Patents

Literature

65 results about "Gunmetal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gunmetal, also known as red brass in the United States, is a type of bronze – an alloy of copper, tin, and zinc. Proportions vary but 88% copper, 8–10% tin, and 2–4% zinc is an approximation. Originally used chiefly for making guns, it has largely been replaced by steel. Gunmetal, which casts and machines well and is resistant to corrosion from steam and salt water, is used to make steam and hydraulic castings, valves, gears, statues, and various small objects, such as buttons. It has a tensile strength of 221 to 310 MPa, a specific gravity of 8.7, a Brinell hardness of 65 to 74, and a melting point of around 1,000 degrees Celsius.

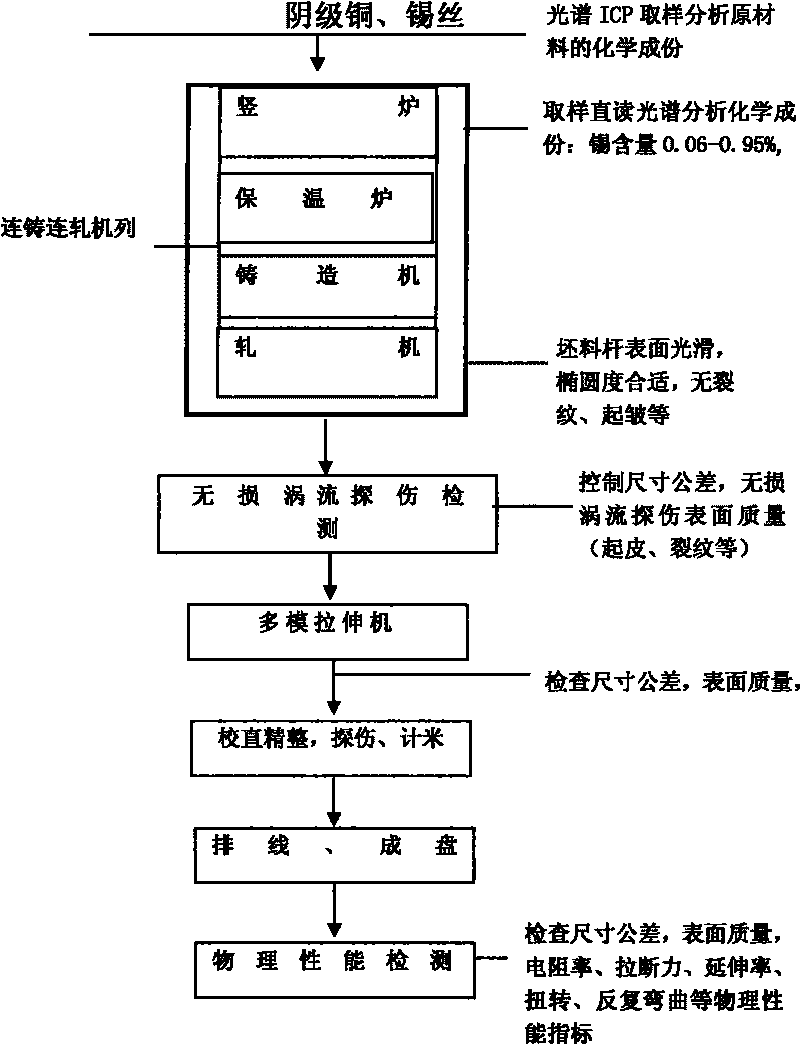

Low tin-copper alloy contact wire for electric railway and manufacturing method thereof

ActiveCN101763910AHigh strengthHigh softening temperatureSingle bars/rods/wires/strips conductorsSpoked wheelsContact wireCopper alloy

The invention relates to a low tin-copper alloy contact wire for an electric railway, which is a tin-copper alloy comprising the following components in parts by weight percent: 0.06-0.97% of tin, less than or equal to 0.10% of impurities and balance of copper. In the manufacturing method of the invention for protecting the low tin-copper alloy contact wire, cast bars the sectional areas of which are 2300mm<2> are used as initial raw materials, and the cast bars are machined by hot rolling for 4-12 times to obtain intermediate blank rods the diameters of which are 25-32mm; the machining rate in each time is 12-25%; and the low tin-copper alloy contact wire comprises the following materials in parts by weight percent: 0.06-0.97% of tin, less than or equal to 0.10% of impurities and the balance of copper. The low tin-copper alloy contact wire fills up the domestic blank, has excellent comprehensive performance indexes and has better economic value and social value.

Owner:沈阳北恒新材料有限公司

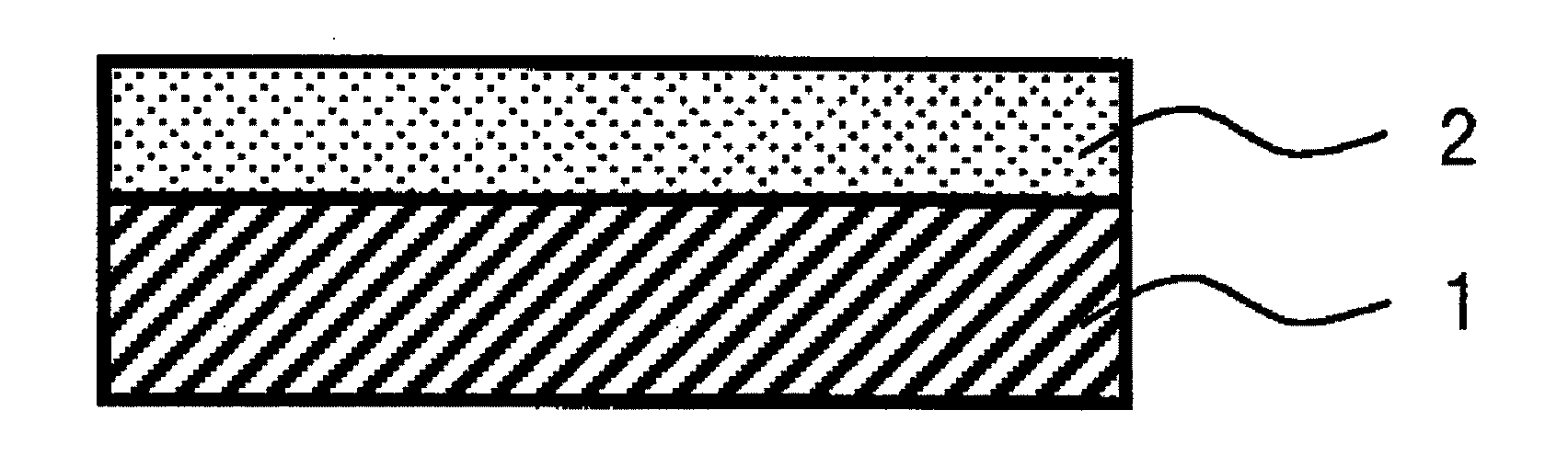

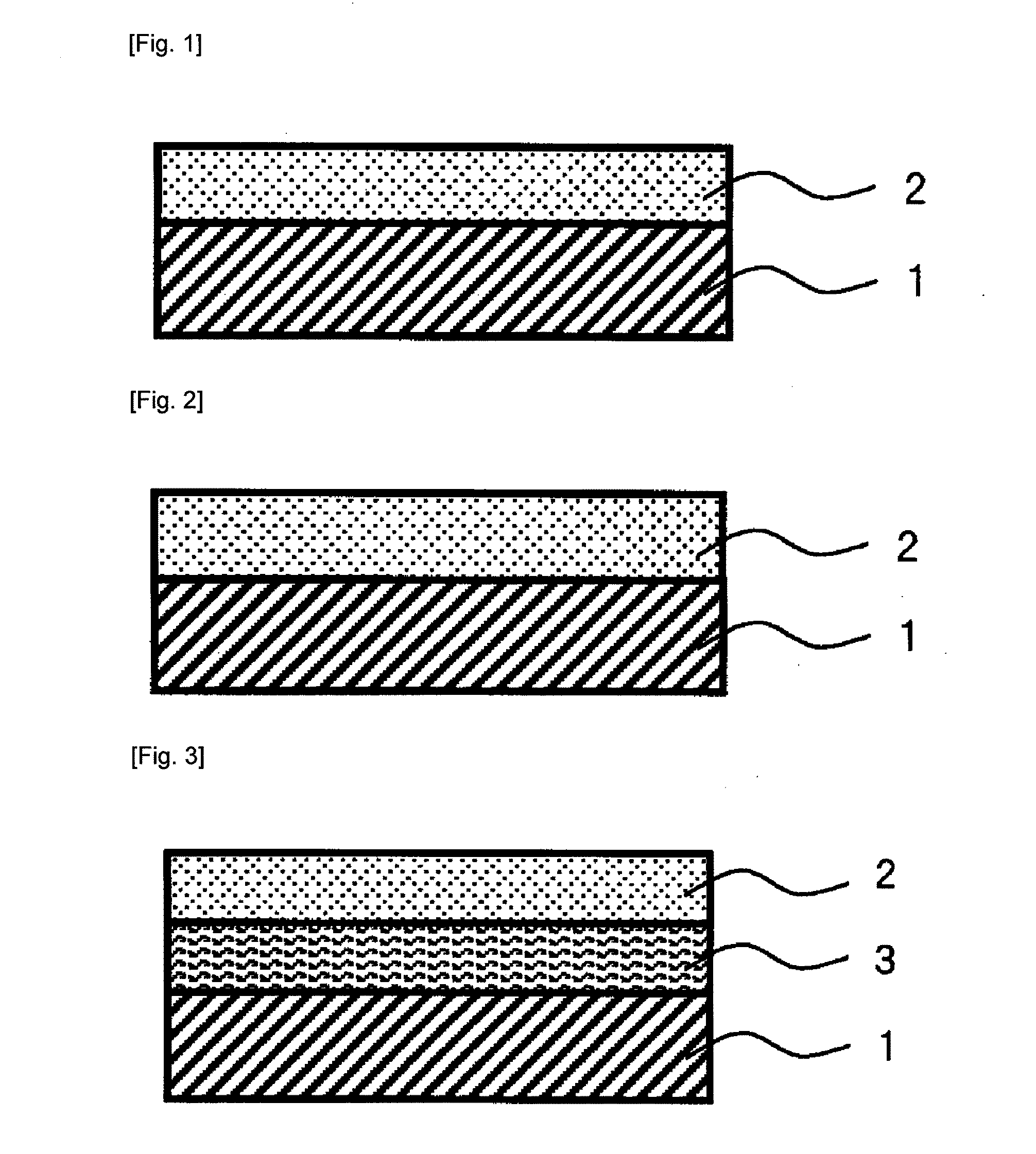

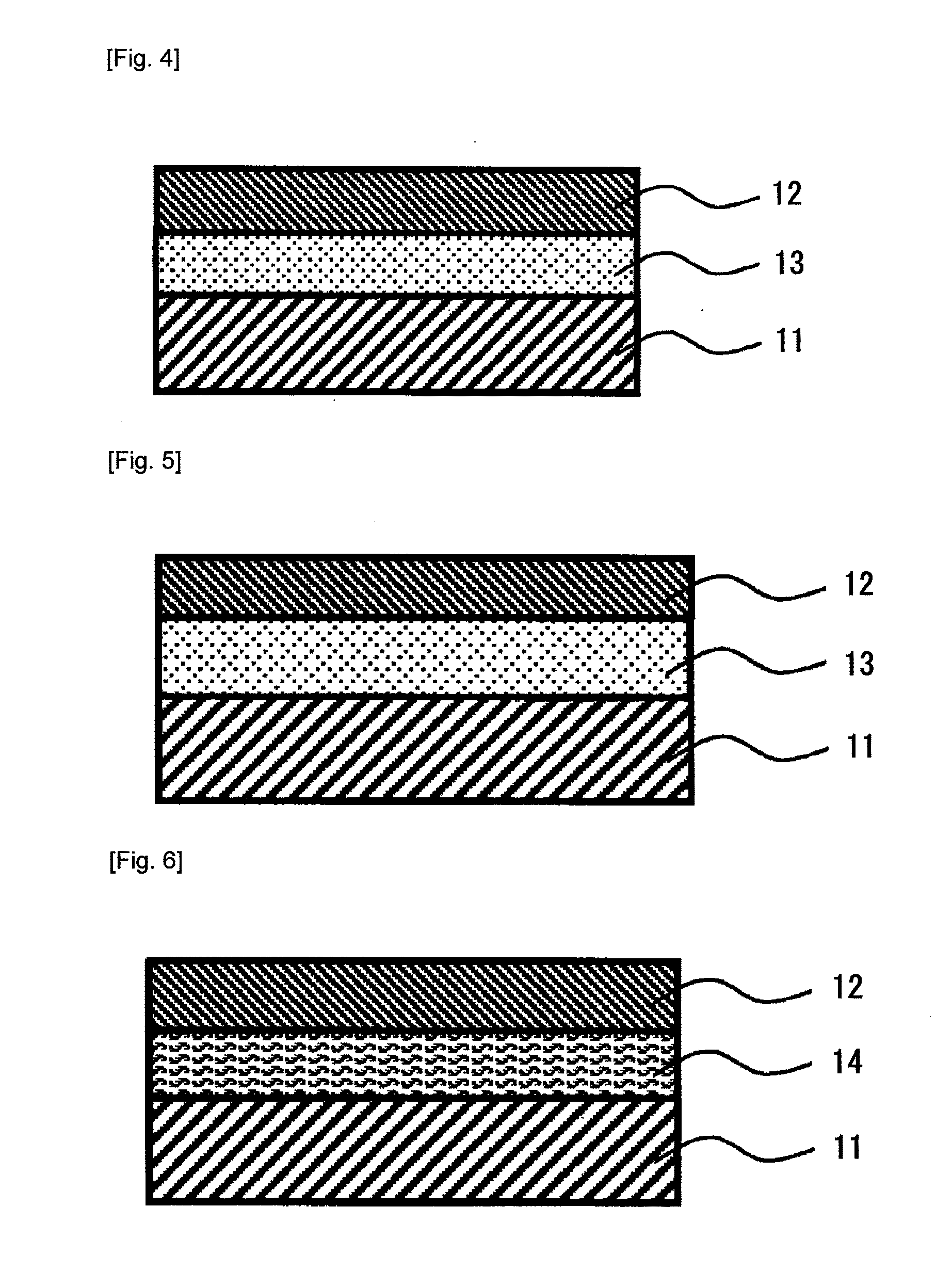

Metallic material for a connecting part and a method of producing the same

InactiveUS20110020664A1Sufficient glossConductive materialVacuum evaporation coatingIndiumMetallic materials

A metallic material for a connecting part, having a rectangular wire material of copper or a copper alloy as a base material, and formed at an outermost surface thereof, a copper-tin alloy layer substantially composed of copper and tin, wherein the copper-tin alloy layer of the outermost surface further contains at least one selected from the group consisting of zinc, indium, antimony, gallium, lead, bismuth, cadmium, magnesium, silver, gold, and aluminum, in a total amount of 0.01% or more and 1% or less in terms of mass ratio with respect to the content of the tin.

