Diamond grinding wheel and preparation method thereof

A diamond grinding wheel and diamond technology, used in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of short dressing gap, insufficient wear resistance, poor wear resistance, etc., and reduce the amount and shape of iron powder. Good retention, ensure the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

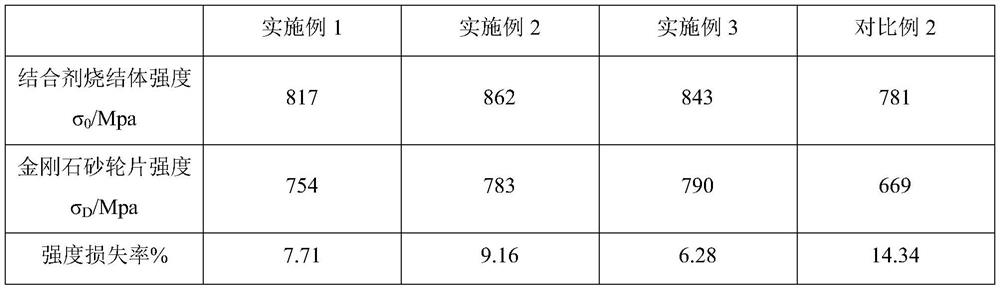

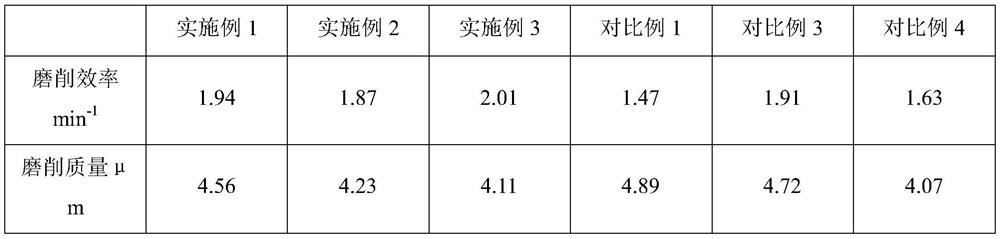

Embodiment 1

[0026] A diamond grinding wheel sheet is composed of the following raw materials in parts by weight: 40 parts of diamond abrasives, 360 parts of composite binder, wherein each part of composite binder includes 45 parts of copper-clad iron powder, 20 parts of iron powder, and 17 parts of copper-tin alloy Powder, 7 parts of aluminum powder, 15 parts of ceramic powder, 4 parts of polyimide pellets, each part of ceramic powder includes 49 parts of silicon dioxide, 17 parts of alumina, 20 parts of boron oxide, 4 parts of zinc oxide, 12 parts of oxide Sodium, 7 parts of lithium oxide and 1 part of titanium dioxide, each part of diamond abrasive includes 22 parts of 200-300 mesh diamond particles, 14 parts of 300-400 mesh diamond particles, and 7 parts of fine diamond particles of 400 mesh or more.

[0027] The preparation method of above-mentioned diamond grinding wheel sheet, comprises the following steps:

[0028] Step 1, get the diamond abrasive of above-mentioned weight portion ...

Embodiment 2

[0037] A diamond grinding wheel sheet is composed of the following raw materials in parts by weight: 60 parts of diamond abrasives, 540 parts of composite binder, wherein each part of composite binder includes 50 parts of copper-clad iron powder, 30 parts of iron powder, and 23 parts of copper-tin alloy Powder, 18 parts of aluminum powder, 22 parts of ceramic powder, 7 parts of polyimide pellets, each part of ceramic powder includes 54 parts of silicon dioxide, 22 parts of alumina, 25 parts of boron oxide, 8 parts of zinc oxide, 16 parts of oxide Sodium, 9 parts of lithium oxide and 6 parts of titanium dioxide, each part of diamond abrasive includes 26 parts of 200-300 mesh diamond particles, 18 parts of 300-400 mesh diamond particles, and 13 parts of 400-mesh fine diamond particles.

[0038] The preparation method of above-mentioned diamond grinding wheel sheet, comprises the following steps:

[0039] Step 1, get the diamond abrasive of above-mentioned weight portion and comp...

Embodiment 3

[0048]A diamond grinding wheel sheet is composed of the following raw materials in parts by weight: 50 parts of diamond abrasives, 450 parts of composite binder, wherein each part of composite binder includes 48 parts of copper-clad iron powder, 25 parts of iron powder, and 20 parts of copper-tin alloy Powder, 13 parts of aluminum powder, 18 parts of ceramic powder, 5 parts of polyimide pellets, each part of ceramic powder includes 52 parts of silicon dioxide, 20 parts of alumina, 23 parts of boron oxide, 6 parts of zinc oxide, 14 parts of oxide Sodium, 8 parts of lithium oxide and 3 parts of titanium dioxide, each part of diamond abrasive includes 24 parts of 200-300 mesh diamond particles, 16 parts of 300-400 mesh diamond particles, and 10 parts of fine diamond particles of 400 mesh or more.

[0049] The preparation method of above-mentioned diamond grinding wheel sheet, comprises the following steps:

[0050] Step 1, get the diamond abrasive of above-mentioned weight portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com