Composite wave-absorbing material suitable for marine environment and preparation method thereof as well as application

A composite wave absorbing material, marine environment technology, applied in metal material coating process, antenna, coating and other directions, can solve the problem of iron-based alloy material unfavorable corrosion resistance, difficult to adapt to wave absorbing material thin, light, wide, strong Development trend and other issues, to achieve the effect of good amorphous formation ability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

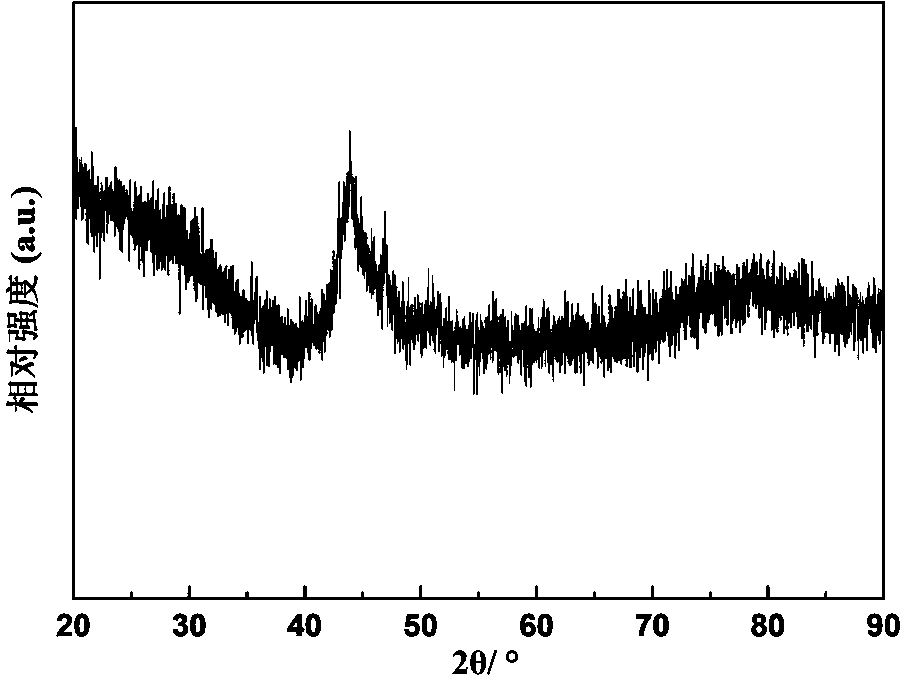

Method used

Image

Examples

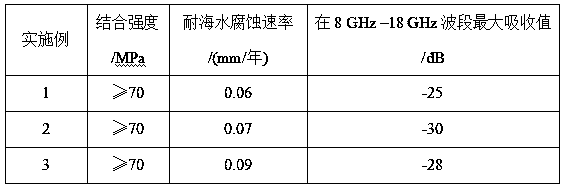

Embodiment 1

[0024] A composite wave-absorbing material suitable for marine environments, comprising iron-based amorphous and hexagonal BCN, wherein the iron-based amorphous content is 95 wt%, and the hexagonal BCN content is 5 wt%; the iron-based amorphous comprises the following components, The specific weight percentages are as follows: 27wt% Cr, 4wt% B, 4wt% Si, 5wt% Cu, 7wt% Ni, 8wt% Mo, and the balance is Fe; the hexagonal BCN is a single-layer structure hexagonal BCN, a double-layer structure hexagonal BCN And at least one of the three-layer structure hexagonal BCN.

[0025] Composite absorbing material is made by the following steps:

[0026] (1) According to the above-mentioned iron-based amorphous composition and weight ratio, weigh a certain amount of low-carbon ferrochrome, high-carbon ferrochrome, ferroboron, ferrosilicon, electrolytic copper, electrolytic nickel, ferromolybdenum and pure iron (including low-carbon chromium The content ratio of iron and high-carbon ferrochrom...

Embodiment 2

[0035] A composite wave-absorbing material suitable for marine environments, comprising iron-based amorphous and hexagonal BCN, wherein the iron-based amorphous content is 90 wt%, and the hexagonal BCN composition is 10 wt%; the iron-based amorphous comprises the following components, The specific weight percentages are as follows: 27wt% Cr, 4wt% B, 4wt% Si, 5wt% Cu, 7wt% Ni, 8wt% Mo, and the balance is Fe; the hexagonal BCN is a single-layer structure hexagonal BCN, a double-layer structure hexagonal BCN And at least one of the three-layer structure hexagonal BCN.

[0036] The preparation method of the iron-based amorphous, the application and construction method of the composite wave-absorbing material in the coating in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0038] A composite wave-absorbing material suitable for marine environments, comprising iron-based amorphous and hexagonal BCN, wherein the iron-based amorphous content is 85 wt%, and the hexagonal BCN composition is 15 wt%; the iron-based amorphous contains the following components, The specific weight percentages are as follows: 27wt% Cr, 4wt% B, 4wt% Si, 5wt% Cu, 7wt% Ni, 8wt% Mo, and the balance is Fe; the hexagonal BCN is a single-layer structure hexagonal BCN, a double-layer structure hexagonal BCN And at least one of the three-layer structure hexagonal BCN.

[0039] The preparation method of the iron-based amorphous, the application and construction method of the composite wave-absorbing material in the coating in this embodiment are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com