Owner:FURUKAWA ELECTRIC CO LTD

High-strength copper tin alloy contact line for high-speed electric railway and manufacturing method thereof

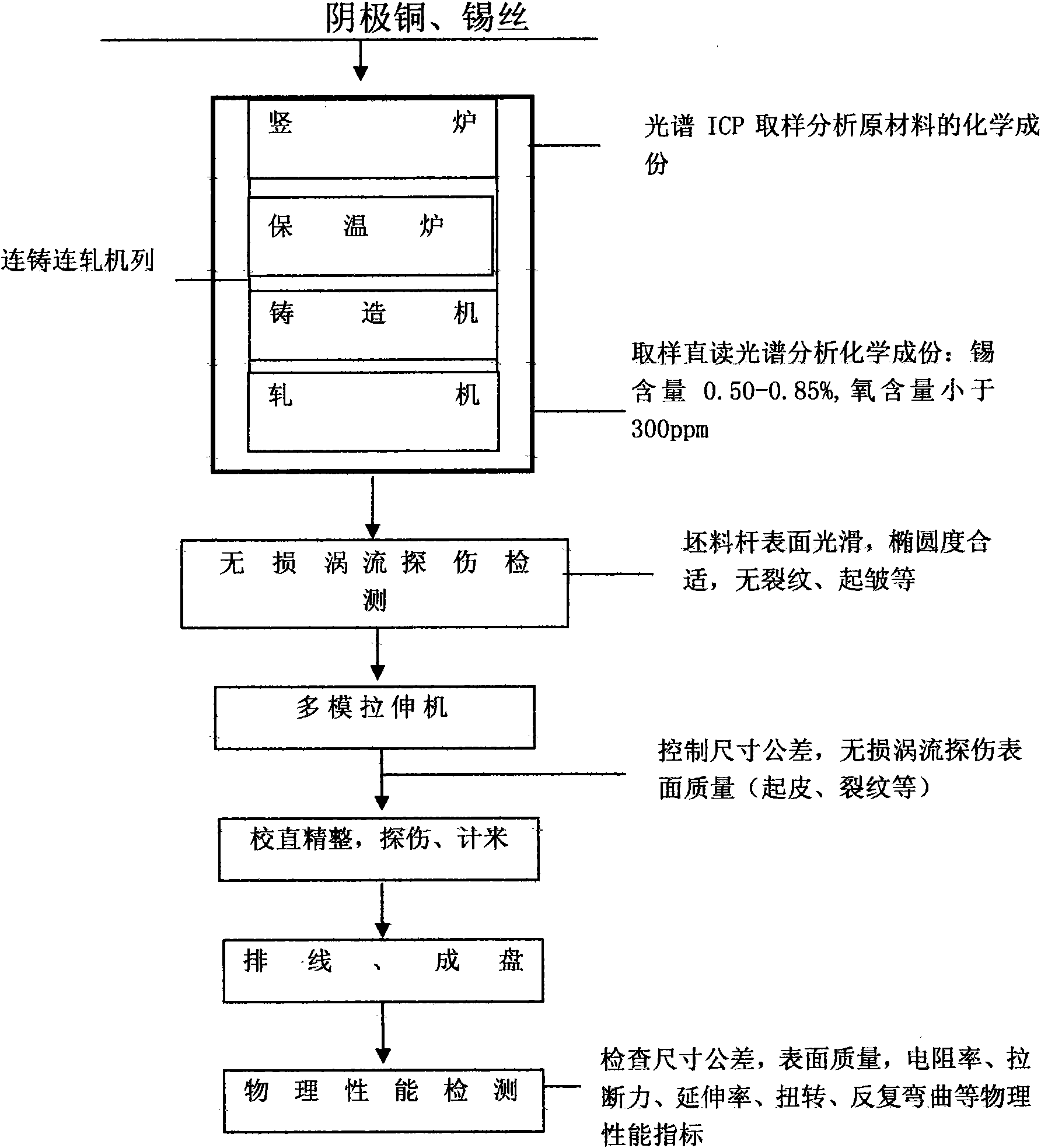

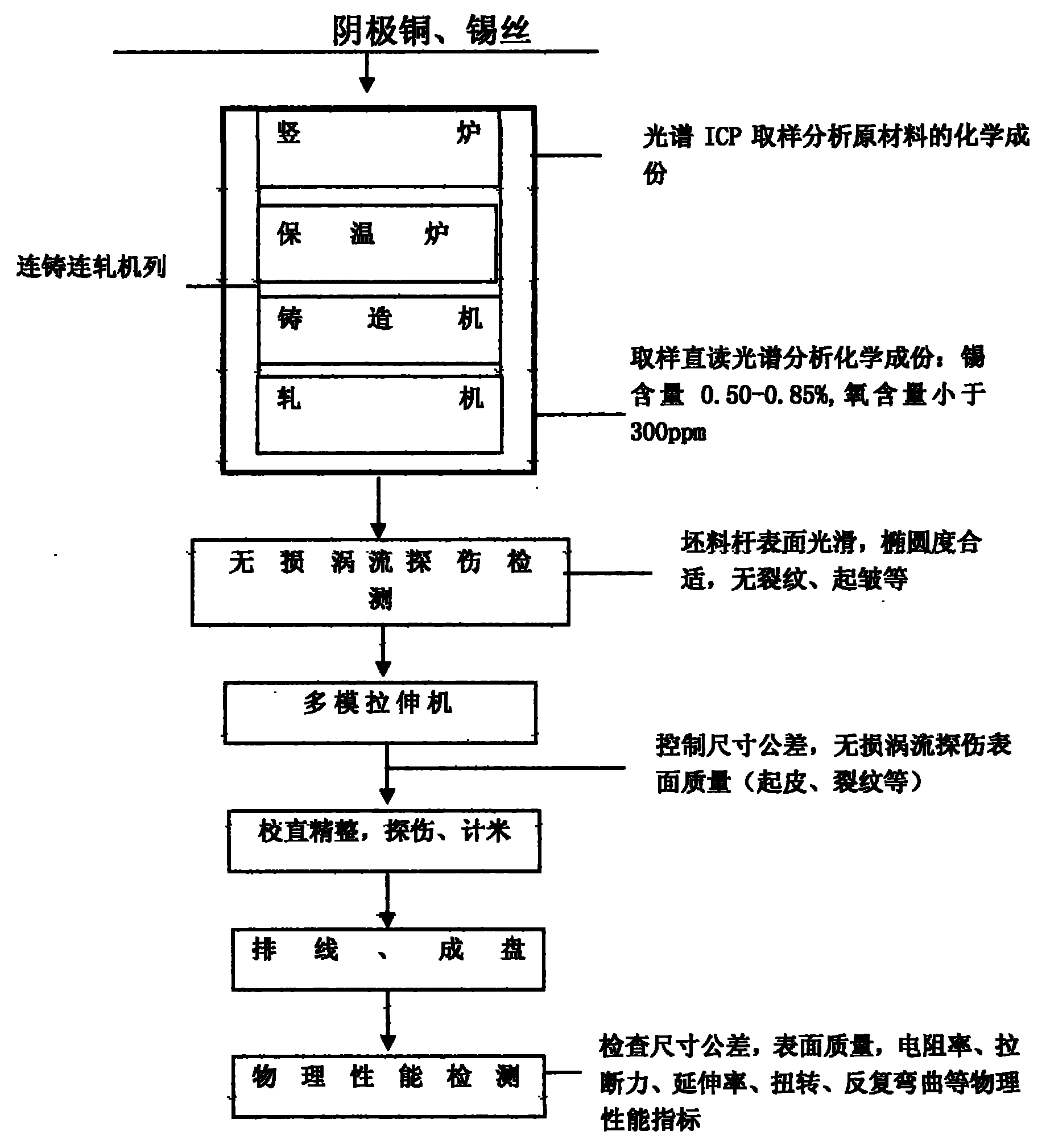

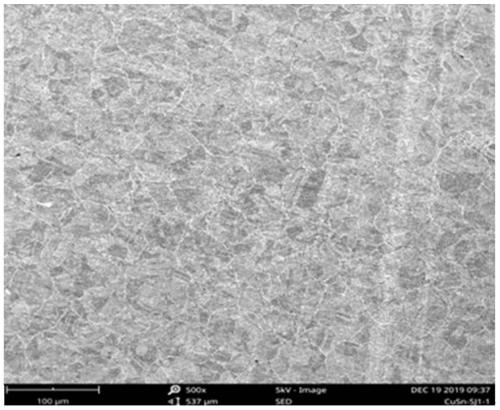

The invention provides a high-strength copper tin alloy contact line for a high-speed electric railway, and in particular relates to a copper tin alloy which comprises the following components in percentage by mass: 0.50 to 0.85 percent of tin, no more than 0.10 percent of impurity and the balance of copper. The invention also provides a manufacturing method for the high-strength copper tin alloy contact line for the high-speed electric railway. Compared with the prior art, the high-strength copper tin alloy contact line of the invention fills in the gaps in China. Because the high-strength copper tin alloy contact line has a series of advantages, such as high strength, high plasticity, small grain size, simple production process, low cost, big batch size and the like, the high-strength copper tin alloy contact line can be applied to the rapid transit railway of which the speed per hour is 250 to 350 km, is expected to get good economic benefit and social benefit, and greatly promotes development of the electric railway industry in China.

Owner:沈阳北恒新材料有限公司

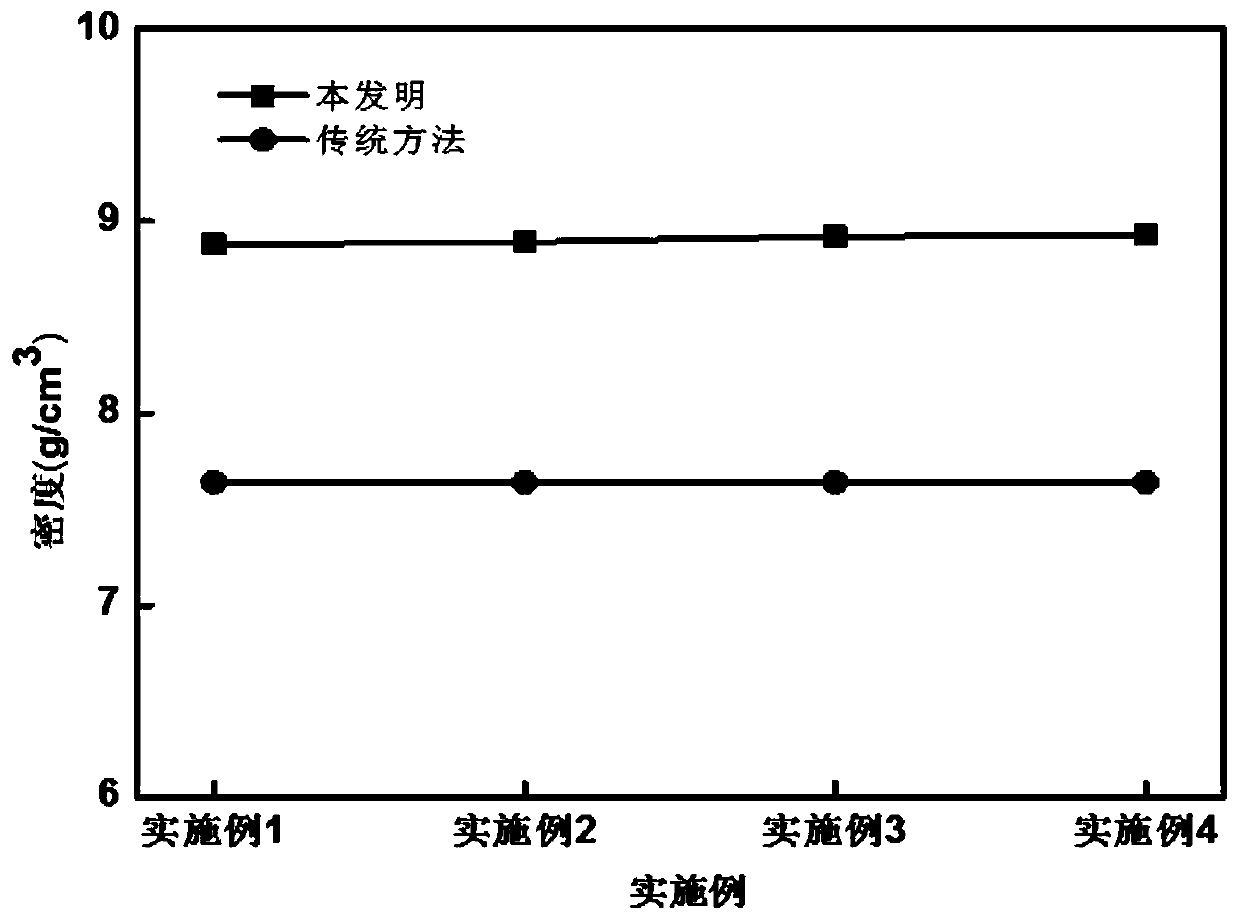

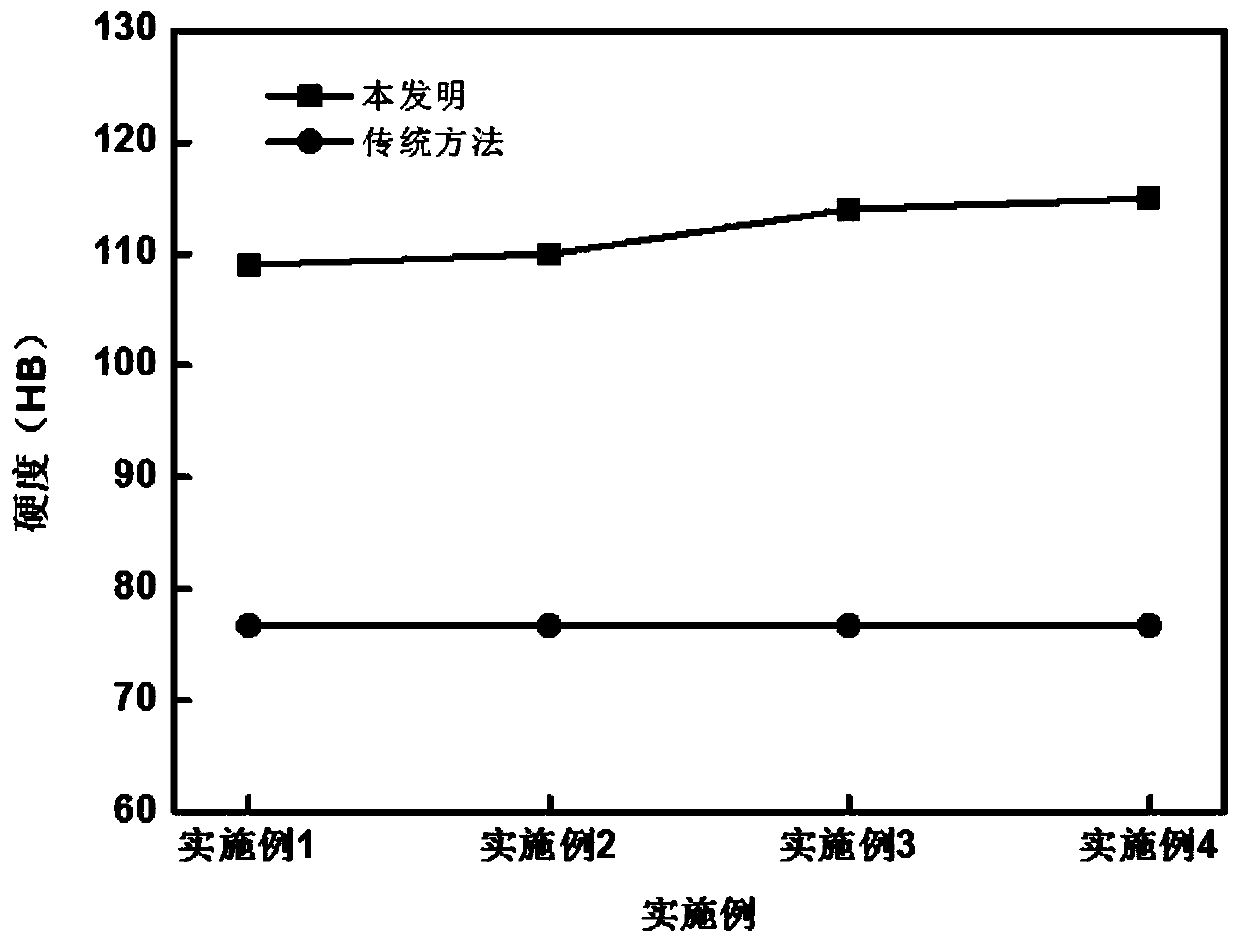

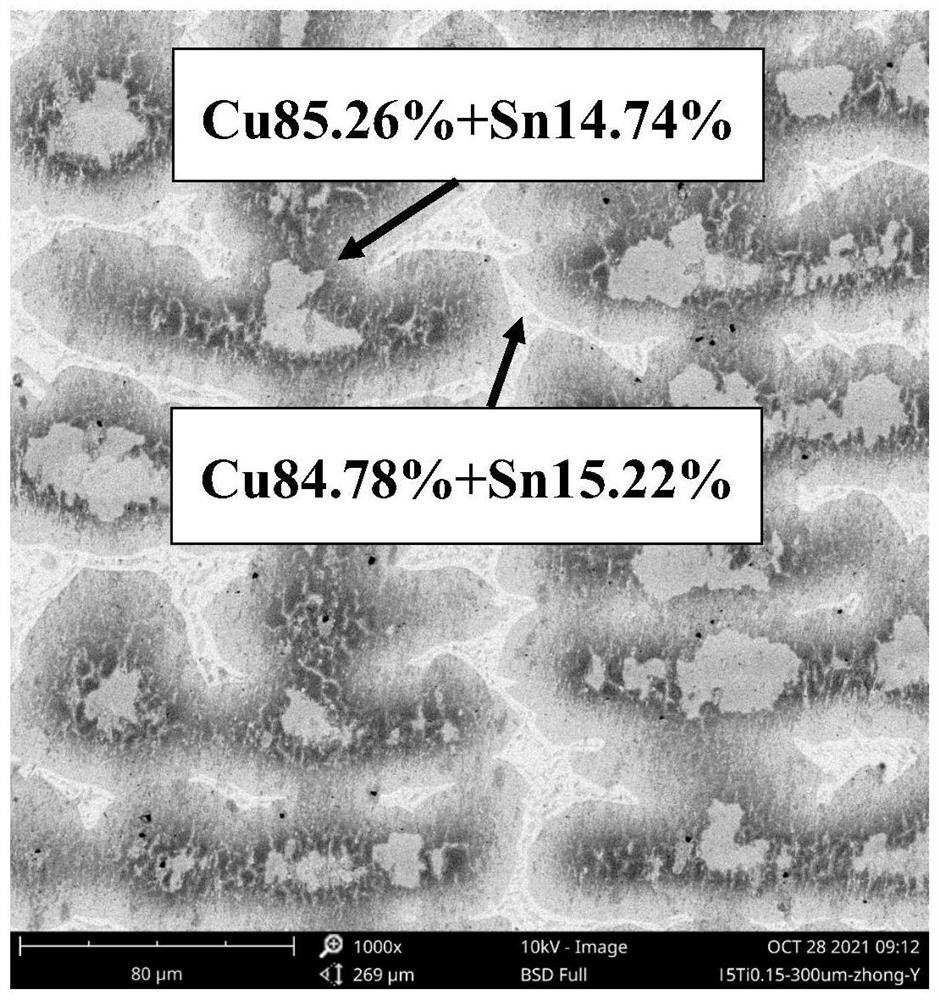

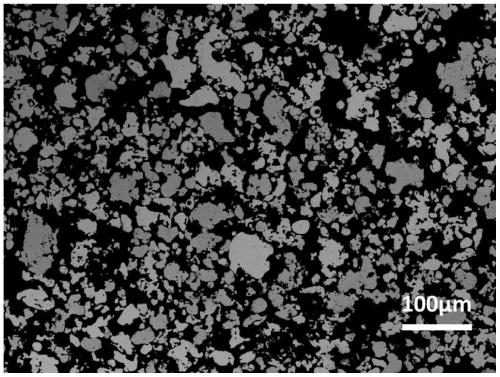

Preparation method of copper-tin alloy with high tin content and high density

The invention discloses a preparation method of copper-tin alloy with high tin content and high density. The preparation method comprises the following steps of step 1, weighing 83.2-84.3wt% of Cu powder, 15.4-16.5% of Sn powder and 0.3% of Ti powder according to the mass percentage, uniformly mixing the components by a ball grinding mill, and thus obtaining mixed powder; step 2, cold-pressing themixed powder in the step 1 to obtain a cold pressed billet, and putting the cold pressed billet into a spray deposition furnace for spray deposition, and obtaining pre-alloyed powder; and step 3, sieving the pre-alloyed powder in the step 2, conducting secondary cold pressing to obtain a secondary cold pressed billet, then putting the secondary cold pressed billet into an atmosphere sintering furnace, introducing inert gas into the furnace, heating and pressurizing the atmosphere sintering furnace, holding temperature for a while, finally decreasing temperature and reducing pressure of the atmosphere sintering furnace, and thus obtaining the copper-tin alloy. The preparation method increases the content of tin in the copper-tin alloy, the distribution of tin is more uniform, and the density and hardness of the copper-tin alloy are ensured.

