A high thermal stability iron-based amorphous coating and its preparation method

A high thermal stability, iron-based amorphous technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problem of losing the properties of amorphous metal materials, achieve thermal stability, wide application Foreground, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

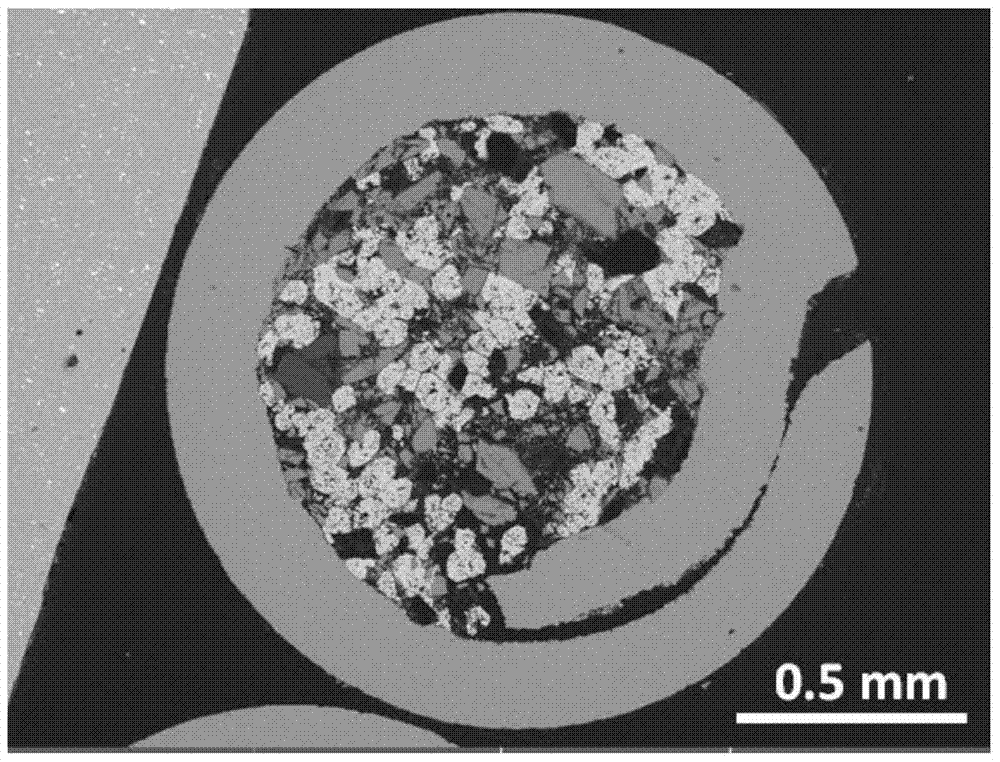

[0036] According to the following proportions: Fe: 50.2%; Cr: 21.5%; Mo: 19.4%; B: 4.0%; C: 3.0%; Si: 1.5%; According to the filling rate of 35.6%, it is loaded into a FeCr alloy U-shaped groove with a width of 1 mm and a thickness of 0.3 mm, clad and rolled to finally form a powder core wire with a diameter of 2 mm. The cross-sectional microstructure of powder core wire is as follows: figure 1 shown. The different components in the powder core are mixed evenly and tightly combined with the skin.

[0037] Carry out sandblasting treatment on the TP91 substrate, keep the distance of sandblasting at about 300cm, and control the air pressure at about 0.5MPa. When sandblasting occurs, sparks appear and metallic luster appears, and sandblasting is completed. After sandblasting, use a wire brush to remove sand particles embedded in the surface.

