Method for reinforcing rail by laser and auxiliary heat source efficient hybrid cladding

a technology of laser and auxiliary heat source, applied in the field of material processing, can solve the problems of rail wear, rail corrosion, rolling contact fatigue, etc., and achieve the effects of reducing the cooling rate, avoiding cracking and spalling of the metal cladding coating, and reducing the temperature gradien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

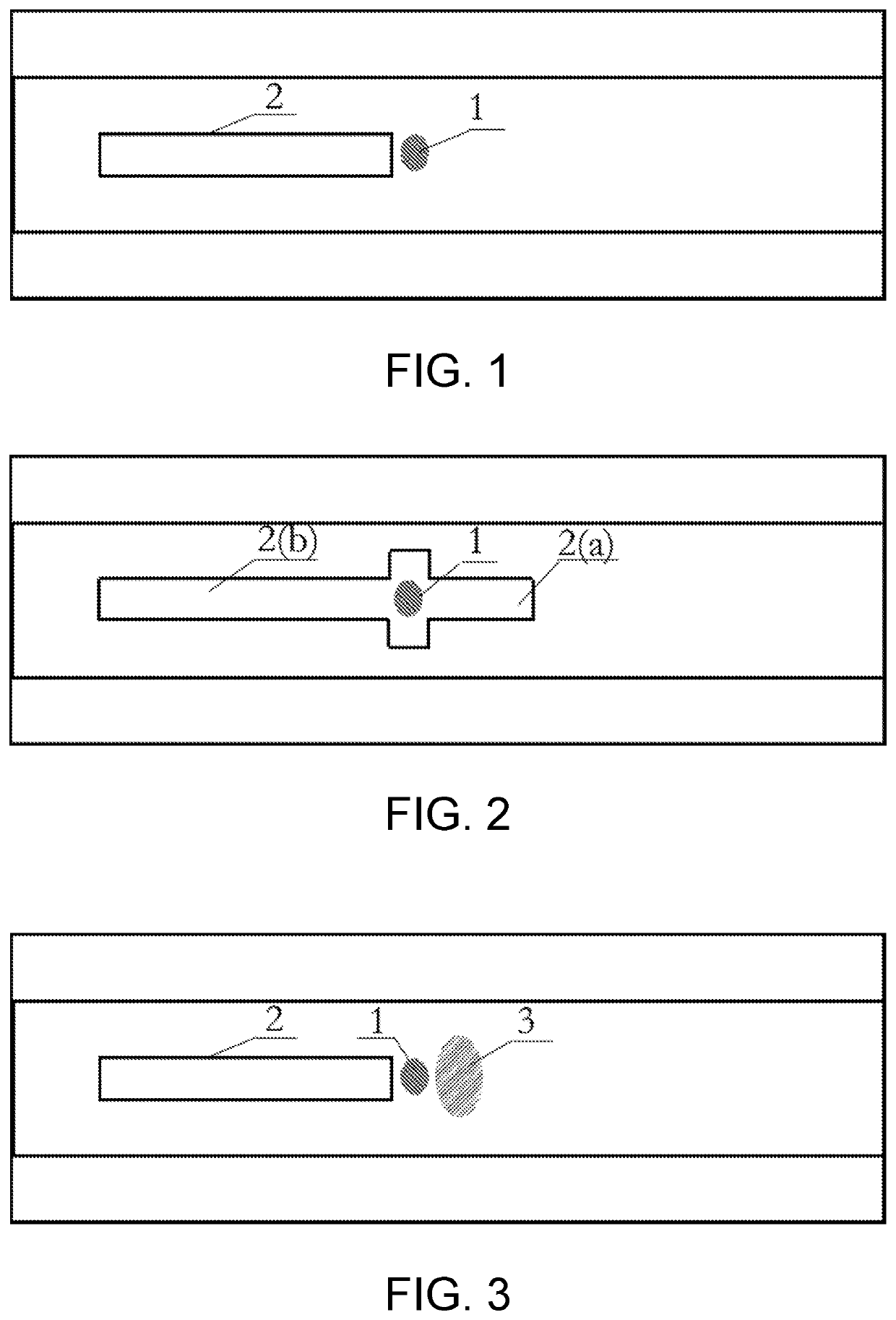

[0048] on-line laser and induction post-heating efficient hybrid cladding at the railway site

[0049]In this embodiment, the service rail is efficiently reinforced or repaired at the railway site, in which induction heating acts as an auxiliary heat source, and an industrial manipulator or a three-dimensional motion axis is used as a machining motion and position control unit. A region to be cladded of a rail surface is heated with the heating temperature and time controlled by an induction heating device and a temperature control part. The induction heating device includes an induction power supply and an induction coil, and the temperature control part includes an infrared thermometer and a temperature controller, in which the induction coil is connected to the induction power supply, the infrared thermometer is connected to the temperature controller, and the temperature controller is connected to the induction power supply via a data line. A detection signal of the infrared thermo...