Owner:XIAN UNIV OF TECH

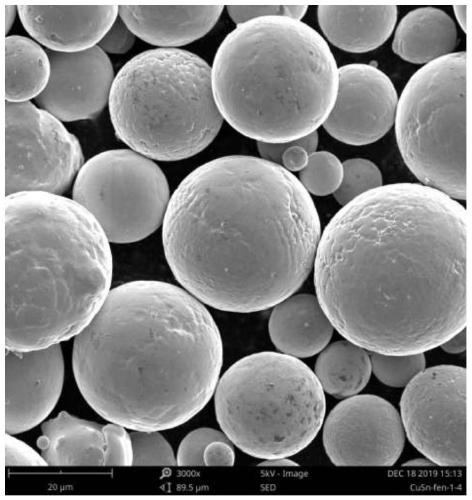

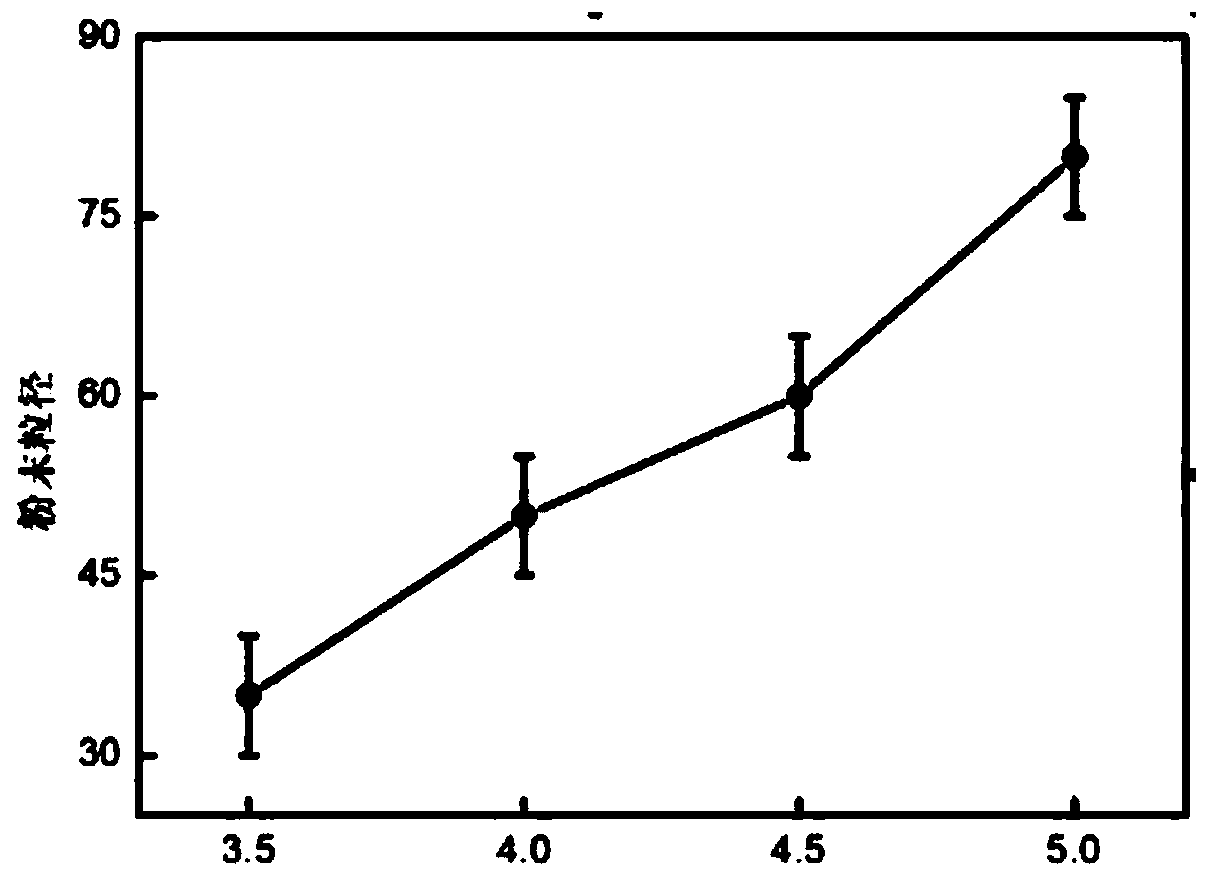

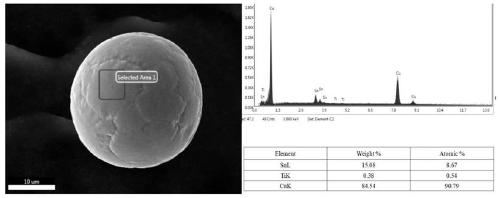

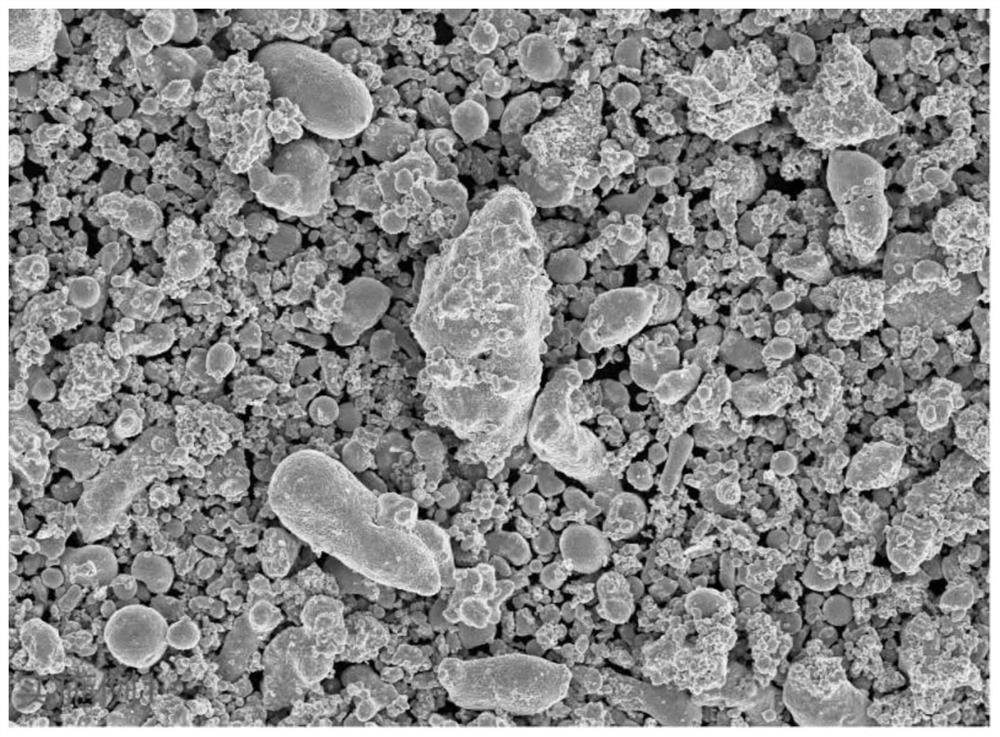

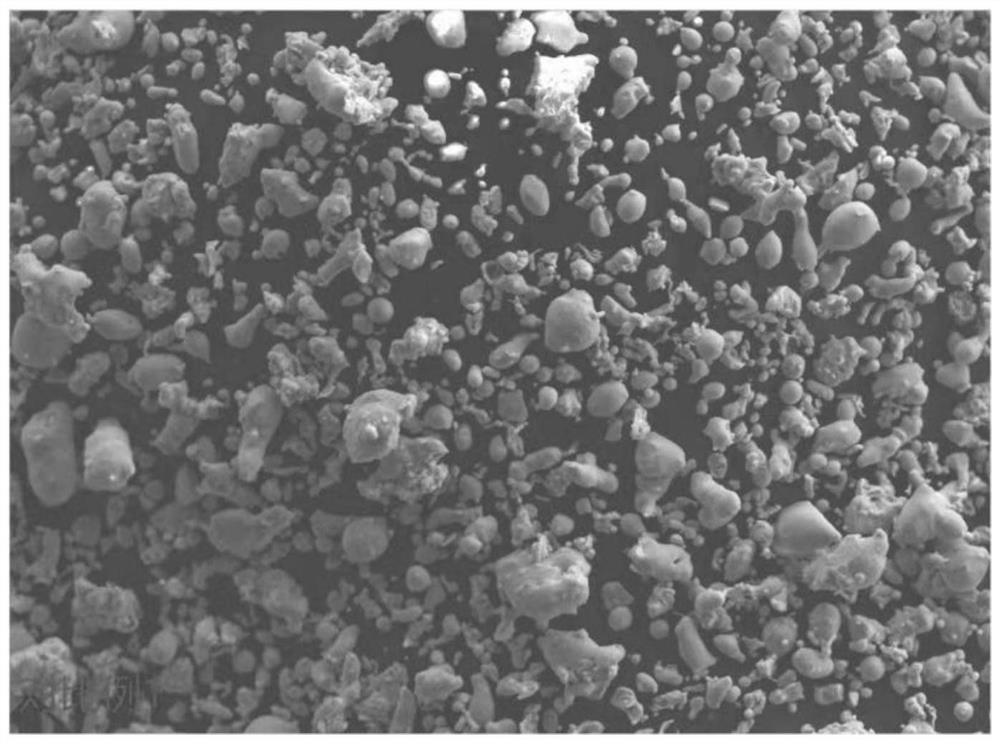

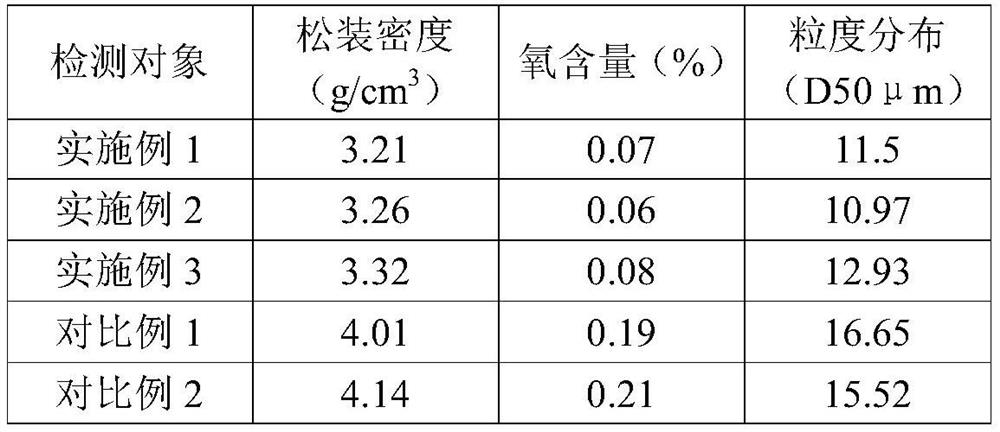

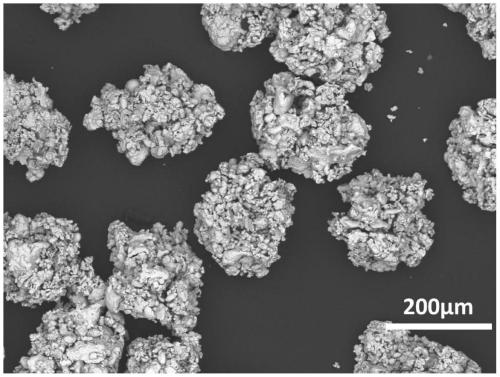

Preparation method of particle size controllable type copper-tin prealloy powder with ultrahigh tin content

The invention discloses a preparation method of particle size controllable type copper-tin prealloy powder with an ultrahigh tin content. The preparation method comprises the following specific stepsthat 1, according to the mass percentage, 77.5%-83.0% of cupper powder, 16.6%-22.1% of Sn powder and 0.4% of Ti powder are fetched in a weighed manner, and all the ingredients are mixed and made intoa cold pressing blank; 2, a crucible is pretreated, the diameter of a nozzle is controlled to be 3.5-5.0 microns, and the cold pressing blank is placed in the crucible; 3, atomizing deposition is conducted, and alloy powder is obtained; and 4, the alloy powder is screened with multiple screen nets, and then the particle size controllable type copper-tin prealloy powder with the ultrahigh tin content is obtained. The particle size of the copper-tin prealloy powder is controllable, the powder is dense, and hollow powder is avoided; by utilizing the copper-tin prealloy powder to prepare copper-tin alloy for superconduction, the problem of insufficient tin content is solved, and the tin is evenly distributed in the alloy.

Owner:XIAN UNIV OF TECH

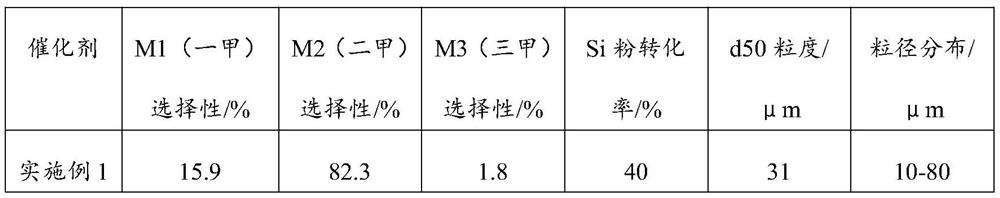

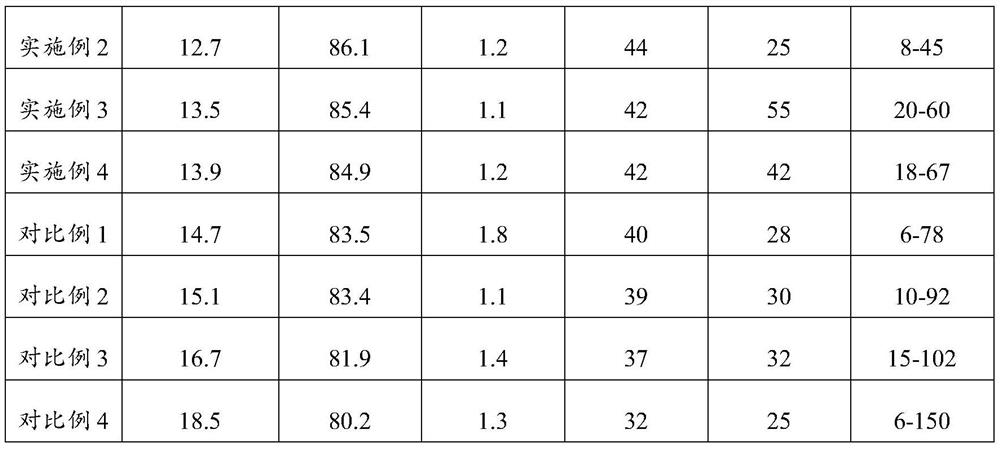

Preparation process of low-content copper-tin alloy powder

The invention discloses a preparation process of low-content copper-tin alloy powder, and relates to the technical field of copper-tin alloy powder processing. The disclosed low-content copper-tin alloy powder is prepared by copper-tin powder mixing, high-energy ball milling and airflow classification processes, and the tin-copper alloy powder obtained by the mechanical alloying preparation process has a microstructure in an irregular scaly shape, a larger specific surface area and a more developed surface, and has the advantages of being higher in chemical catalytic activity, higher in low-temperature sintering activity, good in low-temperature alloying effect and the like. The process is simple and easy and convenient to operate; and by adopting the processes of airflow classification, dispersion treatment and the like, the copper-tin alloy powder product has good dispersity, the average grain diameter D50 and grain fineness distribution can be adjusted and controlled according to user requirements, the application performance of the product is greatly improved, and product quality requirements of customers are met.

