Method for plasma surfacing of cobalt-based alloy in inner hole of cylinder

A plasma stack and cobalt-based alloy technology, applied in plasma welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as easy cracks, reduce dilution, etc., achieve reduced cooling speed, improved wear resistance, and low heat input Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

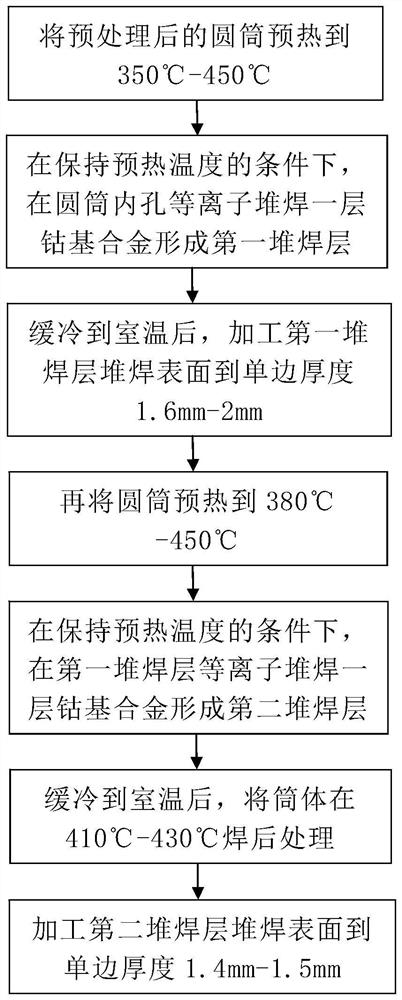

[0034] see figure 1 , a method for plasma overlaying cobalt-based alloys in a cylindrical inner hole provided by an embodiment of the present invention includes the following steps:

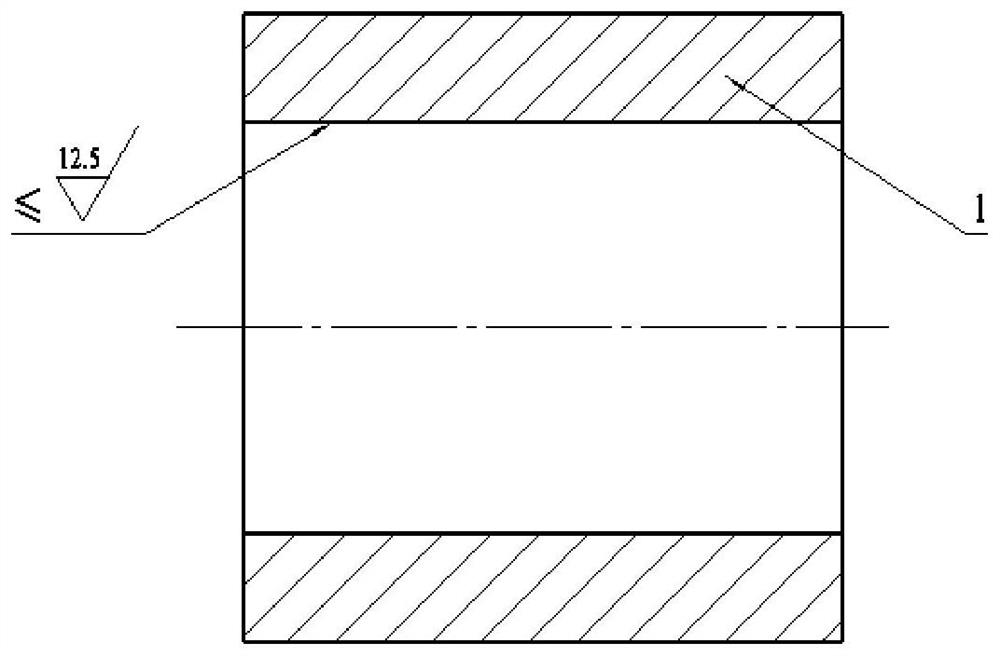

[0035] Step 1) Preheat the cylinder to 350°C-450°C in order to reduce the cooling rate after welding and avoid cracks. Among them, the cylinder is made of austenitic stainless steel, and the surface roughness of the inner hole is ≤12.5. Before preheating the cylinder, use alcohol to clean the surface of the inner hole of the cylinder to ensure that there is no foreign matter such as rust and oil on the surface that affects the welding quality, and to avoid defects such as pores in the weld metal.

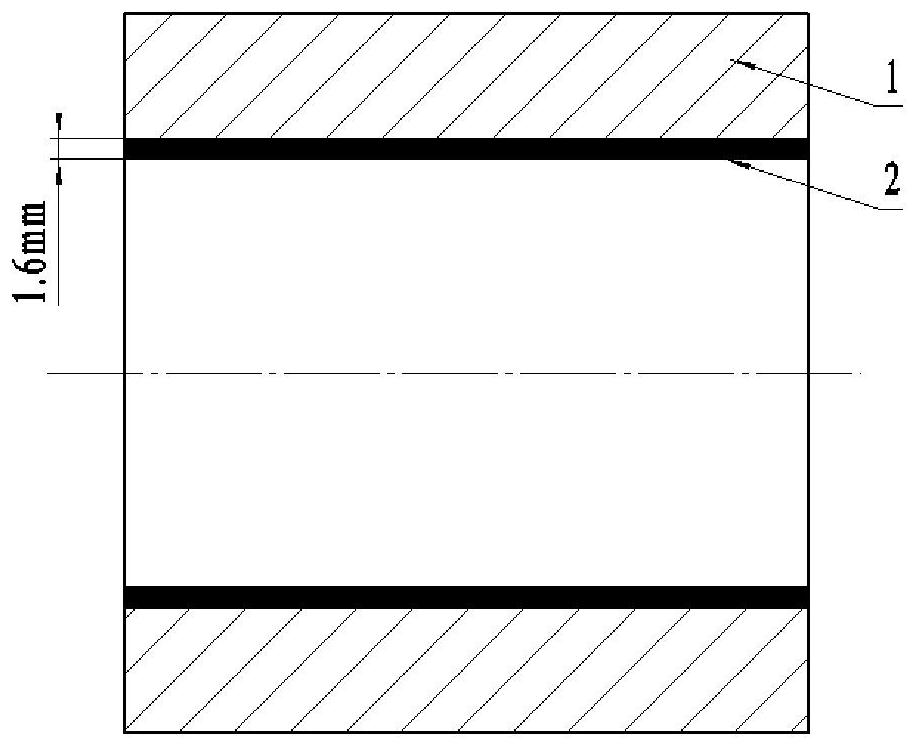

[0036] Step 2) Under the condition of maintaining the preheating temperature, a layer of cobalt-based alloy is plasma surfacing on the inner hole of the cylinder to form a first surfacing layer.

[0037] Among them, the process of surfacing the first surfacing layer includes:

[0038] The welding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com