embodiment 2

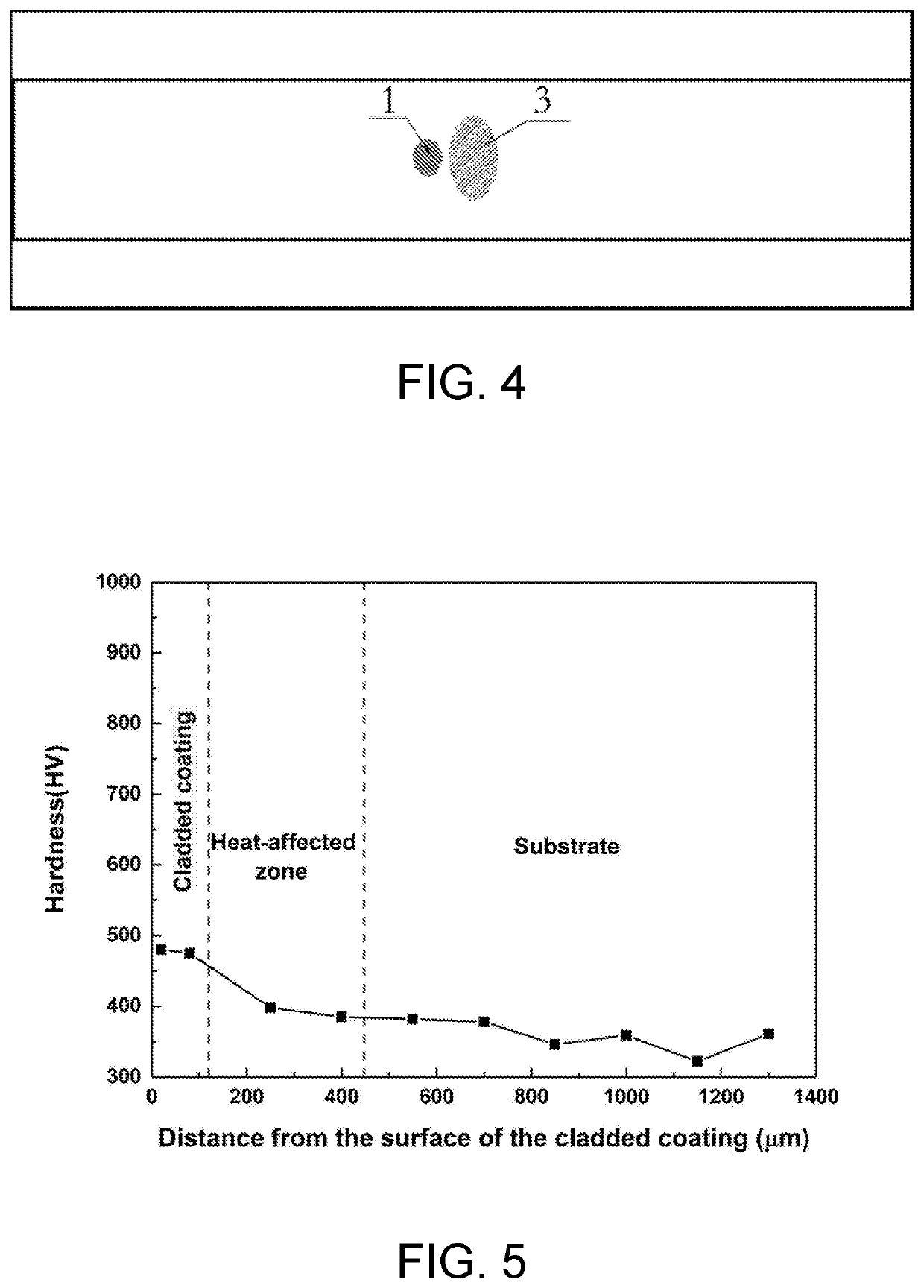

[0059]Embodiment 2: on-line laser, induction preheating and induction post-heating efficient hybrid cladding at the railway site

[0060]In this embodiment, the service rail is efficiently reinforced or repaired at the railway site, in which induction heating acts as an auxiliary heat source, the induction heating control part is the same as that in Embodiment 1, and an industrial manipulator or a three-dimensional motion axis is used as a machining motion and position control unit. The laser spot is focused in the middle of the induction coil, as shown in FIG. 2. Basic implementation steps for preparing a metal cladded coating on a rail surface by laser, induction preheating and induction post-heating hybrid cladding are as follows.

[0061](1) Select nickel-based alloy powder as cladding material, the main chemical compositions (Wt. %) of which are: (0.01-0.50) C, (20-30) Cr, (5-10) W, (3-5) Si, (0-3) B, (5-10) Fe and Ni balance.