Owner:湖南省天心博力科技有限公司

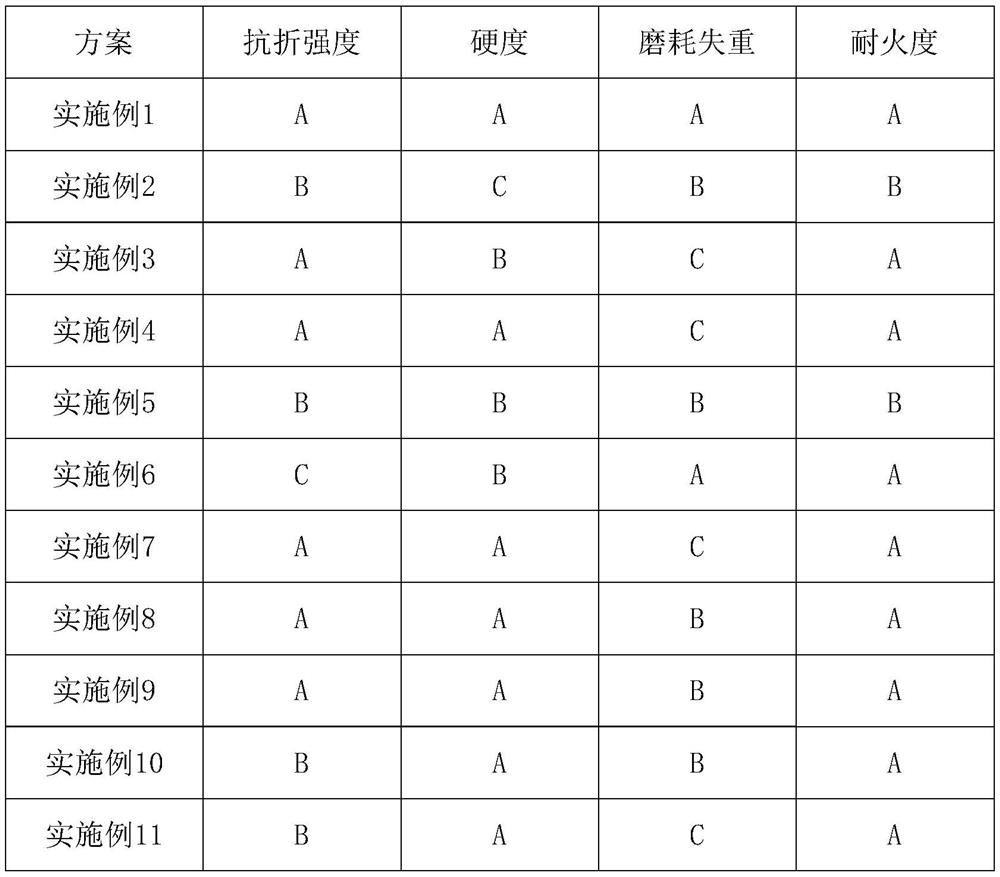

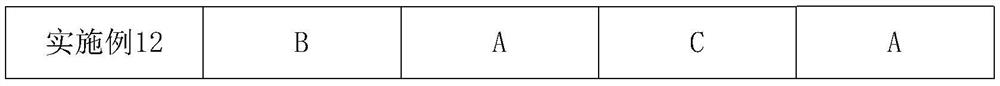

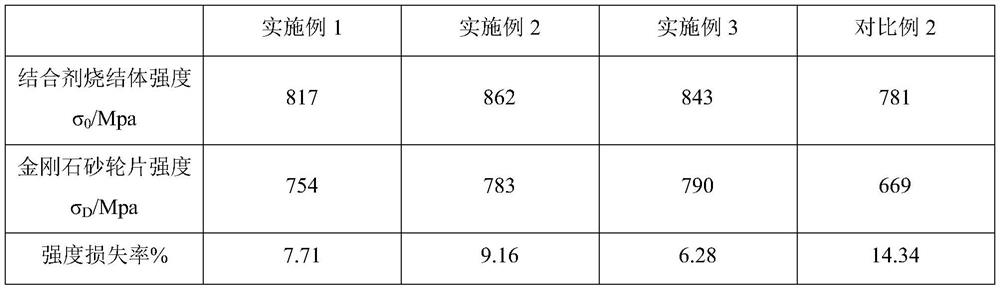

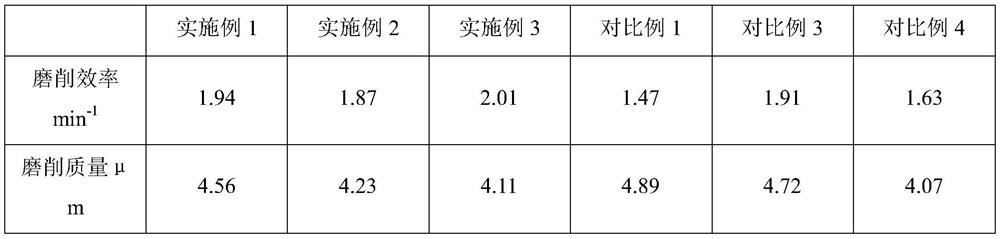

High-performance metallic bond, grinding wheel comprising high-performance metallic bond and preparation method of grinding wheel

PendingCN112936117AEasy to controlExtended service lifeAbrasion apparatusGrinding devicesGunmetalIron powder

The invention belongs to the technical field of grinding materials and grinding tools, and particularly relates to a high-performance metallic bond, a grinding wheel comprising the metallic bond and a preparation method of the grinding wheel. The metallic bond is prepared from the materials in parts by weight: 30-70 parts of copper-tin alloy powder, 5-15 parts of nickel powder, 1-10 parts of silver powder, 5-15 parts of iron powder and 1-5 parts of aluminum oxide powder. The metallic bond further comprises 1-10 wt% of silicon dioxide powder and 10-25 wt% of cobalt powder. The preparation method of the grinding wheel containing the high-performance metallic bond includes the steps that the metallic bond and diamond are mixed for 12-24 h through a high-speed mixing machine; and the mixture of the metal powder and diamond abrasive particles are sintered under the conditions that the temperature is 500-1500 DEG C and the pressure is 1-20 T by using a mold, and demolding is conducted to obtain the grinding wheel containing the high-performance metallic bond. The metallic bond is good in holding performance, the service life of the grinding wheel is long, the bond is good in sharpness, good in heat conductivity and good in heat resistance, and the grinding wheel is uniform in hardness and stable in quality by adopting a heating and pressurizing method.

Owner:上海橄榄精密工具有限公司

Composite binding agent grinding wheel for steel rail grinding and preparation method of composite binding agent grinding wheel

ActiveCN111633574AImprove toughnessHigh thermal conductivityAbrasion apparatusGrinding devicesFiberCarbon fibers

The invention relates to a composite binding agent grinding wheel for steel rail grinding. The composite binding agent grinding wheel comprises, by weight percent, 28%-45% of modified resin powder, 18%-25% of copper-tin alloy powder, 4%-12% of carbon fibers, 5%-10% of wollastonite, 1%-3% of a wetting agent and the balance grinding materials. The composite binding agent grinding wheel is good in self-sharpening performance, long in service life and high in safety coefficient, the problems happening to grinding under the extreme conditions of high frequency, high pressure and dry grinding duringsteel rail grinding can be solved, and the composite binding agent grinding wheel is used for grinding a steel rail and has the advantages that pressure capable of being borne during grinding is large, the grinding mileage is long, and steel rails are not burnt.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Acidic cyanide-free copper-tin alloy electroplating bath

The invention discloses an acidic cyanide-free copper-tin alloy electroplating bath. The electroplating bath is an acidic system and adopts inorganic salt as the main salt, a dispersing agent and a gloss agent are added and used in the electroplating bath, and the system can be used for effectively increasing the current efficiency of a process, thus the deposition velocity of an electroplating layer is increased, and the defect that an alkali cyanide-free copper-tin alloy electroplating layer is thinner is overcome. The electroplating bath disclosed by the invention is simple in operation, low in cost and wide in current density range; and the prepared electroplating layer is uniform and bright in appearance, good in binding force and high in corrosion resistance. The electroplating bath disclosed by the invention contains no cyanide and lead and no other heavy metal additives and organic complexing agents, so that the electroplating bath is safe and environment-friendly, the damage of the electroplating bath to the ecological environment is effectively avoided, and the wastewater treatment cost is effectively reduced.

Owner:江门市瑞期精细化学工程有限公司

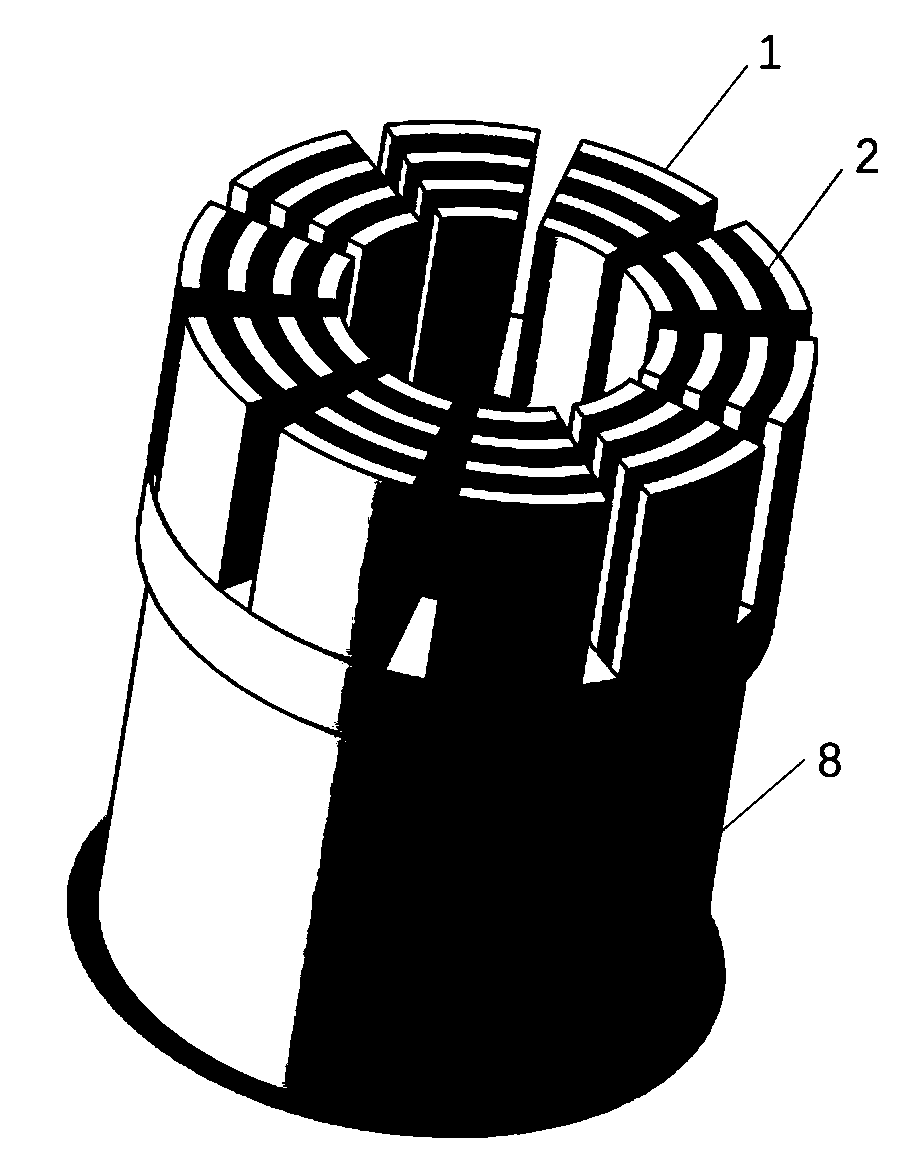

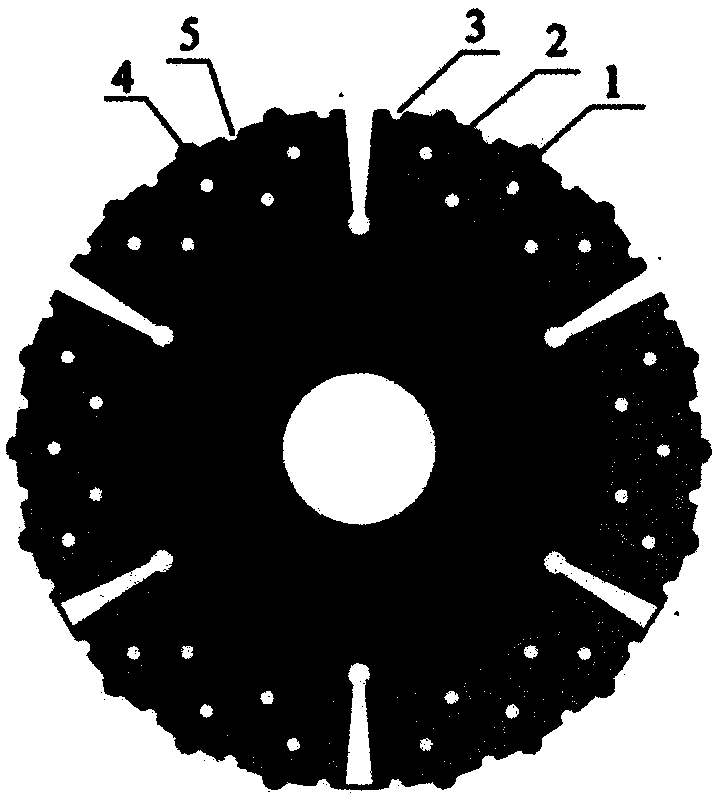

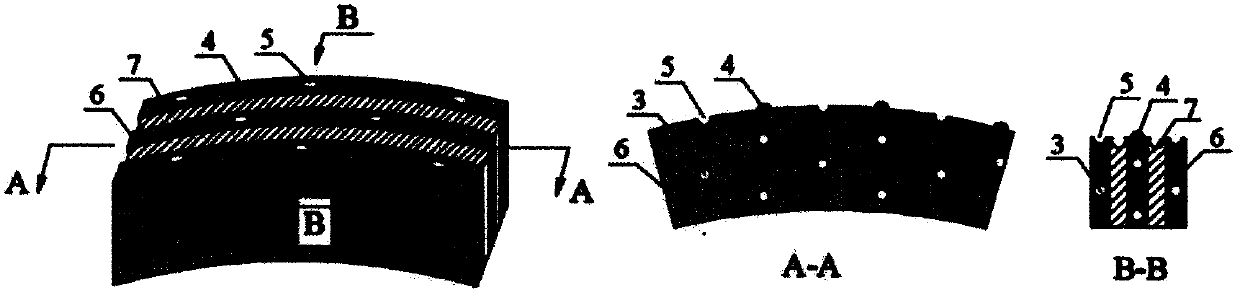

Diamond drilling bit with a plurality of sets of serrated structures automatically formed by weakened matrix with order positioning and manufacture process

InactiveCN108612483AGood edgeImprove rock breaking efficiencyDrill bitsTransportation and packagingGunmetalOrganosolv

The invention discloses a diamond drilling bit with a plurality of sets of serrated structures automatically formed by weakened matrix with order positioning. The diamond drilling bit with a pluralityof sets of serrated structures automatically drill teeth formed by weakened matrix with order positioning comprises drill teeth and a steel body. The drill teeth are composed by working layer sheetswith the thickness of 0.2-1.5mm and interlayer sheets with thickness of 0.2-1.5mm. The working layer sheets are made from metal powder, tungsten carbide powder and diamond, and the interlayer sheets are made from graphite powder, ceramic powder and copper-tin alloy powder. Organic solvents are separately added for preparing slurry materials, and the slurry materials are poured to form a mold, andafter vacuum baking and low-temperature sintering, a sheet blank is formed; the weakened matrix particles are positioned and arranged orderly according to the designed concentration and are embedded in the predetermined position of the working layer sheet blank; and the working layer sheets and the interlayer sheets are alternately packed into a graphite mold at intervals to form the drill teeth,then the steel body is installed, and after hot pressed sintering, the drilling bit is formed. During the drilling process of the diamond drilling bit, a pie appears in a working lip face, at the sametime, the interlayer sheets are subjected to advanced abrasion, then a groove appears, and a working face of the drilling bit form a serrated shape; and during drilling, the exposure is fast, the efficiency is high, and the energy consumption is low.