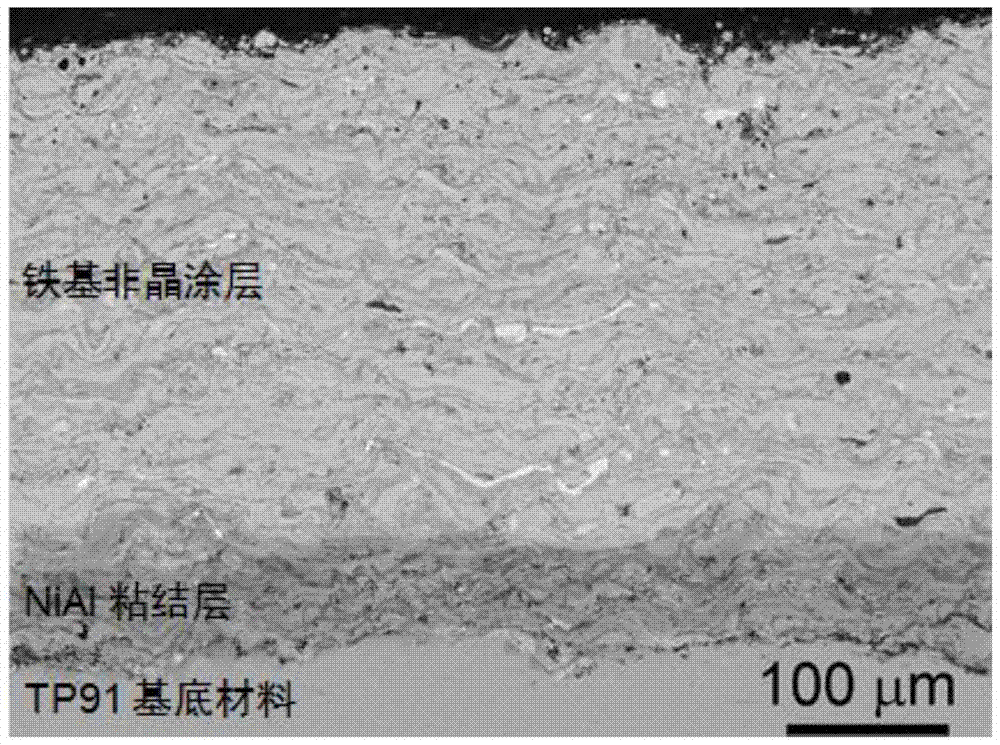

[0038] Then arc spraying is used to prepare a NiAl primer layer on the sandblasted base material with commercial NiAl wire as the raw ma...

Embodiment 2

[0042] According to the following proportions: Fe: 50.2%; Cr: 22.5%; Mo: 17.2%; B: 5.0%; C: 4.0%; Si: 0.7%; According to the filling rate of 35.6%, it is loaded into a FeCr alloy U-shaped groove with a width of 1 mm and a thickness of 0.3 mm, clad and rolled to finally form a powder core wire with a diameter of 1.6 mm.

[0043] The 304 stainless steel substrate is sandblasted, the sandblasting distance is kept at about 300cm, the air pressure is controlled at about 0.5MPa, sparks appear during sandblasting and metallic luster appears, and the sandblasting is completed. After sandblasting, use a wire brush to remove sand particles embedded in the surface. Then arc spraying is used to prepare a NiAl primer layer on the sandblasted base material with commercial NiAl wire as the raw material. The coating thickness is about 100 μm. Spraying parameters: the distance between the spray gun and the substrate surface: 200mm; voltage: 30V, current : 220A, air pressure: 0.55MPa, spray gu...

Embodiment 3

[0046] According to the following proportions: Fe: 52.0%; Cr: 19.3%; Mo: 17.2%; B: 5.0%; C: 4.0%; Si: 2.0%; According to the filling rate of 35.6%, it is loaded into a FeCr alloy U-shaped groove with a width of 1 mm and a thickness of 0.3 mm, clad and rolled to finally form a powder core wire with a diameter of 2.0 mm.

[0047] For the 6063 aluminum alloy base material used in automobile engines, 24# stone sand is selected for sand blasting, the sand blasting distance is kept at about 300cm, and the air pressure is controlled at about 0.4MPa. After sandblasting, use a wire brush to remove sand particles embedded in the surface. The iron-based amorphous coating was prepared by arc spraying and the powder core wire prepared by our institute was used as raw material. Spraying parameters are as follows: distance between spray gun and substrate surface: 200mm; voltage: 30V, current: 220A, air pressure: 0.55MPa, spray gun moving speed: 600mm / s, coating thickness: 270μm.

[0048] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com