[0062](2) Polish a region to be cladded of a rail surface ...

embodiment 3

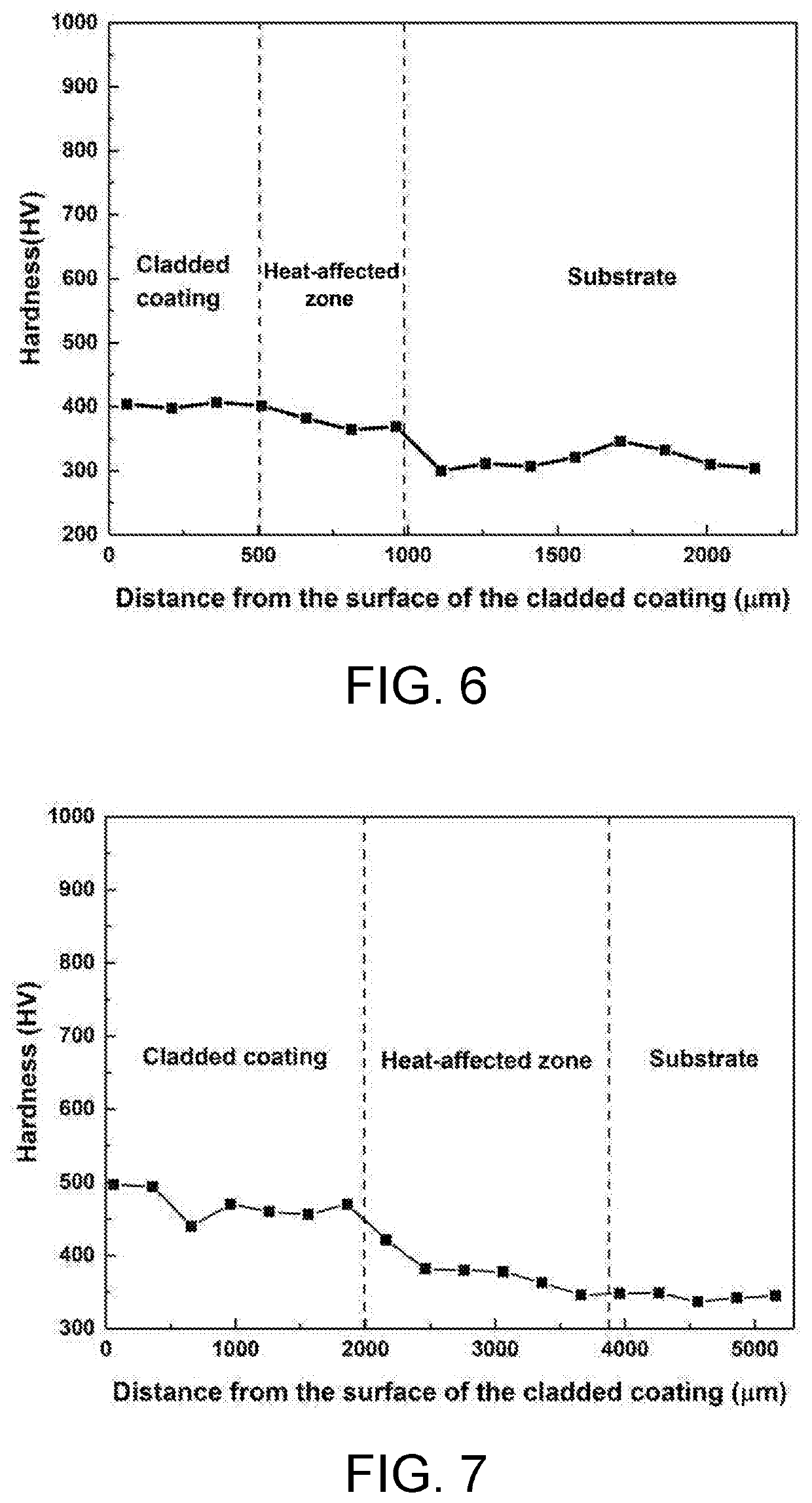

[0070] off-line laser, induction heating and oxyacetylene flame (or propane torch) heating efficient hybrid cladding on a rail surface

[0071]In this embodiment, off-line reinforcement or repair is performed on the rail, in which induction heating and oxyacetylene flame (or propane torch) act as the auxiliary heat source. The laser spot is focused in front of the induction coil, and the oxyacetylene flame (or propane torch) preheats a rail surface to be cladded, as shown in FIG. 3. The laser and the induction coil move in the same direction at the same speed, and the induction heating synchronously preheats the laser molten pool and the heat-affected zone of the rail. The basic implementation steps are as follows:

[0072](1) Select cobalt-based alloy powder as cladding material, the main chemical compositions (Wt. %) of which are: (0.01-0.5) C, (20-35) Cr, (1-10) Ni, (1-3) Si, (5-15) W, (0-3) B, (0.5-2) Mn and Co balance.

[0073](2) Polish a region to be cladded of a rail surface to remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com