Owner:CENT SOUTH UNIV

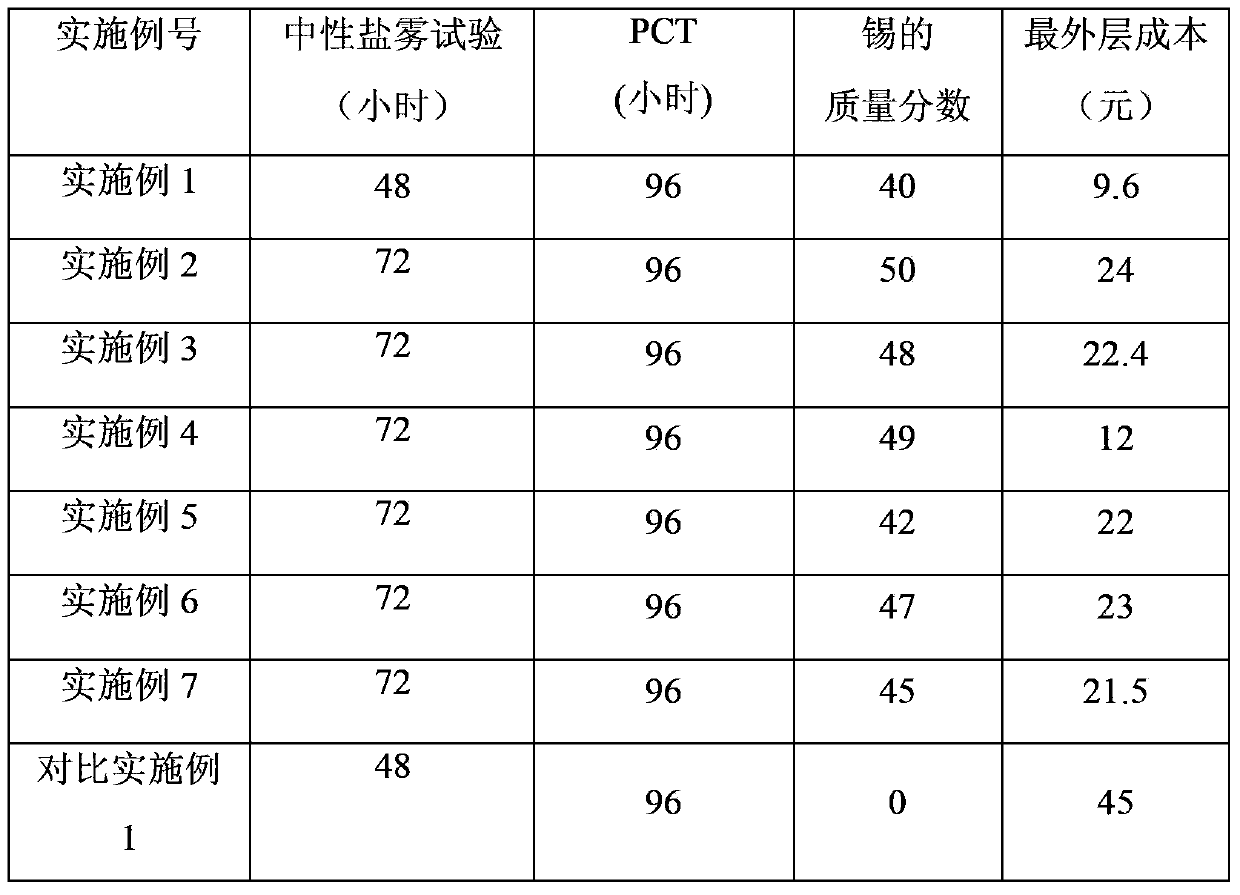

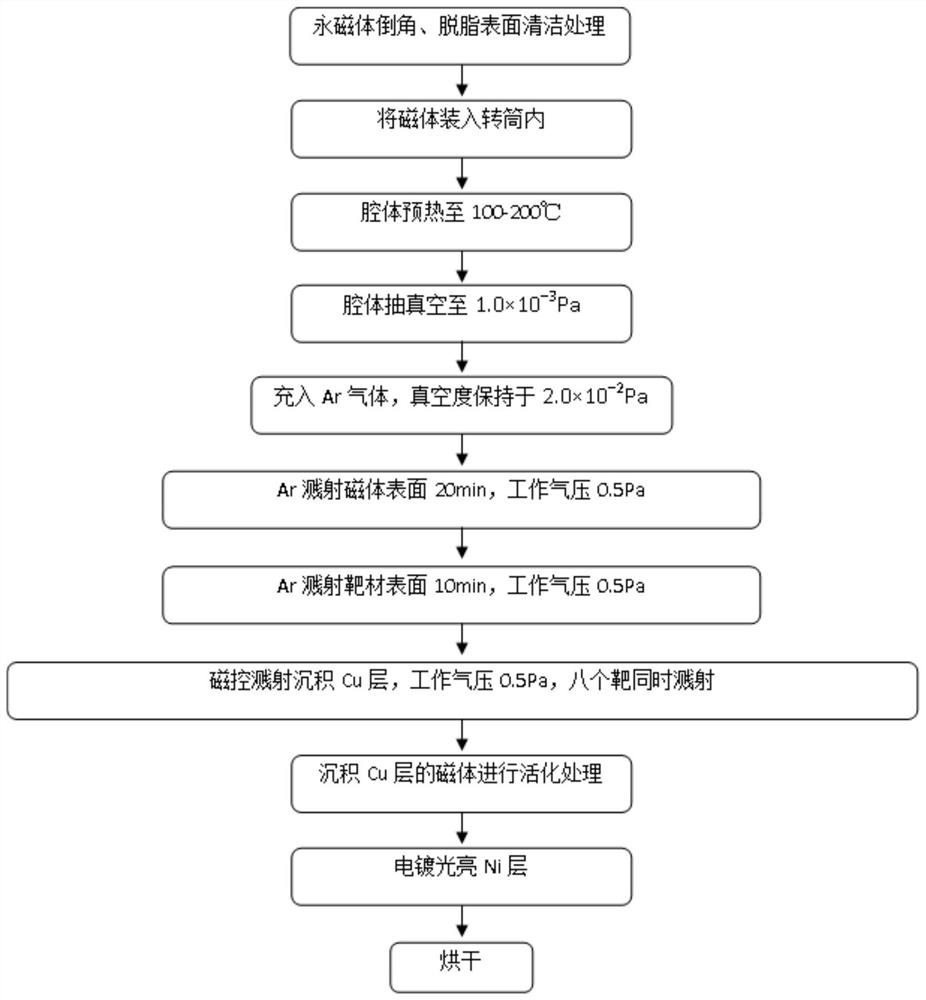

Method for white copper-tin electroplating on permanent magnetic material

The invention relates to a method for white copper-tin electroplating on a permanent magnetic material, wherein the method comprises the following steps: (1) chamfering and polishing; (2) degreasing and removing oil; (3) pickling and derusting; (4) carrying out acid liquid activation; (5) electronickelling to form a nickel-plated layer; (6) electrocoppering to form a copper-plated layer; and (7) electroplating with a Cu-Sn alloy to form a Cu-Sn alloy-plated layer: adopting a Cu-Sn alloy electroplating solution, electroplating the permanent magnetic material formed with the copper-plated layer to form the Cu-Sn alloy-plated layer. After the treatment, the electroplating binding force of the plated layer is the same as that of electronickelling; the anticorrosion ability of the plated layer is the same as that of multilayer nickel electroplating; and 20% of electroplating costs can be saved, and using problems of a crowd allergic to nickel is avoided.

Owner:TIANJIN SANHUAN LUCKY NEW MATERIAL CO LTD +1

Diamond grinding wheel and preparation method thereof

ActiveCN113601407AImprove sharpnessGood self-sharpeningAbrasion apparatusGrinding devicesAl powderIron powder

The invention discloses a diamond grinding wheel. The diamond grinding wheel is composed of, by weight, 40-60 parts of diamond grinding materials and 360-540 parts of composite binding agents, and each composite binding agent comprises, by weight, 45-50 parts of copper-coated iron powder, 20-30 parts of iron powder, 17-23 parts of copper-tin alloy powder, 7-18 parts of aluminum powder, 15-22 parts of ceramic powder and 4-7 parts of polyimide particle balls. The invention further discloses a preparation method of the diamond grinding wheel. The diamond grinding wheel not only has good diamond holding force, but also has good self-sharpening property.

Owner:浙江稳可磨具股份有限公司

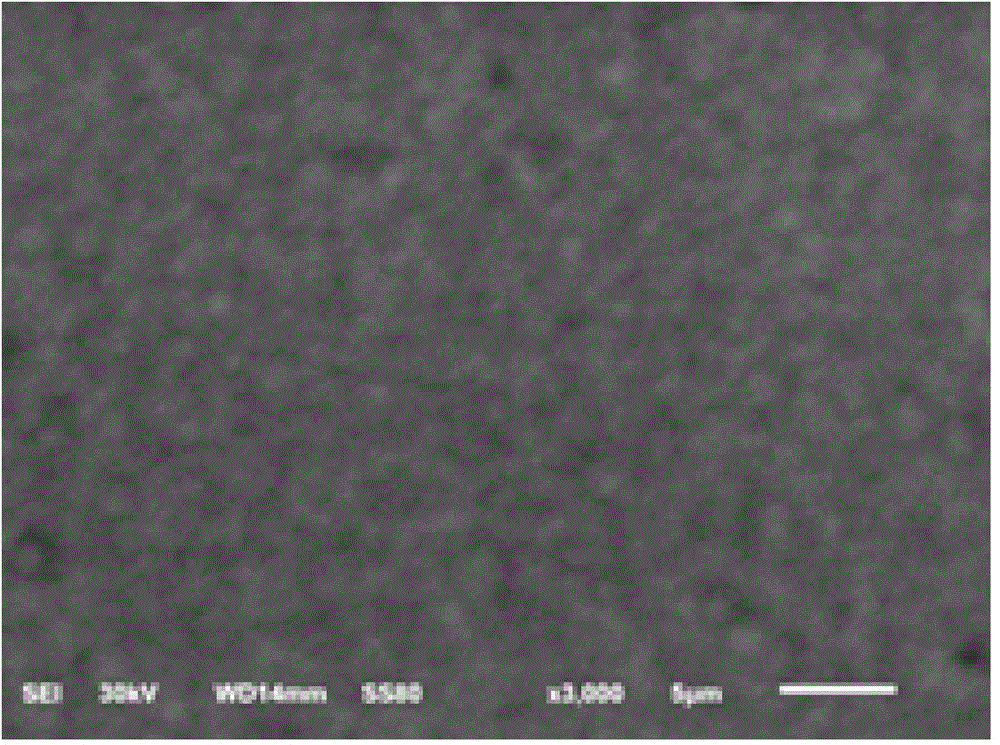

Preparation method for reducing apparent density of copper-tin alloy powder

The invention discloses a preparation method for reducing apparent density of copper-tin alloy powder. The preparation method comprises the following steps that a high-purity copper plate and pure tin powder are selected as raw materials, and water at 0 DEG C-5 DEG C are taken as an atomized water source during atomization; charcoal is added in the smelting process, the steel casting temperature is 1200 DEG C-1300 DEG C, and powder is dehydrated and dried after atomization; hydrogen is introduced by using a boat pushing type reduction furnace for reduction; alloy powder obtained after reduction is screened; and mixing and blending are conducted to obtain the finished copper-tin alloy powder. The apparent density of the prepared alloy powder ranges from 3.0 g / cm < 3 > to 3.5 g / cm < 3 >, and compared with the apparent density of finished alloy powder prepared through a traditional atomization method ranges from 3.5 g / cm < 3 > to 4.0 g / cm < 3 >, the apparent density of the alloy powder is greatly reduced, and the shape maintaining performance of the pressed powder is facilitated; and a high-quality raw material is provided for a high-end diamond tool, and the sharpness and the wear resistance of the diamond tool are effectively improved. In addition, due to the fact that the atomized water temperature is low, the powder cooling speed is increased after the molten steel is crushed, the oxidation time in the powder flying process is shortened, and therefore powder with the low oxygen content is obtained.

