Welding process method suitable for large-section medium-thickness plate box column

A welding process and large-section technology, applied in welding media, welding equipment, welding equipment, etc., can solve problems such as inappropriateness, improve welding quality, prevent defects such as cracks, and improve the first pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

[0031] A welding process suitable for large-section medium-thick plate box columns, comprising the following steps:

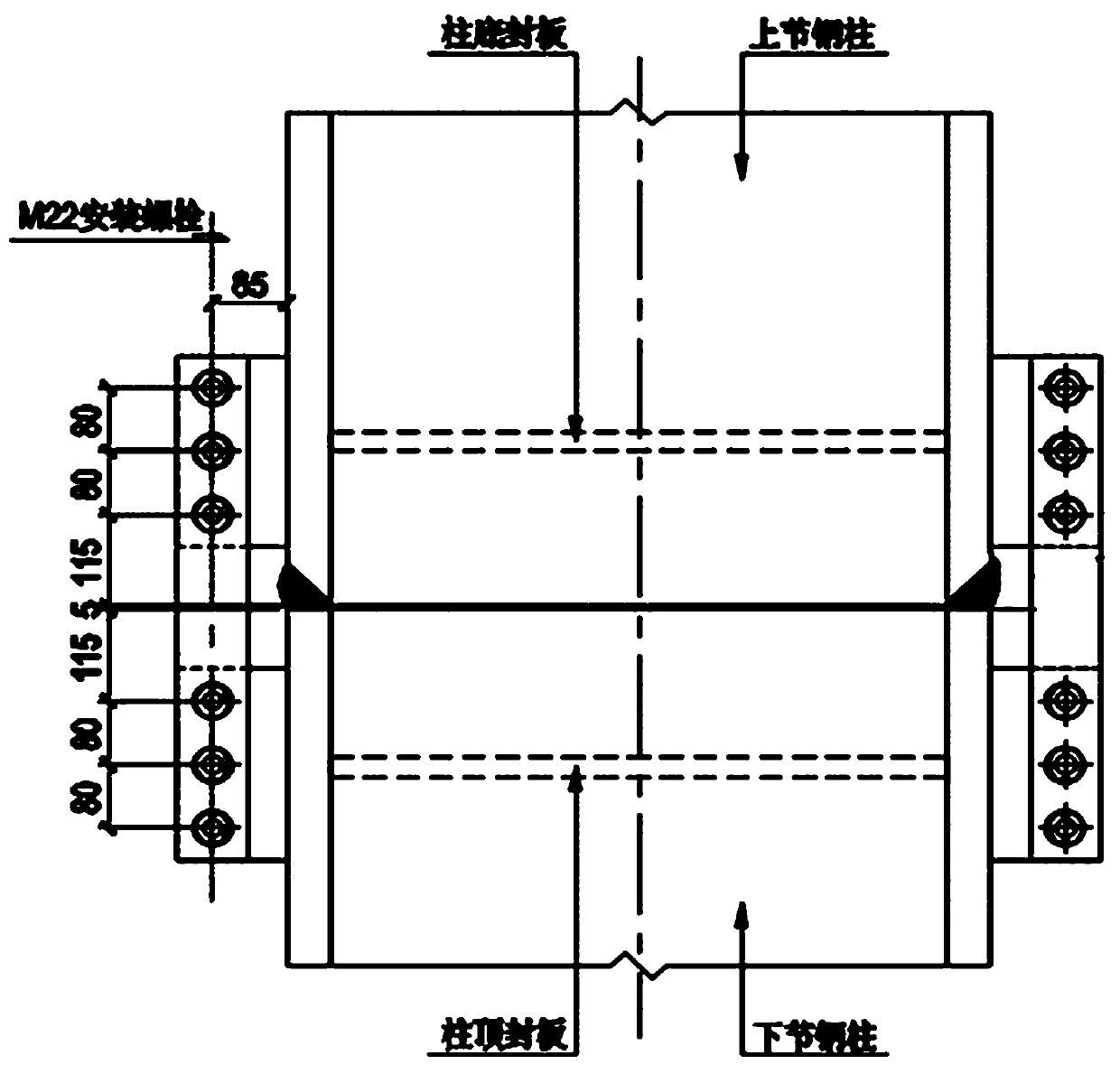

[0032] Step (1) The general principle to be followed in welding: the welding of the four outer box butt transverse joints of the upper and lower columns of the box-shaped column and the cross-shaped butt joint transverse joints in the cavity generally follow the internal and external, front and rear, left and right symmetry, and the same direction and the same specification The principle of welding.

