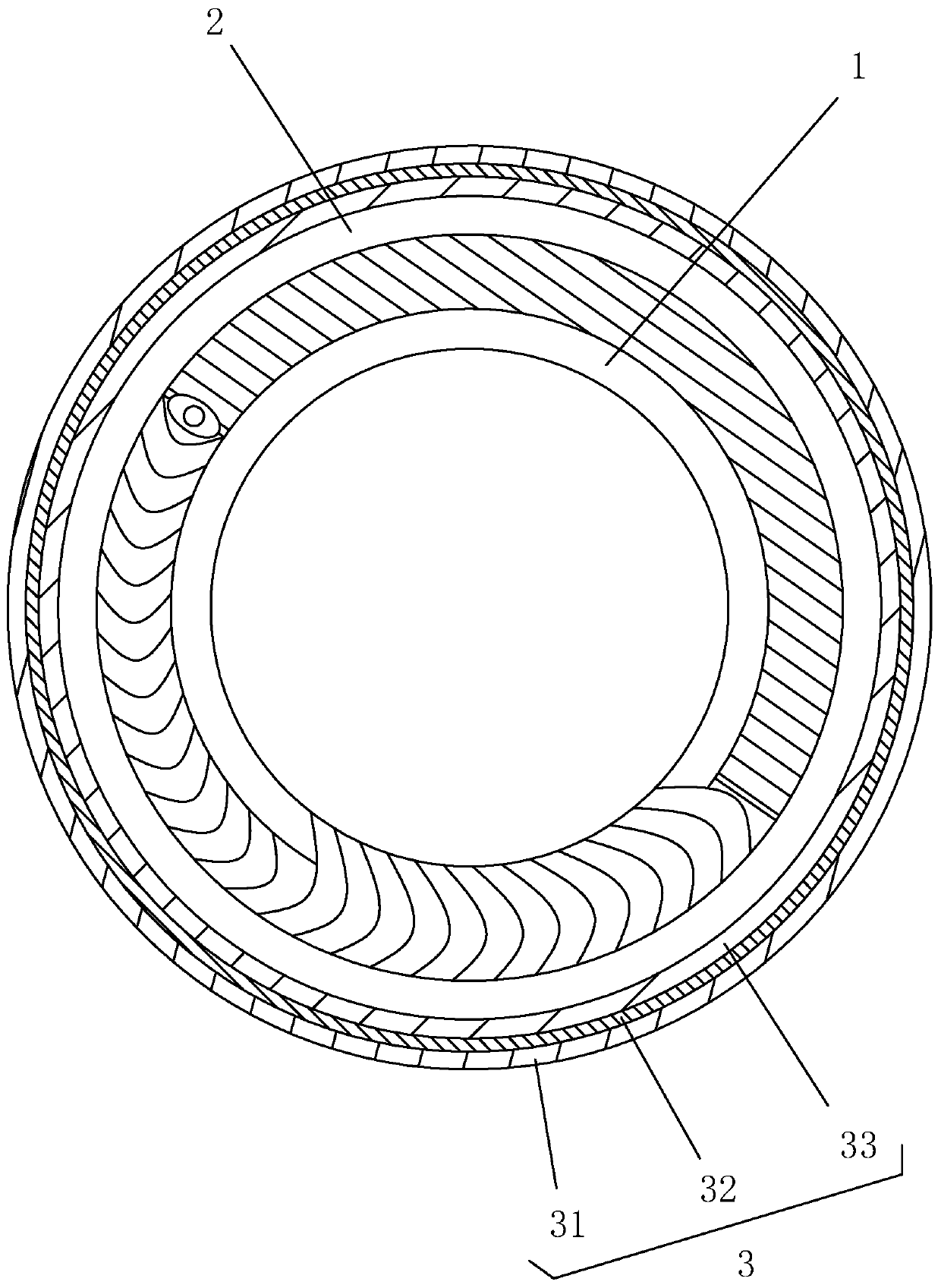

[0041] S3: Sleeve the sleeve 2 outside the end of the pipe 1, and the gap between the sleeve 2 and the pipe 1 is 2mm. Such as figure 2 and image 3 As shown, when welding, a layer of insulation pipe 3 is placed on...

Embodiment 2

[0048] A casing joint welding process for pipes, the difference from Embodiment 1 is that the gap between the casing 2 and the pipe 1 is 2.5mm. The welding process parameters in step S4 are as follows: first layer: welding current 110A, arc voltage 12V, welding speed 7cm / min, argon gas flow 9L / min; other layers: welding current 130A, arc voltage 15V, welding speed 5.5cm / min min, argon flow rate 11L / min. S7: First remove the cracked weld metal, and use the set low current welding method to repair the cracks in multiple passes. The welding process parameters of the low current welding method are set as welding current 100A, arc voltage 12V, welding speed 7cm / min, argon Air flow 9L / min. In multi-pass repair welding, the next repair welding is performed when the temperature after the previous repair welding drops to within 55°C.

Embodiment 3

[0050] A casing joint welding process for pipes, the difference from Embodiment 1 is that the gap between the casing 2 and the pipe 1 is 3 mm. The welding process parameters in step S4 are as follows: first layer: welding current 110A, arc voltage 12V, welding speed 8cm / min, argon gas flow rate 10L / min; other layers: welding current 130A, arc voltage 15V, welding speed 6cm / min , Argon gas flow rate 12L / min. S7: First remove the cracked weld metal, and use the set low current welding method to repair the cracks in multiple passes. The welding process parameters of the low current welding method are set as welding current 110A, arc voltage 12V, welding speed 8cm / min, argon The air flow rate is 10L / min. In multi-pass repair welding, the next repair welding is performed when the temperature after the previous repair welding drops to within 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com