Owner:江苏萌达新材料科技有限公司

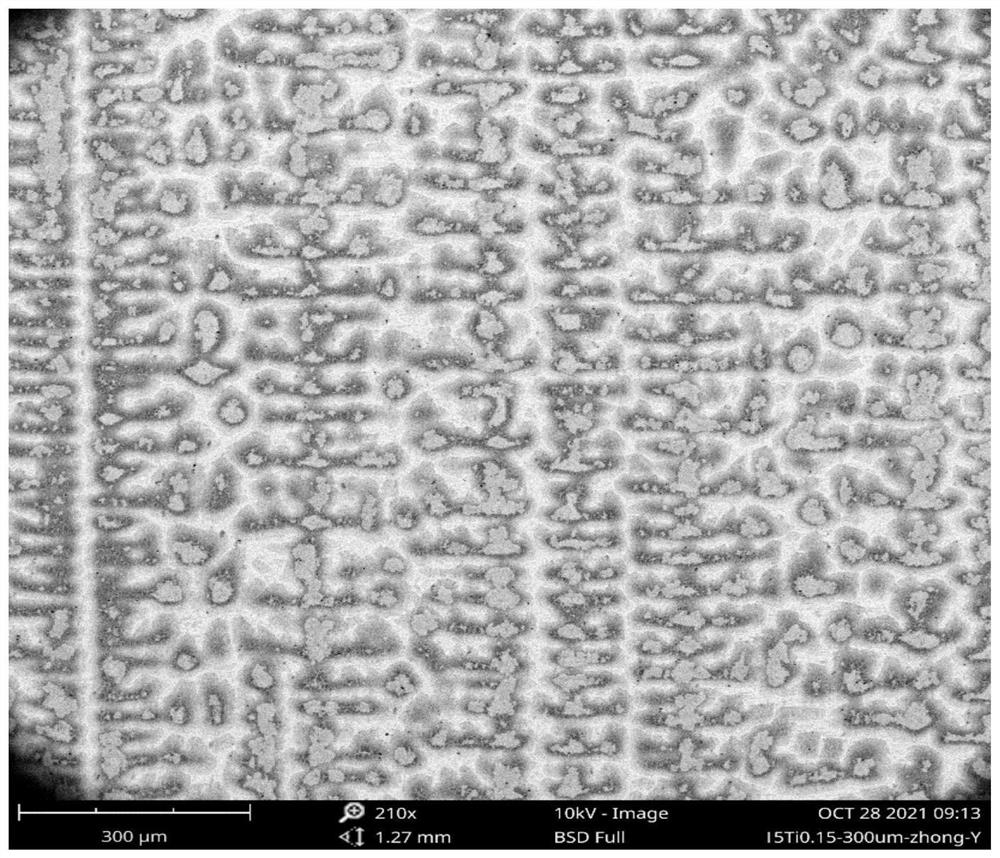

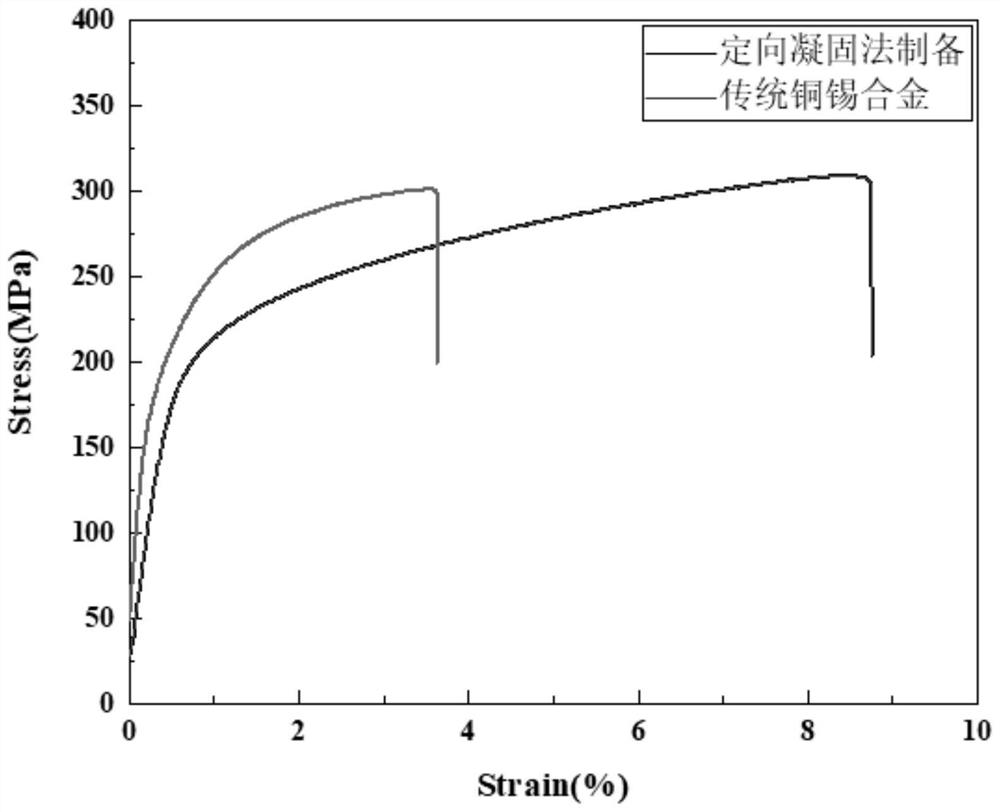

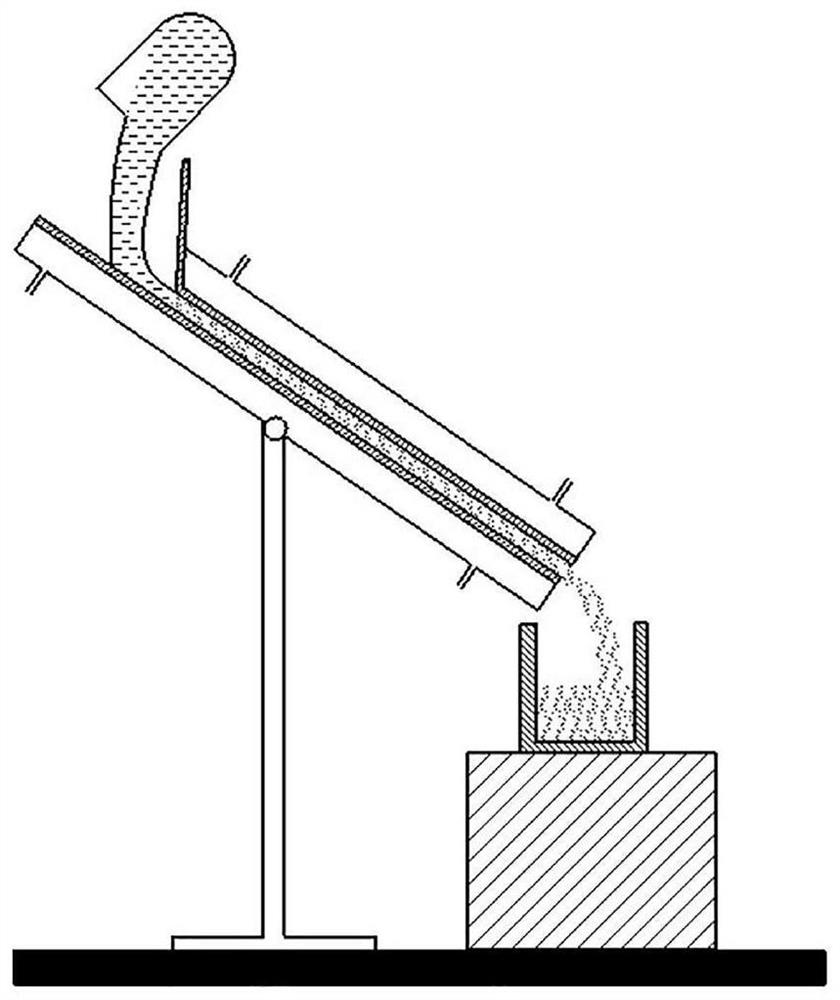

Directional solidification preparation method of high-tin-content and high-plasticity copper-tin alloy

The invention discloses a directional solidification preparation method of a high-tin-content and high-plasticity copper-tin alloy, which comprises the following steps of: 1, weighing a Cu block, Sn and Ti, and pretreating; 2, materials obtained in the step 1 are sequentially put into a magnesia crucible, Ti is put into a feeding hopper for standby application, and a furnace door of a directional solidification furnace is closed; 3, the furnace is vacuumized, then induction melting heating is adopted, molten copper-tin alloy is obtained, a trace titanium element is added into a melt, and heat preservation is conducted to achieve melt homogenization; 4, the molten metal is poured into a constant-temperature cylindrical graphite crucible below for drawing, and a directionally solidified copper-tin alloy cast ingot is obtained after drawing is finished; the problems of low tin solid solubility caused by solute segregation in the existing copper-tin alloy preparation process and poor material plasticity and toughness caused by high intermetallic compound content are solved, meanwhile, the alloy structure is improved, and fine orientation lt is obtained; 001gt, 001gt; and the growing crystal grains synchronously realize directional solidification preparation of the high-solid-solubility and high-plasticity copper-tin alloy.

Owner:XIAN UNIV OF TECH

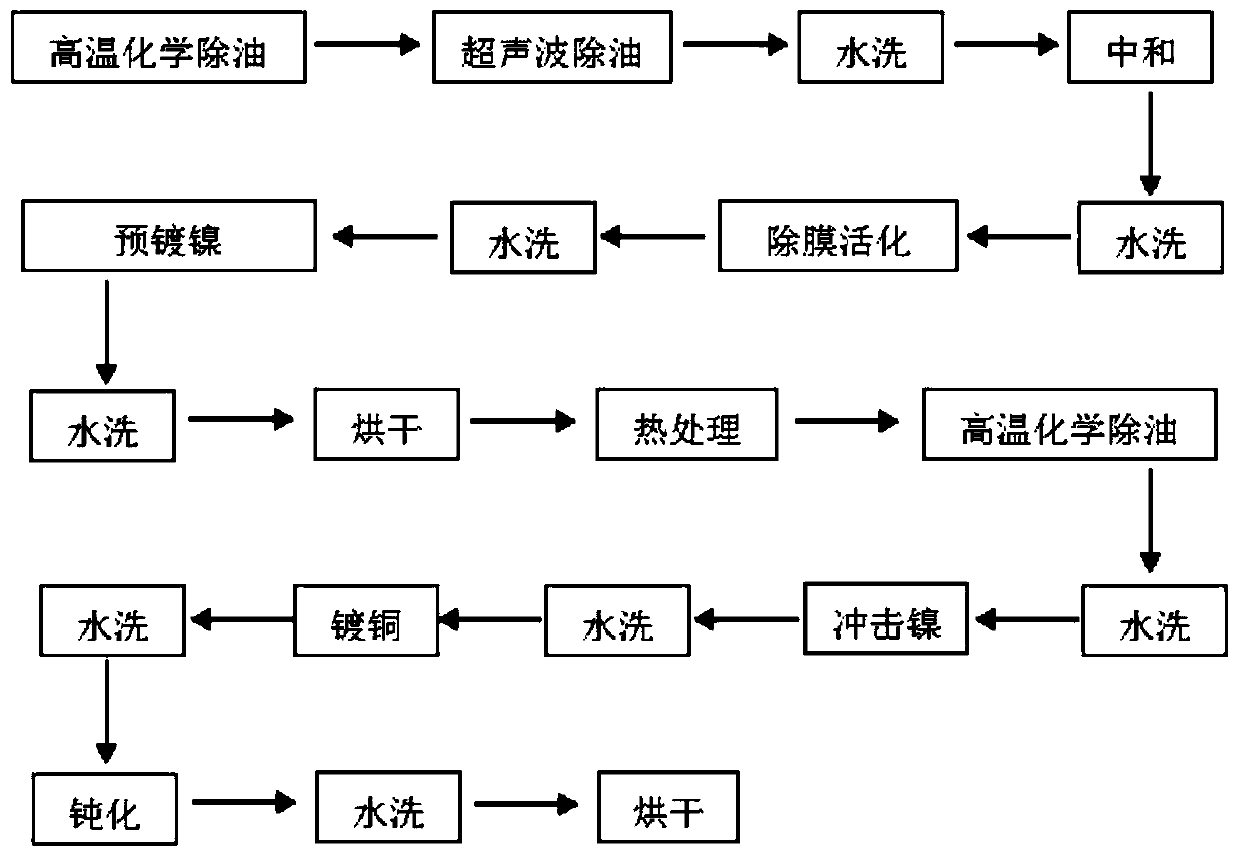

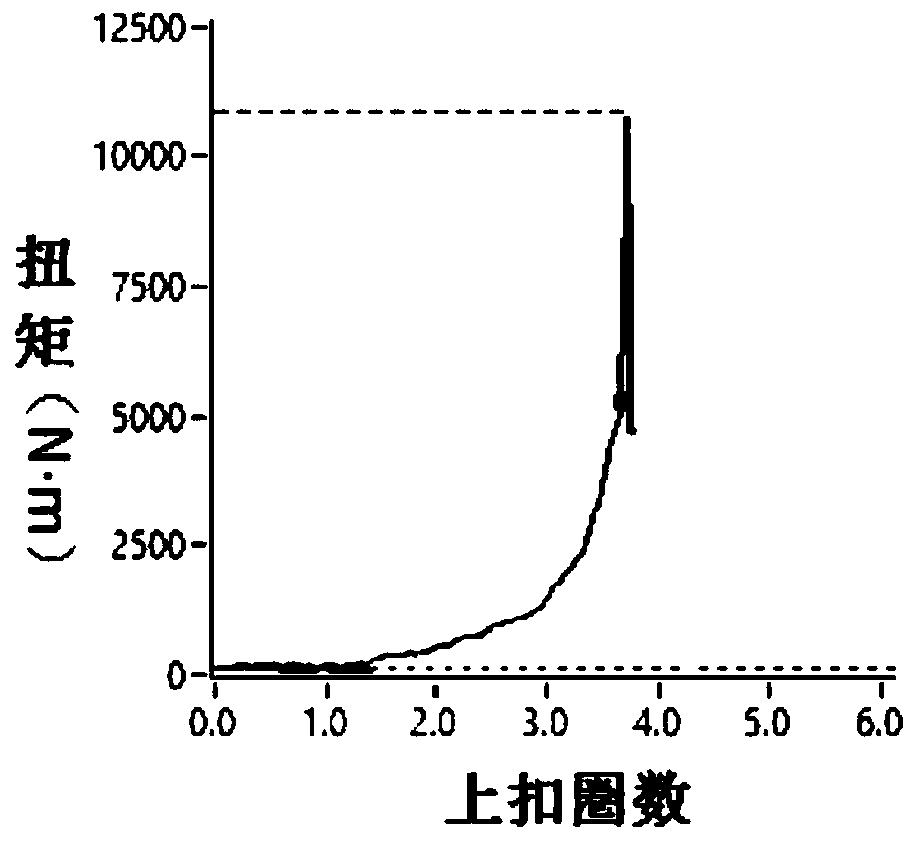

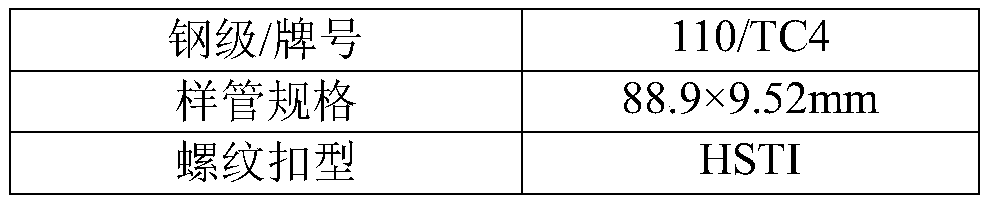

Method for plating tin-copper alloys on surfaces of TC4 titanium alloys and TC4 titanium alloy module

The invention provides a method for plating tin-copper alloys on surfaces of TC4 titanium alloys and a TC4 titanium alloy module. The method comprises the steps that the surfaces of TC4 titanium alloytarget modules are treated to remove oil stains on the surfaces of the target modules; a first electroplating process is adopted to preplate tin on the surface-treated target modules to form nickel pre-plated layers on the surfaces of the target modules; the target modules are heated after the nickel preplating treatment; a second electroplating process is adopted to perform the nickel impact treatment on the heated target modules to form nickel impacted layers; and a third electroplating process is adopted to plate the copper-tin alloys on the surfaces of the nickel impacted layers to form copper-tin alloy layers. The method can be adopted to prepare the uniform and compact copper-tin alloy layers with excellent wear resistance on the surfaces of the TC4 titanium alloy target modules; and the process is stable in process and convenient to operate, so that the application field of the TC4 titanium alloy target modules can be greatly widened.

Owner:HENGYANG VALIN STEEL TUBE

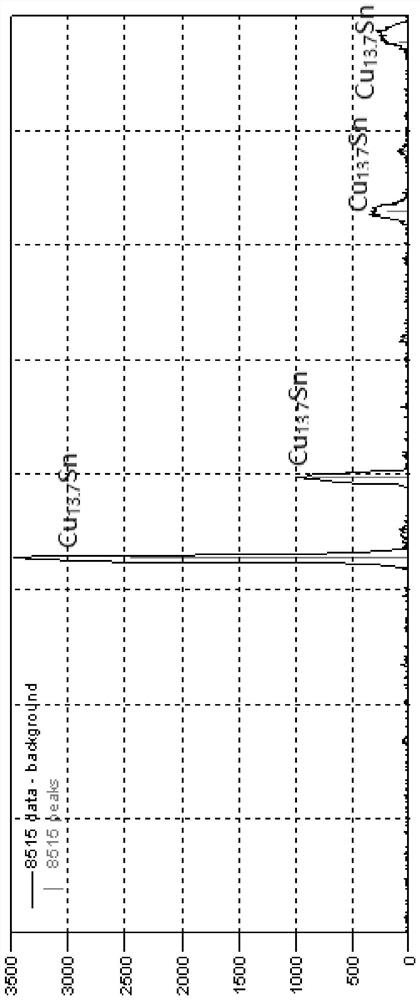

Preparation method of CuSn10 powder with low bulk density

PendingCN111331129AImprove performanceEasy to compressTransportation and packagingMetal-working apparatusGunmetalShrinkage rate

The invention discloses a preparation method of CuSn10 powder with low bulk density. The method is characterized by comprising the following steps: selecting pure copper powder prepared by a water atomization method, wherein the granularity of the water atomization pure copper powder is -200 meshes; selecting copper-tin alloy powder prepared by a water atomization method, wherein the granularity of the copper-tin alloy powder is -200 meshes, and the tin content is greater than 10-30%; mixing the pure copper powder and the copper-tin alloy powder according to a proportion, wherein the proportion of the copper to the copper-tin alloy powder is selected to be larger than 0-2.0 times according to the tin content of the copper-tin alloy powder; putting the mixed powder into a reduction furnaceat a reduction temperature of 400-700 DEG C; and crushing and screening the sintered powder, and adjusting the particle size distribution to obtain finished powder. The formed product is stable in performance and good in compressibility and flowability, a pressed green part is high in strength, the shrinkage rate of the powder after sintering is stable, and the structure is fine and uniform.

Owner:杭州屹通新材料股份有限公司

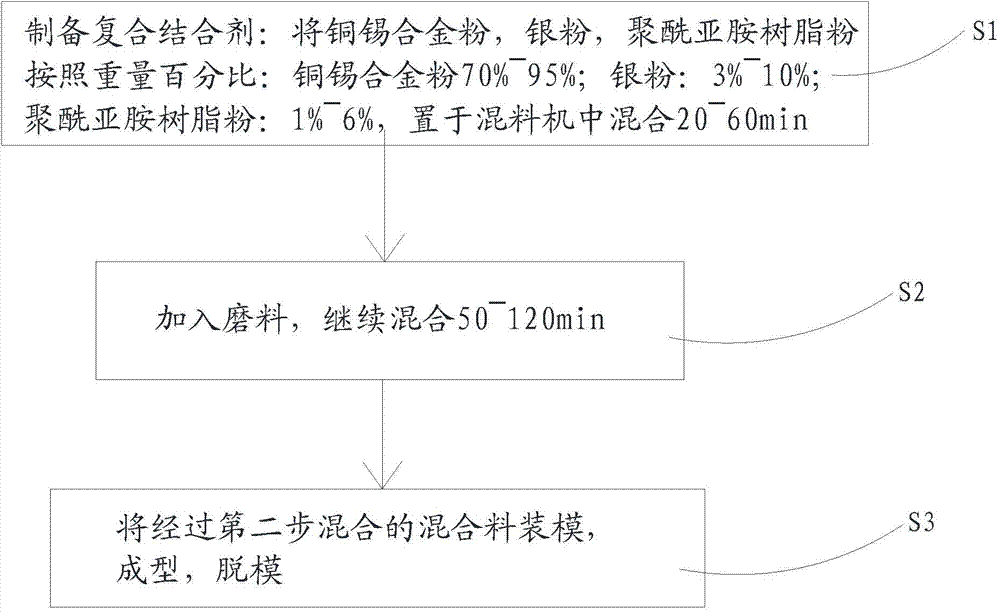

Slotted wheel and manufacturing method thereof

InactiveCN104759992AImprove heat resistanceExtended service lifeAbrasion apparatusGrinding devicesHeat resistanceMaterial removal

The invention provides a slotted wheel. Manufacturing material components of the slotted wheel comprise copper-tin alloyed powder, sliver powder and polyimide resin powder, and the components comprise, by weight, 70%-95% of the copper-tin alloyed powder, 3%-10% of the silver powder and 1%-6% of the polyimide resin powder. The slotted wheel is good in heat resistance, long in service life, high in sharpness, great in cutting capacity and high in material removal rate, the processing work cycle can be shortened, the quality of the workpiece surface is good, and no burn or crack occurs.