[0033] Step (2) Welding sequence and section division:

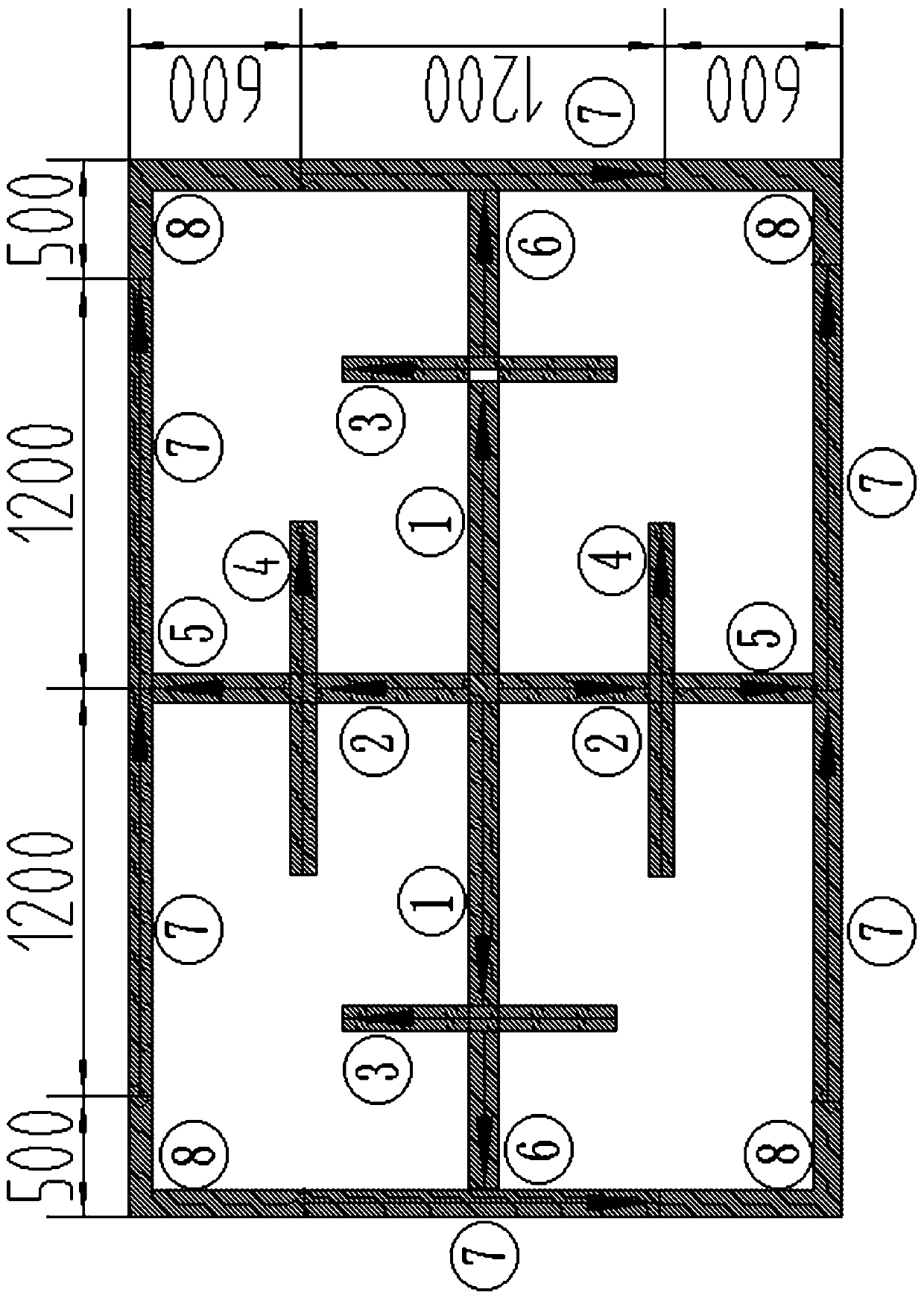

[0034] A. If figure 1As shown, first divide the welding area into eight sections, which are ① section, ② section, ③ section, ④ section, ⑤ section, ⑥ section, ⑦ section and ⑧ section, and the welding sequence Section ①→section ②→section ③→section ④→section ⑤→section ⑥→section ⑦→section ⑧, where ①-⑥ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com