Iron-based amorphous-nanocrystal composite coating and preparation method thereof

A nanocrystalline composite, iron-based amorphous technology, applied in coatings, metal material coating processes, etc., can solve the problems of low amorphous content of coatings, poor corrosion resistance of coatings, and reduced corrosion resistance of coatings. , to achieve the effect of strong amorphous formation ability, improved corrosion resistance and improved organizational uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

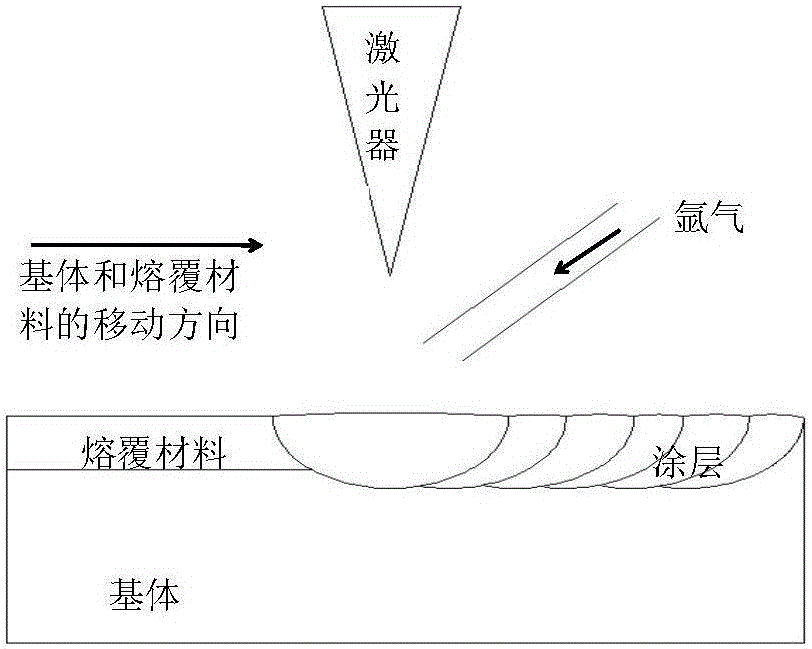

Method used

Image

Examples

Embodiment 1

[0053] 20 grams each of the six raw materials of Fe-C, Fe-B, Fe-Cr, Co, Mo and Y were placed on the copper mold in the vacuum furnace. The components of these six raw materials are shown in Table 1. First vacuum the vacuum furnace to 1×10 -2 Pa, after changing high-purity argon for 3 times, adjust the vacuum to 1×10 -1 Pa, carry out the smelting of the alloy, in order to make the alloy smelting evenly, repeat the smelting 3 times, turn over the alloy at the end of each smelting, adopt the mode of cooling with the furnace to lower the temperature, and obtain the composition of Fe 44.5 co 8.5 Cr 14 Mo 26 C 3 B 1 Y 3 smelting alloys. The obtained smelted alloy was cut into 20mm×20mm×0.2mm samples, and 2mm thick low-carbon alloy steel was selected as the base material.

[0054] Sandpaper is used to grind the surface of the smelted alloy sample and the low-carbon alloy steel, after removing the oxide layer on the surface, cleaning with absolute ethanol and drying to obtain ...

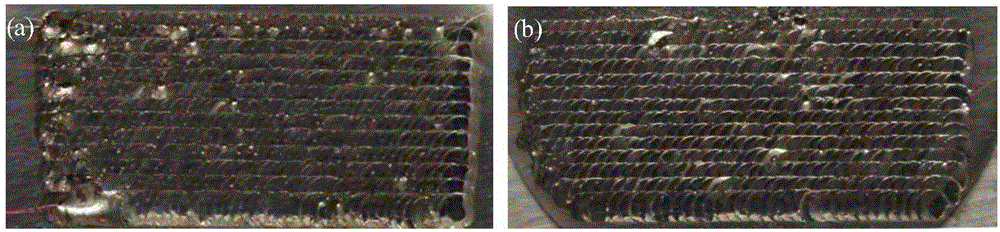

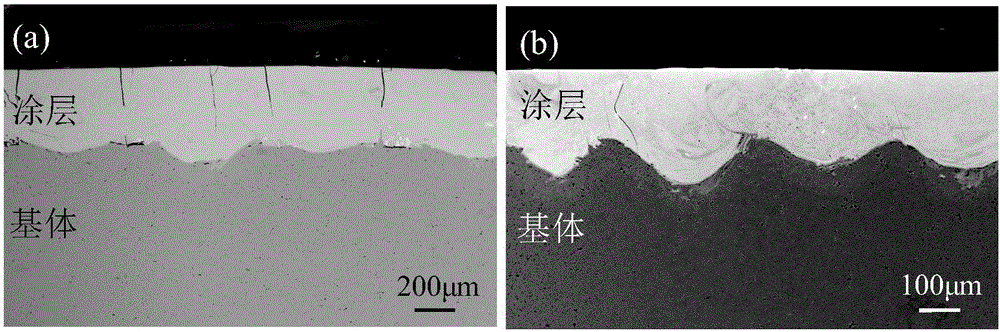

Embodiment 2

[0061] The smelted alloy is prepared in the same manner as in Example 1, the obtained smelted alloy composition is consistent with the alloy composition in Example 1, and the composite coating is obtained by smelting in the same manner as in Example 1. The difference with Example 1 is that the laser During the cladding process, the laser power is 19.2w, the pulse frequency is 0.5Hz, the pulse width is 5.0ms, and the laser energy density is 104J / mm 2 , the pulse energy is 7.3J, the cladding rate is limited to 0.3mm / s, and the superposition rate is 50%.

Embodiment 3

[0063] The smelted alloy is prepared in the same manner as in Example 1, the obtained smelted alloy composition is consistent with the alloy composition in Example 1, and the composite coating is obtained by smelting in the same manner as in Example 1. The difference with Example 1 is that the laser During the cladding process, the laser power is 19.2w, the pulse frequency is 1.0Hz, the pulse width is 5.0ms, and the laser energy density is 104J / mm 2 , the pulse energy is 7.3J, the cladding rate is limited to 0.3mm / s, and the superposition rate is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com