Owner:SHENZHEN CHANGXING TECH

Preparation process for improving bending forming of copper-tin alloy strip

ActiveCN114536018AHigh strengthImprove heat resistanceFurnace typesOther manufacturing equipments/toolsGunmetalCopper alloy

The invention discloses a preparation technology for improving bending forming of a copper-tin alloy strip. The technological process comprises the steps of burdening, smelting, casting, saw cutting, heating, hot rolling, face milling, intermediate rolling, edge shearing, acid pickling, finished product rolling, two-stage low-temperature annealing, cleaning, performance detection, finished product shearing and packaging and warehousing. According to the invention, the production process and method of the copper alloy material containing less than 0.2 wt.% of trace tin meet the requirements of high strength and good formability of the material at the same time.

Owner:中铝洛阳铜加工有限公司

High-tin copper-tin alloy electroplating solution and process for barrel plating

The invention discloses a high-tin copper-tin alloy electroplating solution for barrel plating. The solution is characterized by comprising pyrophosphate which is used as a complexing agent, monopotassium phosphate which is used as conducting salt, soluble copper salt and soluble tin salt which are used as main salts, phosphoric acid and potassium hydroxide which are used as a pH regulator of the electroplating solution, a stabilizer of the electroplating solution, and an appropriate amount of compound additives, wherein the concentration of pyrophosphate is 100-350g / L, the concentration of monopotassium phosphate is 40-120g / L, the concentration of the copper salt is 3-20g / L, the concentration of the tin salt is 3-20g / L, the concentration of the stabilizer is 1-12g / L, and the concentration of the compound additives is 1-20ml / L. The electroplating solution disclosed by the invention is simple in component, easy to maintain and applicable to a wide current density range; a plating is bright; a bright high-tin copper-tin alloy plating with a good matrix bonding force can be obtained in a manner of barrel plating.

Owner:SUR PRECISION METAL TECH

Ultrathin permanent magnet with coating deposited on surface

ActiveCN112662939ASolve the problem of magnetic performance degradationMagnetic does not affectPermanent magnetsInductances/transformers/magnets manufactureSputteringGunmetal

The invention discloses an ultrathin permanent magnet with a coating deposited on the surface. The permanent magnet is a thin sheet with the thickness of less than or equal to 1mm, and the permanent magnet comprises the following components in percentage by mass: 26.0-35.0% of Pr-Nd, 0-8.0% of Dy, 0-8.0% of Tb, 0-5.0% of Nd, 0.5-2.5% of B, 0-2.8% of Al, 0-1.0% of Cu and the balance of Fe. A Cu-Ni combined coating is deposited on the surface of the permanent magnet thin sheet, the Cu-Ni combined coating comprises a copper-tin alloy sputtering layer deposited on the surface of the permanent magnet thin sheet through sputtering and a nickel-based protective layer deposited on the surface of the copper-tin alloy sputtering layer through electroplating or chemical plating, the tin content in the copper-tin alloy sputtering layer is gradually decreased to zero from the bottom layer to the surface, the surface layer is a pure copper layer, and the copper-tin alloy sputtering layer is a gradient coating. According to the ultrathin permanent magnet, advantages that a magnetron sputtering process does not need acid pickling pretreatment, and a prepared film layer is deposited firmly and is compact and corrosion-resistant are combined, and the problem that in the surface treatment process of the permanent magnet, an acid pickling solution and an electroplating solution erode a matrix structure so that the magnetic performance is reduced is solved.

Owner:TAIYUAN UNIV OF TECH

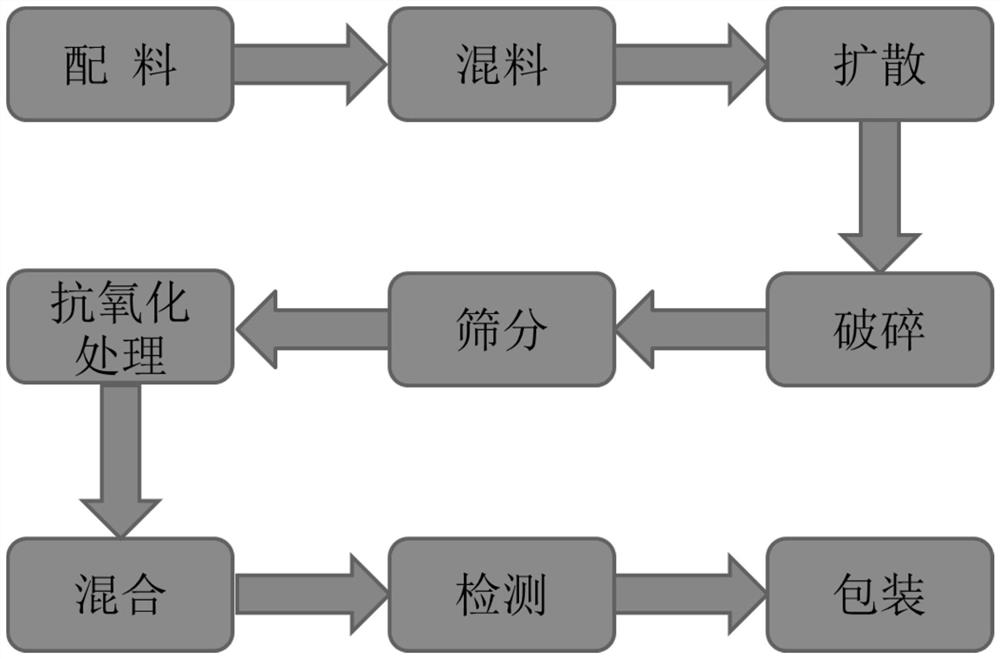

Method for preparing copper-tin alloy powder through diffusion

PendingCN113976896ADiffusion is fastInhibition of segregationTransportation and packagingMetal-working apparatusGunmetalGadolinium

The invention provides a method for preparing copper-tin alloy powder through diffusion. The method comprises the following steps that 1, weighing and mixing 49%-95% of copper powder, 4%-50% of tin powder and 0.1%-1% of copper-gadolinium alloy powder; 2, carrying out ball milling, wherein the mass ratio of milling balls to the mixed powder is 7: 3-3: 2, the ball milling time is 3-8 h, and the ball milling rotating speed is 50-80 r / min; 3, carrying out diffusion, wherein the protective atmosphere is hydrogen and nitrogen mixed gas, and the diffusion temperature of a reduction furnace is 200-500 DEG C; 4, crushing; and 5, after screening and anti-oxidation treatment, obtaining diffused copper-tin alloy powder. The obtained copper-tin alloy powder is uniform and stable in particle size, wide in sintering process window, fine and smooth in structure and good in cold press formability, the use proportion of the copper-tin alloy powder in diamond tools is increased, the problem of composition segregation of the copper-tin alloy powder is solved, the problem can be effectively solved, and the copper-tin alloy powder is widely applied to the diamond tools.

Owner:HENAN HUANGHE WHIRLWIND CO LTD

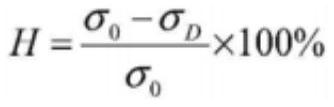

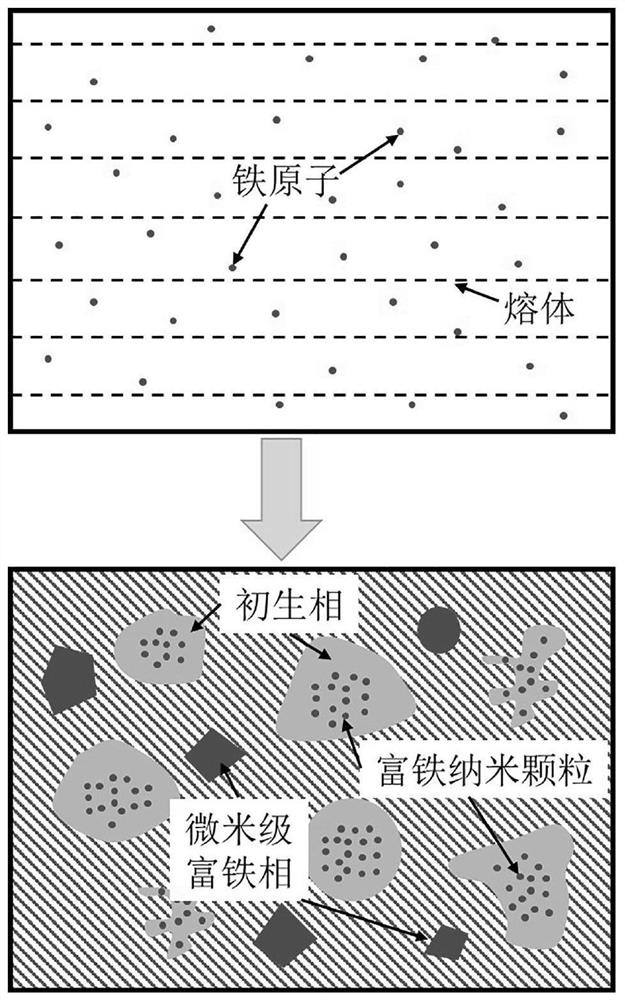

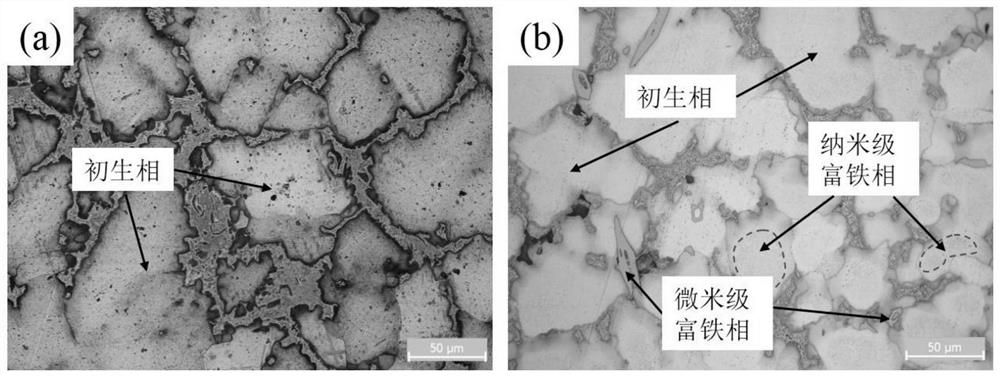

Method for simultaneously improving intensity, ductility and abrasion resistance of copper-tin alloys

The invention discloses a method for simultaneously improving intensity, ductility and abrasion resistance of copper-tin alloys, and belongs to the technical field of material preparation. The methodcomprises the steps of preparing raw materials of 8-15% of Sn,1-8% of Fe, 0.8-1.2% of P, and the balance Cu, placing the raw materials in a medium frequency induction heating furnace, performing heating for melting, then treating molten mass by a quick cooling method, controlling the cooling rate and the supercooling degree of the molten mass, and adjusting and controlling the proportion of nanoscale iron enriched phases and intercrystalline micron order iron enriched phases in a primary phase. The intensity and the ductility of the alloys are reinforced by using the nanoscale iron enriched phase, the abrasion resistance of the alloys is improved by an intercrystalline micron order iron enriched phase, and through controlling the proportion of the nanoscale iron enriched phase to the micron order iron enriched phase, high-strength high-ductility high-wear-resistance copper-tin alloys are obtained. The alloys are simple in components, the preparation technology is short in technologicalprocesses, the method is low in cost, castings are good in properties, and the method is suitable for fields of high speed rails, heavy trucks, aerospace and the like, and has favorable application prospects.

Owner:KUNMING UNIV OF SCI & TECH

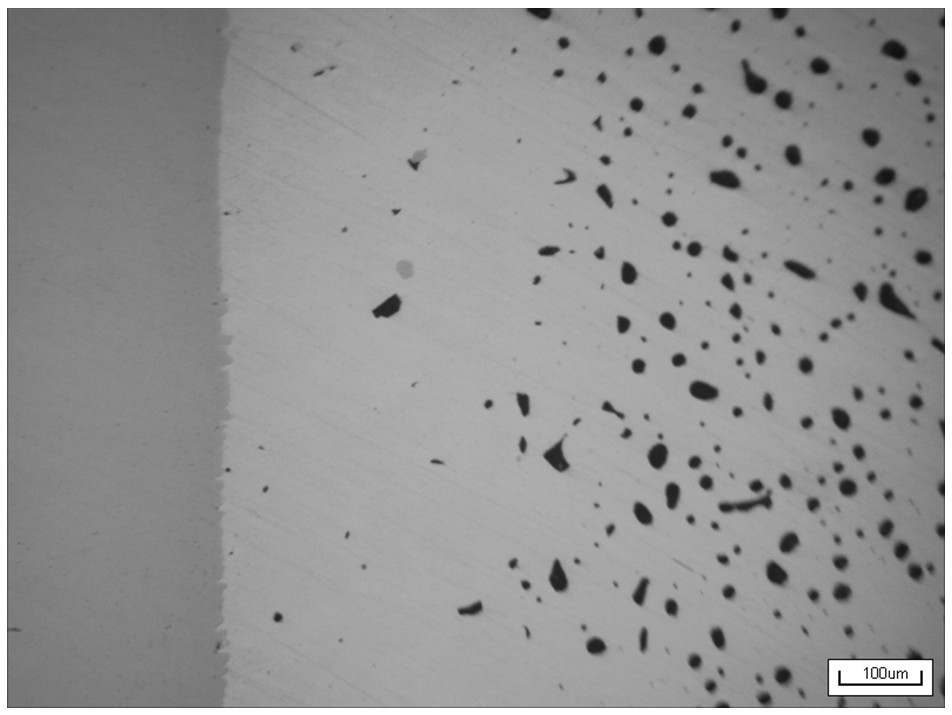

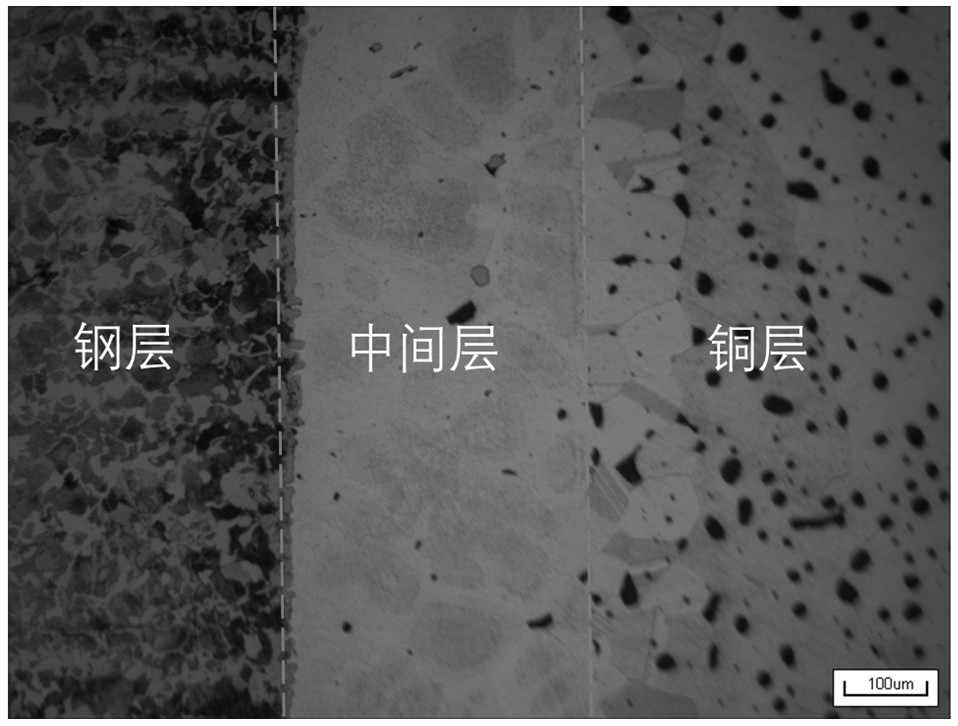

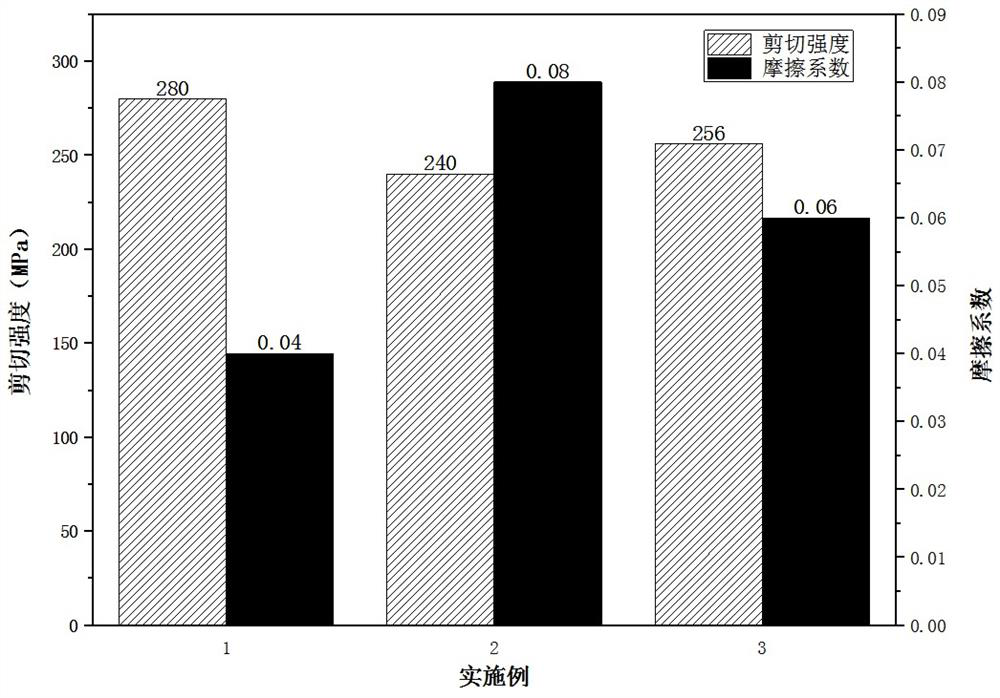

Welding method of high-bonding-strength copper-steel bimetallic antifriction wear-resistant composite material

ActiveCN113118716AAvoid it happening againHigh bonding strengthNon-electric welding apparatusGunmetalQuenching

The invention relates to a welding method of a high-bonding-strength copper-steel bimetallic antifriction wear-resistant composite material, and belongs to the technical field of dissimilar connection of bimetallic composite materials. The method comprises the following operation steps that (1) a steel sheet and a copper alloy sheet which are the same in area size are taken and subjected to surface sand blasting and rough polishing treatment correspondingly; (2) copper-tin alloy powder is pressed into a sheet-shaped green body; (3) the sheet-shaped green body is placed on a steel sheet, sintering and cladding are conducted in a mesh belt furnace, and a steel sheet cladding piece with a cladding layer is obtained; (4) the cladding layer surface of the steel sheet cladding piece and the copper alloy sheet are folded, diffusion welding is conducted in a vacuum sintering furnace, and a welding piece is obtained; and (5) the welding piece is subjected to low-temperature annealing treatment and water quenching, the copper-steel bimetallic composite material is obtained, and the shear strength of a welding interface is 240-280 MPa. According to the method, the bonding strength of the cladding layer and the steel layer is greatly improved, and due to the fact that the cladding layer is very thin, the defects of shrinkage porosity, shrinkage cavity, cracking and the like in common fusion welding are overcome.

Owner:HEFEI UNIV OF TECH

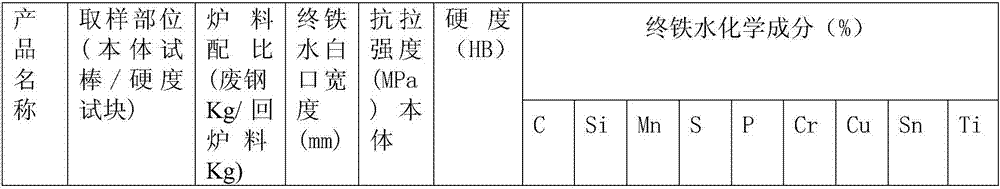

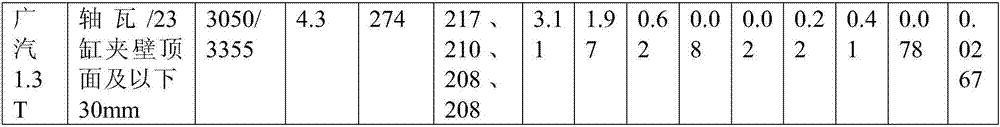

Technology method for improving surface hardness of cylinder barrel of thin-wall gray pig iron air cylinder

The invention belongs to the technical field of gray cast iron smelting, and in particular relates to a process method for improving the surface hardness of a thin-walled gray cast iron cylinder barrel. It includes batching, smelting, forming and cooling steps. The batching is made of high-quality scrap steel and returned iron as the main raw materials. The weight ratio of scrap steel and returned iron is 1:1.1-1.2, and the composition of each alloy is controlled by weight percentage: Carbon: 3.1-4.1 %; silicon: 1.8‑2%; manganese: 0.6‑0.65%; sulfur: 0.04‑0.08%; phosphorus: 0.02‑0.025%; copper: 0.4‑0.6%; ;Titanium: less than or equal to 0.03%, the balance is iron. The invention adds copper and tin alloys to the ingredients, uses low-titanium scrap steel to control the titanium content, effectively suppresses the whitening of thin-walled parts of castings, greatly improves the strength and hardness of castings, and effectively reduces production costs.

Owner:WUHU YONGDA TECH

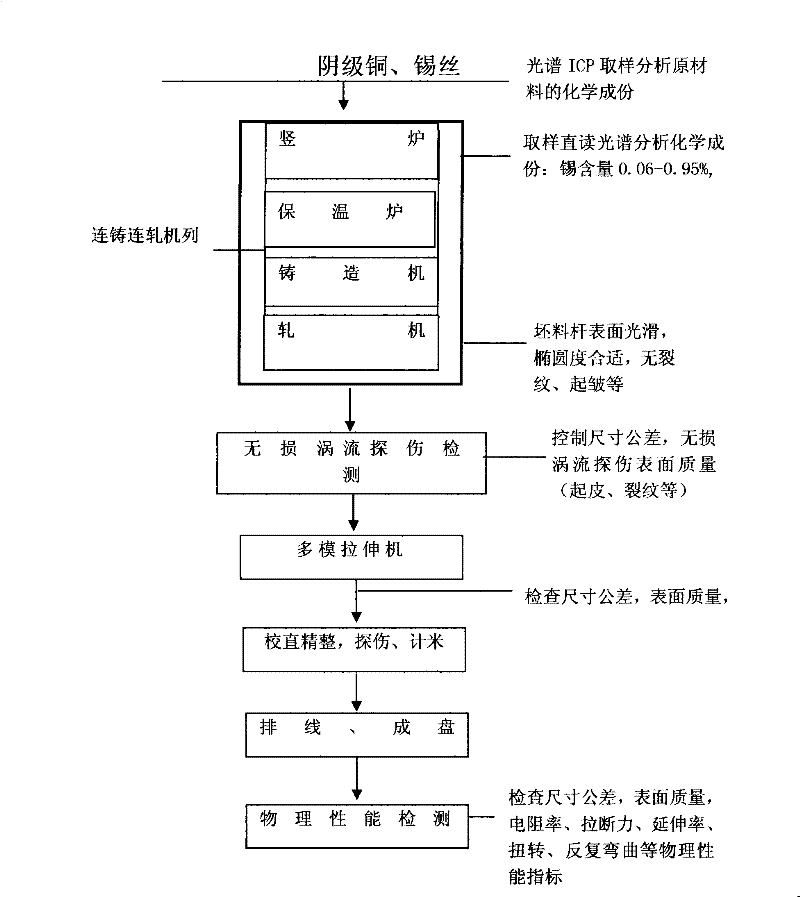

Low tin-copper alloy contact wire for electric railway and manufacturing method thereof

ActiveCN101763910BHigh strengthHigh softening temperatureSingle bars/rods/wires/strips conductorsMetal/alloy conductorsGunmetalMachining

The invention relates to a low tin-copper alloy contact wire for an electric railway, which is a tin-copper alloy comprising the following components in parts by weight percent: 0.06-0.97% of tin, less than or equal to 0.10% of impurities and balance of copper. In the manufacturing method of the invention for protecting the low tin-copper alloy contact wire, cast bars the sectional areas of whichare 2300mm<2> are used as initial raw materials, and the cast bars are machined by hot rolling for 4-12 times to obtain intermediate blank rods the diameters of which are 25-32mm; the machining rate in each time is 12-25%; and the low tin-copper alloy contact wire comprises the following materials in parts by weight percent: 0.06-0.08% of tin, less than or equal to 0.10% of impurities and the balance of copper. The low tin-copper alloy contact wire fills up the domestic blank, has excellent comprehensive performance indexes and has better economic value and social value.

Owner:沈阳北恒新材料有限公司

Production method of copper-tin alloy strip

PendingCN114525390AImprove performanceHigh strengthProcess efficiency improvementMetal rolling arrangementsGunmetalHot working

The invention relates to a production method of a copper-tin alloy strip. The production method comprises the following steps: S1, smelting raw materials; s2, horizontal continuous casting; s3, surface milling; s4, rough rolling and edge cutting; s5, cleaning for the first time; s6, performing first intermediate annealing; s7, intermediate rolling; s8, intermediate annealing for the second time; s9, finish rolling; s10, cleaning for the second time; the production method provided by the invention is based on the fact that domestic copper strip enterprises widely have horizontal continuous casting units and cold rolling mills, hot processing such as hot rolling and hot extrusion is not involved, the technological process is controllable, the equipment investment cost is low, large-scale production is easy, and the comprehensive performance of the prepared copper-tin alloy strip is excellent.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

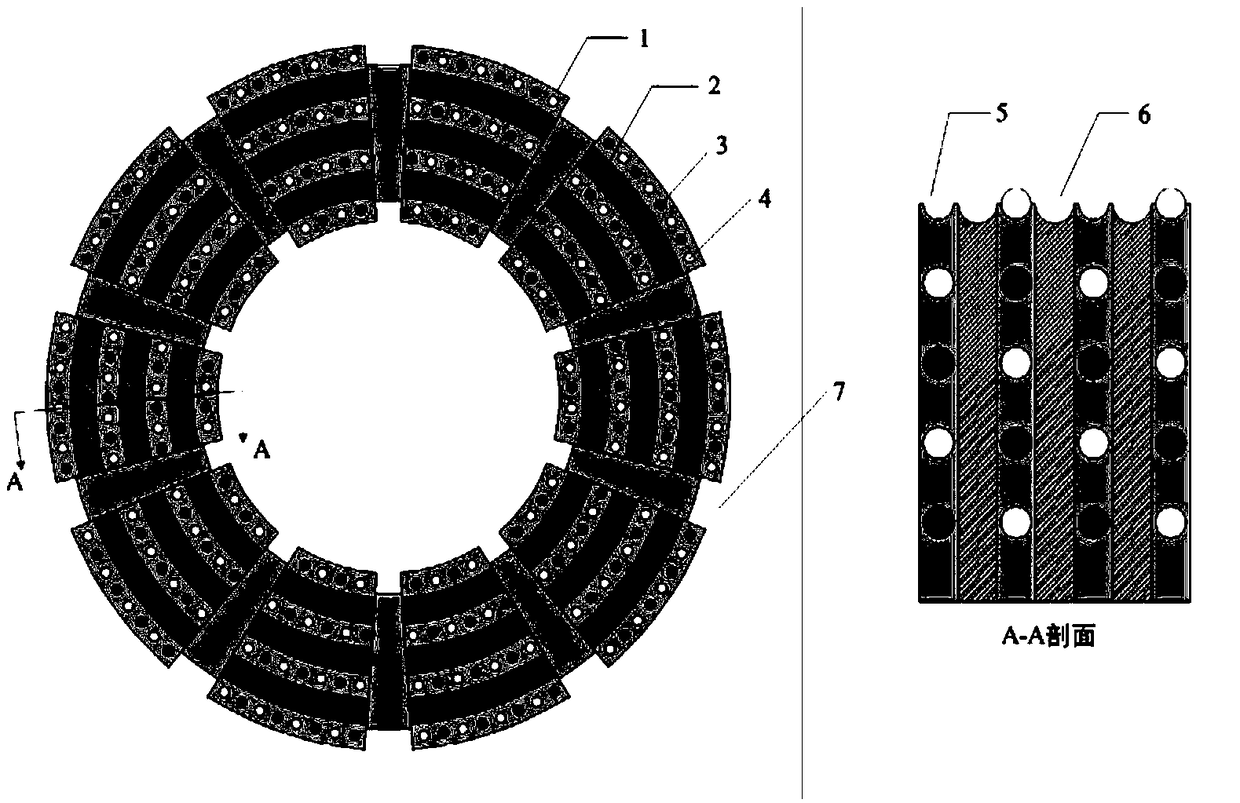

Multi-set-gear-shaped diamond saw blade self-formed by orderly positioning and weakening of carcasses and manufacturing process of saw blade

InactiveCN110877130AImprove sharpnessExtended service lifeMetal sawing tool makingMetal sawing toolsGunmetalOrganic solvent

The invention discloses a multi-set-gear-shaped diamond saw blade self-formed by orderly positioning and weakening of carcasses and a manufacturing process of the saw blade. The saw blade is composedof segments and a base body, and the segments are formed by compounding working layer sheets and middle separation layer sheets, wherein the thicknesses of the working layer sheets and the middle separation layer sheets are 0.2-2.0 mm. Segment working layers are made of metal powder and diamond, separation layers are made of graphite powder, ceramic powder and copper-tin alloy powder, organic solvents are added to the working layers and the separation layers, and the working layers and the separation layers are manufactured into working layer sheet blanks and middle separation layer sheet blanks separately; weakened carcass particles are embedded in predetermined positions with pit structures of the working layer sheet blanks, and then the working layer sheets and the middle separation layer sheets are alternately assembled at intervals and sintered into the segments of the saw blade; and the segments are welded to the base body to manufacture the saw blade with a diameter of 100-2500mm. In the cutting working process, the weakened carcass particles fall off automatically, the middle separation layers are worn in advance, pits and grooves are formed in working lip planes of the segments, so that the working plane of the saw blade is of a multi-set-gear-shaped structure, and the saw blade has the advantages such as high efficiency, long life and low energy consumption.

Owner:EZHOU JINFENG SUPERHARD MATERIALS CO LTD

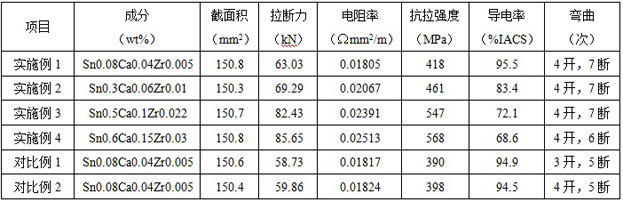

High-strength and high-conductivity copper-tin alloy contact wire and preparation process thereof

PendingCN112281018AHigh strengthImprove conductivityConductive materialMetal/alloy conductorsSolution treatmentGunmetal

The invention relates to a high-strength and high-conductivity copper-tin alloy contact wire and a preparation process thereof. The high-strength and high-conductivity copper-tin alloy contact wire comprises the following chemical components: 0.01wt%-0.8wt% of Sn, 0.01wt%-0.3wt% of Ca, 0.005wt%-0.05wt% of Zr and the balance Cu and inevitable impurities, wherein the chemical components of the copper-tin alloy contact wire are sequentially added in batches according to the sequence of Cu, Sn, Ca and Zr. The preparation process comprises the steps of smelting, upward continuous casting, solutiontreatment, aging treatment, continuous extrusion and drawing forming. The copper-tin alloy contact wire prepared by the method has higher strength and conductivity, and the application range of the copper-tin alloy contact wire is widened.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP KANG YUAN NEW MATERIALS CO LTD

Powder metallurgy composite material with high compounding ratio and manufacturing method

ActiveCN112453385AImprove mechanical propertiesImprove wear resistanceTransportation and packagingMetal-working apparatusGraphite carbonGunmetal

The invention relates to the technical field of powder metallurgy, and provides a powder metallurgy composite material with high compounding ratio. The powder metallurgy composite material comprises,by weight, 80-95 parts of copper-tin alloy powder, 5-10 parts of phosphor copper powder, 5-15 parts of micro wax powder, 1-10 parts of calcium carbonate powder and 5-15 parts of nano graphite carbon tubes. A manufacturing method comprises the steps of blank manufacturing, presintering quenching, oil immersion, deoiling, re-pressing and sintering shaping, and the strength and wear resistance of thematerial can be effectively improved.

Owner:成都威仕达新材料科技有限公司

Air conditioner compressor discharge pipe joint assembly and manufacturing method thereof

ActiveCN107339227BImprove consistencyNo chemical cleaning process requiredPositive displacement pump componentsSoldering apparatusGunmetalStructural engineering

The invention discloses a connector assembly of an exhaust pipe of an air-conditioner compressor. The connector assembly comprises an exhaust copper pipe and a steel flange. The exhaust copper pipe is fixedly connected with the steel flange through phosphorous-copper brazing. The steel flange comprises a steel flange body. A through hole used for penetrating through the exhaust copper pipe is formed in the steel flange body in the axial direction, and a conical surface is arranged on the portion, located on the large end face of the steel flange body, of the through hole. Copper-tin alloy layers are arranged on the conical surface and between the steel flange body and the exhaust copper pipe correspondingly. According to the connector assembly of the exhaust pipe of the air-conditioner compressor, the steel flange in the connector assembly of the exhaust pipe is fixed to the exhaust copper pipe after being coated with the copper-tin alloy layers so that hydrogen-shielding brazing can be conducted on the assembly through phosphorous-copper solder at a temperature not higher than the recrystallization temperature of the exhaust copper pipe, environmental friendliness is achieved, the consistency is good, no chemical cleaning procedure is needed, and the brazing strength and the airtightness can be effectively ensured; and the grain size of the copper pipe is smaller than or equal to 0.2 mm, and the service life greatly prolonged.

Owner:南通亿峰机械零部件制造有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com